A kind of sludge soil conditioner and its preparation method and device

A soil conditioner and sludge technology, which is used in fertilization devices, sludge treatment, soil conditioning materials, etc., can solve the problems of large composting area, high technical and management requirements, and large one-time investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

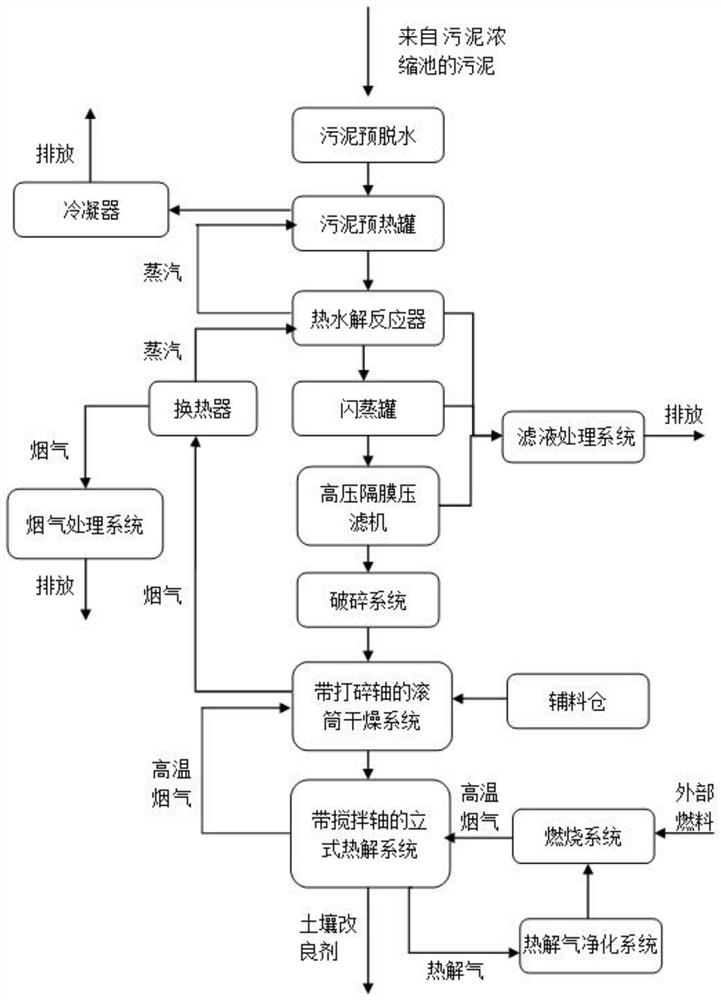

[0051] The invention provides a kind of preparation method of sludge soil conditioner, comprises the following steps:

[0052] The sludge is pre-dehydrated to obtain the first sludge;

[0053] performing a thermal hydrolysis reaction on the first sludge to obtain a second sludge;

[0054] The second sludge is dewatered and pulverized by pressure filtration in sequence to obtain sludge granules;

[0055] The sludge granules are mixed with biomass auxiliary materials and subjected to a pyrolysis reaction to obtain a sludge soil conditioner.

[0056] The invention pre-dehydrates the sludge to obtain the first sludge.

[0057] In the present invention, the source of the sludge is preferably a sludge concentration tank of a municipal sewage plant; the moisture content of the sludge is preferably 97-99%. The present invention has no special limitation on the dehydration time, as long as the water content of the first sludge can be guaranteed to be 80-90%.

[0058] After the firs...

Embodiment 1

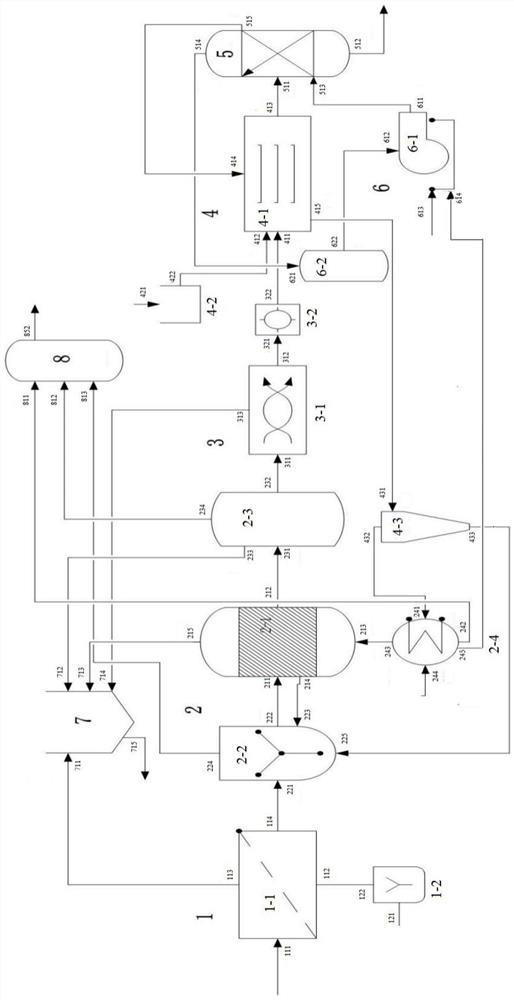

[0119] The sludge with a water content of 97% in the concentration tank of the municipal sewage plant is transported to the belt dehydrator 1-1 by a sludge pump, and after adding an appropriate amount of chemicals, it is dehydrated to a water content of 85% to obtain the first sludge;

[0120] The first sludge is transported to the sludge preheating tank 2-2 through the sludge pump and heated to 70°C, then transported to the thermal hydrolysis reactor 2-1 through the sludge pump, under the condition of 220°C and 4MPa Under thermal hydrolysis reaction for 40 minutes, the treated sludge is pumped to the flash tank 2-3 to remove a large amount of water vapor, and the water content is reduced to 75%, and the second sludge sludge is obtained;

[0121] Transport the second sludge to a high-pressure diaphragm filter press 3-1 through a sludge pump, press filter for 2 hours under the condition of 1.5MPa, obtain a sludge cake with a moisture content of 45%, and transport the sludge cake...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com