Method for burning of low nitrogen oxides in coal-burning boiler

A low-nitrogen oxide, coal-fired boiler technology, which is applied in the combustion of solid fuels, combustion equipment, lighting and heating equipment, etc. Slagging and other problems are prone to occur in the reburning zone and the reburning zone.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

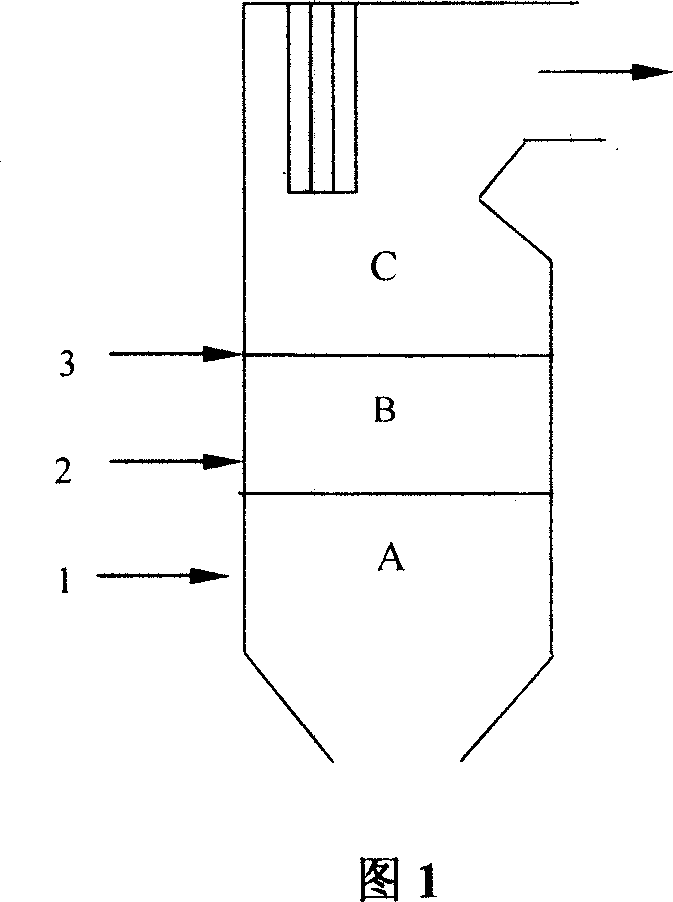

[0005] Specific embodiment one: in this embodiment, a method for low nitrogen oxide combustion in a coal-fired boiler is realized through the following steps: (1) sending conventional particle size pulverized coal, which accounts for 80% to 85% of the calorific value of the boiler fuel, into the The main combustion zone at the lower part of the boiler furnace is burned with the horizontal thick-lean air combustion technology under the condition that the excess air coefficient is 0.8-1.05; The pulverized coal, which accounts for 15% to 20% of the calorific value of the boiler fuel, is injected as reburning fuel from above the main combustion zone to form a reburning zone. The excess air coefficient at the outlet of the reburning zone is controlled at 0.85 to 0.95, and the residence time of flue gas in the reburning zone is 0.2 Seconds to 0.8 seconds, the reburning fuel is burned with horizontal rich-lean combustion technology or direct-flow combustion; (3) Inject the overburning...

specific Embodiment approach 2

[0006] Specific embodiment two: the difference between this embodiment and specific embodiment one is that in step (1), the conventional particle size pulverized coal that accounts for 82% to 84% of the boiler fuel calorific value is put into the main combustion zone of the boiler furnace bottom. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0007] Specific embodiment three: the difference between this embodiment and specific embodiment one is that in step (1), the conventional particle size pulverized coal that accounts for 83% of the boiler fuel calorific value is put into the main combustion zone of the boiler furnace bottom. Other steps are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com