Nozzle, nozzle wall and compressed air energy storage afterburning chamber

A technology of nozzles and central nozzles, which is applied in the field of nozzle walls, compressed air energy storage supplementary combustion chambers, and nozzles, and can solve problems such as high NOx emissions, small investment, and impact on system energy storage efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

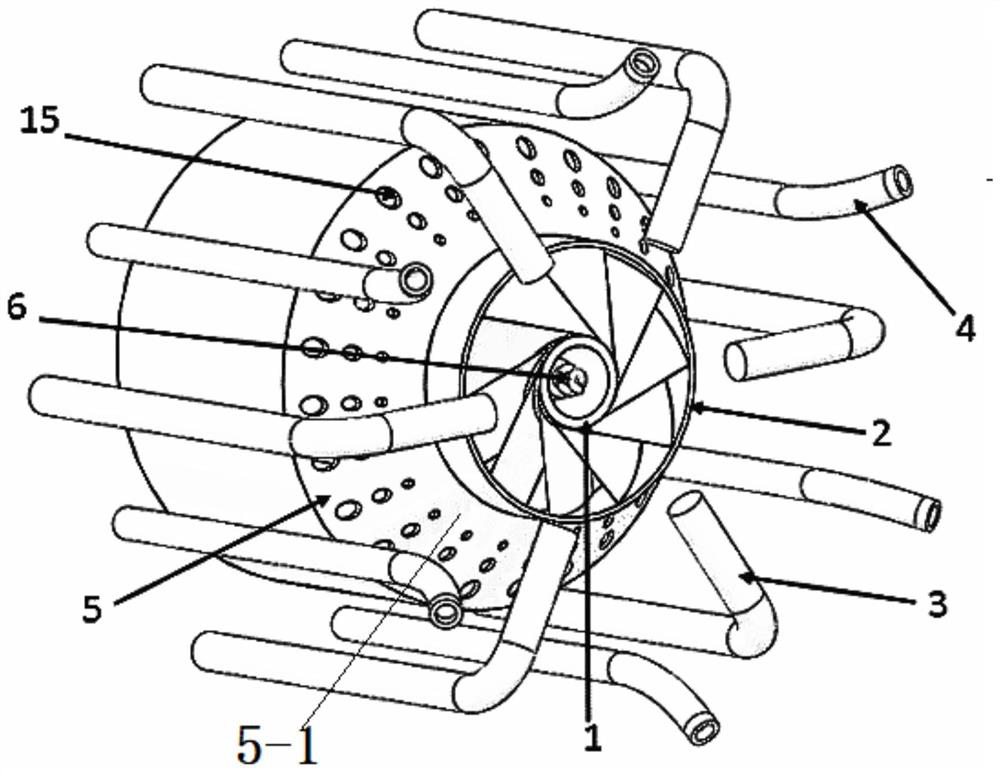

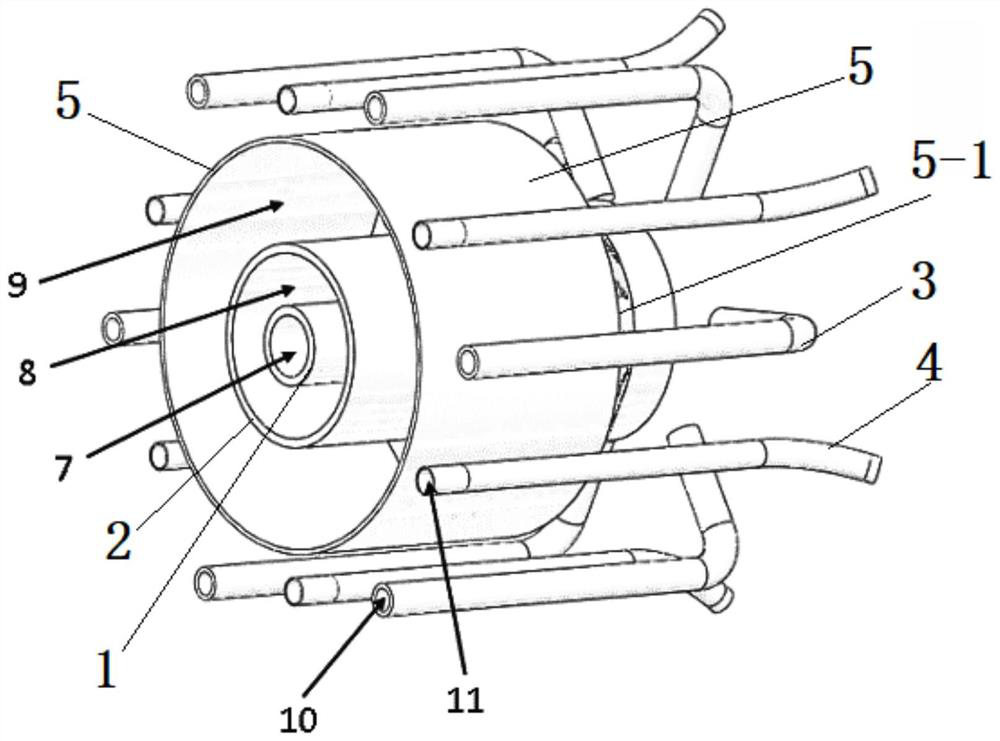

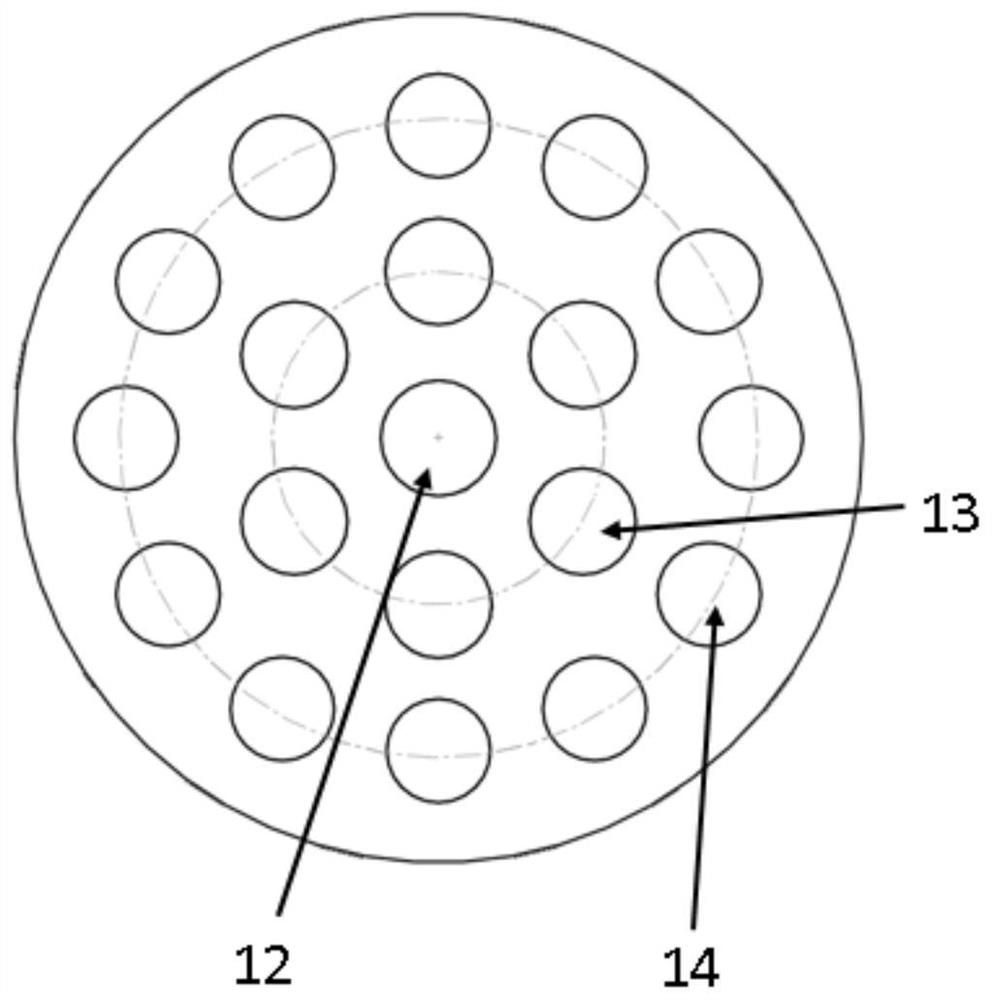

[0033] As shown in Fig. 1(a) and Fig. 1(b), the nozzle of the present invention includes a plurality of L-shaped back spray lances 3, a plurality of main fuel lances 4, and a central fuel cylinder 1 and a swirl air cylinder arranged coaxially from the center to the outside. 2 and the straight air cylinder 5; the outlet end of the central fuel cylinder 1 is provided with a spiral atomizing nozzle 6, and the specific form of the spiral atomizing nozzle 6 can be: a spiral structure 6-1 is arranged in the inner cavity of the outlet end of the central fuel cylinder 1, The helical structure 6-1 and the outlet end of the central fuel cylinder 1 together form the helical atomizing nozzle 6. For details, refer to Figure 5 , the overall structure of the helical structure 6-1 is a tapered structure with the same pitch and a gradual radius. With reference to Fig. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com