Incineration processing method and device for wet sludge

A treatment method and technology of a treatment device, which are applied in the field of wet sludge incineration treatment and wet sludge incineration treatment device, can solve the problems of high cost of harmless treatment, complicated system and complicated system, and simplify the incineration treatment process. , The effect of high combustion efficiency and high material concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A papermaking sludge produced by a paper mill has a moisture content of 70%, a low calorific value of about 3200kJ / kg, a sulfur content of 0.05%, and an alkali metal content of about 0.05%. According to the method of the present invention, the Martin grate furnace is used to directly incinerate. The wet sludge is added to the furnace whose temperature has risen to about 900°C, and the wet sludge starts to dry and catch fire; part of the air required for incineration is blown in from the bottom of the grate, and the water evaporated from the sludge is added to the furnace, and the furnace A reducing atmosphere is formed above the grate to suppress the production of NOx during incineration; another part of the air required for incineration is sprayed into the furnace from above the grate to burn out the sludge; due to the low water content and high calorific value of the sludge, Therefore, the temperature of the furnace can be maintained at about 850°C without adding auxi...

Embodiment 2

[0024] A papermaking sludge produced by a paper mill has a water content of 50%, a low calorific value of about 4000kJ / kg, a sulfur content of 0.06%, and an alkali metal content of about 0.01%. According to the method of the present invention, a circulating fluidized bed boiler is used incinerate. The sludge and a large amount of coal are fed into the furnace from the coal inlet of the boiler through the screw feeder. The temperature of the furnace is controlled at 800-950 ° C, and limestone powder is added to the furnace for desulfurization, and the formation of NOx is suppressed by graded air distribution. Applying the method of the invention to a circulating fluidized bed boiler can provide hot water or steam to the outside for heat supply or power generation while incinerating wet sludge.

Embodiment 3

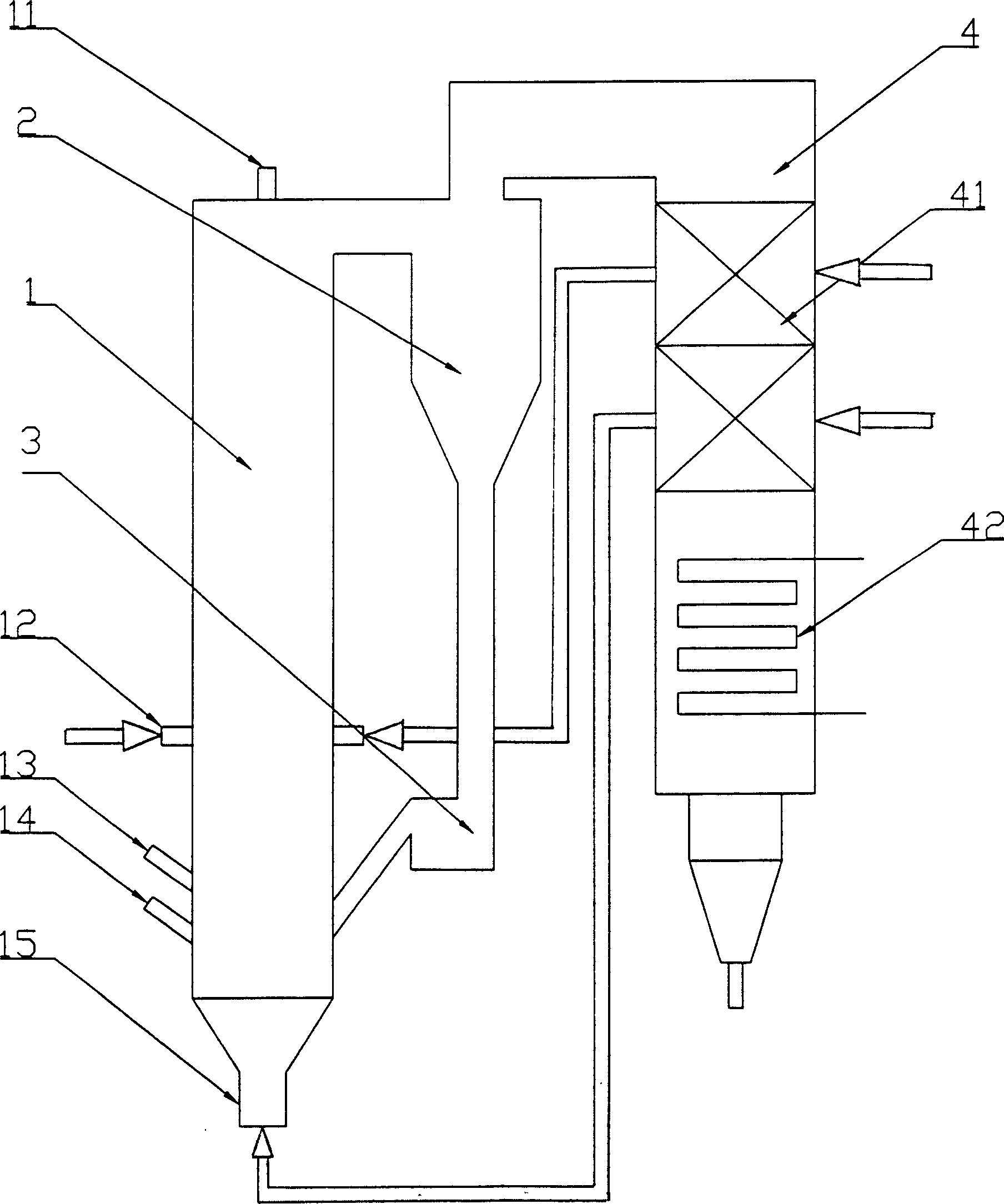

[0026] A kind of sewage sludge produced by a domestic sewage plant, with a water content of 90%, a low calorific value of about 400kJ / kg, a sulfur content of 0.38%, and an alkali metal content of about 0.002%. According to the device of the present invention, a circulating fluidized bed wet sludge incinerator is used for incineration. The circulating fluidized bed wet sludge incineration device is composed of a furnace 1, a separator 2, a feeder 3 and a tail flue 4. The furnace 1 is insulated on the side wall, and the wet sludge is directly fed from the sludge inlet 11 on the furnace top. Add the furnace 1, the waste sawdust is added into the furnace 1 from the auxiliary fuel inlet 13 at the bottom of the furnace 1, and the limestone is added into the furnace 1 from the limestone inlet 14 at the bottom of the furnace 1, and the air required for incineration is divided into primary air and secondary air, respectively from The primary tuyere 15 at the bottom of the furnace 1 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com