Wide Duty Boiler Water Wall Internally Threaded Tube with Arc Transition Section Fins

A technology of internal threaded pipe and internal thread, which is applied to steam boilers, steam boiler accessories, and components of steam boilers, etc., can solve the problems of increased boiler flow resistance and increased energy consumption of feed pumps, and achieves enhanced turbulent flow intensity, heat transfer, etc. The effect of improving the characteristics and increasing the heat exchange area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

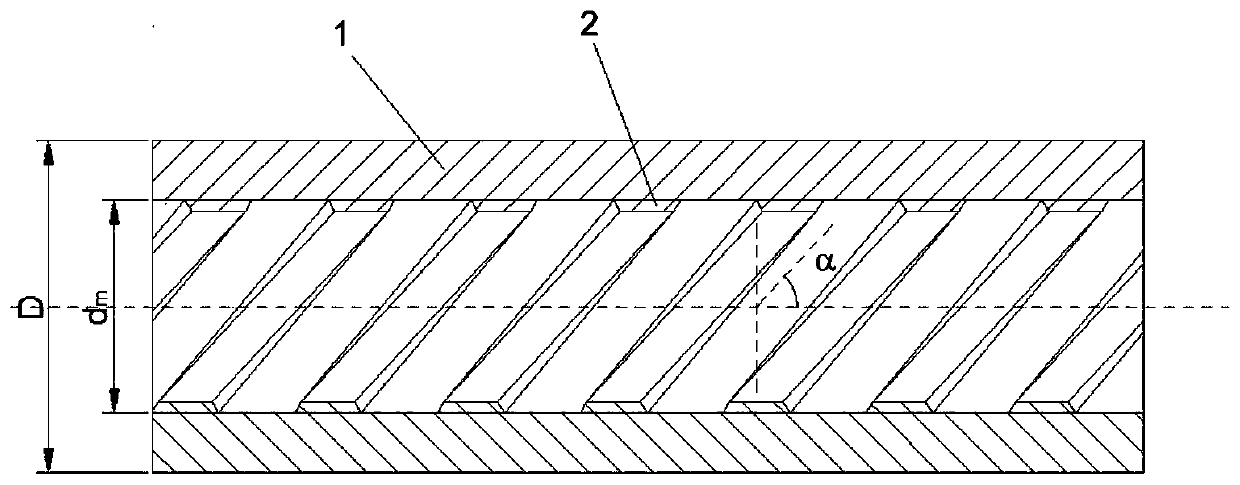

[0021] Such as figure 1 As shown, a wide-load boiler water-cooled wall internally threaded pipe with arc-shaped transition section ribs includes a pipe body 1 and internally threaded fins 2 arranged in a spiral shape on the inner wall of the pipe body 1. The internally threaded ribs The angle α between the helical direction of the sheet 2 and the pipe axis direction is 30°-65°; the angle β between the side surface of the internal thread fin 2 and the pipe axis direction is 45°-60°; the internal thread rib The slices 2 are arranged at equal intervals, and the number of fins is 4 to 6.

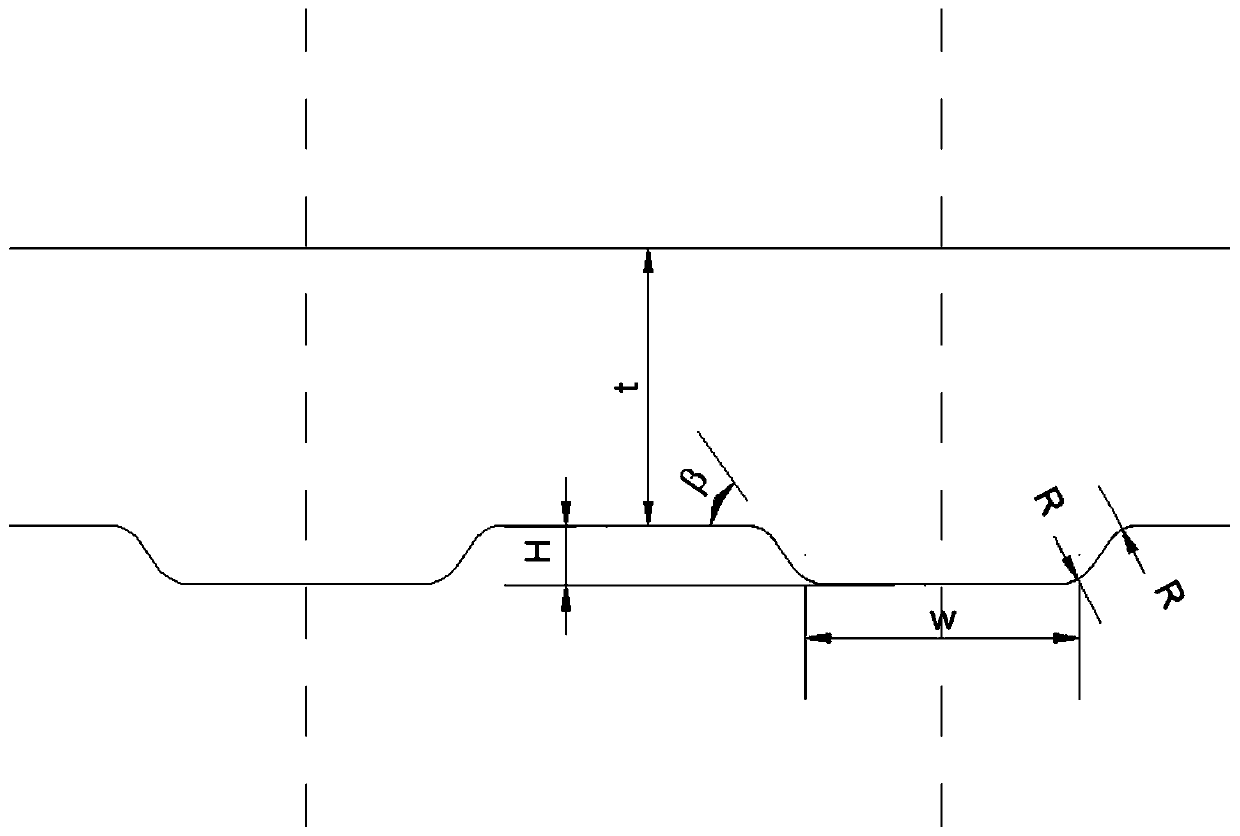

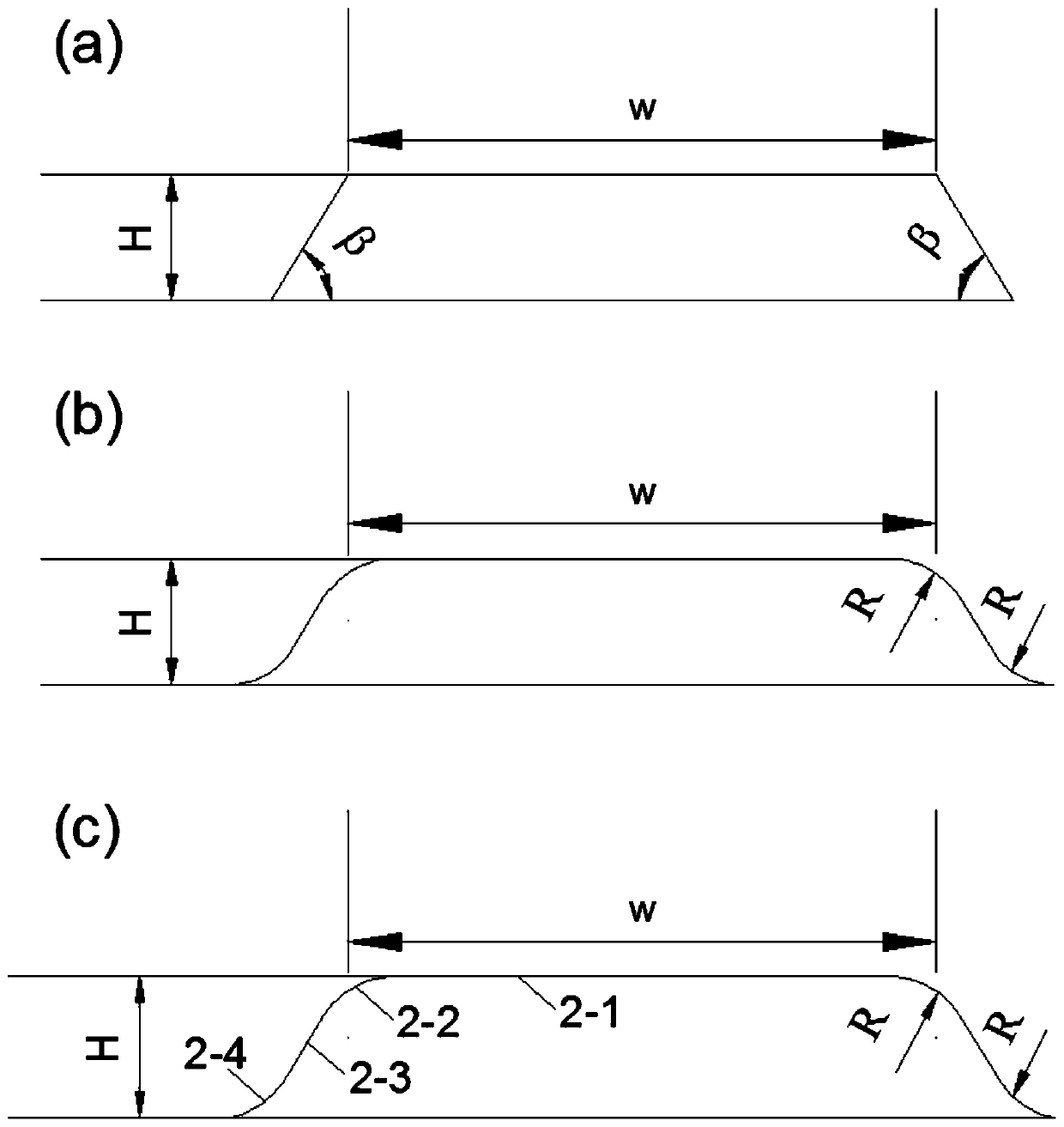

[0022] Such as figure 2 , 3 As shown, the cross-sectional shape of the internal thread fin 2 of the present invention is an isosceles trapezoid, and the connection surface between its side 2-3 and the fin top surface 2-1 and the pipe body 1 is an arc section, and the top arc surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com