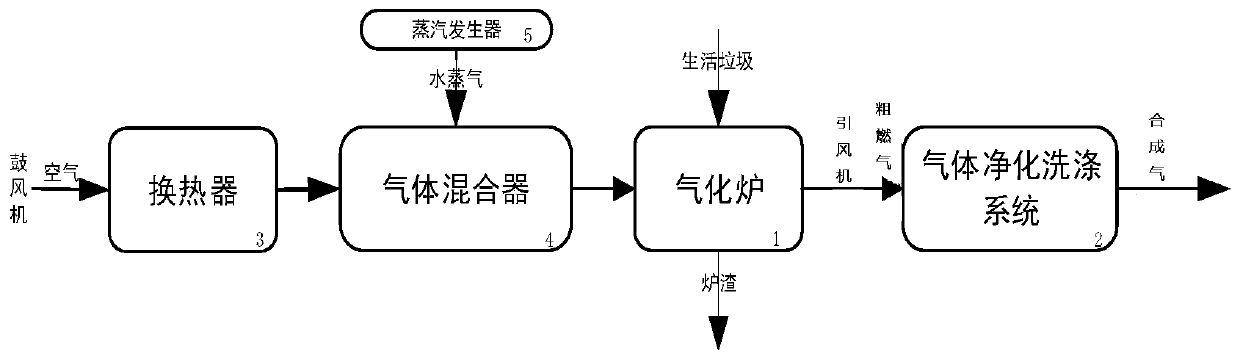

Garbage gasification system using air and steam as gasification agents

A gasification system and gasification agent technology are applied in the system field of high temperature gasification of domestic waste, which can solve the problems of low gas calorific value, waste heat loss, low gasification efficiency, etc. The effect of reducing sensible heat loss and overcoming technical defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Domestic garbage that has been pre-treated enters the gasifier 1 through the conveying device. During the material descending process, the air blown in by the blower and the high-temperature gas formed after heat exchange in the heat exchanger 3 enter through the gas mixer 4 inlet. After being mixed with the steam generated by the steam generator 5 in the gas mixer 4, it enters the gasifier 1 under the action of the fan, and in the gasification gas, the gasification agent interacts with domestic waste, and reacts in a high temperature environment to form coarse The fuel gas passes through the gas outlet of the gasifier, and passes through the gas purification and washing system 2 under the action of the fan to produce clean syngas for resource utilization.

[0018] In the gasification layer of the gasifier 1, the oxygen in the air and the materials are combusted to generate carbon dioxide, which releases a large amount of heat. Then, under the action of high temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com