Ultra-low-load operation system and operation method for coal-fired generating units

A generator set and coal-fired technology, which is applied in the direction of machines/engines, mechanical equipment, steam engine devices, etc., can solve the problems of denitrification reactor exhaust gas temperature drop performance deterioration, boiler combustion instability, coal mill instability, etc., to achieve Guarantee the efficiency of denitrification catalytic reaction, alleviate the pressure of peak regulation, and shorten the time of start-up and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

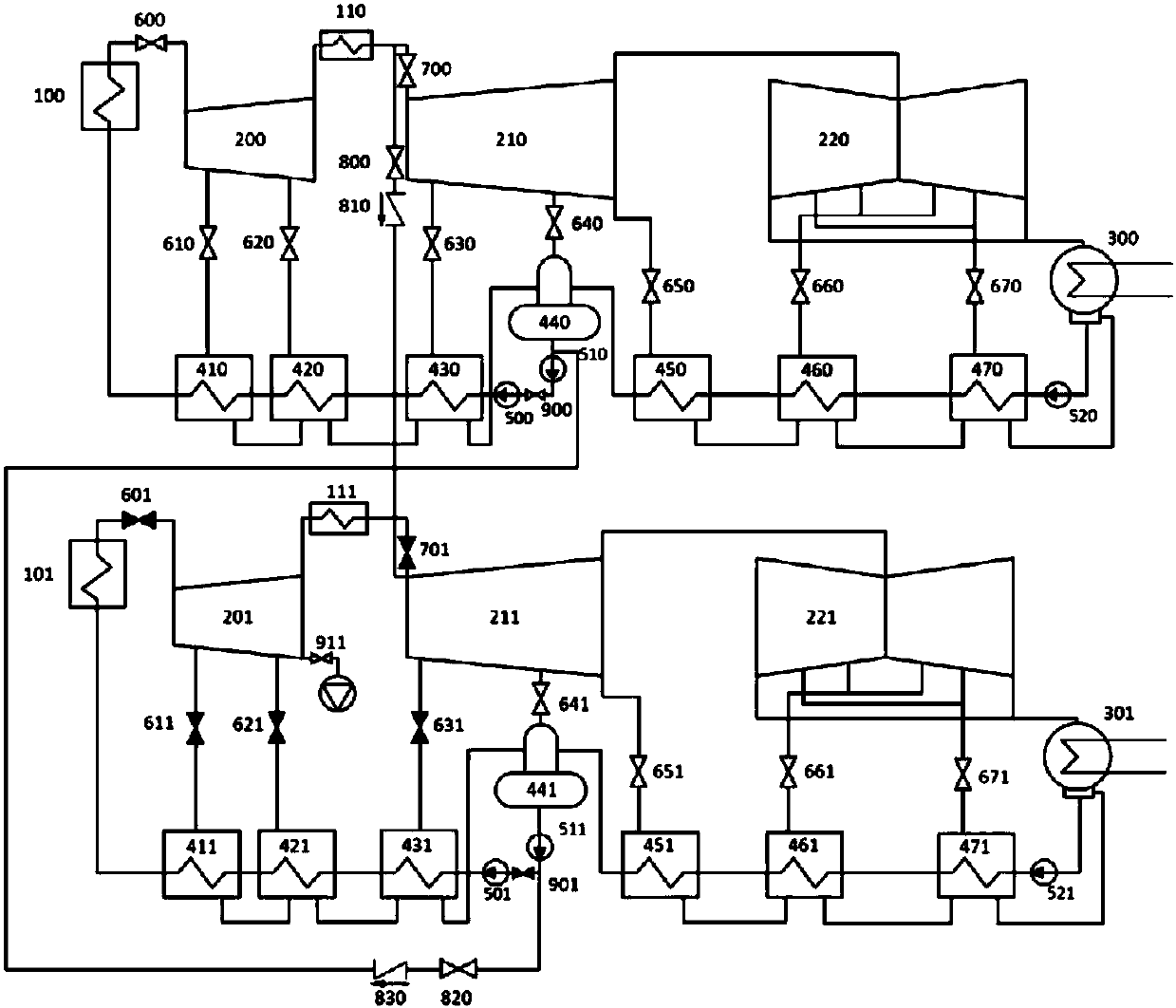

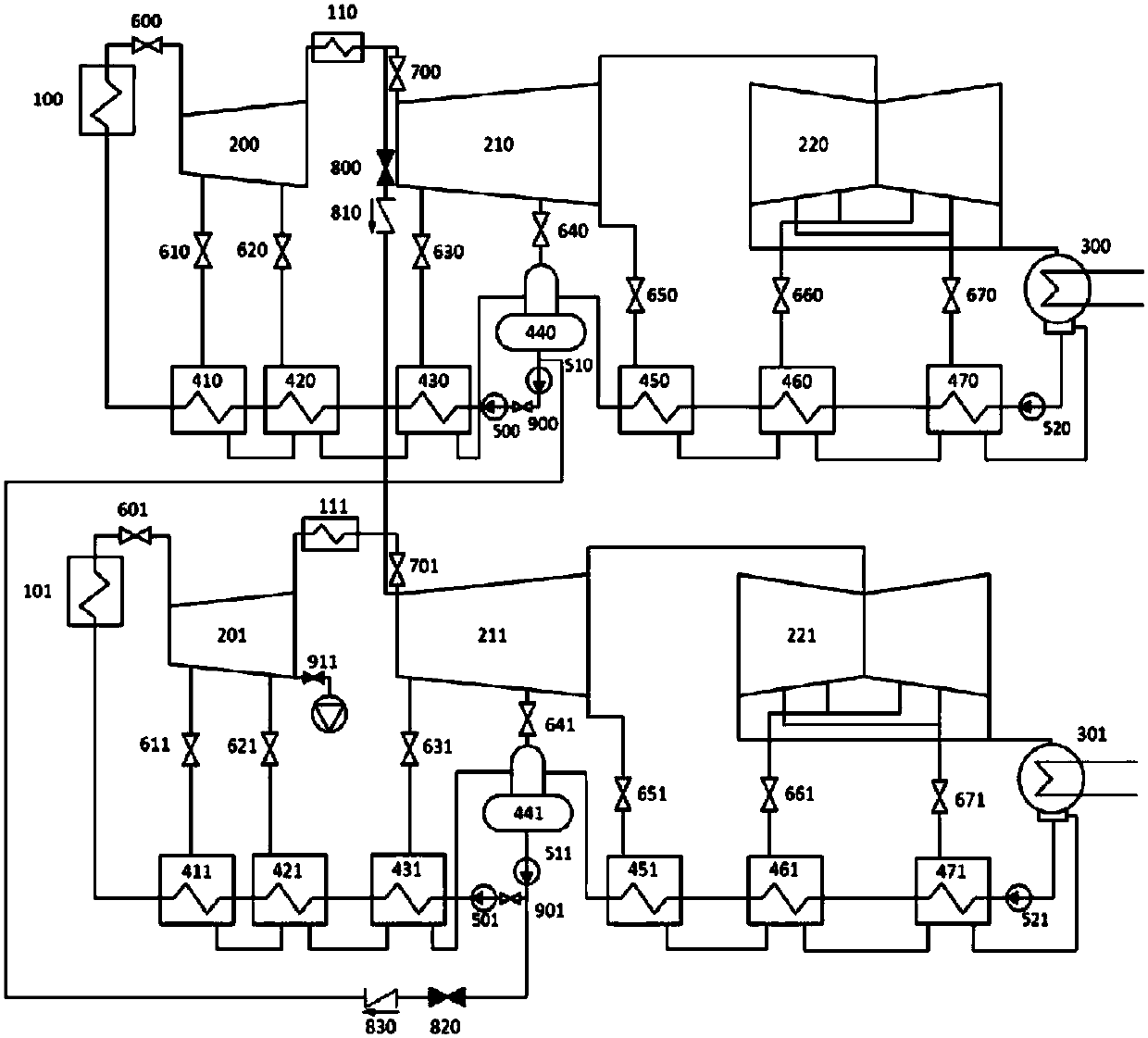

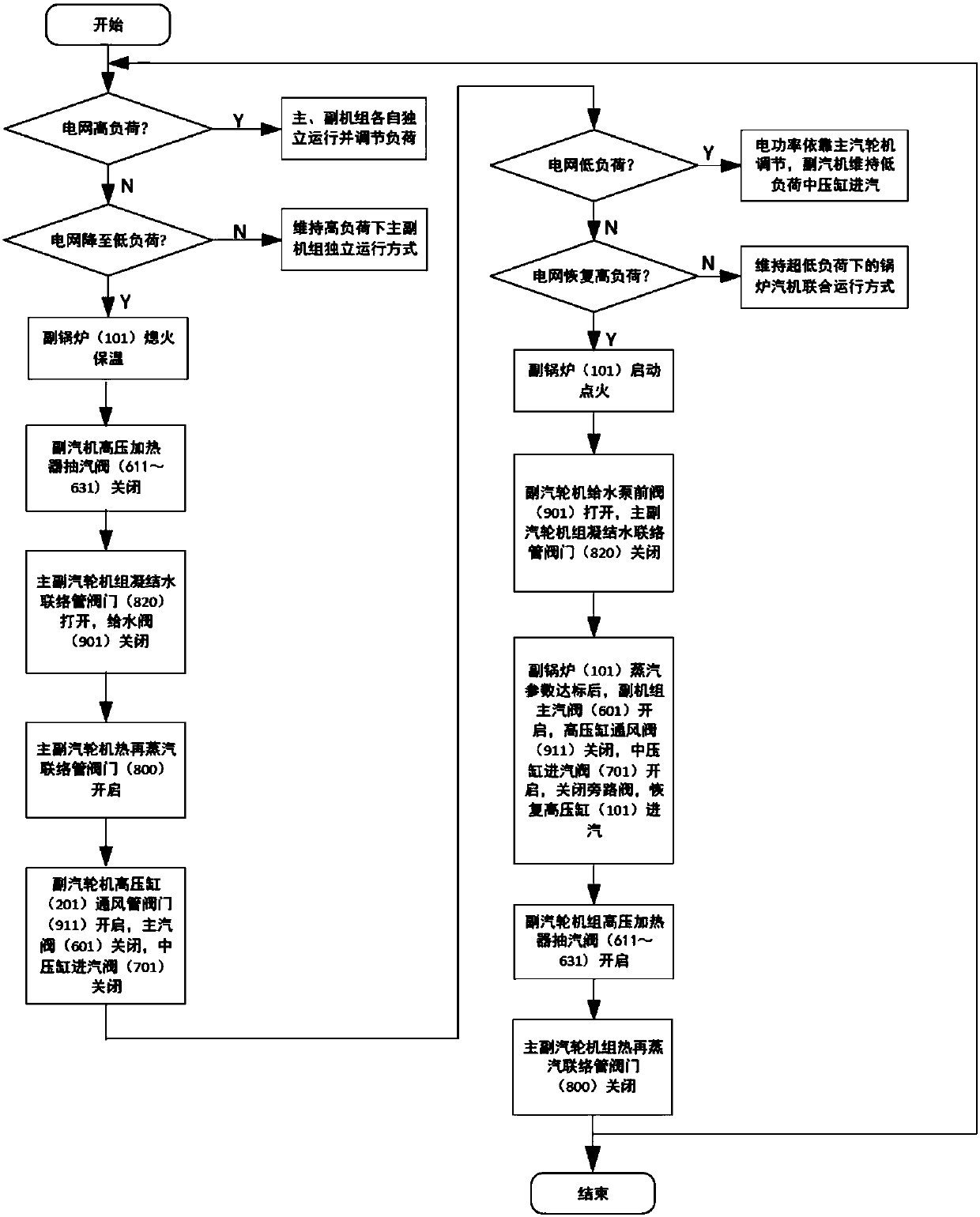

[0026] Such as figure 1 As shown, a coal-fired generating set system is composed of a main generating set and an auxiliary generating set. A typical structure of a low-pressure heater and a deaerator.

[0027]The structure of the main generating set is that the boiler 100 is connected to the main steam valve 600, the main steam valve 600 is connected to the high pressure cylinder 200 of the steam turbine, the high pressure cylinder is connected to the reheater 110, the reheater 110 is connected to the medium pressure cylinder inlet valve 700, and the medium pressure cylinder is connected to the steam inlet valve 700. The steam valve 700 is connected to the medium pressure cylinder 210, the medium pressure cylinder 210 is connected to the low pressure cylinder 220, the low pressure cylinder and the condenser 300, the condenser 300 is connected to the condensate pump 520, and the condensate pump 520 is connected to the regenerative heater 470. The regenerative heater of steam t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com