Internal circulating fluidized bed gasification furnace adapted to organic solid waste treatment

A fluidized bed gasifier and solid waste technology, applied in incinerators, combustion air/fuel supply, combustion methods, etc., can solve the problems of geographical restrictions, low calorific value of sludge, and inability to realize on-site disposal, etc. achieve the effect of avoiding delamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

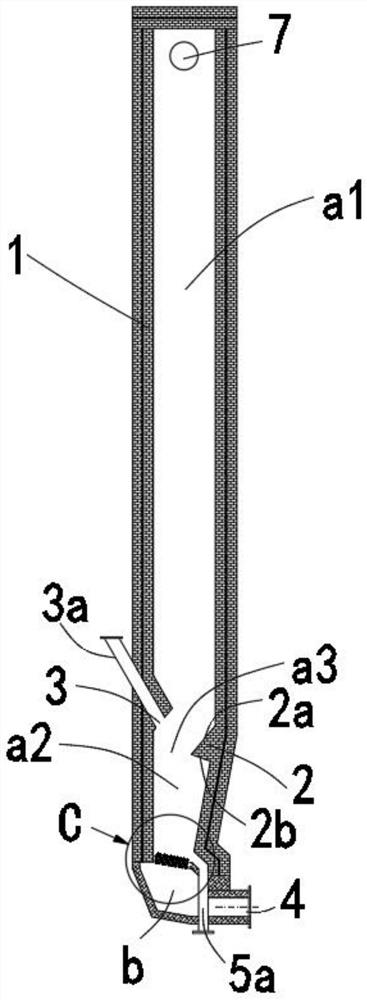

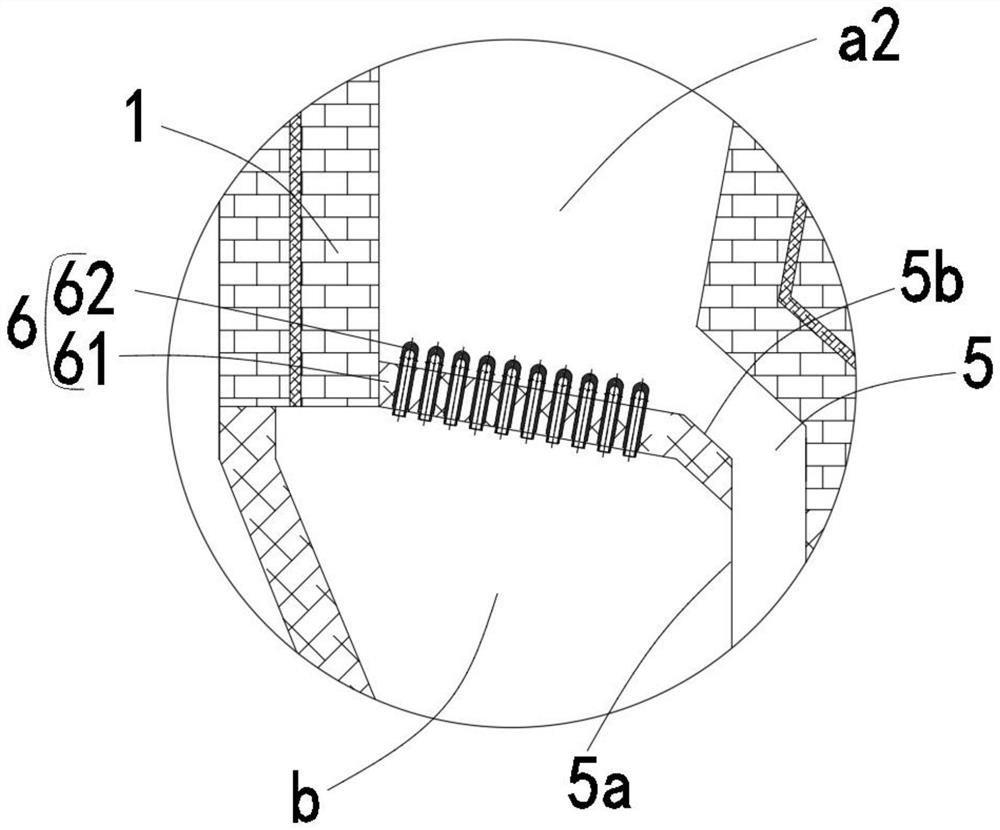

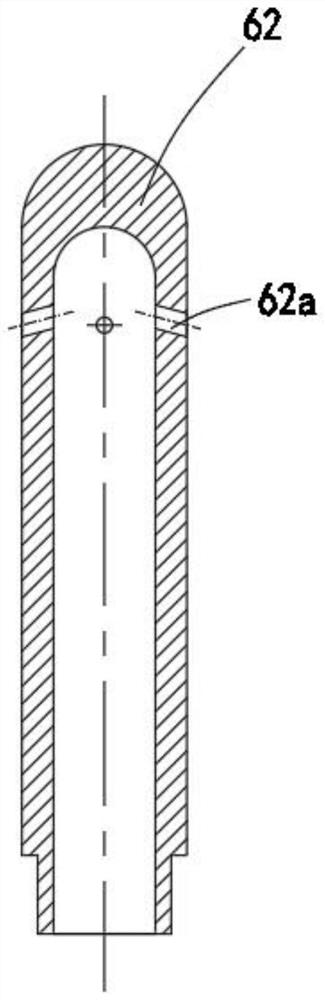

[0039] Specific example: a sewage plant to be disposed of sludge 100 tons / day (moisture content 80%), using gasification coupling drying integrated process, according to energy balance, dry 100 tons of wet sludge with a moisture content of 80% to 30% moisture rate of dry sludge, an additional 0.6t / h of biomass needs to be supplemented while utilizing the energy of dry sludge. The dried dry sludge and supplemented biomass are respectively conveyed to the biaxial screw, fully stirred and mixed, and then sent to the internal circulating fluidized bed gasifier. The equivalence ratio of the system is 0.28, and 1100m3 / h of air is required for gasification of dry sludge and biomass mixture. The air is pressurized by the blower and sent to the air chamber at the bottom of the gasifier evenly distributed, and then flows out through the air guide holes of the air cap on the air distribution plate, driving the bed material and materials to turn over and disturb continuously, and the ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com