Fly ash carbon content soft measurement method and coal-fired boiler combustion optimization method and system

A fly ash carbon content, coal-fired boiler technology, applied in design optimization/simulation, special data processing applications, etc., can solve problems such as strong hysteresis, inability to optimize boilers, and large errors, and achieve the effect of improving boiler combustion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

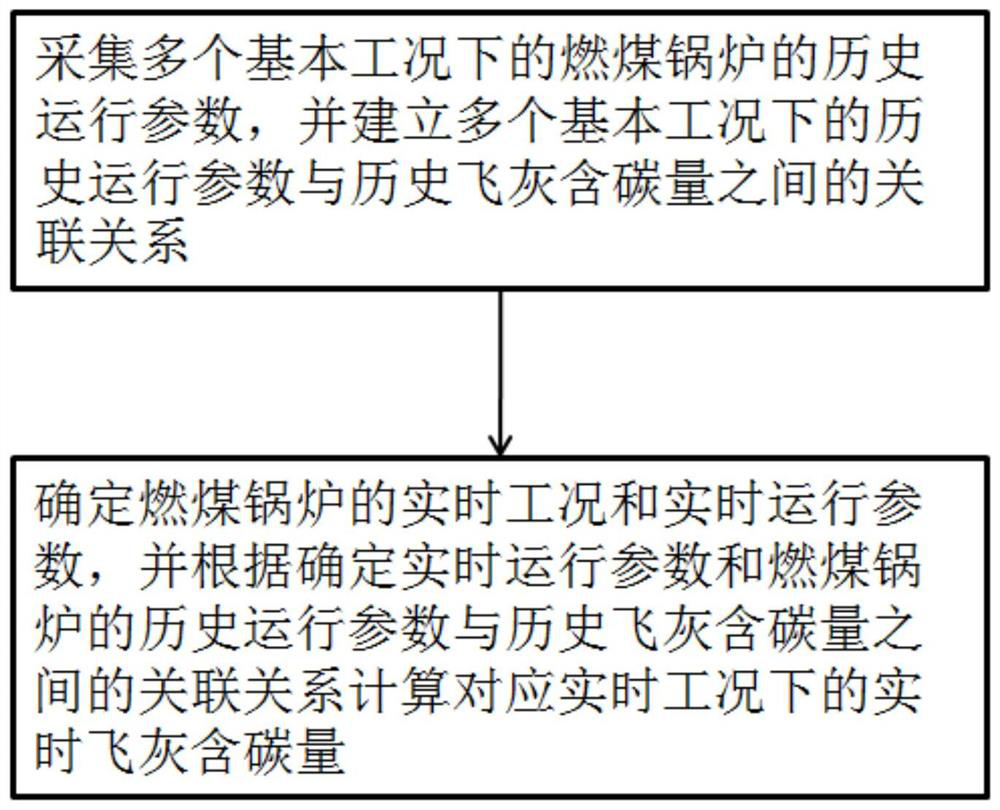

[0049] refer to figure 1 , Propose embodiment 1 of the present application, embodiment 1 proposes a kind of fly ash carbon content soft measuring method, comprises the following steps:

[0050] Step 1. Collect the historical operating parameters of coal-fired boilers under multiple basic working conditions, and establish the correlation between the historical flue CO concentration and the historical fly ash carbon content under multiple basic working conditions;

[0051] Step 2. Determine the real-time working conditions and real-time operating parameters of the coal-fired boiler, and calculate the real-time fly ash carbon content corresponding to the real-time working conditions according to the real-time operating parameters and the association relationship established in the step 1.

[0052] The multiple basic working conditions of the coal-fired boiler in the step 1 correspond to a typical boiler load and a typical interval range of coal volatile matter, and the typical lo...

Embodiment 2

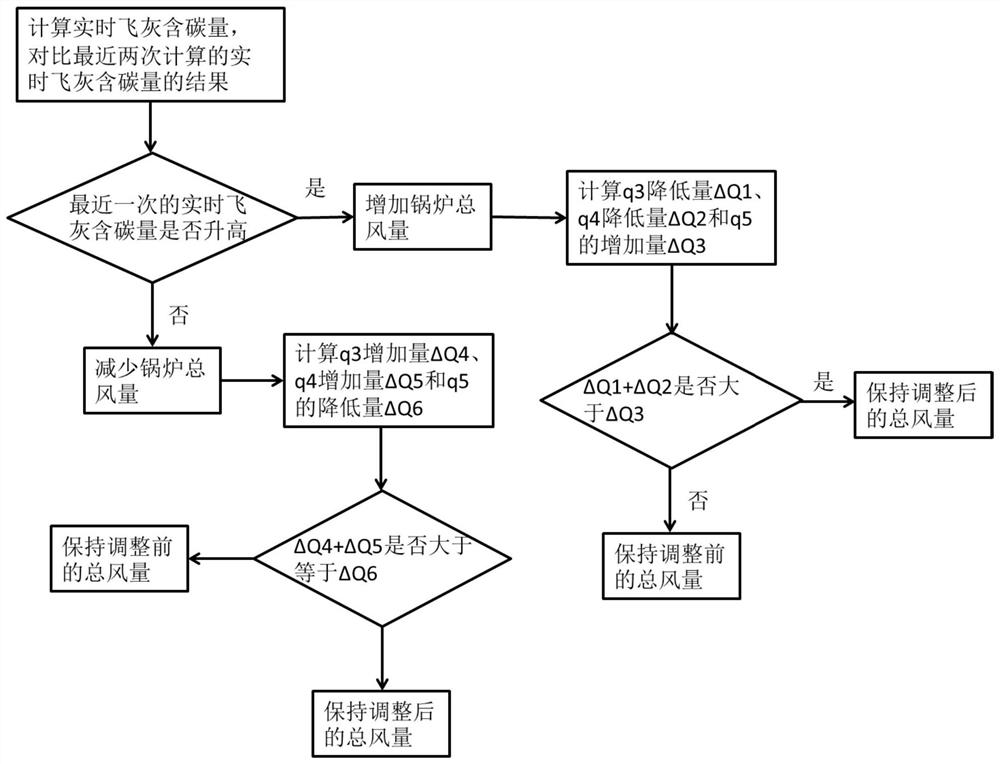

[0080] refer to image 3 , Embodiment 2 proposes a method for optimizing combustion of a coal-fired boiler, specifically comprising the following steps:

[0081] Step 1, adopt the fly ash carbon content soft measurement method as described in embodiment 1 to calculate the real-time fly ash carbon content in the coal-fired boiler;

[0082] Step 2. Compare the last two calculated real-time fly ash carbon contents, and adjust the total boiler air volume according to the changes of the last two real-time fly ash carbon contents.

[0083] In the step 2, specifically, when the carbon content of the latest real-time fly ash increases by 0.1%, the total air volume of the boiler is increased by 0.04%. Increase ΔQ3, if ΔQ1+ΔQ2>ΔQ3, keep the adjusted total air volume, if ΔQ1+ΔQ2≤ΔQ3, keep the total air volume before adjustment;

[0084] When the latest real-time fly ash carbon content decreases by 0.1%, reduce the total boiler air volume by 0.04%. After adjustment, calculate the q3 inc...

Embodiment 3

[0089] refer to Figure 4 , Embodiment 3 proposes a combustion optimization system for a coal-fired boiler based on the combustion optimization method for a coal-fired boiler in Embodiment 2, including:

[0090] The data acquisition module is used to collect historical operating parameters of coal-fired boilers under multiple basic working conditions, and collect real-time working conditions and real-time operating parameters of coal-fired boilers;

[0091] An association relationship establishment module, used to establish an association relationship between the historical flue CO concentration of coal-fired boilers and the historical fly ash carbon content under multiple basic working conditions;

[0092] The fly ash carbon content soft measurement module is used to calculate the real-time fly ash carbon content according to the real-time operating parameters of the coal-fired boiler and the correlation relationship established in the correlation relationship establishment mod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com