Method and device using high temperature air and high temperature steam as gasification agents for coal gas production

A technology of high-temperature steam and high-temperature air, which is applied in the manufacture of combustible gas and the petroleum industry. It can solve the problems of high gas outlet temperature, unfavorable terminal gas use, and large sensible heat loss, and achieve more combustion and gasification reaction and combustion gasification. The reaction is complete and thorough, and the effect of increasing the calorific value of gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The difference between the present invention and the prior art will be described below in conjunction with the accompanying drawings; and the present invention will be further described.

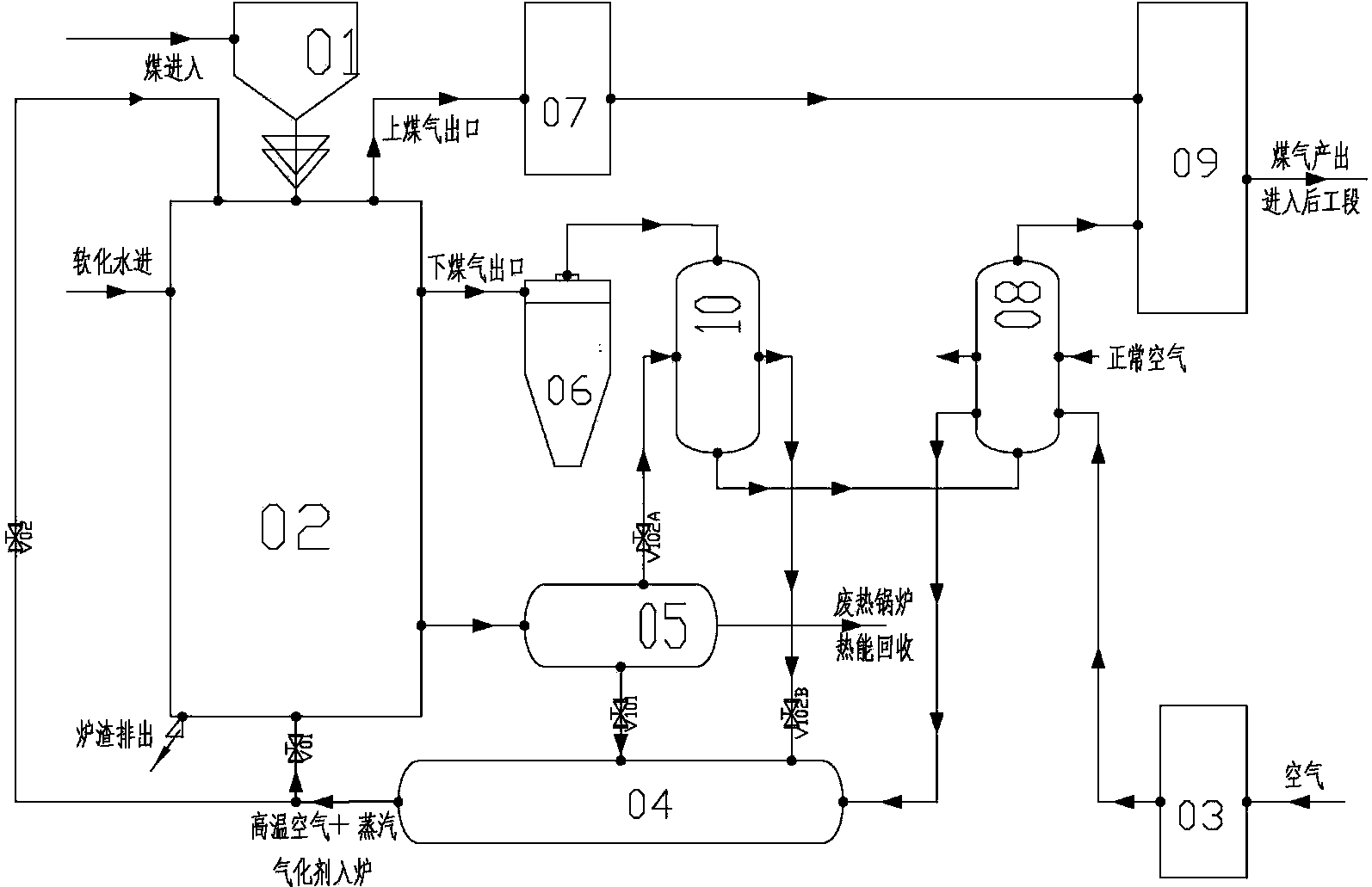

[0050] figure 1 It is a coal gas generation process and device that uses high-temperature air and high-temperature steam as gasification agents, and is mainly composed of the following process equipment:

[0051] Coal bunker 01, gas generator 02, blower 03, mixer 04, jacketed drum 05, dust collector 06, electric coke collector 07, air cooler 08, washing cooler 09, heat exchanger 10.

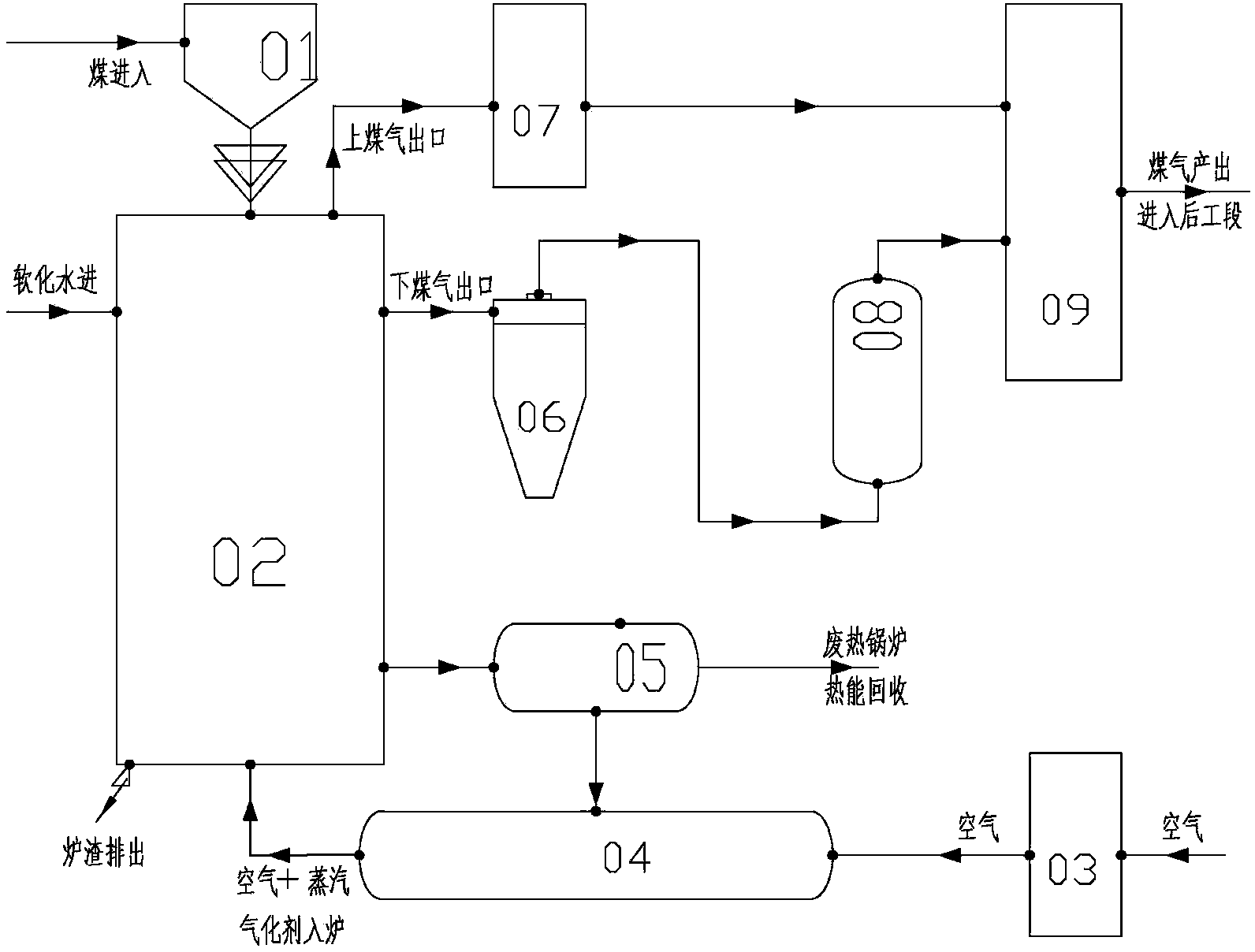

[0052] figure 2 It is a traditional coal gas generation process and device that uses air and steam as gasification agents. For comparison, it is mainly composed of the following process equipment:

[0053] Coal bunker 01, gas generator 02, blower 03, mixer 04, jacketed steam drum 05, dust collector 06, electric coke collector 07, air cooler 08, washing cooler 09.

[0054] attached figure 1 The blowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com