EGR (exhaust gas recirculation) control system of engine and control method thereof

A control system and control method technology, applied in the direction of engine control, machine/engine, mechanical equipment, etc., can solve the problems of engine fuel consumption increase, carbonization, and EGR rate not meeting the optimal requirements, so as to improve thermal efficiency and structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

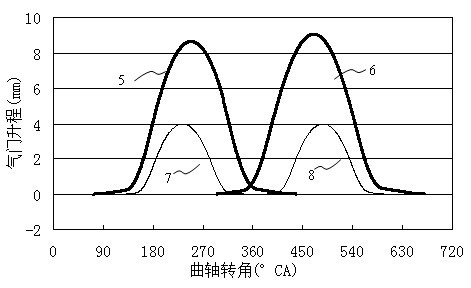

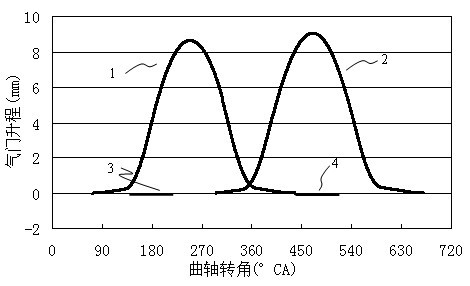

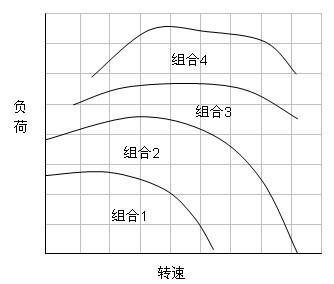

[0019] The EGR control system of the engine of this embodiment includes an electronic control unit and a valve train, and the valve train is provided with an intake valve consisting of a first intake valve and a second intake valve corresponding to each cylinder block, and an intake valve composed of a first intake valve and a second intake valve. An exhaust valve consisting of an exhaust valve and a second exhaust valve, the intake valve is controlled by an intake camshaft, the exhaust valve is controlled by an exhaust camshaft, the first intake valve, the second The intake valves are respectively controlled by two cams with different lift ranges arranged on the intake camshaft, and the first exhaust valve and the second exhaust valve are respectively controlled by two different lift ranges arranged on the exhaust camshaft. The electric control unit is connected with the engine control system, and controls the operation of the cams on the intake camshaft and exhaust camshaft t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com