Center-feeding cyclone pulverized coal combustion device adopting pre-combustion chamber and double-layer jet flow to separate secondary air

A pulverized coal combustion and jet separation technology, which is applied in the direction of burners, combustion methods, combustion types, etc., can solve the problems of high emissions, serious slagging, poor flame stability, etc., achieve enhanced graded combustion, and reduce NOx emissions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

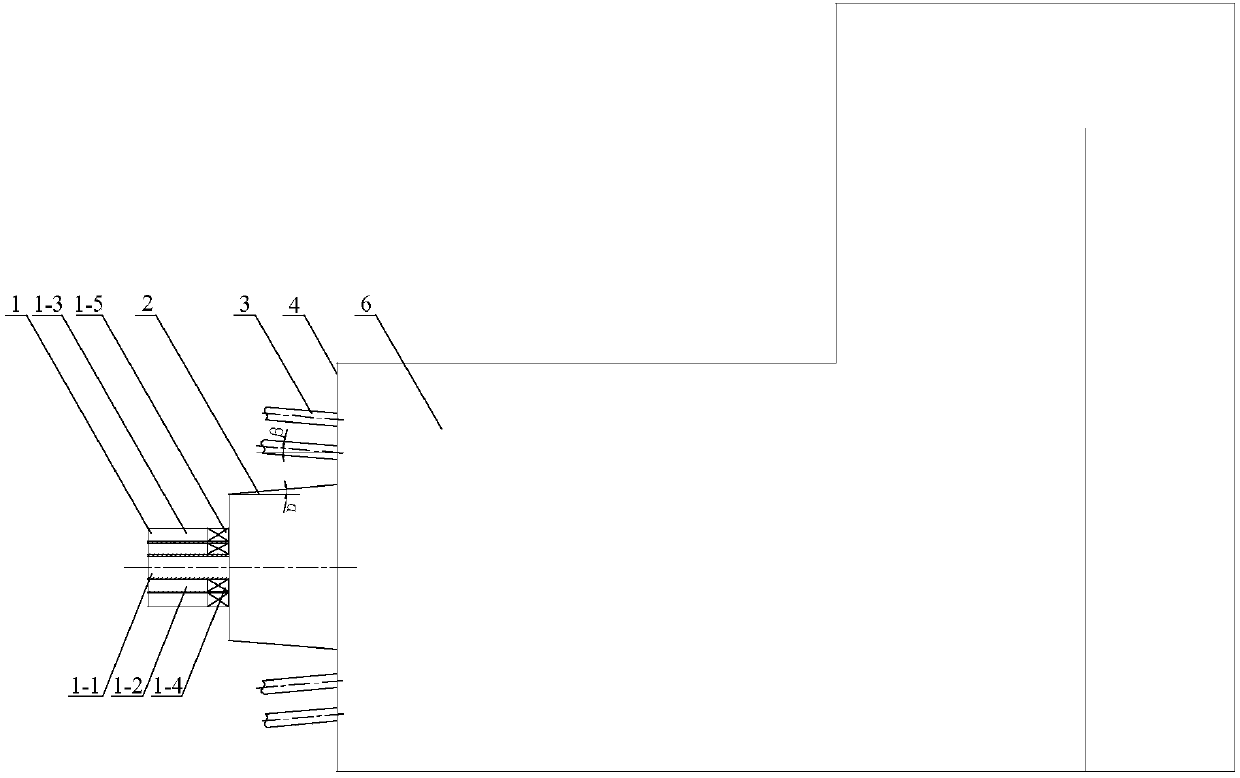

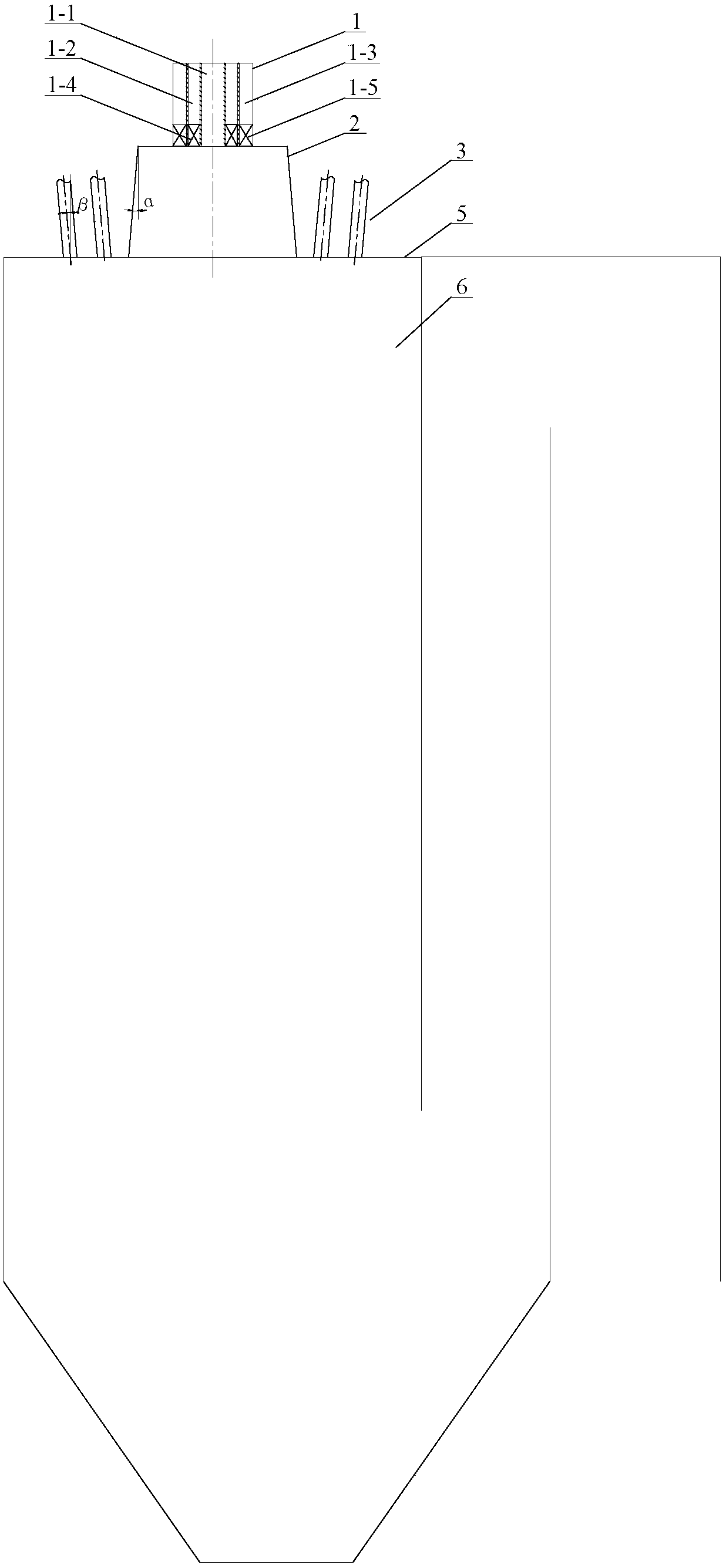

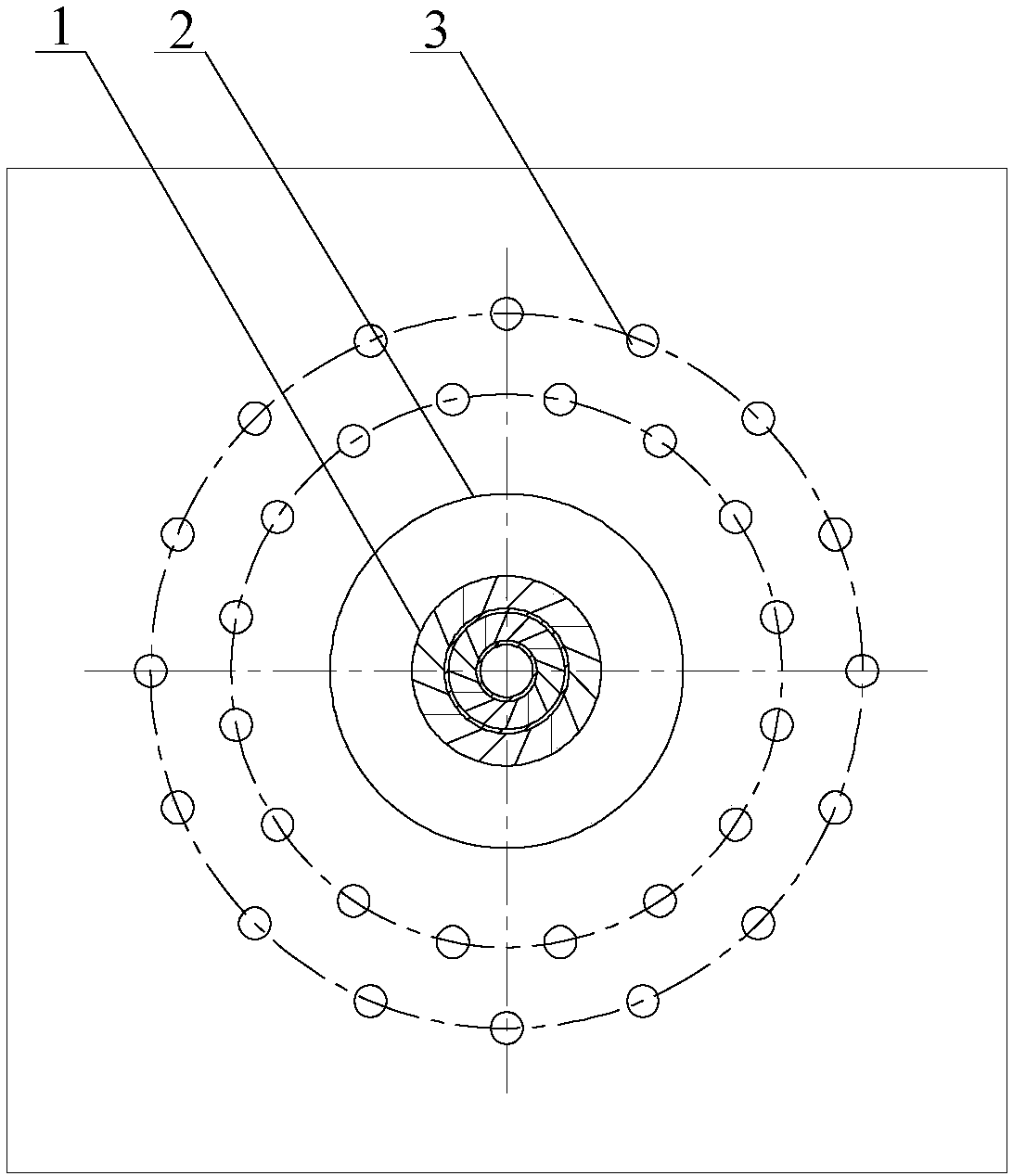

[0033] Specific implementation mode one: as Figure 1~4 As shown, the central powder-fed swirl pulverized coal combustion device using the pre-combustion chamber and double-layer jet flow separation secondary air in this embodiment includes a swirl pulverized coal burner 1, a pre-combustion chamber 2 and a plurality of separated secondary air nozzles 3. The pulverized coal combustion device is installed on the front wall 4 of the boiler or placed on the roof 5 of the vertical boiler; the swirl pulverized coal burner 1 includes a primary air duct 1-1, a secondary air duct in the swirl The air duct 1-2 and the secondary air duct 1-3 outside the swirl flow, the secondary air duct 1-2 inside the swirl flow is arranged outside the primary air duct 1-1, and the secondary air duct 1-3 outside the swirl flow 3. Set outside the secondary air duct 1-2 in the swirl flow, the primary air duct 1-1, the secondary air duct 1-2 in the swirl flow and the secondary air duct 1-3 outside the swir...

specific Embodiment approach 2

[0037] Specific implementation mode two: as figure 1 and figure 2 As shown, the pre-combustion chamber 2 in this embodiment is cast from high-strength refractory materials, and the diameter of the inlet end of the pre-combustion chamber 2 is 1.5 to 3 times the outer diameter of the secondary air pipe 1-3 outside the swirling flow. The length of the chamber 2 is 0.8-2 times of the outer diameter of the secondary air pipe 1-3 outside the swirling flow, and the expansion angle α between the inlet end and the outlet end of the pre-combustion chamber 2 is 0-45°. Such a design can ensure the stable combustion of pulverized coal, and at the same time blow the gas flow of pulverized coal in the pre-combustion chamber out of the pre-combustion chamber in time to avoid slagging in the pre-combustion chamber. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0038] Specific implementation mode three: as figure 1 and figure 2 As shown, in this embodiment, the distance between the radial axis between the separated secondary air nozzle 3 and the outlet of the pre-chamber 2 is 0.6-2 times the diameter of the pre-chamber. Such a design can prevent the separated secondary air from mixing with the pulverized coal airflow prematurely, which is beneficial to reduce fuel-type NOx; at the same time, adjusting the radial spacing according to the different coal quality can improve the adaptability to the coal type. . Other compositions and connections are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com