A method for reducing the oxygen content of titanium powder produced by hydrodehydrogenation

A technology of hydrogenation dehydrogenation and oxygen content, applied in the field of powder metallurgy, can solve the problems of large specific surface area of titanium powder, restricting the application range, excessive impurity content, etc., and achieve the effect of fast reaction speed, sufficient reduction reaction and strong reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] (1) The gaseous metal sodium is fed into the inductively coupled plasma torch with the mixed gas A as the working gas and the side gas at a rate of 2 g / min, and the metal sodium is excited and ionized to obtain a strong reducing inductively coupled plasma torch. Gas A is composed of helium and argon in a volume ratio of 1:9. The operating power of the plasma torch is 135kW, the temperature of the plasma torch is 12000K, the working gas flow is 60slpm, the side gas flow is 350slpm, and the system pressure is 30kPa;

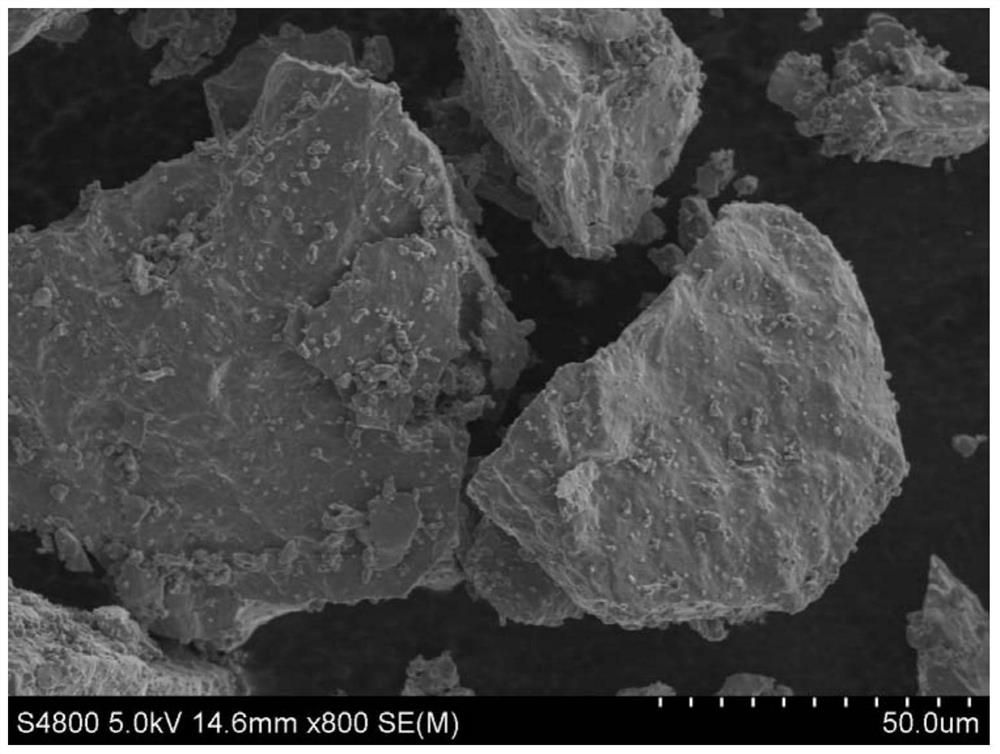

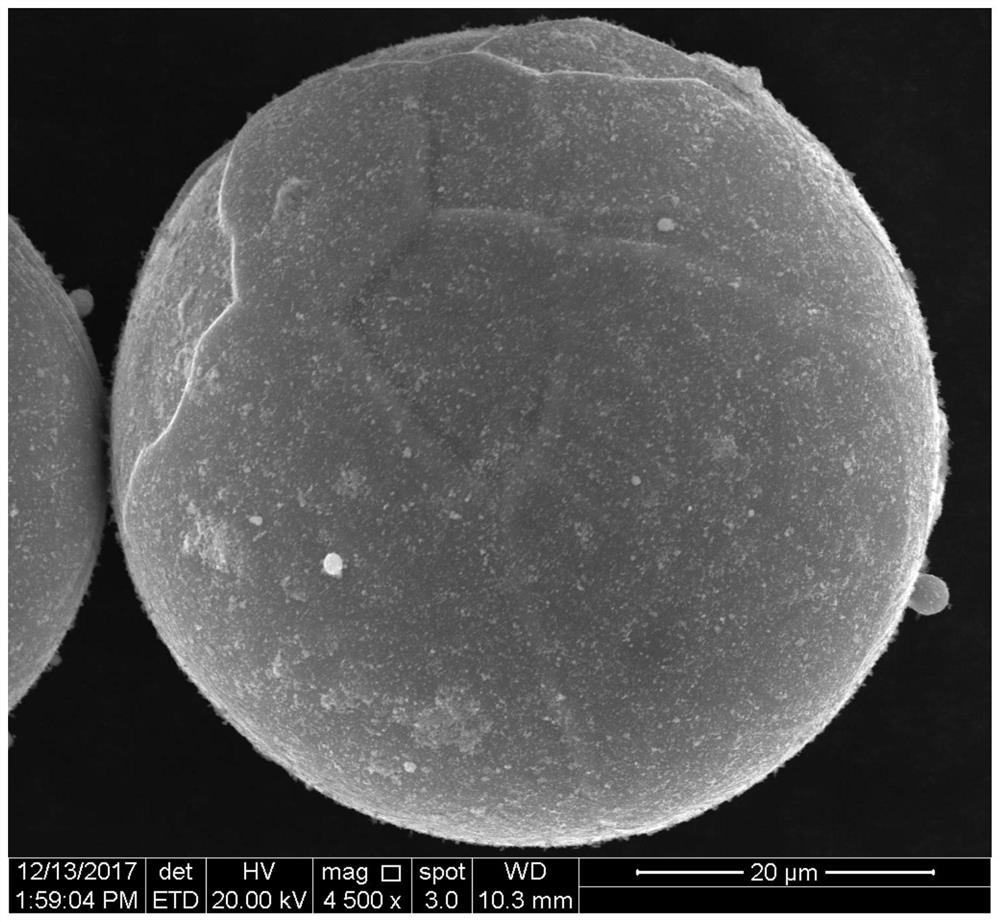

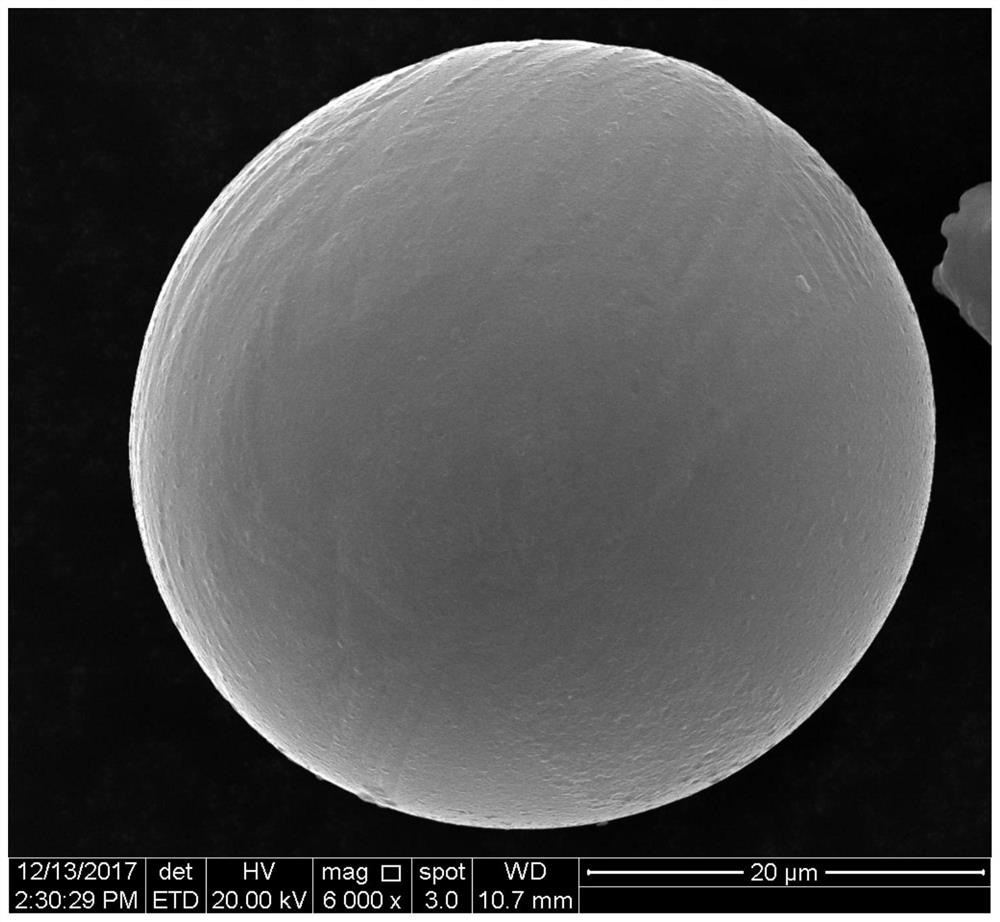

[0047] (2) Using the mixed gas A as the powder feeding gas, the titanium powder with a particle size range of 30-50 microns and an oxygen content of 3500 ppm is prepared by a hydrogenation dehydrogenation method (see figure 1 ) into the strongly reducing inductively coupled plasma torch established in step (1) in a fluidized state, the powder feeding rate is 40 g / min, after the titanium powder is melted, the oxygen element reacts with the active metal in the ...

Embodiment 2

[0050] (1) The liquid sodium-potassium alloy is fed into the inductively coupled plasma torch with the mixed gas A as the working gas and the side gas at a rate of 3 g / min, and the metal sodium is excited and ionized to obtain a strong reducing inductively coupled plasma torch, Mixed gas A is composed of helium and argon in a volume ratio of 3:22. The operating power of the plasma torch is 140kW, the temperature of the plasma torch is 13000K, the working gas flow is 70slpm, the side gas flow is 400slpm, and the system pressure is 37kPa;

[0051] (2) Using the mixed gas A as the powder feeding gas, the titanium powder with a particle size range of 70 to 120 microns and an oxygen content of 2700 ppm, prepared by a hydrogenation dehydrogenation method, is fed into a fluidized state to create a strong reducing sensitivity in step (1). The plasma torch should be coupled, and the powder feeding rate is 60g / min. After the titanium powder is melted, the oxygen element in it reacts with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com