Low-nitrogen oxide discharging coal powder tangential combustion device

A low-NOx, tangential combustion technology, applied in burners, combustion methods, combustion types, etc., can solve problems such as expensive investment and operation and maintenance costs, increase operation regulation performance, strengthen turbulent mixing, and achieve low NOx The effect of emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

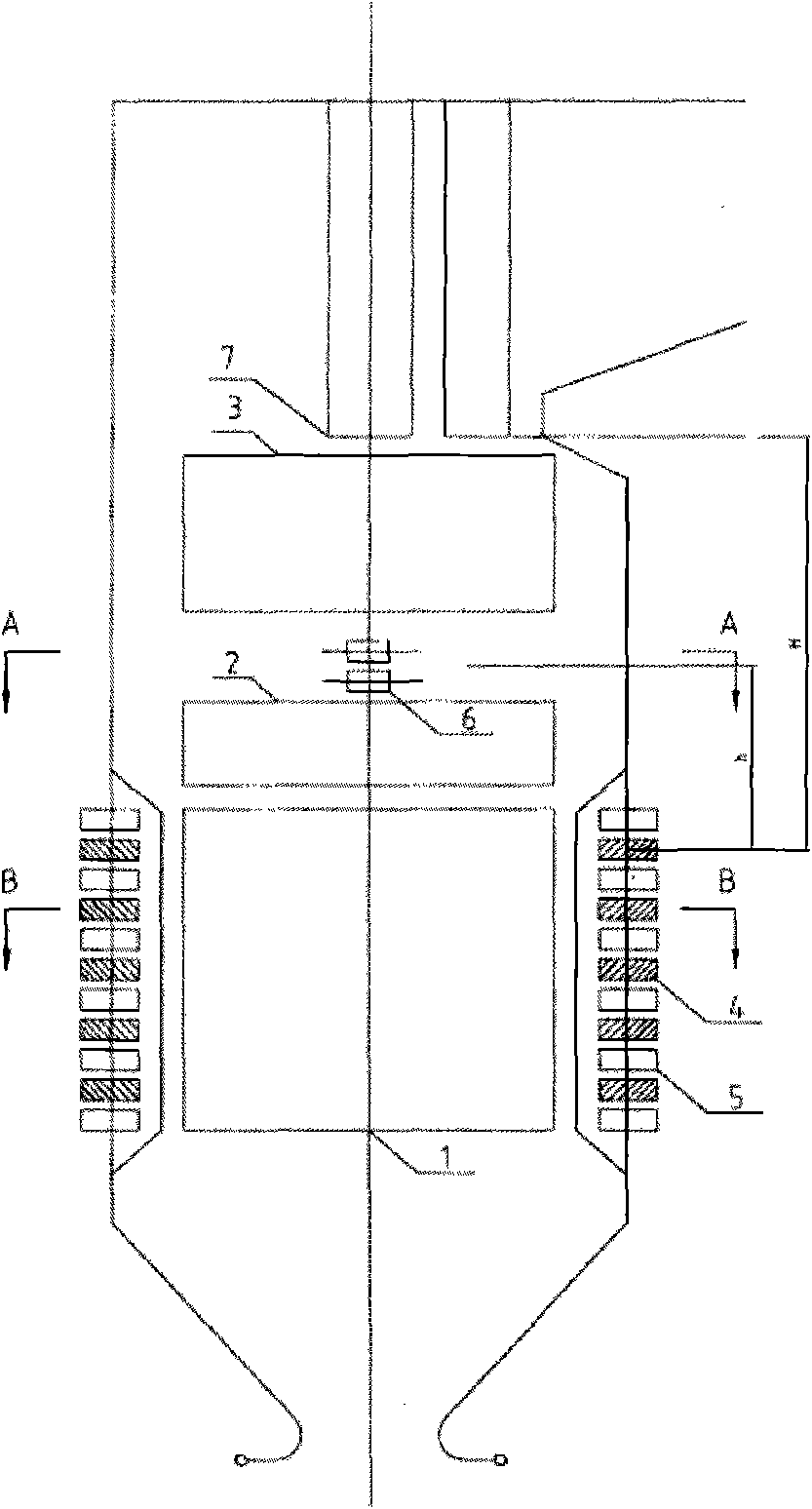

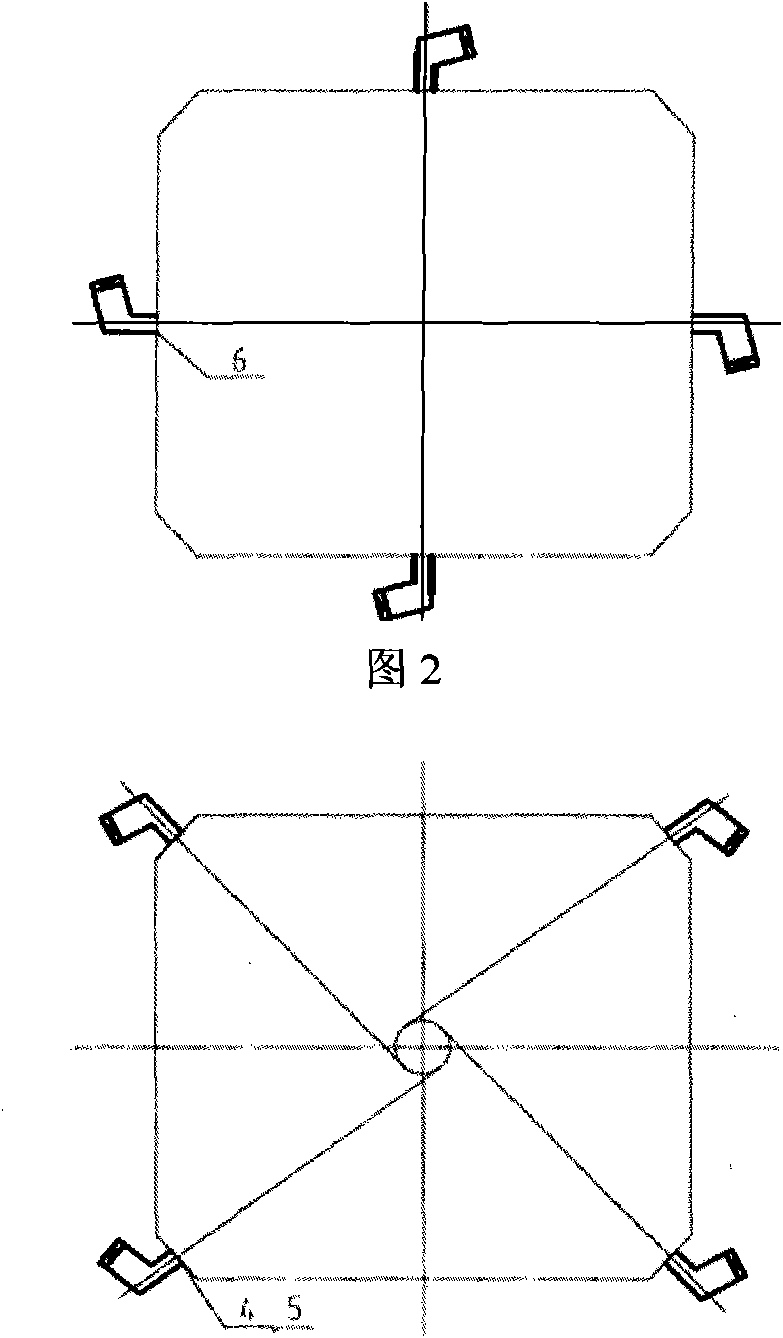

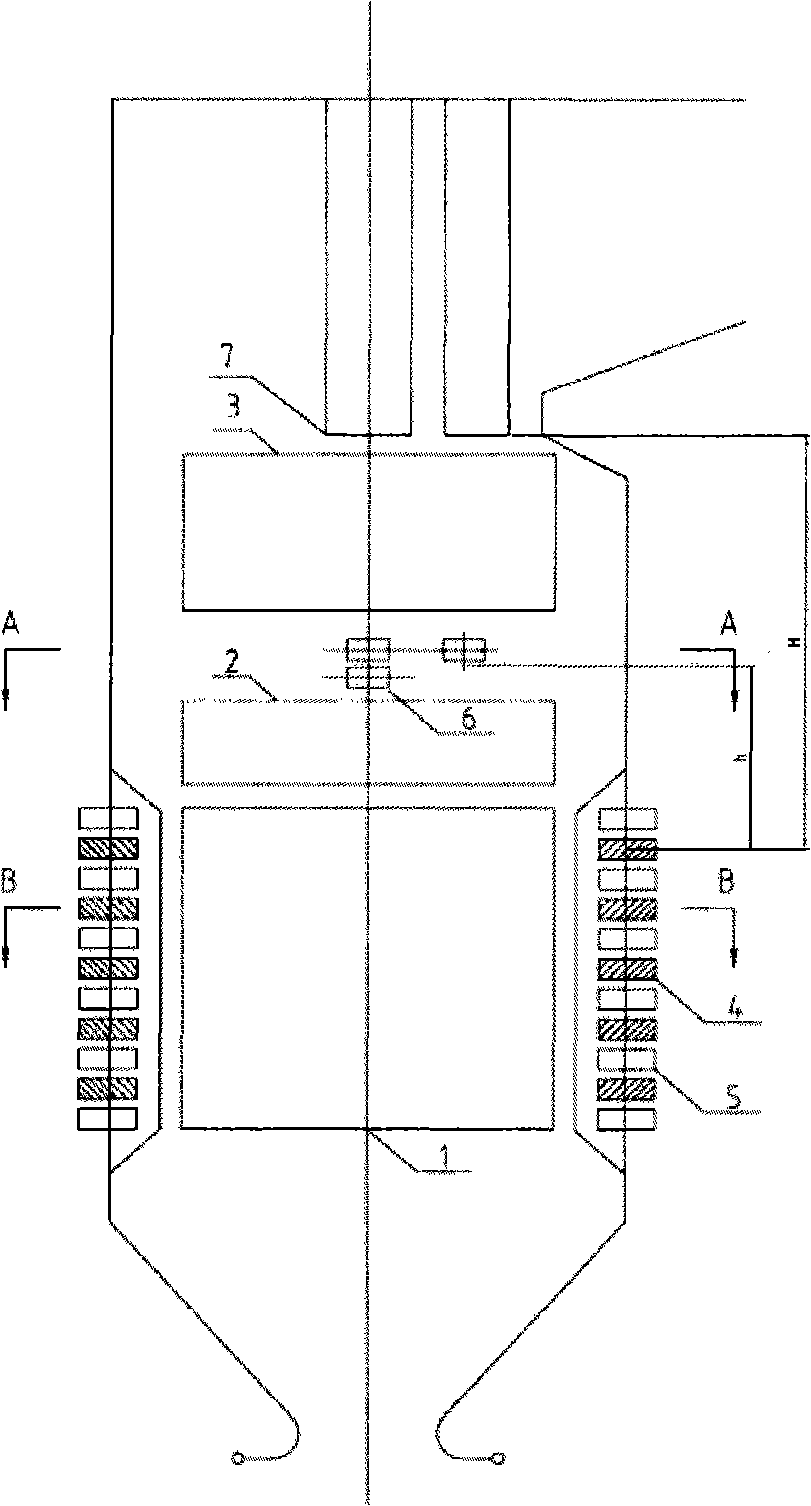

[0025] like figure 1 As shown, it is a schematic diagram of a low-NOx emission pulverized coal tangential combustion device, which is suitable for four-corner tangential coal-fired boilers in thermal power plants. Along the furnace height direction, the furnace is divided into main combustion areas according to the characteristics of the pulverized coal combustion area 1, Reduction zone 2 and burnout zone 3. In the main combustion area, the main burner group is composed of multi-layer primary air nozzles 4 and secondary air nozzles 5, which are arranged on the four corners of the furnace. The structure and arrangement of the nozzles are the same as the usual four-corner tangential combustion system, such as image 3 shown, for figure 1 In the middle B-B sectional view, the axis of the primary air nozzle 4 / secondary air nozzle 5 is tangent to an imaginary tangent circle centered on the center of the furnace, and the actual flow will form a swirling airflow in the furnace.

[...

Embodiment 2

[0030] like Figure 4 As shown, it is a schematic diagram of another low-NOx emission pulverized coal tangential combustion device, which is suitable for four-corner tangentially circular coal-fired boilers in thermal power plants. Along the furnace height direction, the furnace is divided into the main combustion area according to the characteristics of the pulverized coal combustion area 1 , reduction zone 2 and burnout zone 3. In the main combustion zone 1, the main burner group is composed of multi-layer primary air nozzles 4 and secondary air nozzles 5, which are arranged on the four corners of the furnace. The structure and arrangement of the nozzles are the same as the usual four-corner tangential combustion system, such as Image 6 shown, for Figure 4 In the middle B-B sectional view, the axes of the primary air nozzle 4 / secondary air nozzle 5 are cut in a circle centered on the center of the furnace, and the actual flow will form a swirling airflow in the furnace. ...

Embodiment 3

[0035] Same as embodiment 2, the difference is that an overburning air nozzle group is arranged on the four walls of the furnace above the primary air nozzle 4 and the secondary air nozzle 5, and the overburning air nozzle 6 is arranged on the center line of each wall. The ratio of the distance h=1800mm between the center of the burn-off air nozzle 6 on each wall of the furnace to the center of the uppermost primary air nozzle 4 and the distance H=18000mm from the center of the uppermost row of primary air nozzle 4 to the bottom of the screen 7 is 0.1: 1. The mass of air passing through the over-combustion air nozzle 6 accounts for 10% of the total combustion air mass of the boiler.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com