Fuel-side flue gas recirculation low-nitrogen combustor and combustion method thereof

A flue gas recirculation and low-nitrogen burner technology, which is applied to gas fuel burners, combustion methods, burners, etc., can solve problems such as poor furnace adaptability, pressure fluctuation influence, poor furnace adaptability, etc., to ensure stable combustion performance, reduce the formation of NOX, and ensure the effect of adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The specific embodiment of the present invention and working process will be further described below in conjunction with accompanying drawing.

[0035] The orientation terms such as up, down, left, right, front and rear in this application document are established based on the positional relationship shown in the drawings. If the drawings are different, the corresponding positional relationship may also change accordingly, so this should not be understood as limiting the scope of protection.

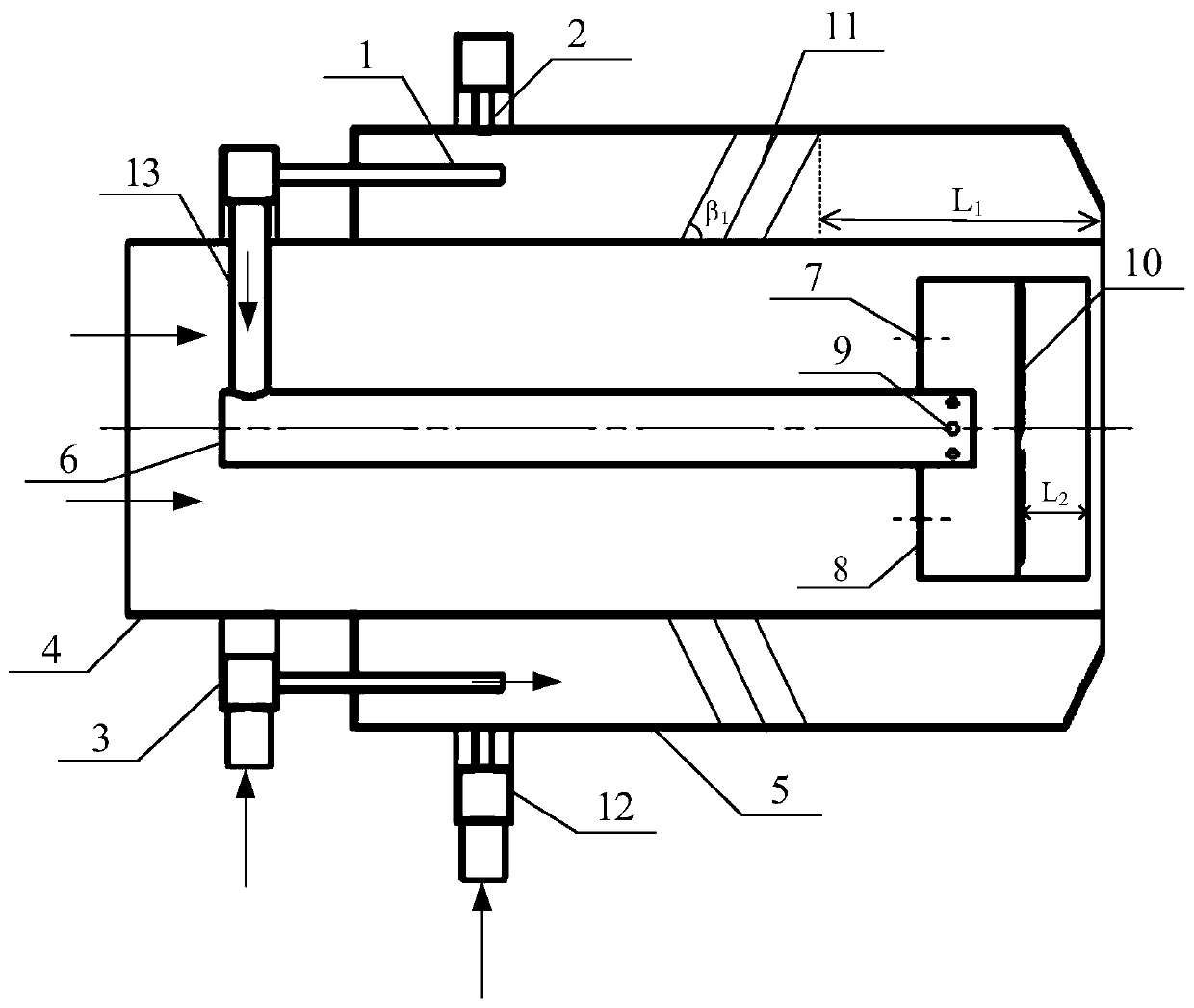

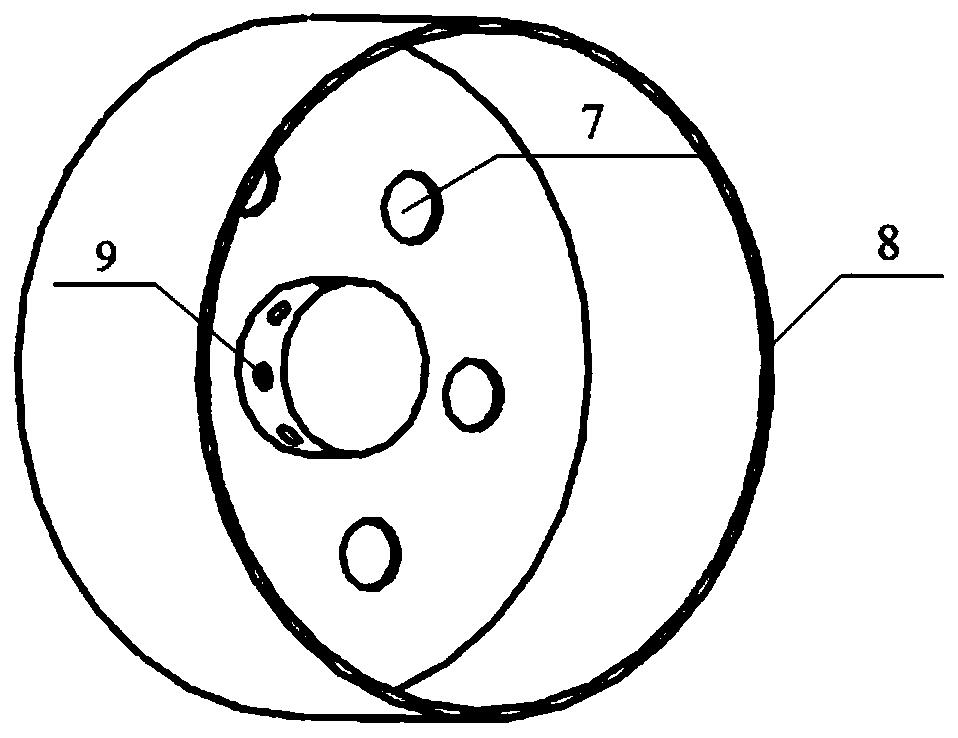

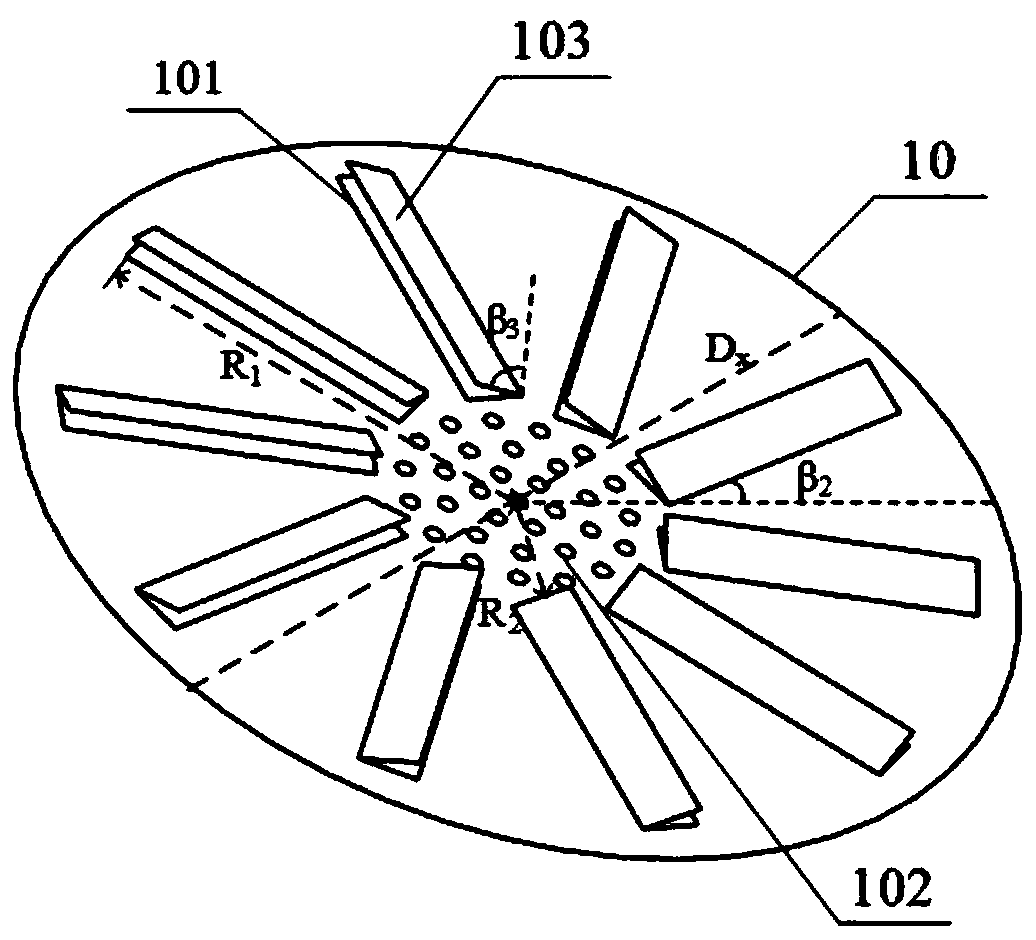

[0036] Such as figure 1 As shown, a fuel-side flue gas recirculation low-nitrogen burner includes an on-duty fuel pipe 6, an air flow channel 4, and a main fuel mixing channel 5 arranged coaxially from the inside to the outside, as well as the fuel distribution ring pipe 3 and the recirculation pipe. Circulating flue gas distribution ring pipe 12. The burner stretches into the combustion chamber, that is, the burner outlet is the combustion chamber.

[0037]The inlet end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com