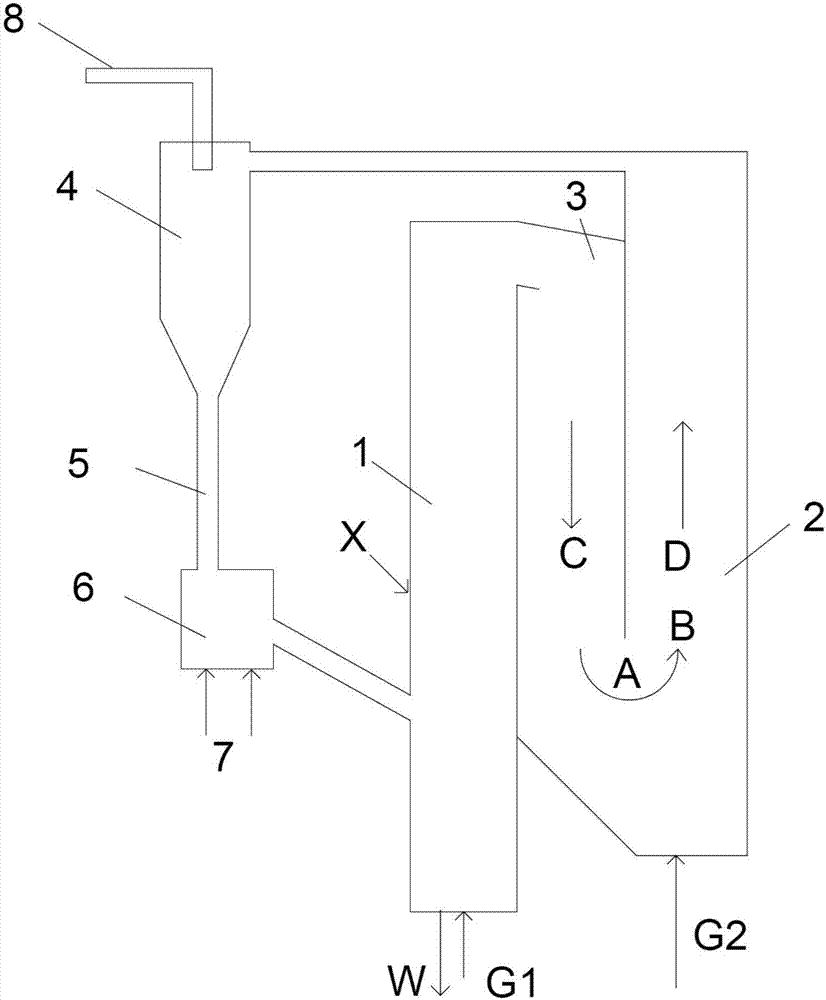

Horizontal type circulating fluidized bed gasification method and device

A technology of circulating fluidized bed and gasification device, which is applied in the direction of gasification process, granular/powdered fuel gasification, and production of combustible gas. Problems such as high carbon content, to achieve effective utilization, improve carbon conversion rate and cold gas efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Example 1, coal with ash melting point (ST) of 1100°C is used, the gasification temperature of the first gasification chamber is 900°C, the operating temperature of the second gasification chamber is 1000°C, the gasification agent is preheated air, the preheating The hot air temperature is 600°C. The carbon content of the slag discharged from the first gasification chamber is 5%, and the carbon content of the fly ash exiting the second cyclone separator is reduced to below 13%.

Embodiment 2

[0050] Example 2, using coal with an ash melting point (ST) of 1200°C, the gasification temperature of the first gasification chamber is 1100°C, the operating temperature of the second gasification chamber is 1150°C, and the gasification agent is preheated air and superheated air The steam mixture, the preheated air temperature is 850°C, the superheated steam pressure and temperature are 9.8MPa and 600°C respectively. The carbon content of the slag discharged from the first gasification chamber is 4%, and the carbon content of the fly ash is reduced to 8%.

Embodiment 3

[0051] Example 3, using coal with an ash melting point (ST) of 1250°C, the gasification temperature of the first gasification chamber is 1050°C, the operating temperature of the second gasification chamber is 1200°C, and the gasification agent is oxygen-enriched air and superheated For the mixture of steam, the temperature of oxygen-enriched air is 200°C, and the temperature of superheated steam is 0.6MPa and 200°C. The carbon content of the slag discharged from the first gasification chamber is 4.5%, and the carbon content of the fly ash is reduced to 9.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com