Gas turbine combustor with active fuel distribution control function

A technology of fuel distribution and active control, applied in combustion chambers, continuous combustion chambers, combustion methods, etc., can solve problems such as increased concentration of unburned hydrocarbon fuels and CO, increased residence time, and potential safety hazards in the stable operation of combustion chambers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

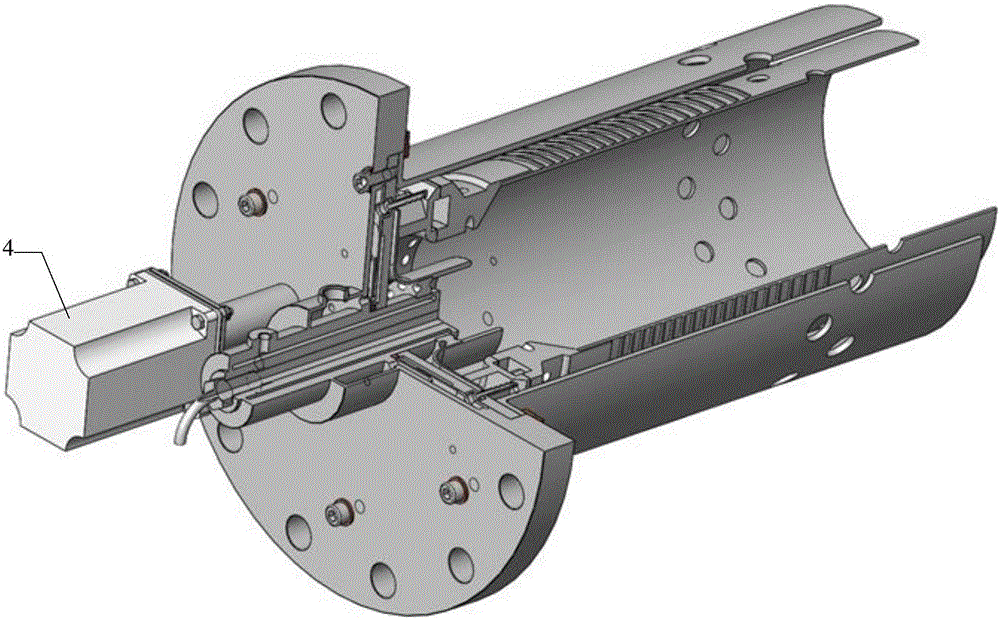

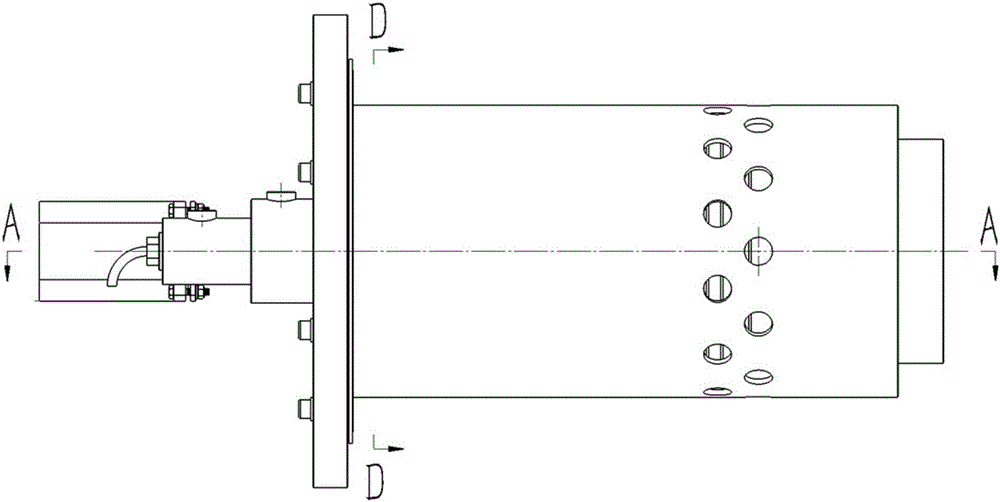

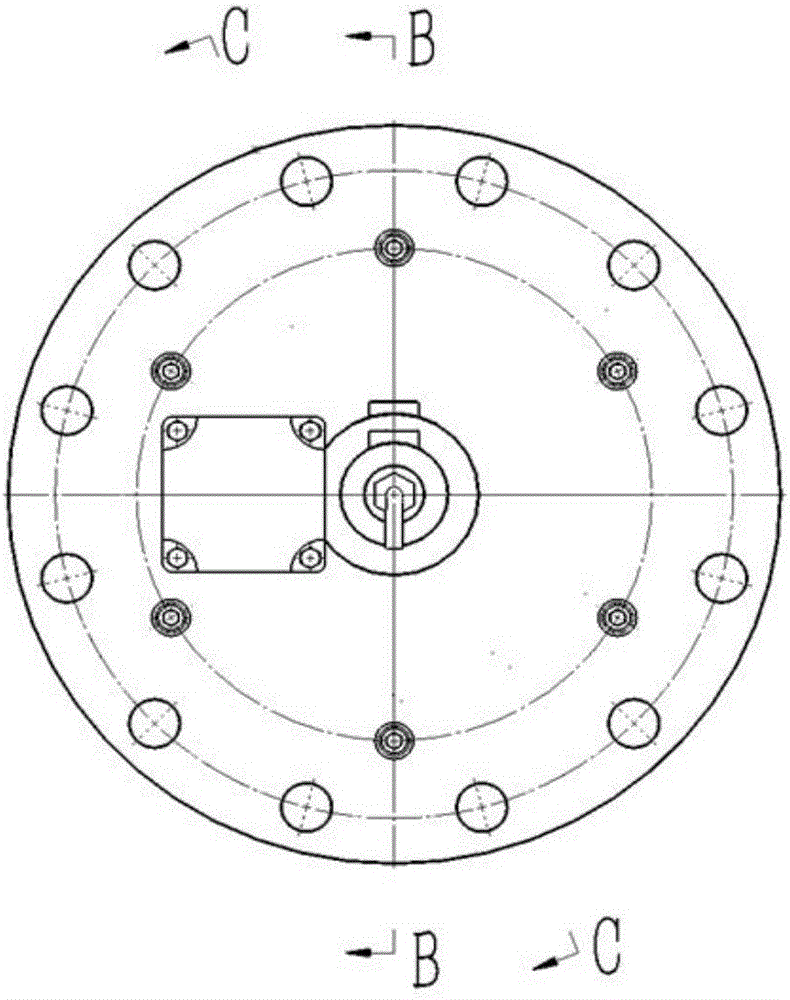

[0050] Exemplary embodiments of the present invention will be described in detail below with reference to the accompanying drawings. The description of the exemplary embodiments is for the purpose of illustration only, and in no way limits the invention and its application or usage.

[0051] Aiming at the defects of gas turbine fuel distribution methods in the prior art, the present invention provides a solution for a gas turbine combustion chamber with the function of actively controlling fuel distribution. The main idea of the present invention is: a fuel distribution control unit is arranged in the combustion chamber; the fuel distribution control unit includes: a motor, a transmission mechanism, and a rotating disk. In addition, m-group dispensing holes are provided on the rotating disk to cooperate with the positioning holes on the fixed disk. Wherein, the number of distribution holes in each group is not equal to each other. Under different load conditions, the motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com