Method for stabilization of refuse incineration fly ash

A technology for waste incineration fly ash and stabilization treatment, applied in the field of waste incineration, can solve problems such as inability to large-scale application, unstable effect, complicated process, etc., and achieve the effects of low cost, large processing capacity and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

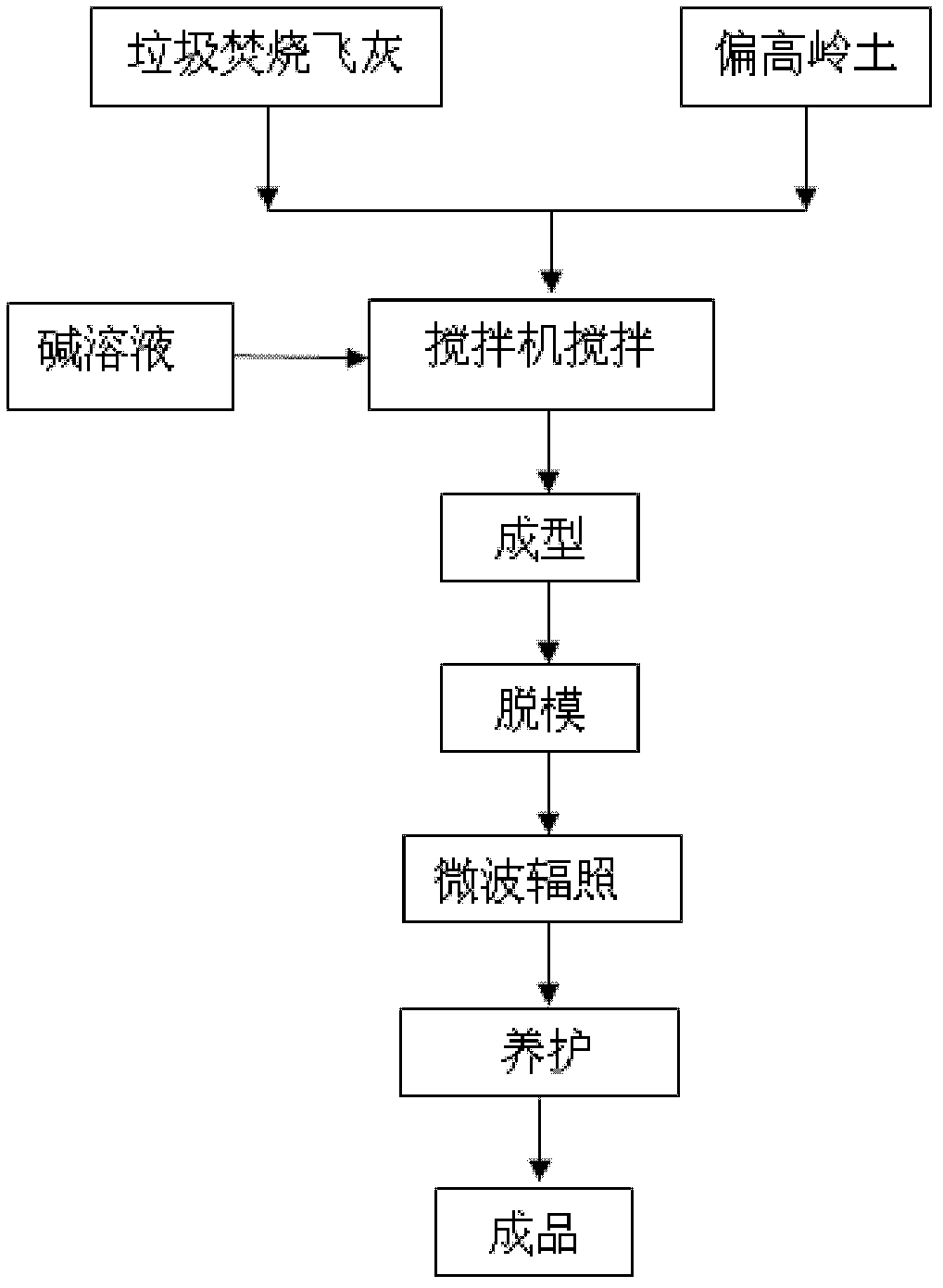

Method used

Image

Examples

Embodiment 1

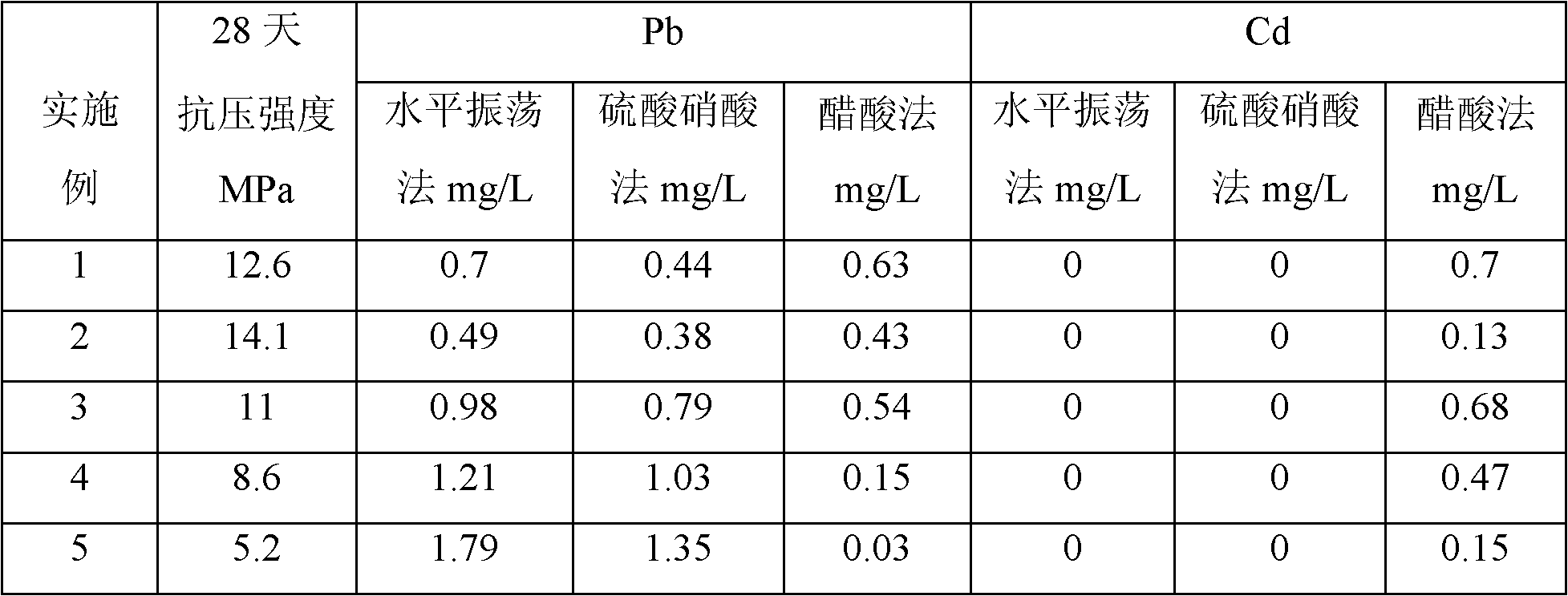

[0024] The fly ash collected by a grate-type domestic waste incinerator bag filter in the south has a moisture content of 3%. The main components of the fly ash and its ingredient metakaolin are shown in Table 1. The fly ash samples were tested according to "Leach Toxic Leaching Method of Solid Waste Horizontal Oscillating Method" (GB5086.2-1997), "Toxic Leaching Method of Solid Waste Sulfuric Acid Nitric Acid Method" (HJ / T299-2007), "Toxic Leaching Method of Solid Waste Acetic Acid Buffer Solution Method" (HJ / T300-2007) was used for leaching toxicity test, and flame atomic absorption method was used to measure the concentration of heavy metals in the leaching solution. The analysis results are shown in Table 2.

[0025] Table 1 Main components of fly ash and metakaolin, %

[0026] material

SiO 2

Fe 2 o 3

al 2 o 3

CaO

MgO

44.23

1.04

35.872

8.094

0.566

fly ash

18.625

2.309 ...

Embodiment 2

[0033] Weigh 850g of domestic waste incineration fly ash and 150g of metakaolin, place them in a cement mortar mixer, stir evenly, add 270ml of aqueous solution containing 30g of NaOH, continue stirring for 25 minutes, inject into the model and vibrate, and let it stand in the air for 24 hours before demoulding Microwave irradiation for 3 minutes, natural curing in the air for 3 days, watering for 3 days (watering once every 7 hours), and then natural curing to the finished product. The strength and leaching test results are shown in Table 3.

Embodiment 3

[0035]Weigh 900g of domestic waste incineration fly ash and 100g of metakaolin, place them in a cement mortar mixer, stir evenly, add 285ml of aqueous solution containing 90g of NaOH, continue stirring for 40min, inject into the mold and vibrate, and let it stand in the air for 24h before demoulding Microwave irradiation for 5 minutes, natural curing in the air for 2 days, watering for 4 days (sprinkling water once every 6 hours), and then natural curing to the finished product. The strength and leaching test results are shown in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com