Symmetrical-combustion W-Type flame boiler

A flame and boiler technology, which is applied in the combustion field of W-shaped flame boilers, can solve the problems of cracking of water wall fins, large temperature deviation of water wall walls, high content of combustibles in boiler fly ash, etc., and achieve the effect of solving the deflection of flow field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

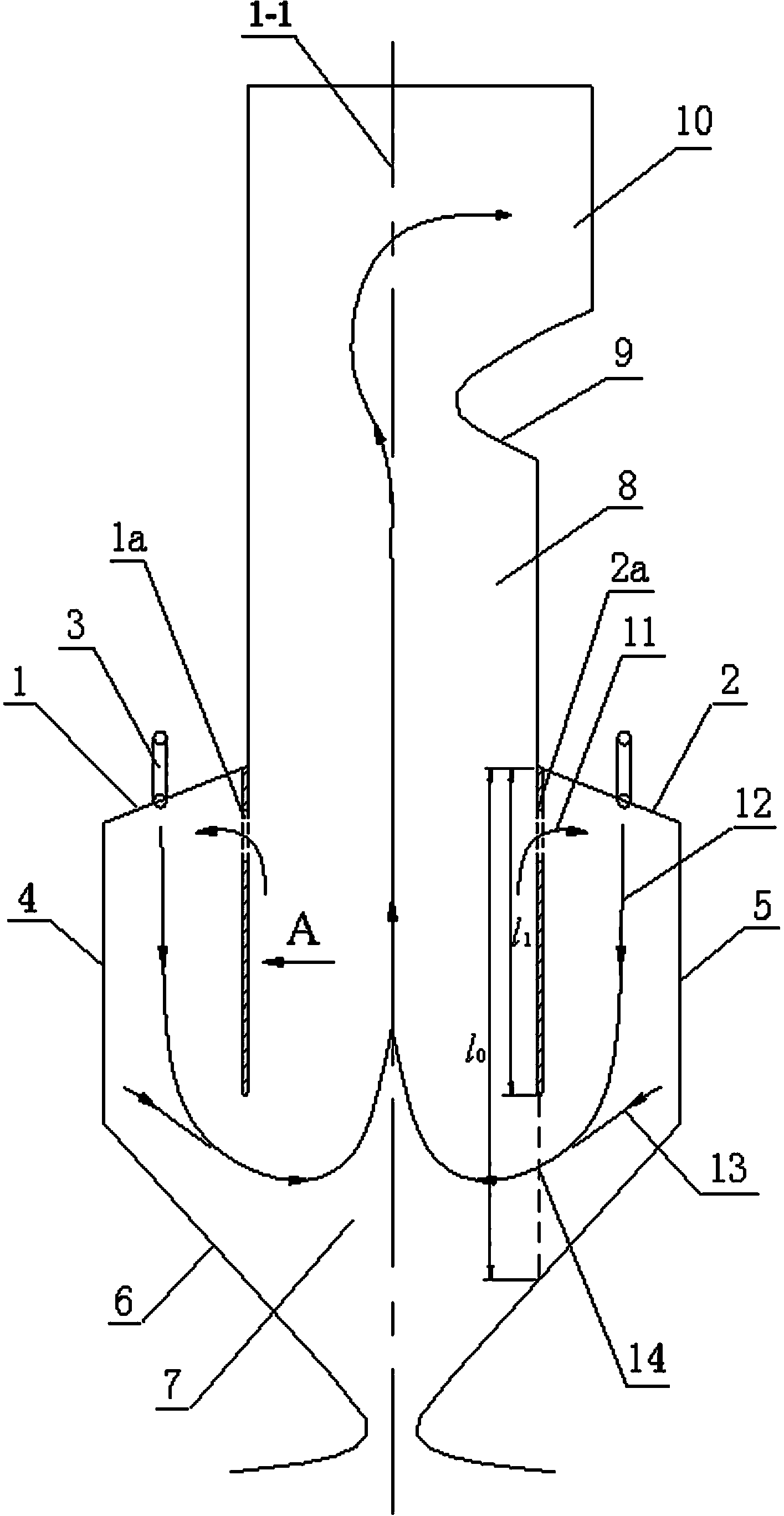

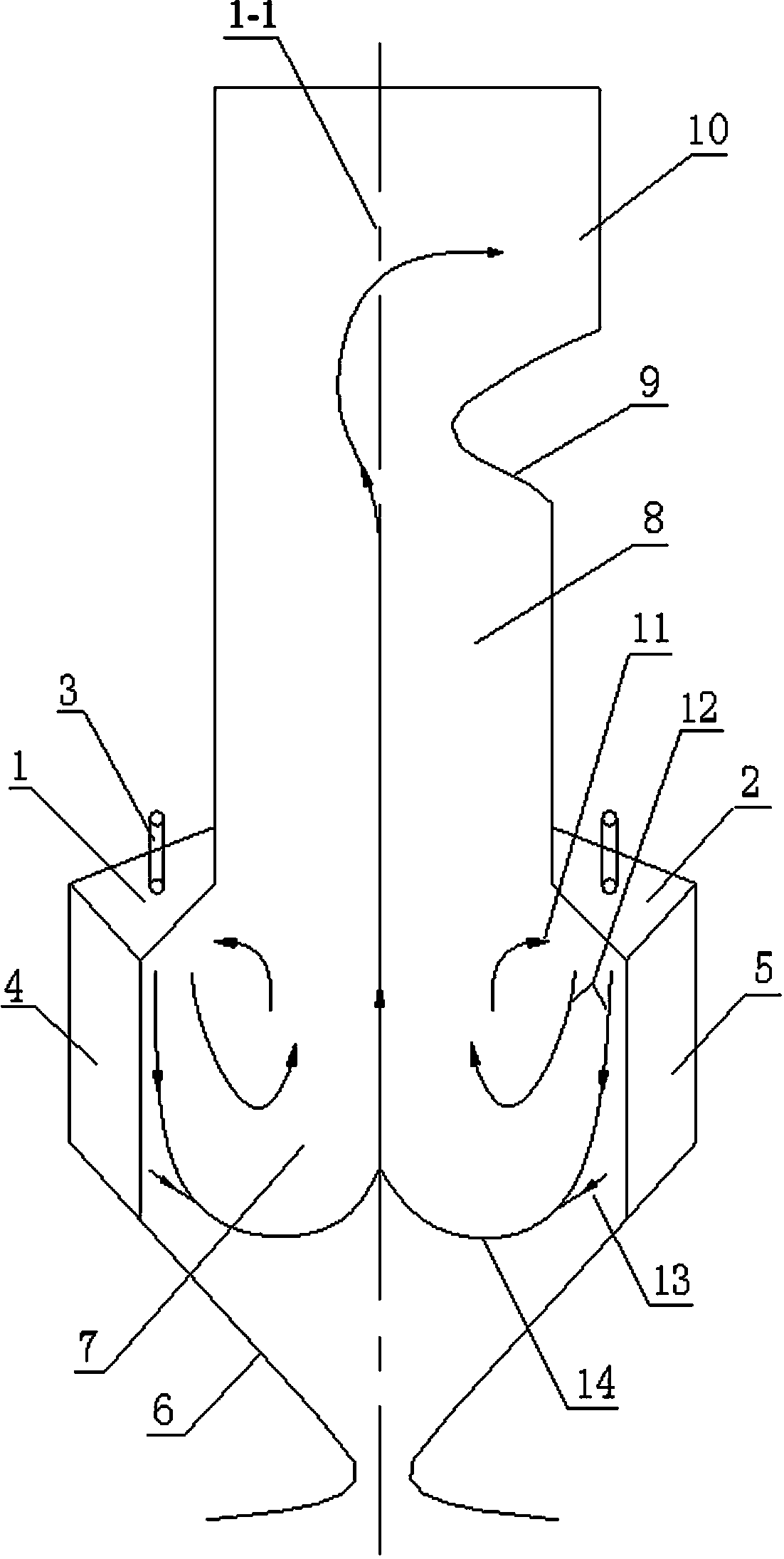

[0019] combine figure 1 with figure 2To illustrate this embodiment, the furnace of a W-shaped flame boiler with symmetrical combustion described in this embodiment is divided into two parts, the lower furnace 7 and the upper furnace 8. The lower furnace 7 consists of a front arch 1, a rear arch 2, a front wall 4, The rear wall 5 and the cold ash bucket 6 are composed; multiple burners 3 are symmetrically arranged on the front arch 1 and the rear arch 2 along the center line 1-1 of the furnace, and communicate with the lower furnace 7 to supply the air-powder mixture injected downward. 12; The graded air 13 is fed symmetrically from the lower part of the front wall 4 and the rear wall 5 to organize graded combustion and adjust the undershoot depth of the flame; The connecting wall 1a under the front arch and the connecting wall 2a under the rear arch symmetrically arranged on the line 1-1, the connecting wall 1a under the front arch and the connecting wall 2a under the rear ...

Embodiment approach 2

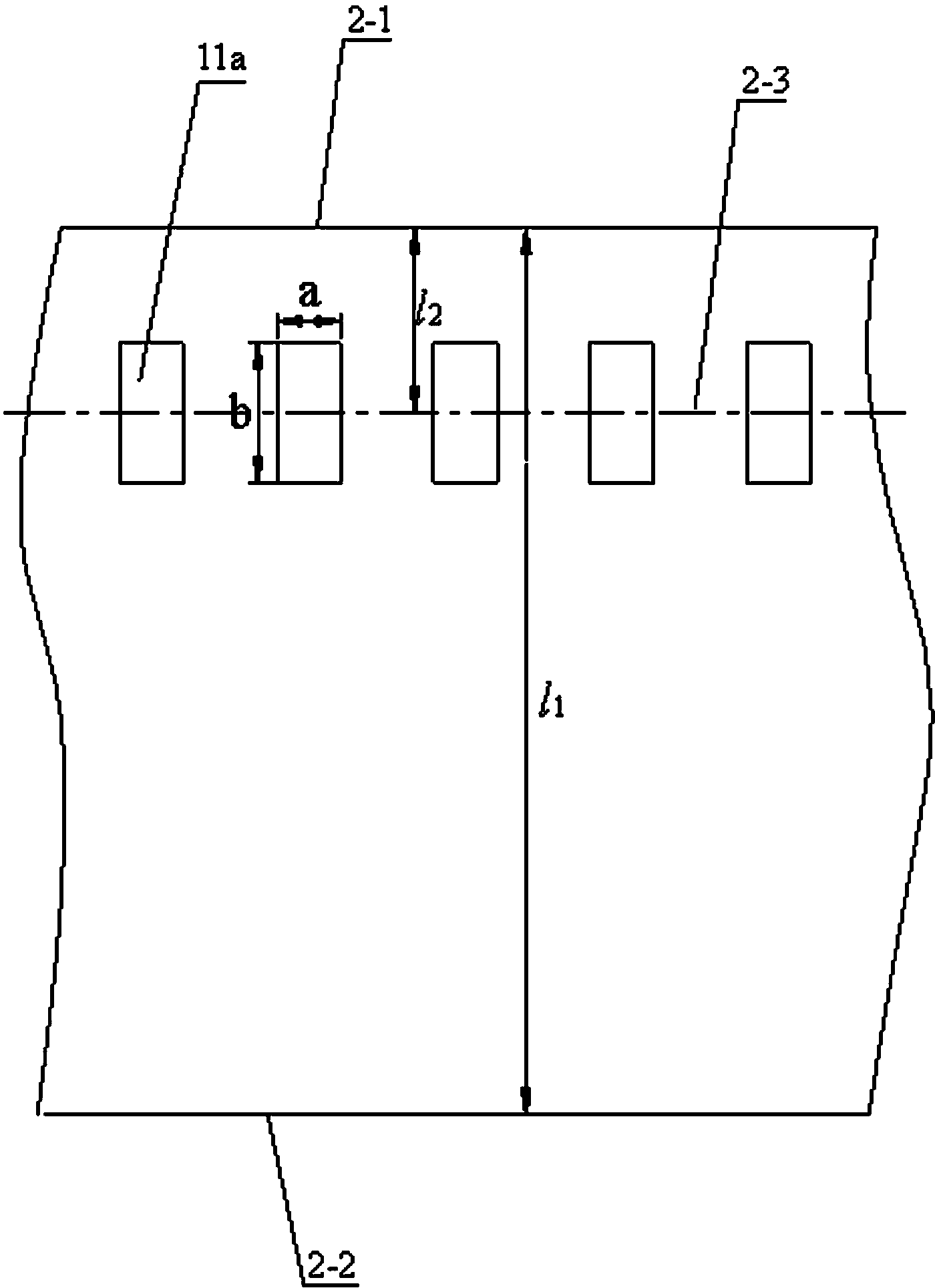

[0022] combine figure 2 To illustrate this embodiment, the W-shaped flame boiler in this embodiment has a row of return flue gas ports 11a evenly arranged along the width direction of the furnace in the upper area of the connecting wall 1a under the front arch and the connecting wall 2a under the rear arch. A return flue gas port 11a corresponds to a plurality of burners 3 in the arch along the furnace width direction, so as to allow the return flue gas 11 to pass through and heat the air powder mixture 12 in the burner area under the arch; -1 to the distance from the centerline 2-3 of the return flue gas port 11a l 2 should meet l 2 / l 1 =0.25~0.35, the width of the return flue gas port 11a a Equivalent diameter of nozzle with burner 3 d Satisfy a / d ≈2, the aspect ratio of the return flue gas port 11a b / a =1.5~2. Other components and connections are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com