Apparatus for adjusting secondary wind direction under W type flame oven arch

A flame furnace and wind direction technology, applied in the direction of adjusting air supply, lighting and heating equipment, combustion methods, etc., can solve the problems of inconvenient adjustment of horizontal deflectors, unstable combustion under high load, and high NOx emissions, so as to avoid local extremes High temperature zone, prolonged mixing process, energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

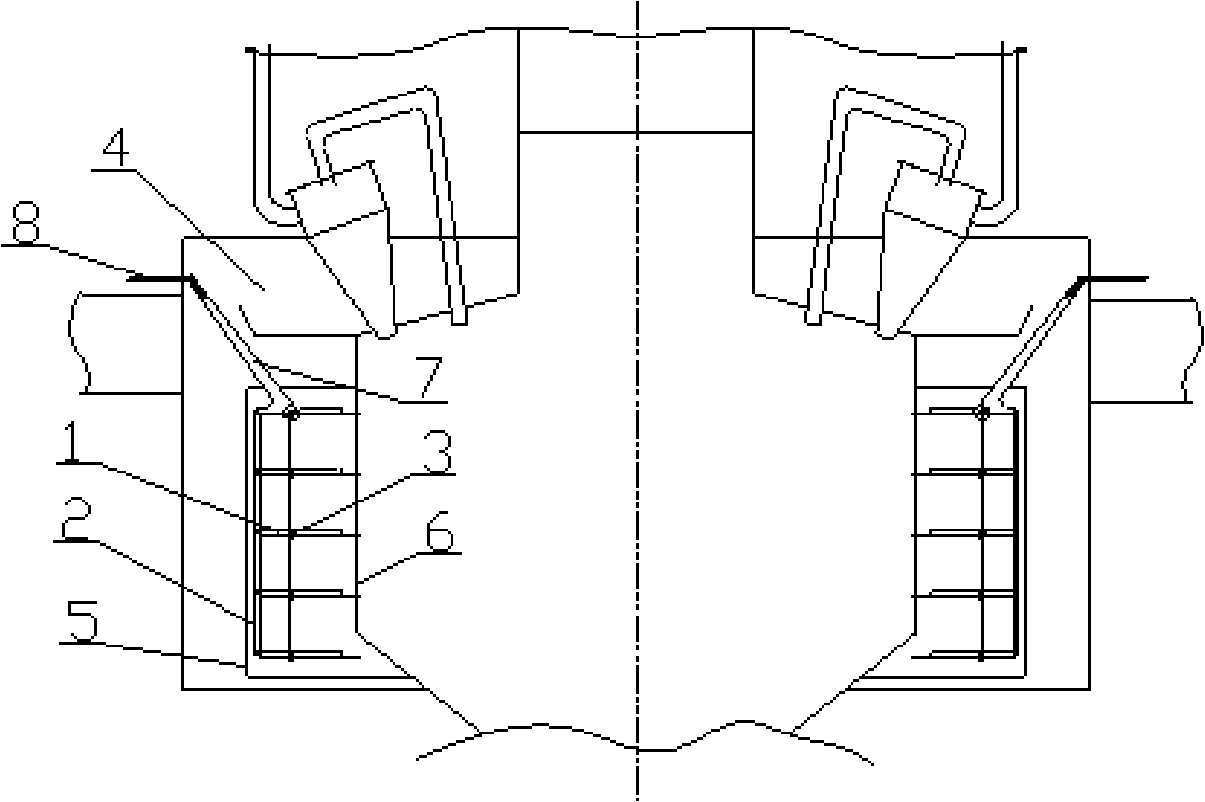

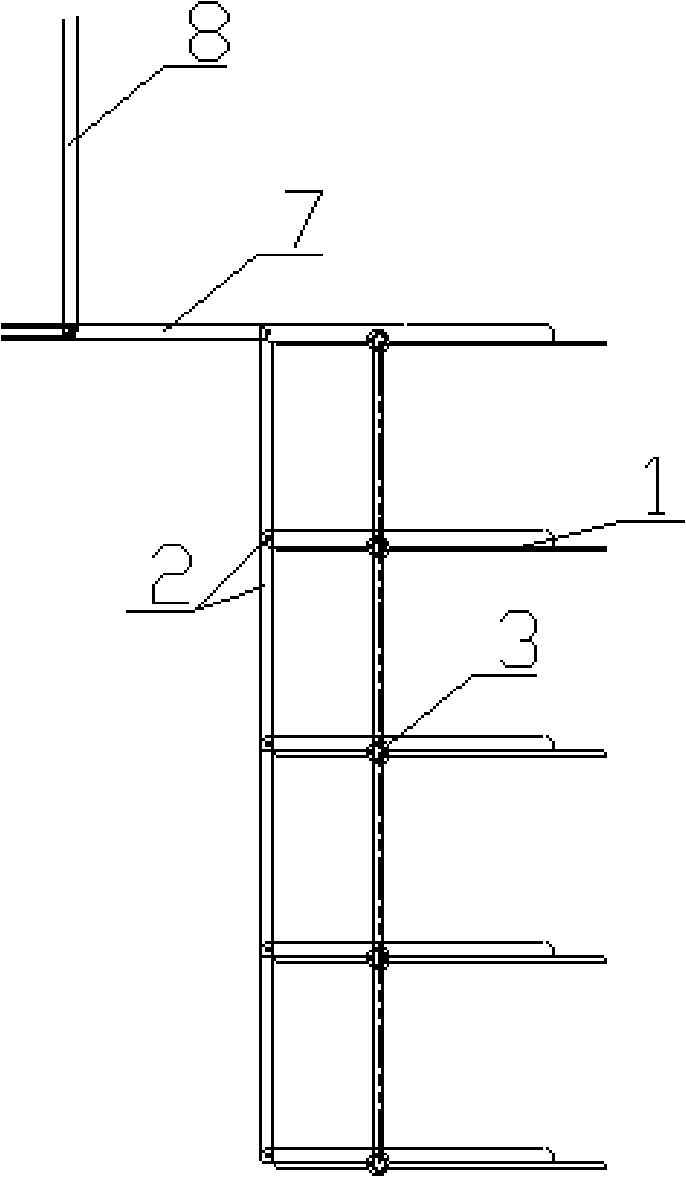

[0024] Example: such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, when the present invention is installed, the equalizing orifice plate 5 is moved backward by 600-800 mm. The guide vanes 1 are made of steel plates, and their quantity and size are determined according to the width and height between the adjusted equalizing orifice plate 5 and the water-cooled wall tube 6 in the secondary air chamber. The installed guide vanes 1 can be as follows: Figure 7 Shown is a whole flat plate, and then on every guide vane 1, a rotating shaft 3 (such as Figure 7 ); also can weld longitudinal dividing plate 12 according to the position and the quantity of W-shaped flame furnace F tuyere in the secondary air distribution chamber 4 under the arch earlier, the longitudinal dividing plate 12 separates the secondary air chamber to form two or more than two Distributing chamber 18, guide vane 1 is installed in distributing chamber 18 then, and guide vane 1 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com