U-shaped coal gasification reaction device used for secondarily separating and deslagging and coal gasification process implementing secondary separating and deslagging by using device

A secondary separation and reaction device technology, applied in the field of coal gasification process, can solve the problems of low energy utilization rate, large amount of fly ash generated, high carbon content of fly ash, etc., to prolong residence time, strengthen slagging ability, expand The effect of gasification reaction space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

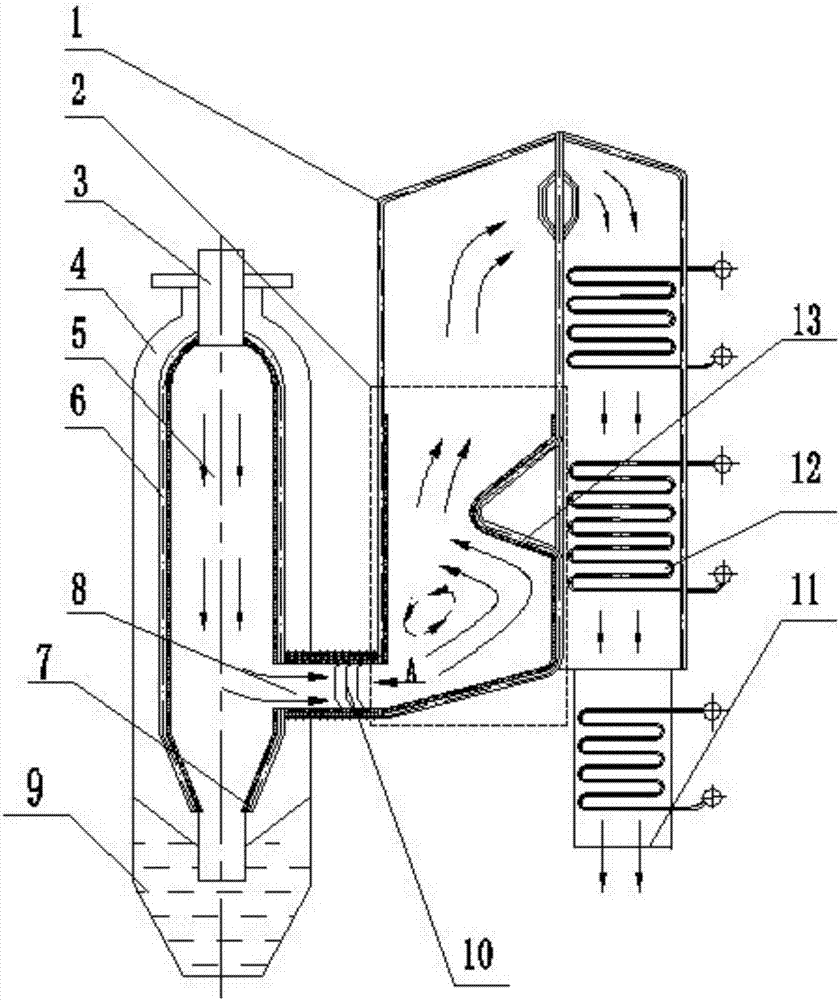

[0036] Specific implementation mode one: combine Figure 1 to Figure 9 Describe this embodiment, a U-shaped coal gasification reaction device for secondary separation and slag removal in this embodiment is composed of a gasification furnace body 4, a horizontal flue 8 and a waste pot 1; the gasification furnace body 4 is composed of a gasification furnace body Composed of burner 3, gasification furnace 5, water wall pipe 6, cooling water pipe 14 and slag pool 9; the waste pot 1 is composed of radiation heat exchange chamber, convection heat exchange chamber, intermediate furnace wall and synthesis gas outlet 11; The gasification furnace body 4 is provided with a gasification furnace 5, the gasification furnace 5 is surrounded by water-cooled wall tubes 6, and the upper part of the gasification furnace body 4 is provided with a gasification furnace burner 3. Furnace burner 3 is connected with gasification furnace 5, and the bottom of said gasification furnace body 4 is provided...

specific Embodiment approach 2

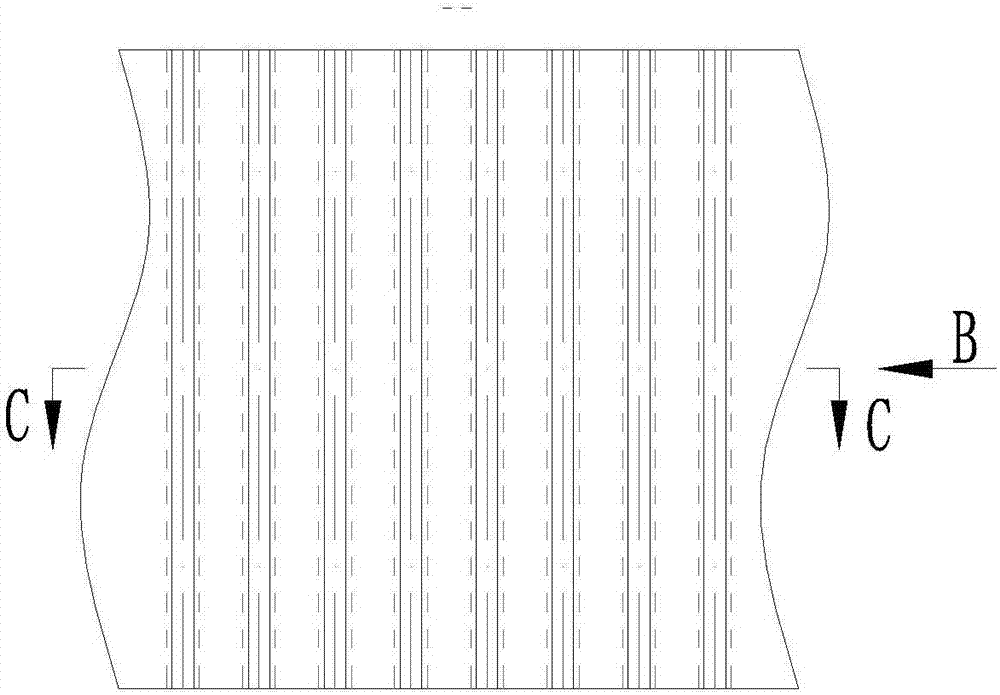

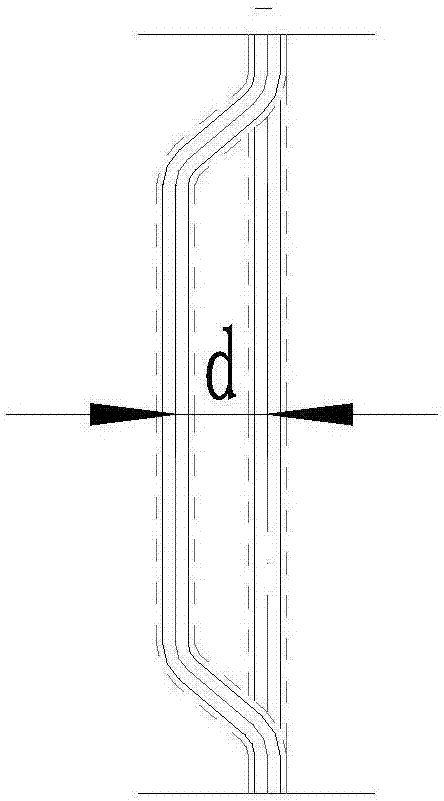

[0037] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that: the lateral gap L between adjacent cooling water pipes 14 in the slag remover 10 is not less than 100 mm, and the longitudinal pitch d is not less than 1 / 4 of the diameter of the cooling water pipes 14 2.5 times. Such setting is convenient to enhance the slagging ability of the gasifier, further reduce the amount of fly ash generated, and at the same time avoid slagging of the slagging device. Others are the same as the first embodiment.

specific Embodiment approach 3

[0038] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the material of the cooling water pipe 14 is the same as that of the water wall pipe 6 . Others are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com