Simulation method and device of combustion characteristic generation numerical value of utility boiler pulverized coal under variable over fire air volume

A power station boiler, combustion characteristics technology, applied in the field of electric power, can solve the problems of inability to measure the overall regular characteristics of combustion, flow and heat transfer in the furnace, impractical and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

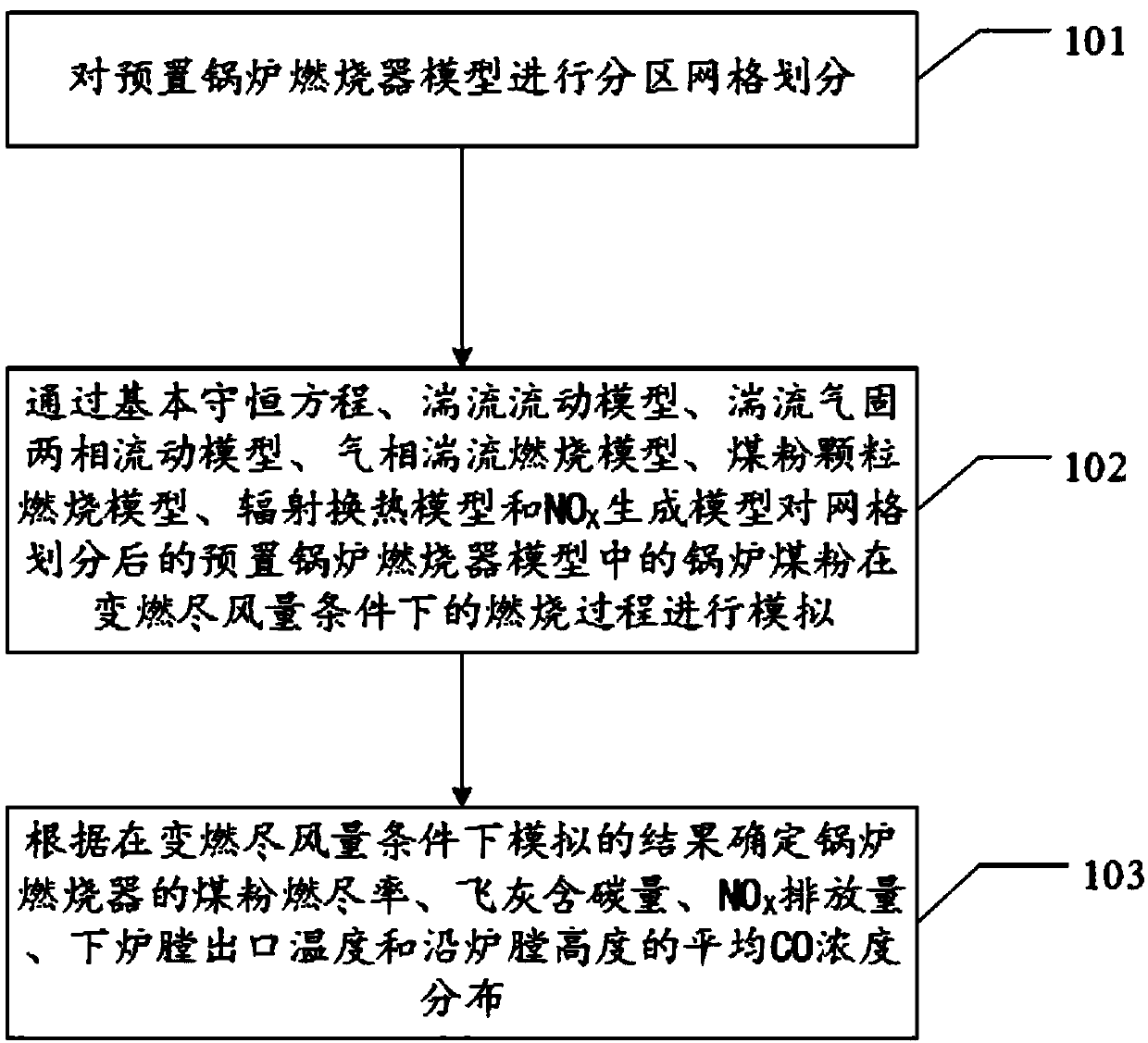

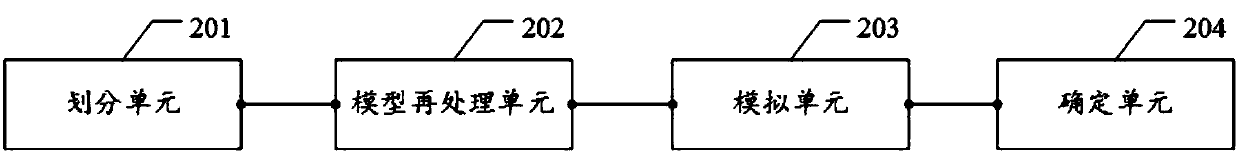

[0014] The embodiment of the present invention provides a method and device for simulating the combustion characteristics of pulverized coal in power plant boilers under variable burn-off air volume, and solves the problem that it is impossible to manufacture full-scale model test benches due to the increasing size of the furnace. In fact, the resulting technical problem is that it is impossible to measure the overall regular characteristics of combustion, flow, and heat transfer in the furnace.

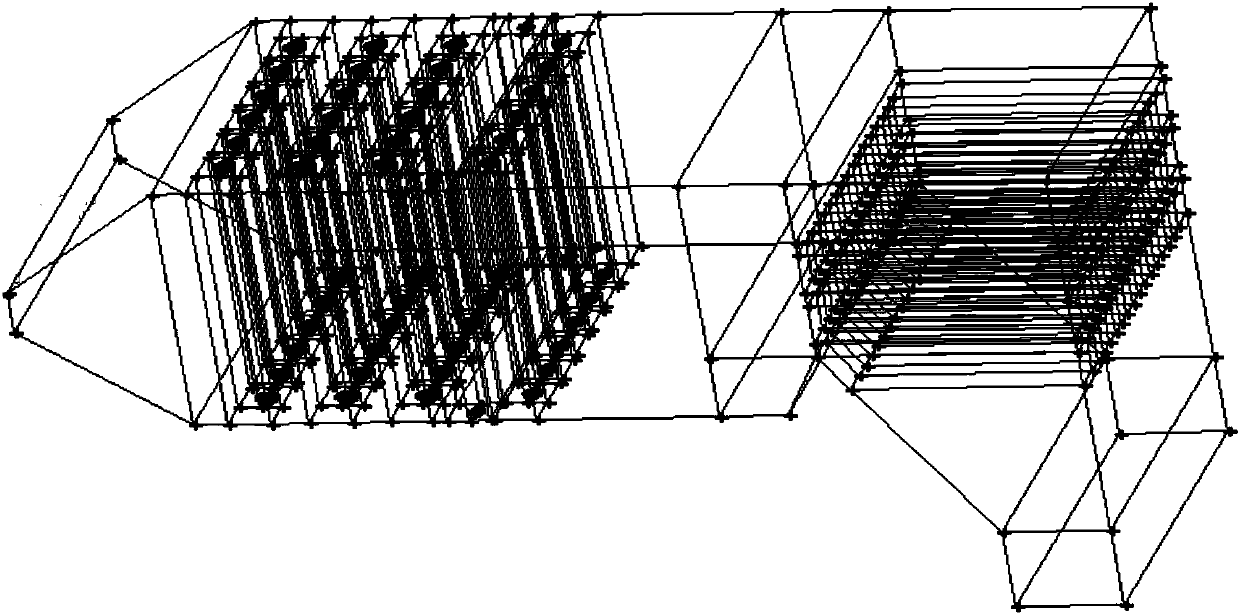

[0015] CFD, software (Computational Fluid Dynamics), that is, computational fluid dynamics, is a branch of fluid mechanics, referred to as CFD. CFD is the product of the combination of modern fluid mechanics, numerical mathematics and computer science, and is a fringe science with strong vitality. It uses computer as a tool and applies various discrete mathematical methods to conduct numerical experiments, computer simulations and analytical research on various problems in fluid mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com