Gasification fly ash grading resource utilization system and method

A technology of recycling and fly ash, applied in combustion methods, climate sustainability, indirect carbon dioxide emission reduction, etc. The effect of burning time, lowering the ignition point, and sufficient combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

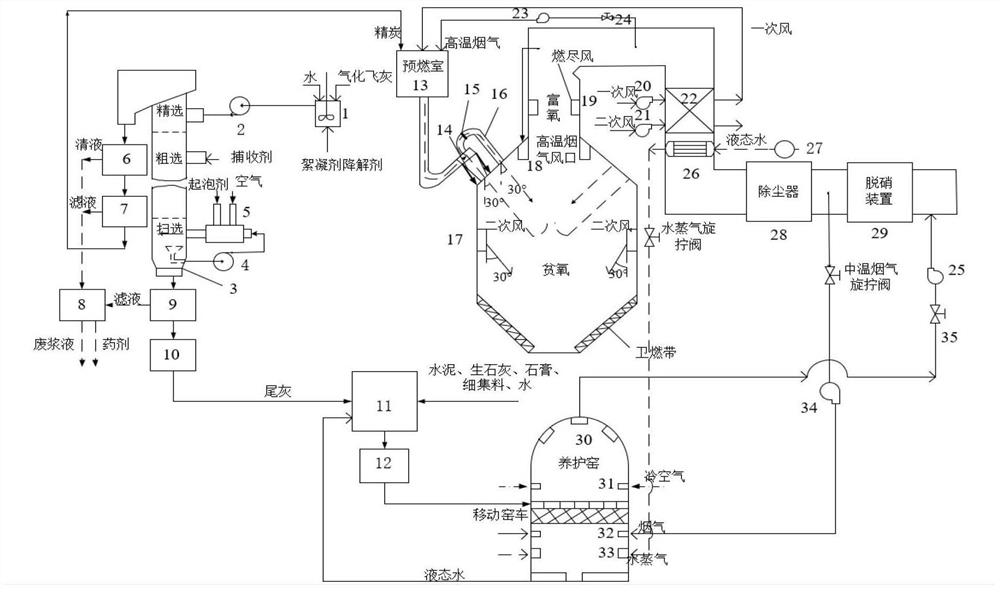

[0029] In order to make the above objects, features and advantages of the present invention more concise and understandable, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0030] The core idea of the present invention is: use the swirl-micro-bubble flotation bed to separate the residual carbon and ash contained in the gasification fly ash, and obtain refined carbon and tail ash after deep processing, and use W-type flame boiler to clean the carbon The fine carbon is burned out, and the tail ash assists other fine aggregates to prepare wall bricks. The flue gas produced by the W-shaped flame boiler and the steam generated by heating at the tail of the boiler are used to maintain the prepared wall bricks, so as to achieve full utilization of solid waste resources and energy. the goal of.

[0031] see figure 1 , a gasification fly ash classification resource utilization system provided b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com