Embodied carbon energy-based machine tool equipment product carbon emission quantification method

A technology of carbon emissions and carbon emissions, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as difficult quantitative calculation of carbon emissions, inconsistent boundaries, etc., to ensure practicality and consistency, The effect of unifying the calculation process and avoiding complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0054] 4.1 Analysis of material flow and energy flow of machine tool equipment products

[0055] 4.1.1 Carbon emission source analysis

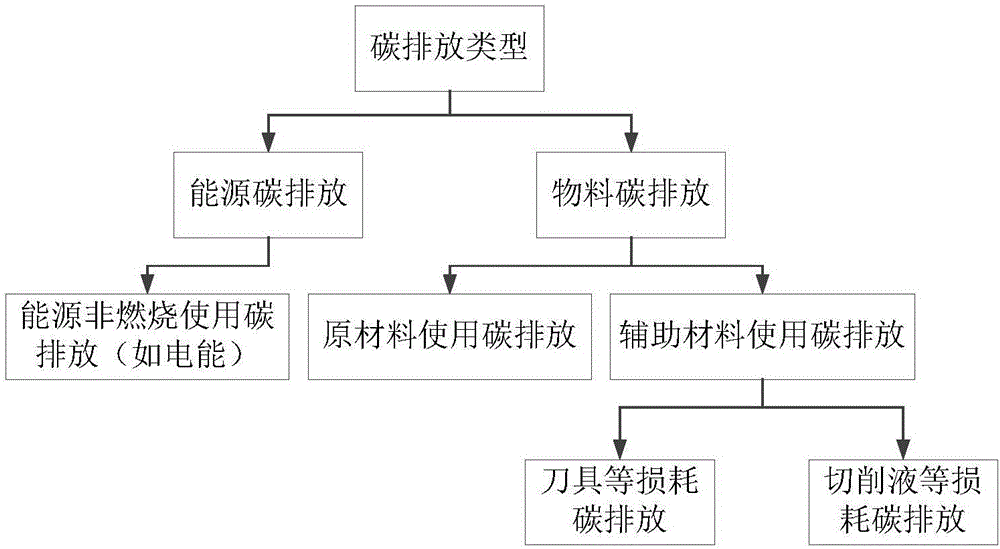

[0056] refer to figure 1 , to quantify carbon emissions, it is first necessary to delineate and classify the carbon emission sources of machine tool equipment products in the life cycle, which are divided into energy carbon and material carbon. Material carbon includes the carbon emissions generated by the raw material acquisition process of each part of machine tool equipment products, and the carbon emissions generated by tool loss and cutting fluid loss of machine tool equipment products.

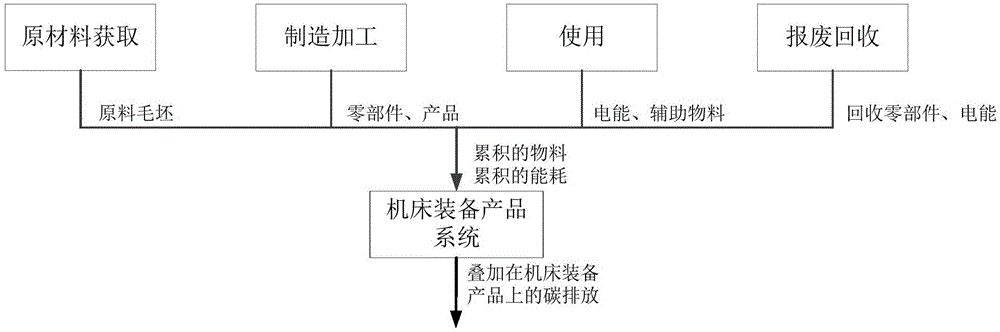

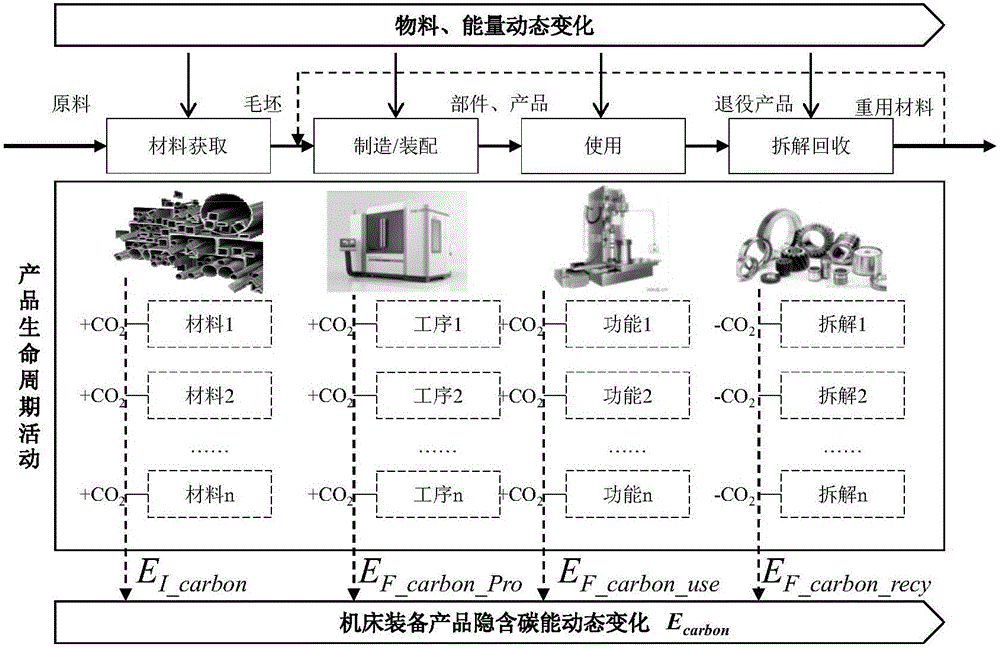

[0057] 4.1.2 Determination of material flow and energy flow

[0058] Further, the material flow and energy flow of machine tool equipment products are analyzed, and the material flow is expressed as the change of materials. In the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com