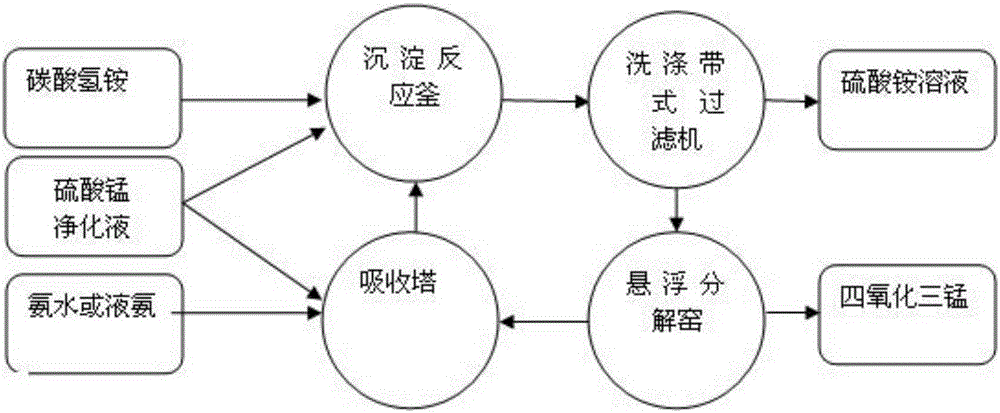

Decomposition and Precipitation Circulation Process for Preparation of Trimanganese Tetroxide with Manganese Sulfate Solution

A technology of manganese tetroxide and manganese sulfate solution, applied in manganese oxide/manganese hydroxide and other directions, can solve the problems of high cost, unenvironmental protection, large consumption of ammonium bicarbonate, etc., and achieve the effect of high degree of automation and reduced energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Inject 65*10 into the coprecipitation reactor 3 L manganese sulfate solution (concentration of manganese is 45g / l), add 5500kg ammonium bicarbonate, control the temperature at 30°C, react for 2 hours, then pump it to the belt filter for filtration, washing, filtration, and then send it to the decomposition kiln break down. When decomposing, control the amount of manganese carbonate entering the kiln to 1286±128kg / hour (8.94±0.89mol) (water content 20%), the decomposition temperature is 800°C, and the tail gas temperature is 110°C. Pass into manganese sulfate solution (the concentration of manganese is 45g / l) the feeding flow rate of manganese sulfate is 11*10 3 L / h, at the same time, the ammonia water with a mass concentration of 10% is charged at a feed rate of 1.46*10 3 L / h is pumped into the absorption tower to ensure that the pH of the reaction solution is about 6.5. The reacted slurry overflows from the discharge port into the coprecipitation reactor, and is pump...

Embodiment 2

[0023] Inject 65*10 into the coprecipitation reactor 3 L manganese sulfate solution (the content of manganese is 45g / l), add 5500kg ammonium bicarbonate, control the temperature at 30°C, react for 2 hours, then pump it to the belt filter for filtration, washing and filtration, and then send it to the decomposition kiln break down. The amount of manganese carbonate entering the kiln is controlled to be 1286±120kg / hour (water content 20%), the decomposition temperature is 800°C, and the tail gas temperature is 110°C. The content is 60g / l), according to the feed amount, it is 8.25*10 3 L / h is pumped into the absorption tower, and liquid ammonia water is injected into the absorption tower at the same time according to the feed rate of 146kg / h. Ensure that the pH of the reaction solution is about 6.5, and the reacted slurry overflows into the coprecipitation reactor, and is pumped to the belt filter for filtration, washing, and filtration, and then sent to the decomposition kiln ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com