Thermal power plant boiler combustion efficiency intelligent analysis system and method

A combustion technology for thermal power plants and boilers, which is applied in the direction of controlling combustion, lighting and heating equipment, etc. It can solve the problems of complex optimization control system, difficulty in achieving ideal results, and difficulty in accurately controlling and adjusting multiple coupling variables. To achieve the effect of improving boiler efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

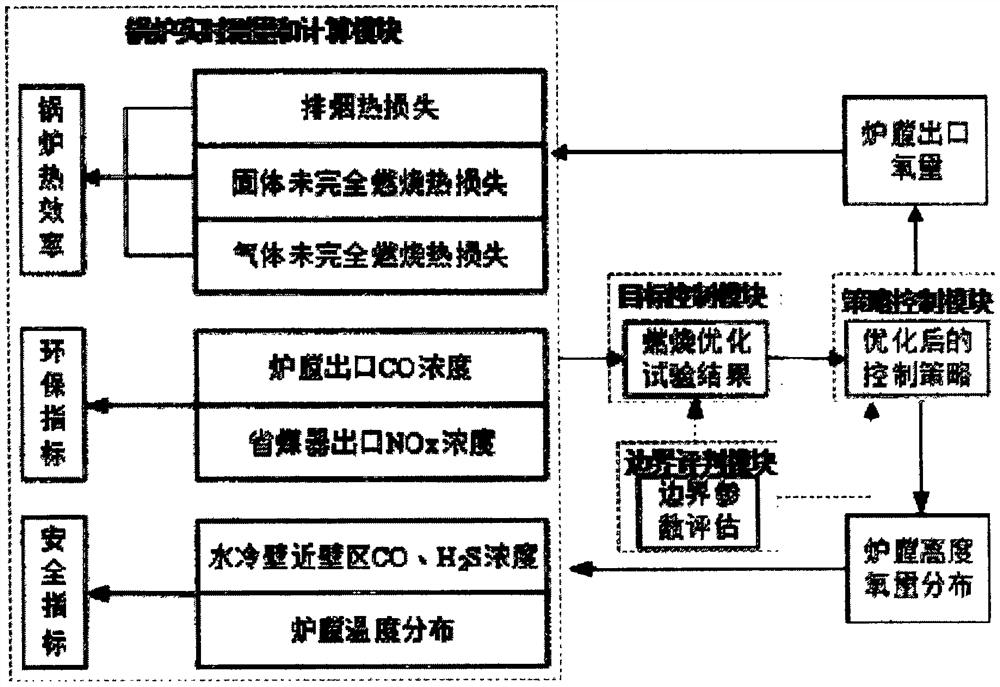

[0015] Please refer to the drawings in the description. In an embodiment of the present invention, an intelligent analysis system for boiler combustion efficiency in a thermal power plant includes a boiler real-time measurement and calculation module, a target control module, a strategy control module, and a boundary judgment module.

[0016] The boiler real-time measurement and calculation module, wherein the heat loss calculation method is based on the "GB / T10184-2015 Power Station Boiler Performance Test Regulations", mainly calculates the heat loss of exhaust gas that has a great influence on the thermal efficiency of the boiler and is closely related to the boundary conditions, and the gas loss. Complete combustion heat loss and solid incomplete combustion heat loss, and other heat losses have little influence and change little, so they are set as constant values, and the boiler efficiency is calculated by the inverse balance method.

[0017] The boiler real-time measureme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com