Method for synthetizing graphene film

A technology for synthesizing graphite and thin films, applied in the directions of graphene, nanotechnology, nanocarbon, etc., to achieve the effect of easy size control and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

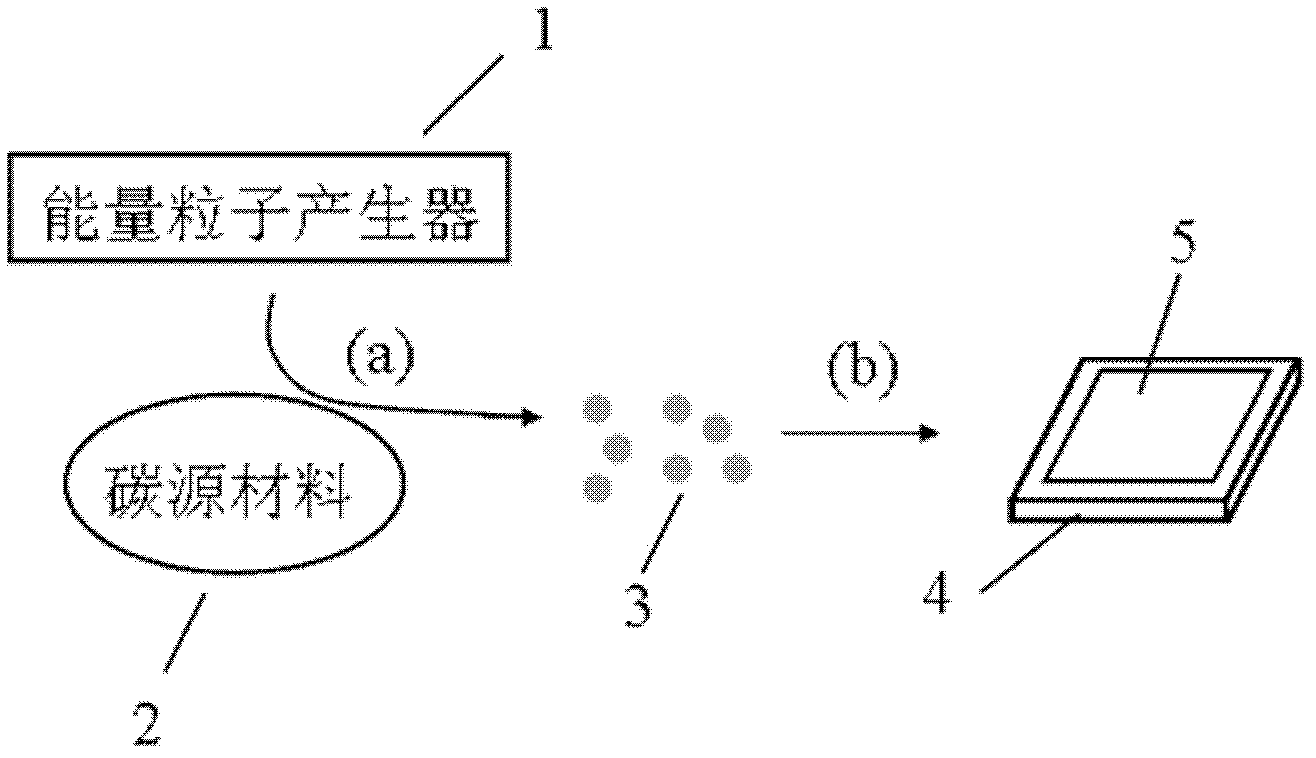

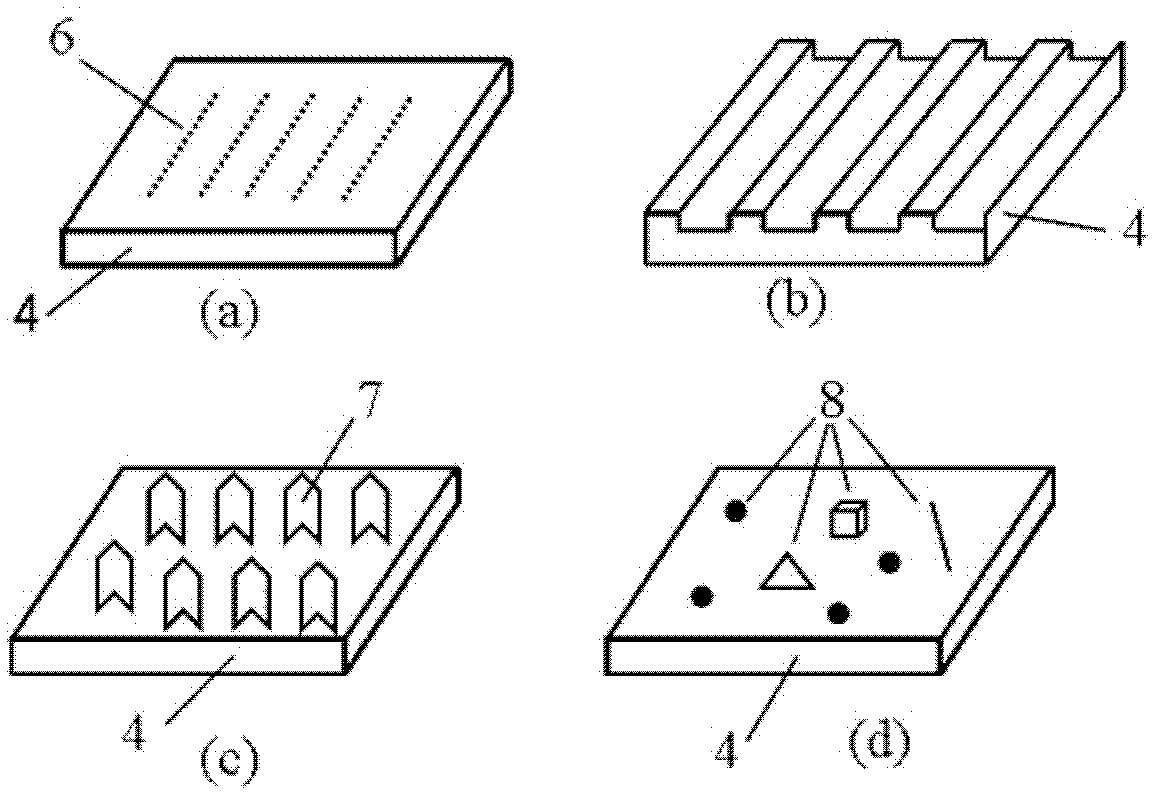

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: grow graphene film on Si (100) substrate

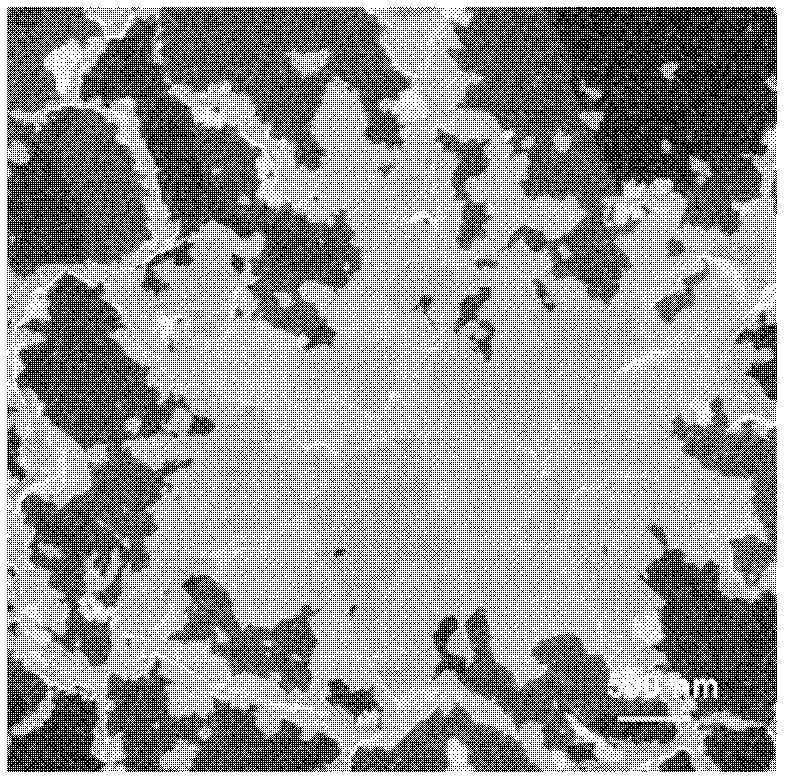

[0034] It includes the following steps: transfer n-type Si(100) to an ultra-high vacuum chamber, heat treat at 600°C for 300min, and then raise the temperature to 1000°C for 3 times, each time for 0.5min, so as to obtain a clean Si(100) surface; keep the substrate The temperature of the bottom Si(100) is 800°C, and H is passed into the ultra-high vacuum chamber 2 with C 2 h 4 mixed gas, and use the electron beam from the electron gun to C 2 h 4 Ionize into active carbon atom groups, and grow graphene film on Si(100) substrate for 5 minutes; finally, the substrate temperature has been lowered at a rate of 20°C / min to 25°C, thereby growing a large-area layer on the Si substrate The number is inconsistent (ranging from 1-3 layers) graphene film. image 3 A scanning electron microscope image of a graphene film grown on a single crystal Si substrate.

[0035] Effect: Si is the core material of contemporary silico...

Embodiment 2

[0038] Embodiment 2: prepare graphene film on polymer polyethylene terephthalate (PET) substrate

[0039] It includes the following steps: the PET substrate is introduced into the ultra-high vacuum chamber, the temperature of the PET substrate is 150°C, methane is passed into the ultra-high vacuum chamber, and the air pressure is kept at 8×10 -4 Torr, using an ion gun to ionize methane with an accelerating voltage of 1keV, so that the ionized methane is deposited on the PET substrate, the deposition time is 5min, and then the sample is annealed for 60min at a temperature of 100°C and synthesized on PET. A graphene film with a thickness of about 33.5nm (100 layers).

[0040]Effect: All kinds of flat panel displays, touch screens and solar cells need transparent electrode films. Flexible devices are attracting more and more attention. PET is a transparent flexible material, and transparent conductive graphene can be directly grown on PET at a relatively low temperature. It laid...

Embodiment 3

[0043] Embodiment 3: grow graphene film on polycrystalline copper substrate

[0044] It includes the following steps: mechanically polish a polycrystalline copper sheet with a thickness of 25 μm, spin-coat polymethyl methacrylate (PMMA) with a thickness of 100 nm on the polished Cu sheet, and transfer it to a high vacuum chamber (2×10 -5 torr), using RF beams to ionize PMMA, while raising the substrate temperature to 1050°C for 10 minutes, and finally lowering the substrate temperature to 25°C to synthesize single-layer graphene on the entire polycrystalline copper substrate. Figure 4 is the synthesized monolayer graphene transferred to SiO 2 Auger electron map on a substrate.

[0045] Effect: The technical method for generating active carbon atoms or carbon-containing active groups is energy particle technology, including but not limited to radio frequency treatment, laser treatment, electron beam treatment, neutron beam treatment, ion beam treatment, plasma treatment, micr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com