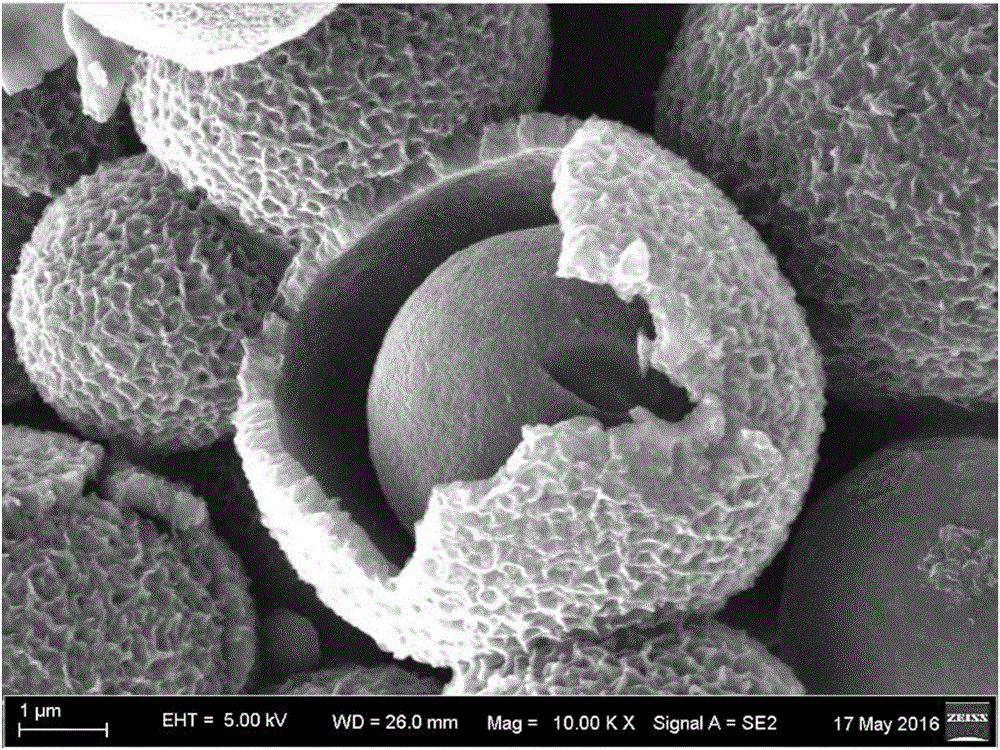

Novel carbon spheres and preparation method and application thereof

A technology of carbon spheres and inner spheres, applied in the field of nanomaterials, can solve the problems of low active material content, low electrode specific capacity and energy density, etc., and achieve the effect of increasing capacity and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

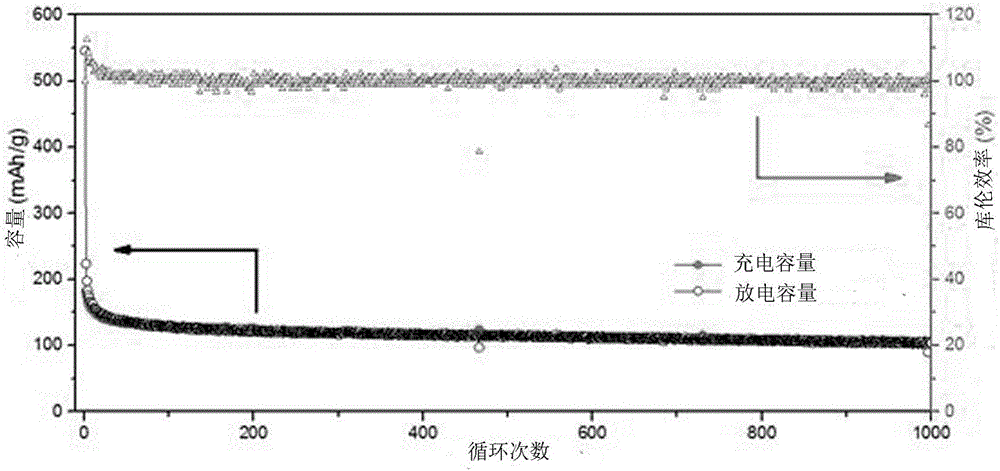

Examples

Embodiment 1

[0030] Follow the steps below to prepare carbon spheres:

[0031] 1. Mix 1mol phenol, 1.5mol formaldehyde, 2mmol sodium carbonate and 500mL deionized water evenly, the concentration of phenol is 2mol / L, the concentration of formaldehyde is 3mol / L, and the concentration of catalyst sodium carbonate is 4mmol / L; at a speed of 15r / min Stir at low temperature for 20 minutes to obtain a precursor solution, then place the obtained solution in an oil bath, stir at a rate of 20 r / min, and simultaneously raise the temperature to 150° C. and keep for 5 hours to obtain a suspension of phenolic resin microspheres. The obtained microsphere solution was suction-filtered, rinsed with deionized water, and placed in an oven at 60° C. for 12 hours to obtain dry phenolic resin microspheres.

[0032] 2. Add the above-mentioned microspheres into 2mol / L hydrochloric acid for 12 hours, take out the sample, and centrifuge 7-8 times with deionized water to make the supernatant of the centrifugation liq...

Embodiment 2

[0036] Follow the steps below to prepare carbon spheres:

[0037] 1. Add 0.03mol resorcinol to a flask protected by nitrogen gas, then add 50mL ethanol and 200mL deionized water to the flask, stir the reactants evenly, then add 2mL ammonia water and 0.03mol formaldehyde to it, The resorcinol concentration is 0.12mol / L, the formaldehyde concentration is 0.12mol / L; the stirring rate is 5000r / min, and the reaction is at room temperature for 12h. Suction filtration, rinse with deionized water, and freeze-dry to obtain resorcinol-formaldehyde resin microspheres.

[0038] 2. Add the above-mentioned microspheres into 1mol / L hydrochloric acid for 15 hours, take out the sample, centrifuge 7~8 times with deionized water to make the supernatant of the centrifugation solution pH=7, then put it in a drying oven, at 60℃ Drying for 6 hours under the hood to obtain cured phenolic resin microspheres.

[0039] 3. Add the obtained cured phenolic resin microspheres into a porcelain boat and pla...

Embodiment 3

[0042] Follow the steps below to prepare carbon spheres:

[0043] 1. Take 0.1mol formaldehyde, 0.16mol urea, 0.4mol formic acid, and 200mL deionized water, and stir to mix the above substances evenly. The concentration of urea is 0.8mol / L, the concentration of formaldehyde is 0.5mol / L, and the concentration of catalyst formic acid is 2mol / L. , standing at room temperature for 48h, a white precipitate was obtained. Centrifuge and wash with water for 5 times, put into an oven at 80°C and dry to obtain a white powder, that is, urea-formaldehyde resin microspheres.

[0044] 2. Take 5g of concentrated hydrochloric acid with a mass fraction of 37% and dissolve it in 25g of deionized water to make a curing agent. Pour the obtained urea-formaldehyde resin powder into the above-mentioned hydrochloric acid solution and let it stand for 12 hours. Centrifuge and wash 8 times with water until the supernatant has a pH of 7, put it in an oven at 80°C and dry it to obtain cured urea-formald...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com