Low-pollution combustion head structure

A combustion head, low-polluting technology, applied in burners, combustion types, combustion methods, etc., can solve problems such as energy waste, high pollution emissions, and long fuel retention time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

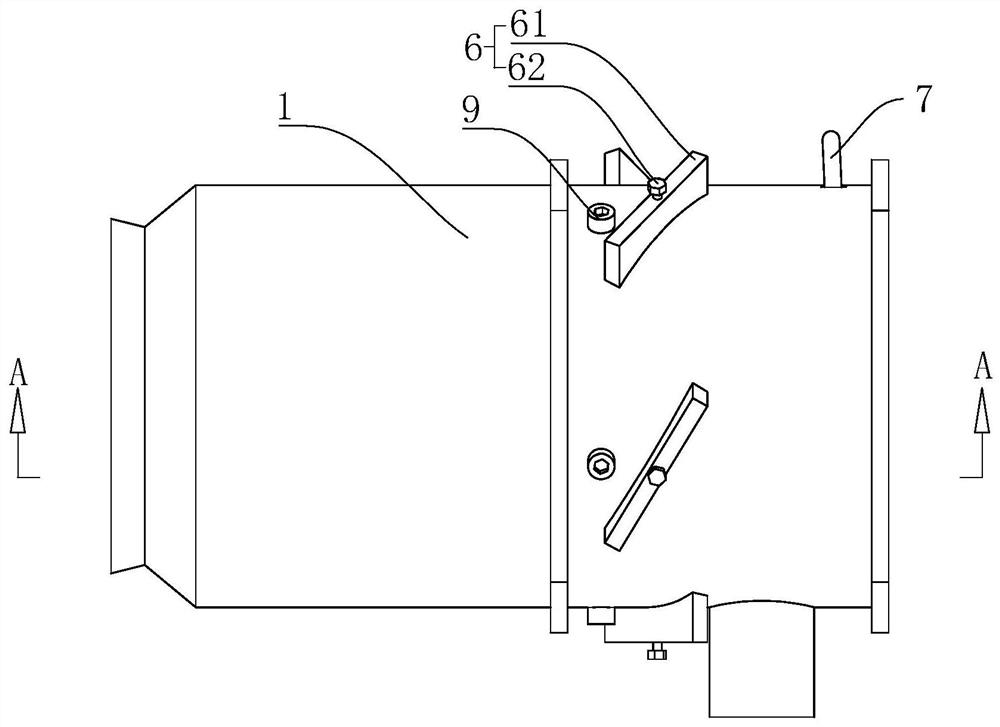

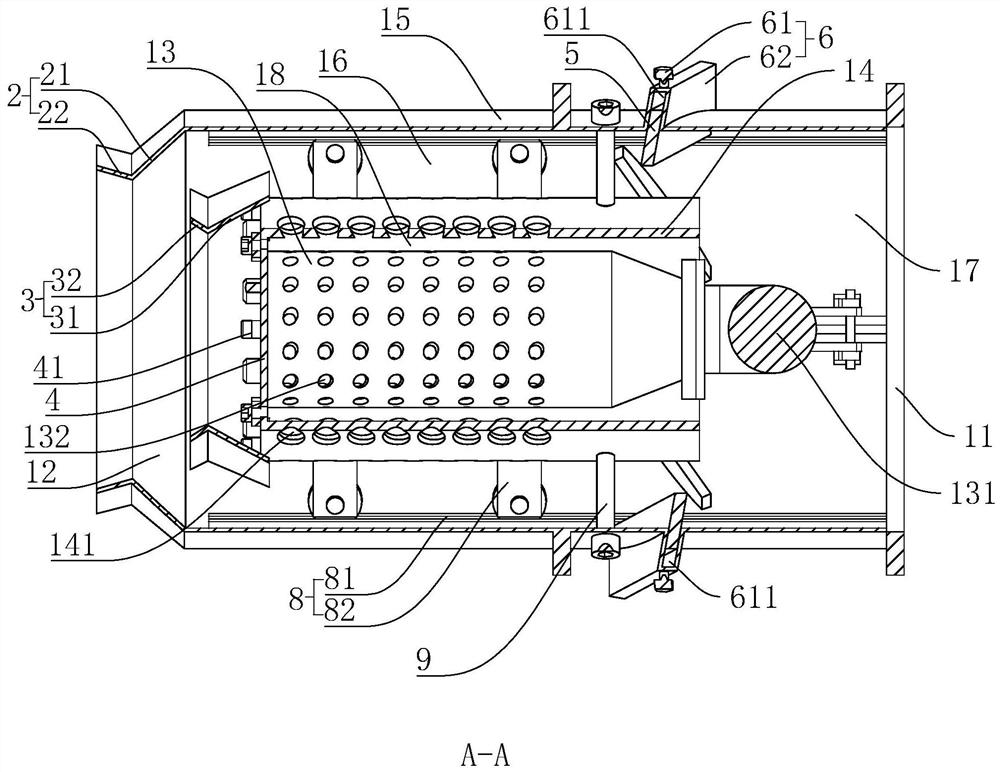

[0039] combine figure 1 and figure 2 , is a low-pollution combustion head structure disclosed in the present application, including a combustion head body 1, the combustion head body 1 is provided with an air inlet 11 and a mixture gas outlet 12, and the air inlet 11 and the mixture gas outlet 12 are respectively arranged on the combustion head On both sides in the length direction of the main body 1 , the air inlet 11 and the mixed gas outlet 12 are oppositely arranged.

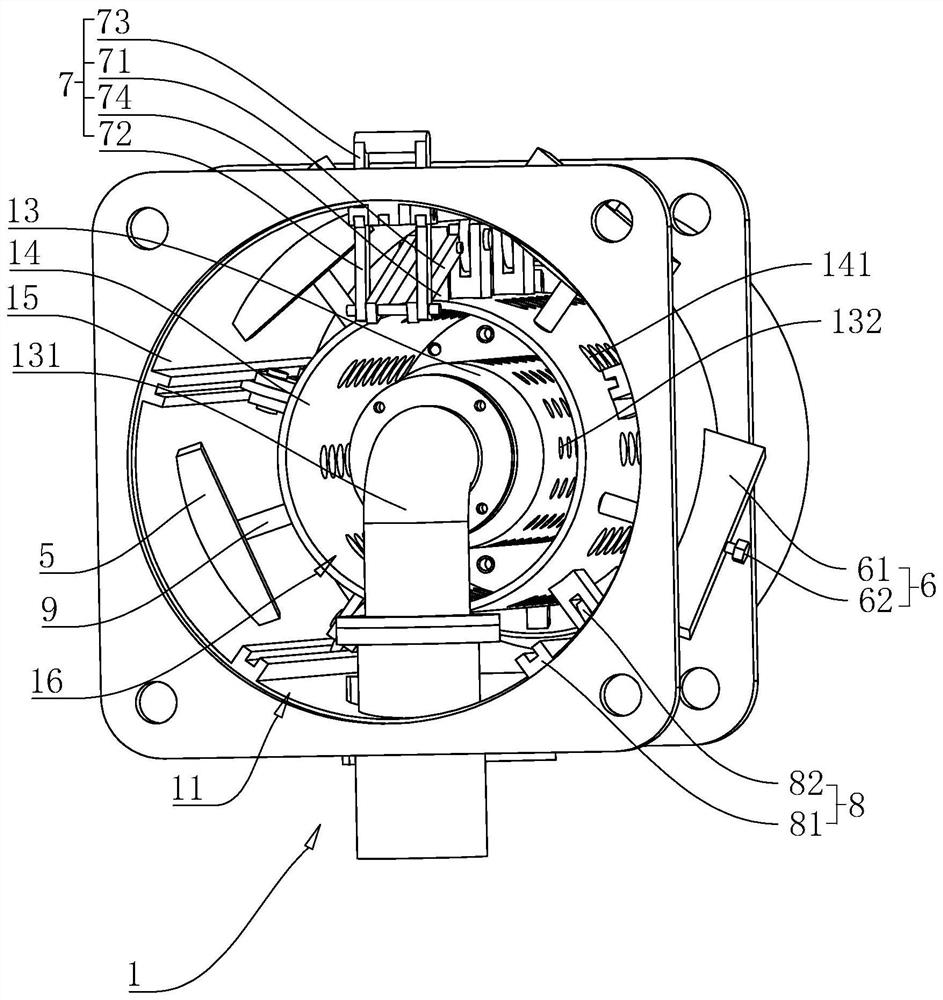

[0040] combine figure 2 and image 3 , the combustion head body 1 includes a gas pipe 13, a primary premixing pipe 14, and a secondary premixing pipe 15 arranged sequentially from the inside and outside, and the gas pipe 13, the primary premixing pipe 14, and the secondary premixing pipe 15 are all cylindrical The axis of the primary premixing pipe 14, the axis of the secondary premixing pipe 15, and the axis of the gas pipe 13 coincide.

[0041] combine figure 2 and image 3 , one end of the second...

Embodiment 2

[0061] The difference between Embodiment 2 and Embodiment 1 is that the combination Figure 4 and Figure 5 , the adjusting blade 5 is arranged in a rectangular shape, the width of the adjusting blade 5 is equal to the distance between the inner wall of the secondary premixing pipe 15 and the outer wall of the primary premixing pipe 14, and a rotating rod is fixed between the adjusting blade 5 and the secondary premixing pipe 15 10. The rotating rod 10 is fixed in the middle of the adjusting blade 5. The secondary premixing pipe 15 is correspondingly provided with a through hole for the rotating rod 10 to pass through. The rotating rod 10 is partly located inside the secondary premixing pipe 15 and partly located on the Outside the secondary premixing pipe 15, the rotating rod 10 is rotatably connected to the secondary premixing pipe 15. Turn the rotating rod 10, and the rotating rod 10 drives the adjusting blade 5 to rotate synchronously. When the adjusting blade 5 rotates u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com