U-shaped coal gasification reaction device and process for coal gasification by using device

A reaction device and a coal gasification technology, applied in the field of U-shaped coal gasification reaction devices, can solve the problems of high carbon content in fly ash, low energy utilization rate, low carbon conversion rate, etc., so as to improve the slag capture efficiency and avoid waste boiler The effect of fouling and fouling and high slagging efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

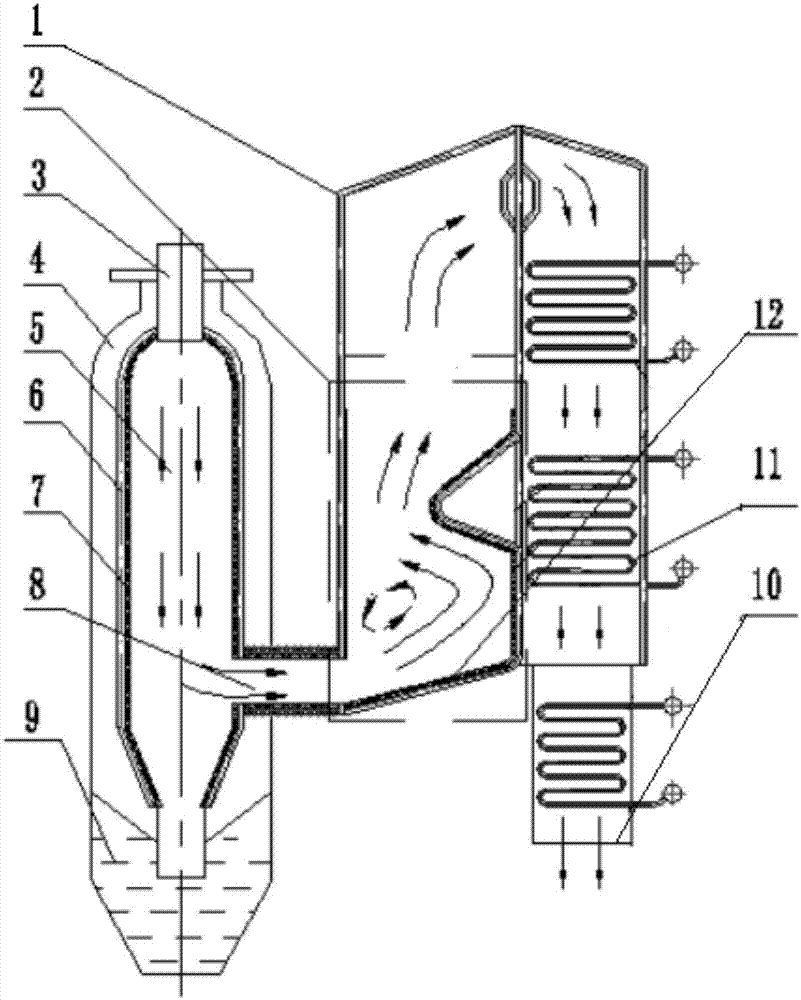

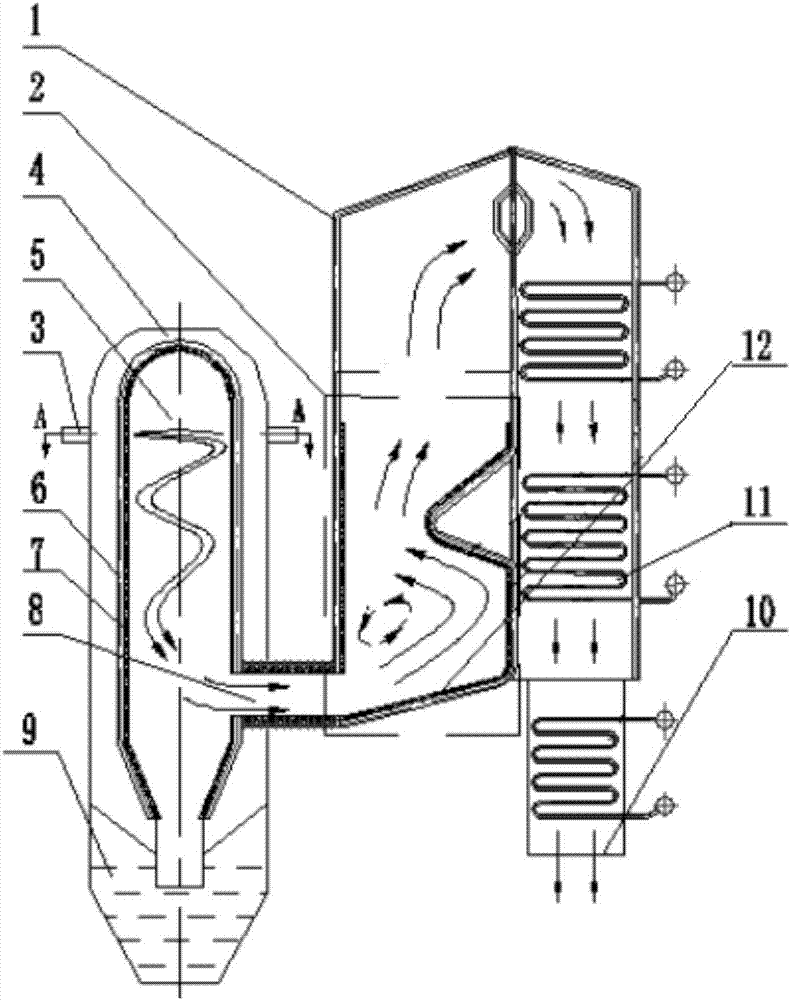

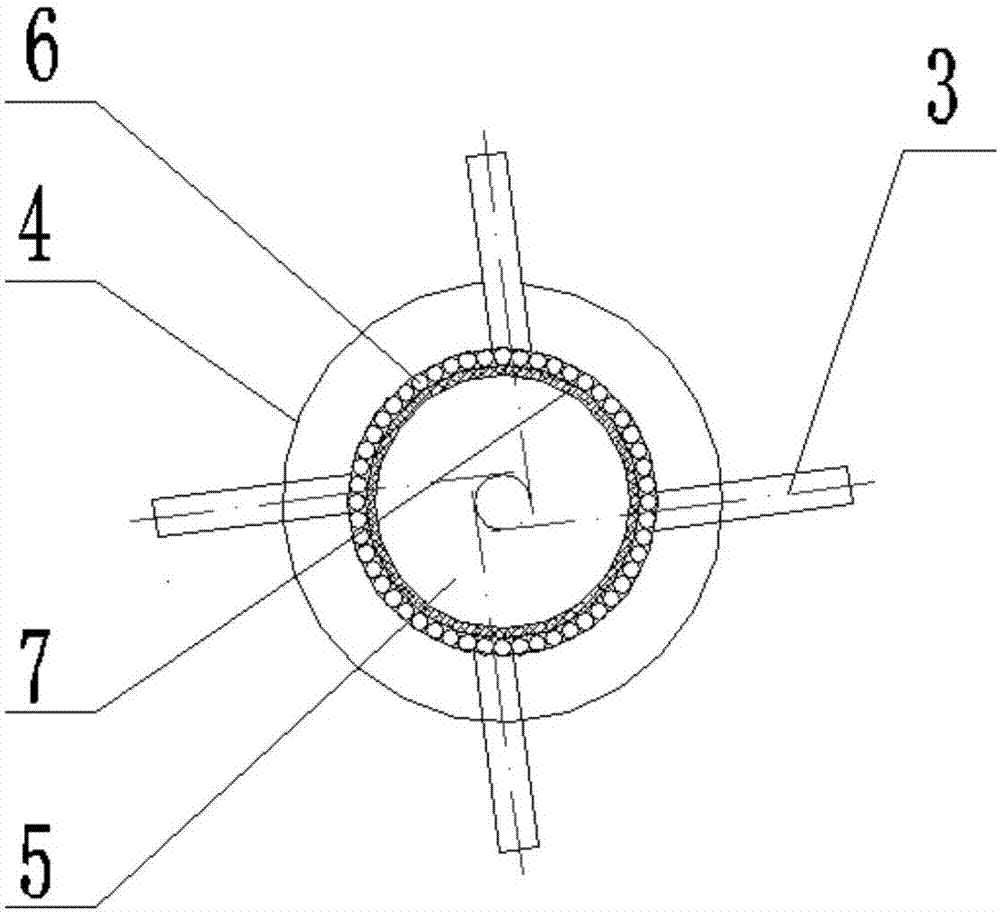

[0027] Specific implementation mode one: combine Figure 1 ~ Figure 3 Describe this embodiment, a U-shaped coal gasification reaction device in this embodiment is composed of a gasification furnace body 4, a horizontal flue 8 and a waste pot 1; the gasification furnace body 4 is composed of a gasification furnace burner 3, a gasification Furnace 5, water-cooled wall pipe 6 and slag pool 9; the waste pot 1 is composed of radiation heat exchange chamber, convection heat exchange chamber, intermediate furnace wall and synthesis gas outlet 10; the gasification furnace body 4 is provided with gas A gasification furnace 5, the gasification furnace 5 is surrounded by water-cooled wall tubes 6, the upper part of the gasification furnace body 4 is provided with a gasification furnace burner 3, and the gasification furnace burner 3 is connected to the gasification furnace 5 The bottom of the gasification furnace body 4 is provided with a slag pool 9, and the slag pool 9 communicates wit...

specific Embodiment approach 2

[0028] Embodiment 2: This embodiment differs from Embodiment 1 in that: the burner 3 of the gasification furnace is a single burner. Others are the same as the first embodiment.

specific Embodiment approach 3

[0029] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the burner 3 of the gasification furnace is vertically arranged on the upper part of the gasification furnace body 4 . Others are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com