Seat air conditioning unit

a seat air conditioner and air conditioning technology, applied in the field of seat air conditioners, can solve the problems of difficult to provide a sufficient cooling effect, difficulty in controlling the temperature of the air to be blown from the seat surface, and difficulty in reducing the air flow rate, so as to reduce the power consumption in the draft mode, improve the draft effect, and reduce the effect of pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

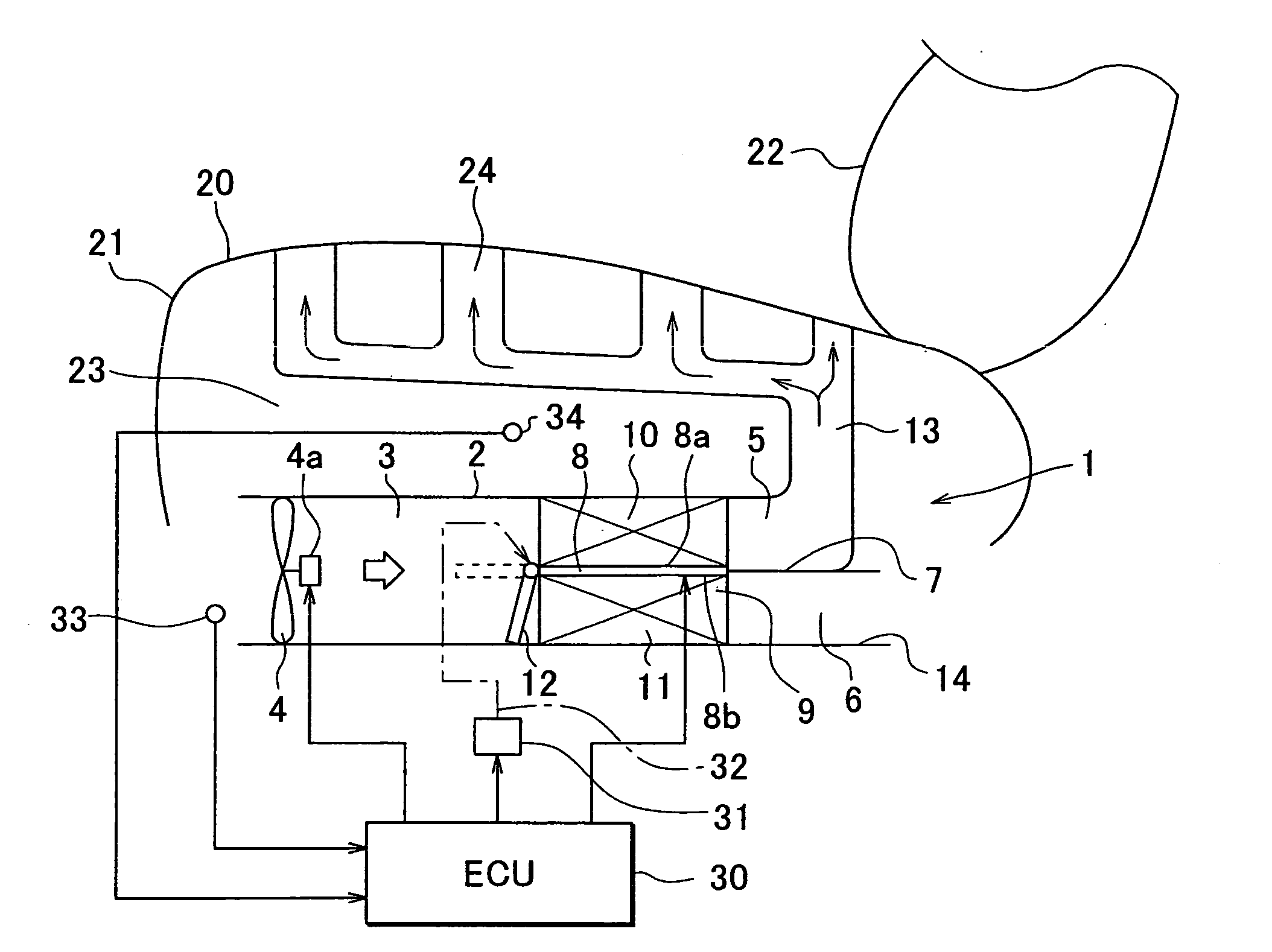

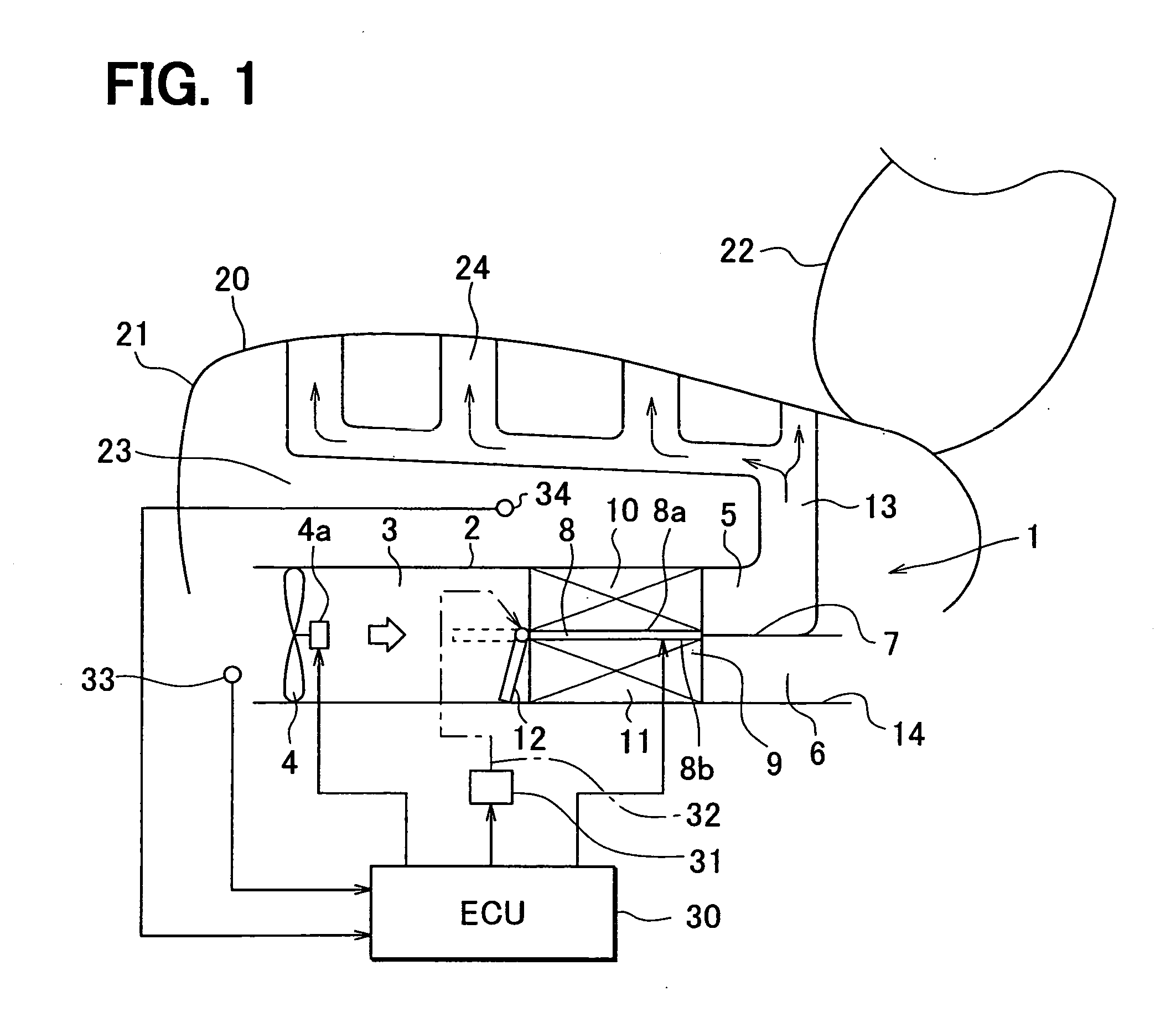

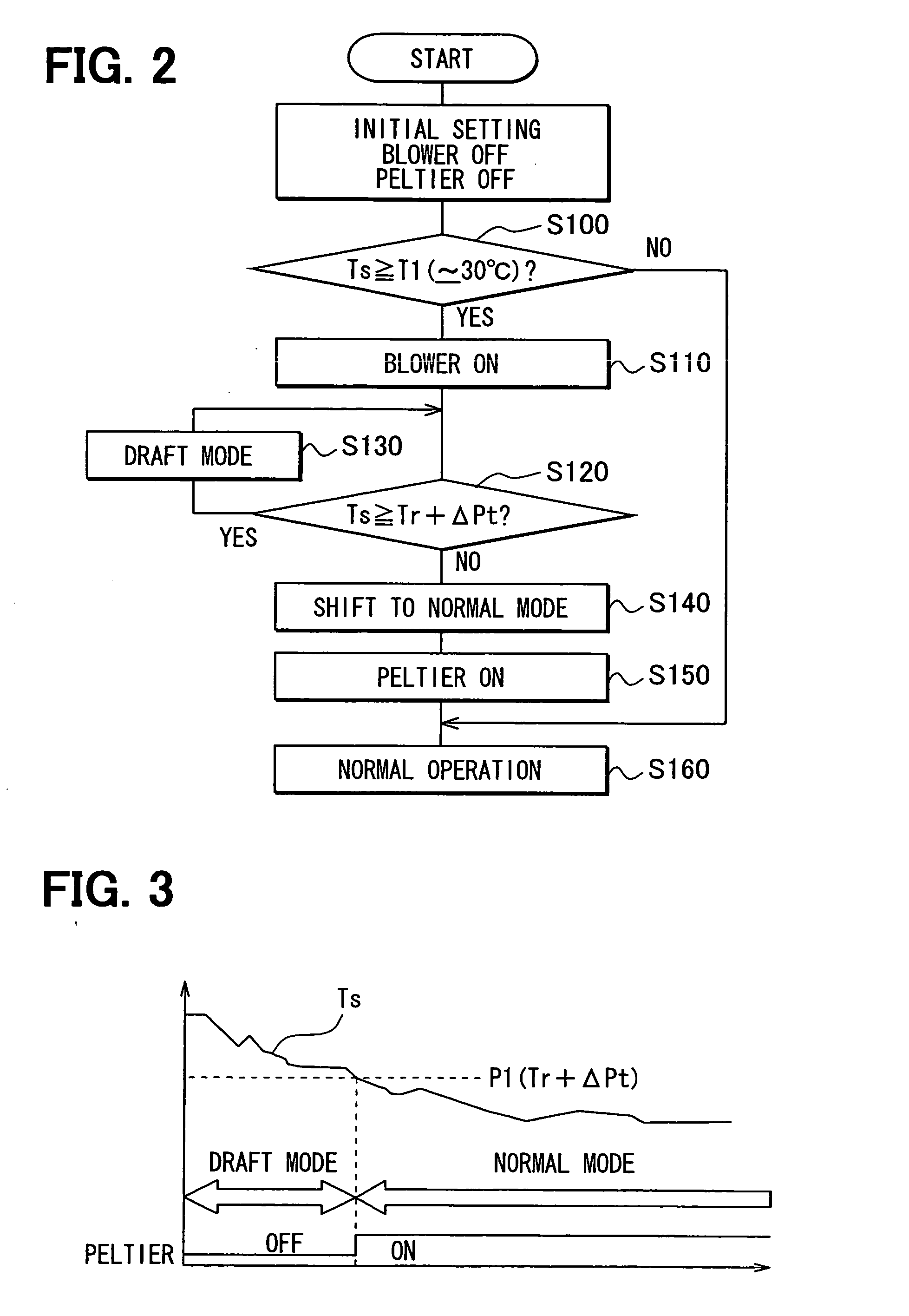

[0033] A first example embodiment of the present invention will now be described with reference to FIGS. 1 to 4. As shown in FIG. 1, a seat air conditioning unit 1 of the first example embodiment is for example mounted to a seat bottom 21 of a seat 20. Alternatively, the seat air conditioning unit 1 can be mounted to a seat back 22.

[0034] The seat air conditioning unit 1 has a duct 2, a blower 4 and a heat exchanger unit 9. The duct 2 forms an inlet port 3 at one end (left end in FIG. 1) and the blower unit 4 is located upstream of the inlet port 3. The heat exchanger unit 9 is located downstream of the blower unit 4 in the duct 2. The blower unit 4 sucks air and blows the air into the duct 2. The seat air conditioning unit 1 is for example used in a vehicle. In this case, the blower unit 4 sucks air inside a passenger compartment. The blower unit 4 is disposed such that the air is fully introduced into a passage space of the duct 2 through the inlet port 3. In FIG. 1, an axial flo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com