A sludge steam conditioning and high drying dehydration coupling incineration integrated device

A steam and high-dry technology, applied in water/sludge/sewage treatment, incinerator, sludge treatment, etc., can solve the problems of high operating cost and large investment, and achieve the reduction of investment cost and operating cost, large investment, The effect of high calorific value of sludge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

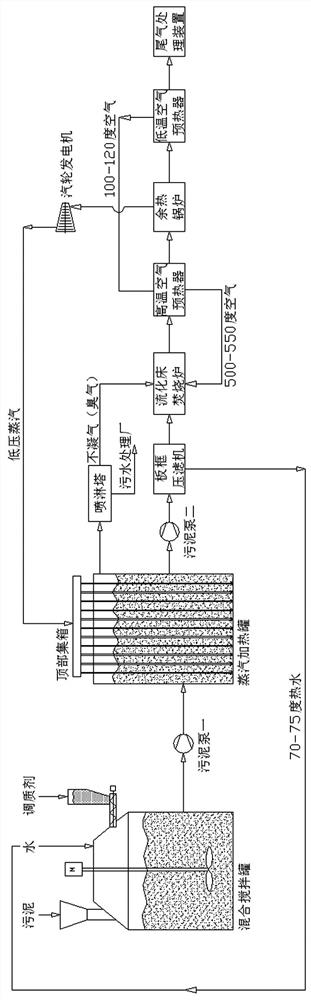

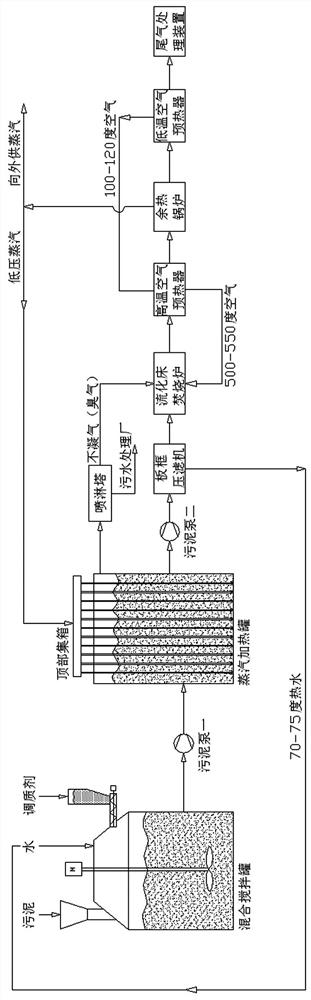

[0010] refer to figure 1 and figure 2 , an integrated method of sludge steam conditioning, high drying, dehydration, coupled incineration, which includes adding sludge with a moisture content of 80%, water and conditioning agent PAM1-2%tDS or PAC4-5%tDS into a mixing tank and stirring evenly , to obtain sludge with a moisture content of 90%, and then send the sludge with a moisture content of 90% to a steam heating tank for heating to 90-100°C, and then send the sludge with a moisture content of 90% at 90-100°C to high pressure The plate and frame filter press dehydrates under the pressure of 5.0MPa to obtain a sludge filter cake with a moisture content of 30-35%; finally, the sludge filter cake with a moisture content of 30-35% is crushed and sent to the fluidized bed for incineration Self-sustaining combustion in the furnace.

[0011] A sludge steam conditioning high-drying dehydration coupled incineration integrated device, which includes a mixing tank, a steam heating t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com