Thermal power generating unit flexible coordination control method suitable for deep peak regulation operation

A thermal power unit, coordinated control technology, applied in the direction of adaptive control, engine control, general control system, etc., can solve the problems of on-site configuration, debugging, maintenance difficulties, etc., to ensure combustion stability, ensure control effect, and satisfy control desired effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

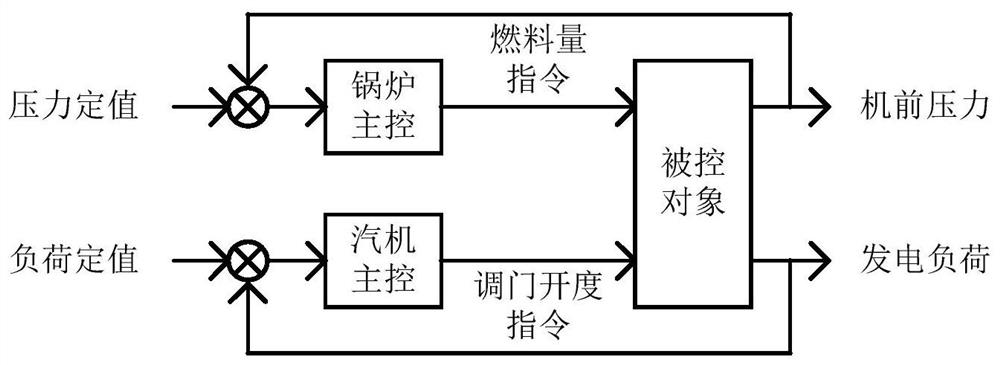

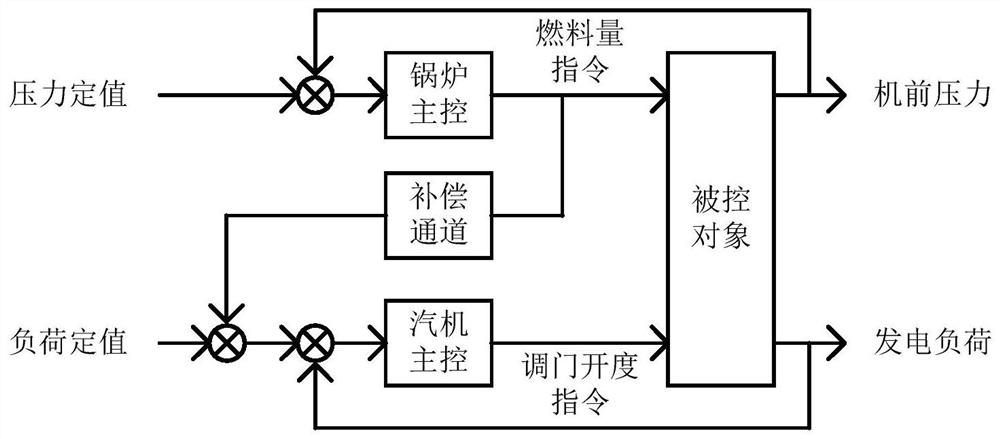

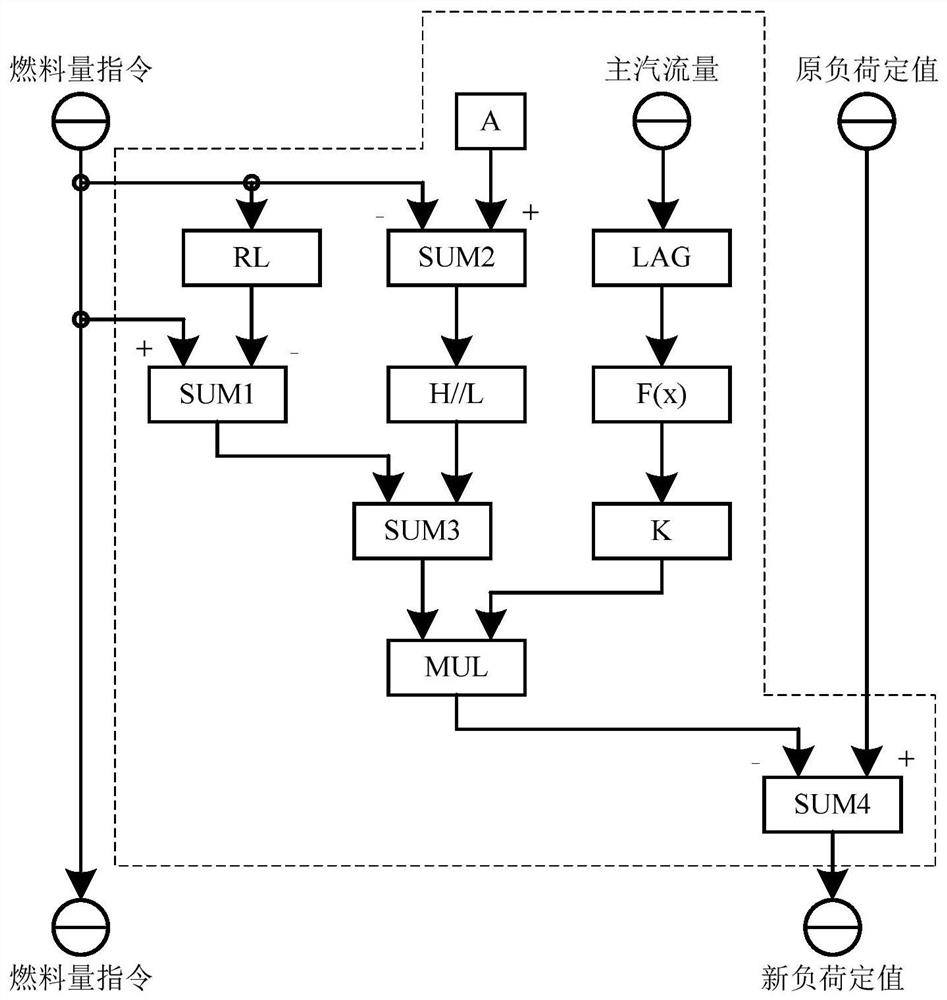

[0023] Aiming at the deficiency that the existing coordinated control system cannot simultaneously satisfy the control quality of the power generation load and the steam pressure before the steam turbine under the normal load condition, and the combustion stability under the deep peak load condition, the present invention proposes a Flexible coordinated control system for deep peak shaving operation of thermal power units. The main features are: on the basis of the traditional machine-to-boiler coordinated control system, a reverse compensation channel for the fuel quantity command to the power generation load command is added; the flexibility factor is constructed by using the main steam flow signal, and the reverse compensation channel is corrected by the product Gain; the offset value of the compensation channel outputs the reverse power generation load command to correct the power generation load command of the unit, and utilizes the closed-loop adjustment characteristics o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com