Fly ash carbon content prediction method based on coal quality prediction and PSO-SVM

A PSO-SVM, fly ash carbon content technology, applied in the direction of nuclear methods, neural learning methods, instruments, etc., can solve the problem that the coal quality cannot be calculated online without considering the coal quality, and it is difficult to obtain the coal quality test data of the coal entering the furnace in real time, etc. problems, to achieve the effect of improving combustion economy, improving forecasting performance, and reducing coal consumption

Pending Publication Date: 2020-10-09

ZHEJIANG ZHENENG TECHN RES INST +1

View PDF0 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

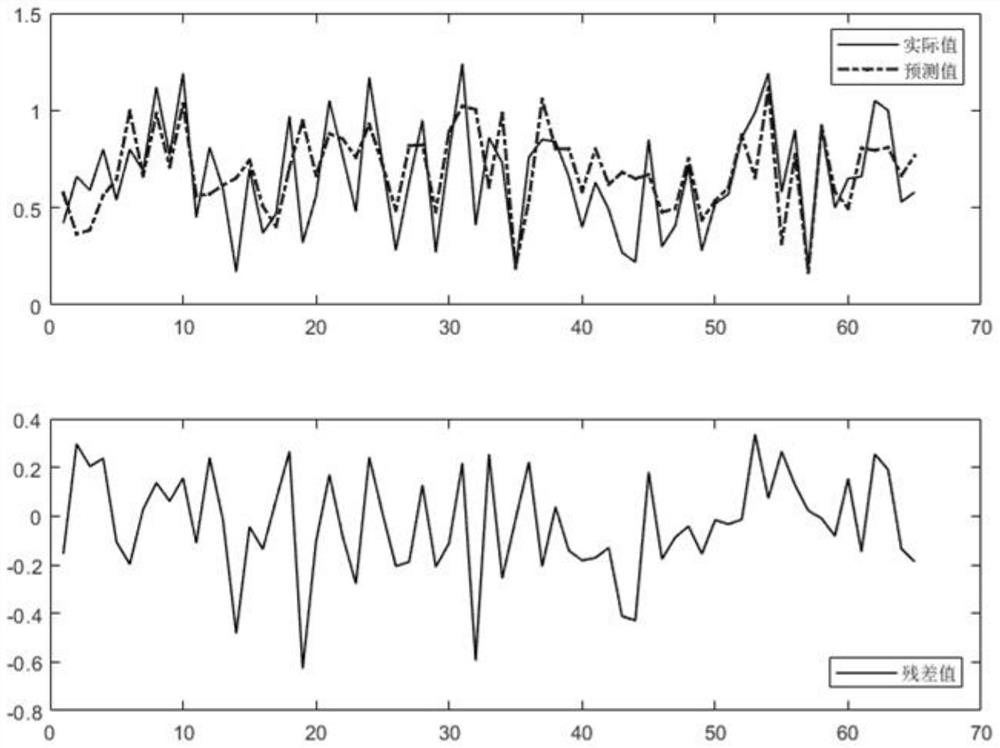

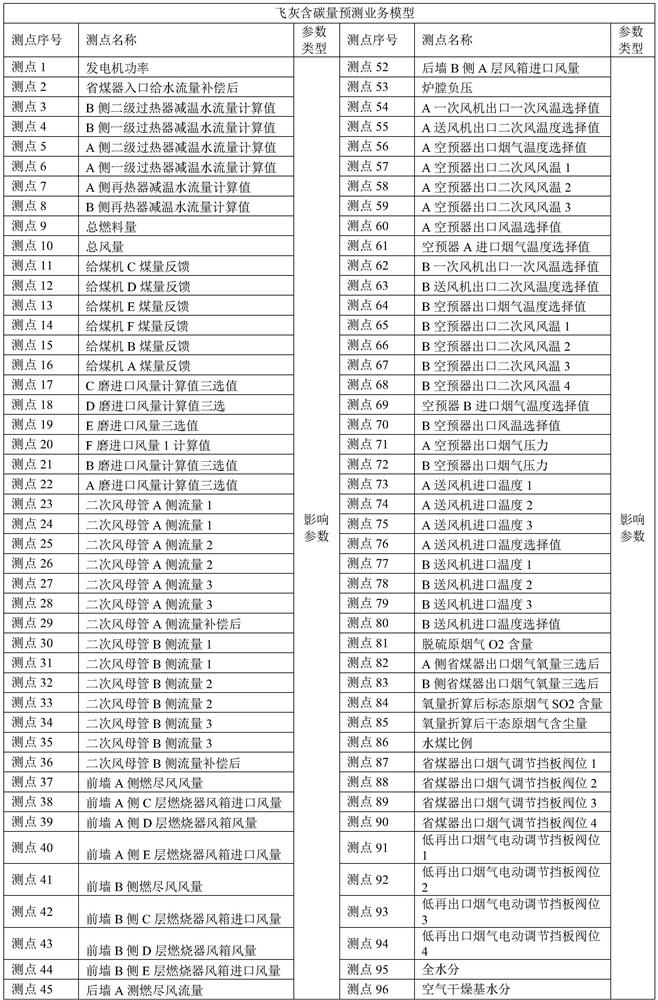

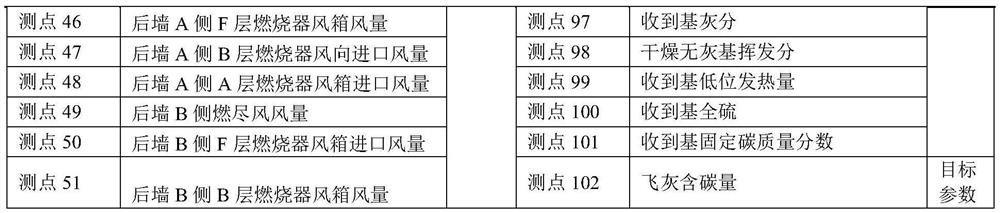

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and a specific example of a 1050MW ultra-supercritical coal-fired unit in the south.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a fly ash carbon content prediction method based on coal quality prediction and PSO-SVM, and the method comprises the steps: 1, selecting and constructing proper coal qualityinfluence parameters and coal quality feature parameters, constructing a coal quality prediction model based on a BP neural network, and carrying out the soft measurement of the coal quality of coal as fired through coal type matching; 2, constructing a support vector machine (SVM)-based fly ash carbon content prediction model. The method has the beneficial effects that the method can be used forsoft measurement of the carbon content of the fly ash, the model is optimized, and the prediction performance of the soft measurement model of the carbon content of the fly ash is further improved. Firstly, a BP neural network model is constructed for coal quality prediction by utilizing coal quality influence parameters so as to obtain relatively accurate coal quality test data; the fly ash carbon content prediction model provided by the invention integrates two technologies of coal quality prediction and fly ash carbon content prediction, realizes accurate measurement of the fly ash carbon content, and has important significance for improving the combustion economy of a boiler, reducing the coal consumption and improving the environment.

Description

technical field [0001] The invention relates to the field of optimization control of the power generation process of a coal-fired unit, and aims at the problem of online application of fly ash carbon content soft measurement, and particularly includes a method for predicting the carbon content of fly ash based on coal quality prediction and PSO-SVM. Background technique [0002] The carbon content of fly ash is one of the most important and basic parameters in boiler operation. It characterizes the important operating characteristics of the boiler and is an important indicator for calculating the heat loss of incomplete combustion of boiler machinery. The unburned combustibles in the fly ash can represent whether the air-to-coal ratio in the boiler combustion control is reasonable, and it is an important loss item that affects the thermal efficiency of the boiler. Accurate and effective measurement of carbon content in fly ash is conducive to adjusting the working conditions...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G06Q10/06G06N20/10G06Q50/06G06N3/04G06N3/08

CPCG06Q10/06375G06Q50/06G06N20/10G06N3/08G06N3/045

Inventor 王豆孟瑜炜杨勤张震伟郭鼎郑必君王立峰安佰京崔凯刘洪涛

Owner ZHEJIANG ZHENENG TECHN RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com