A kind of municipal sludge vertical drying and incineration equipment

An urban sludge, vertical technology, applied in lighting and heating equipment, water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, etc., can solve the problem of high manufacturing cost, difficult maintenance, complicated incineration process, etc. problems, to achieve the effect of simple structure, simplified processing technology, and resource-based processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

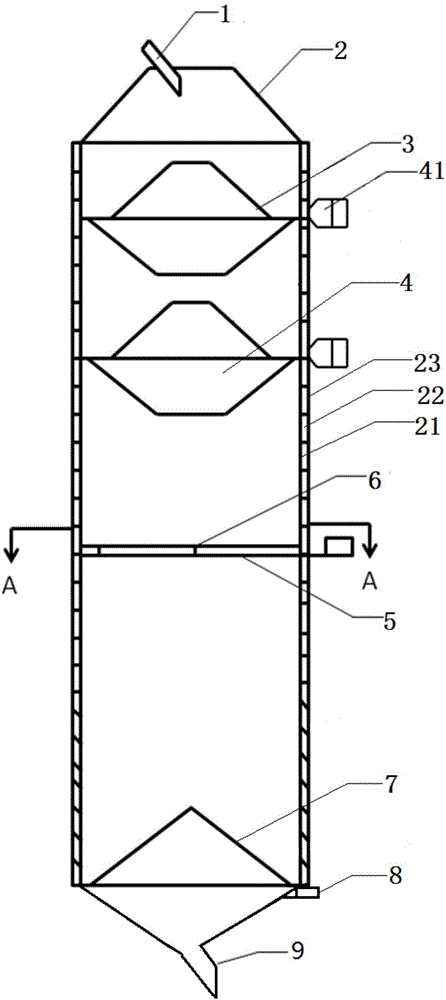

[0016] Example: refer to figure 1 , 2 As shown, a kind of municipal sludge vertical drying and incineration equipment includes a furnace body 2, a feed pipe 1 arranged at the top of the furnace body 2, and a slagging pipe 9 arranged at the bottom of the furnace body 2; From top to bottom, there are preheating area, drying area, incineration area, cooling area and crushing area in sequence.

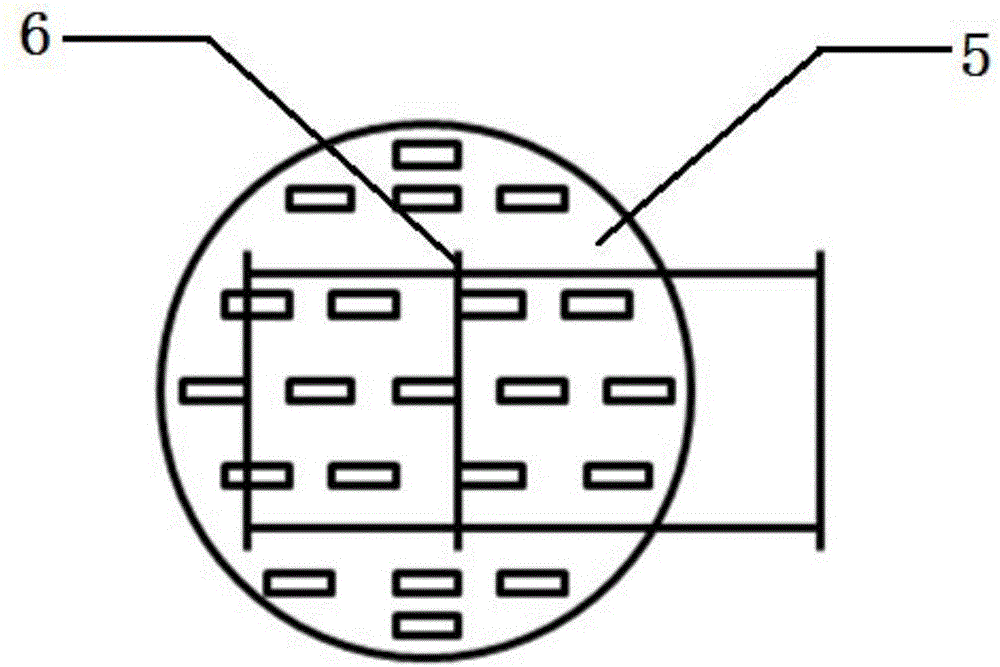

[0017] The preheating zone of the present invention is located below the feed pipe 1, and is composed of multiple groups of bulk material grate cones 3 and preheating grate basins 4 stacked up and down at different angles, and each side of the preheating grate basin 4 is equipped with a corresponding There is a vibrating motor 41; the drying area includes a drying grate 5 and a scraper 6 arranged on the drying grate 5; the incineration area is located below the drying grate 5 and is used for sludge self-sustaining incineration; the cooling area is connected with the incineration area The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com