Patents

Literature

39results about How to "Efficient incineration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

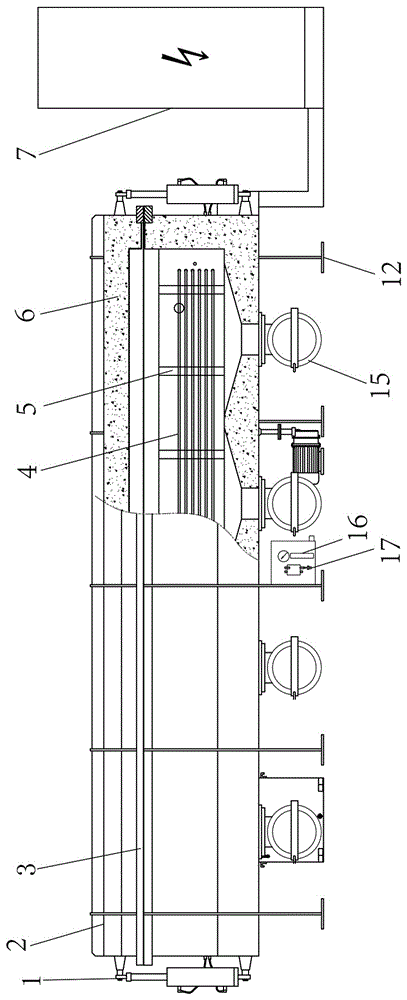

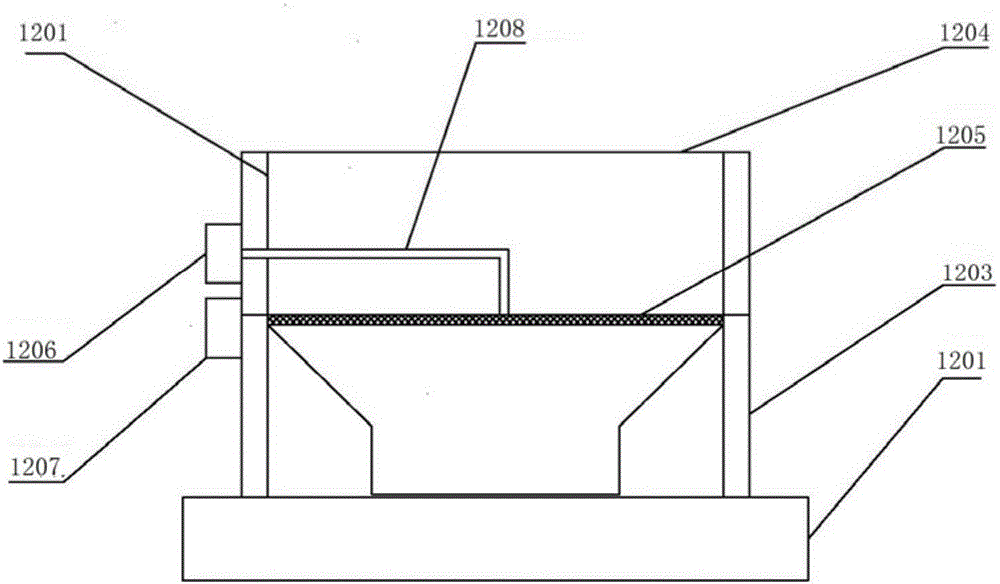

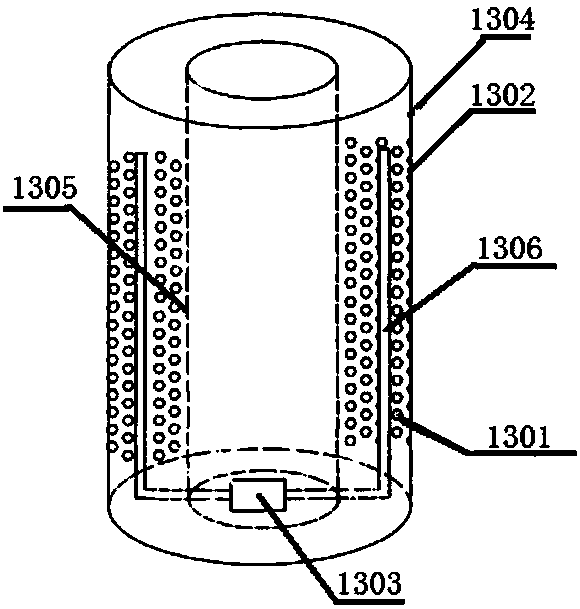

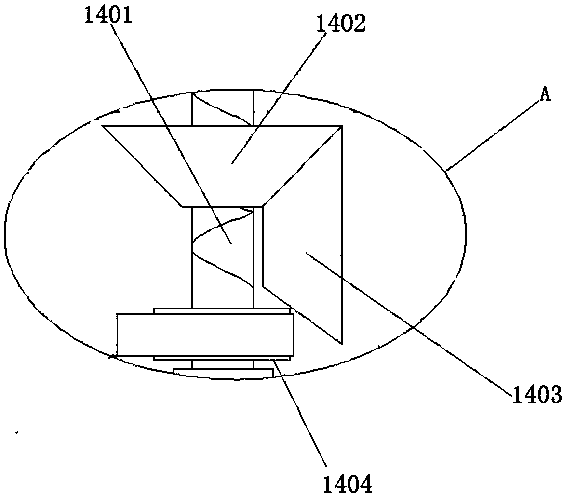

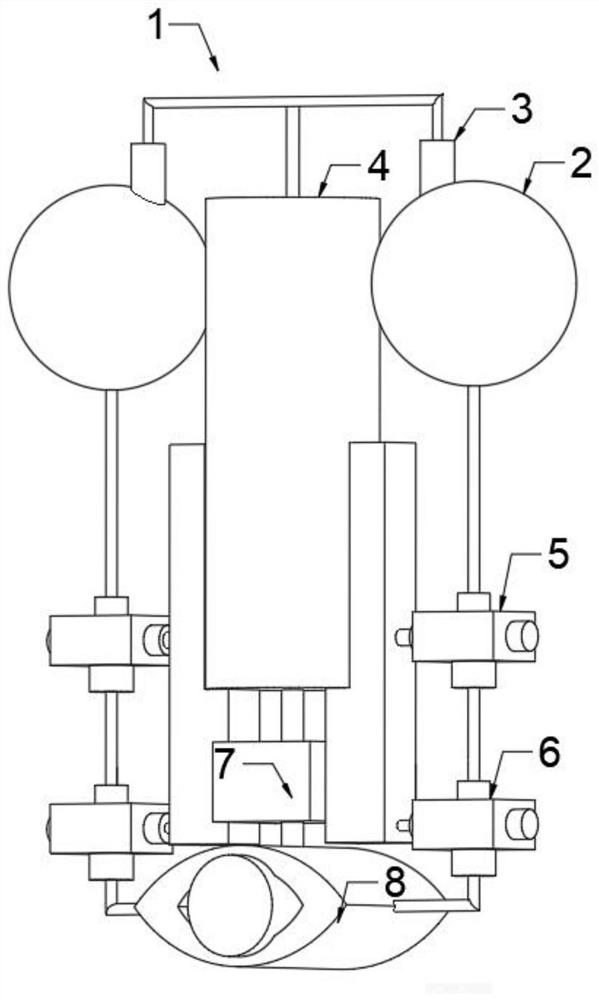

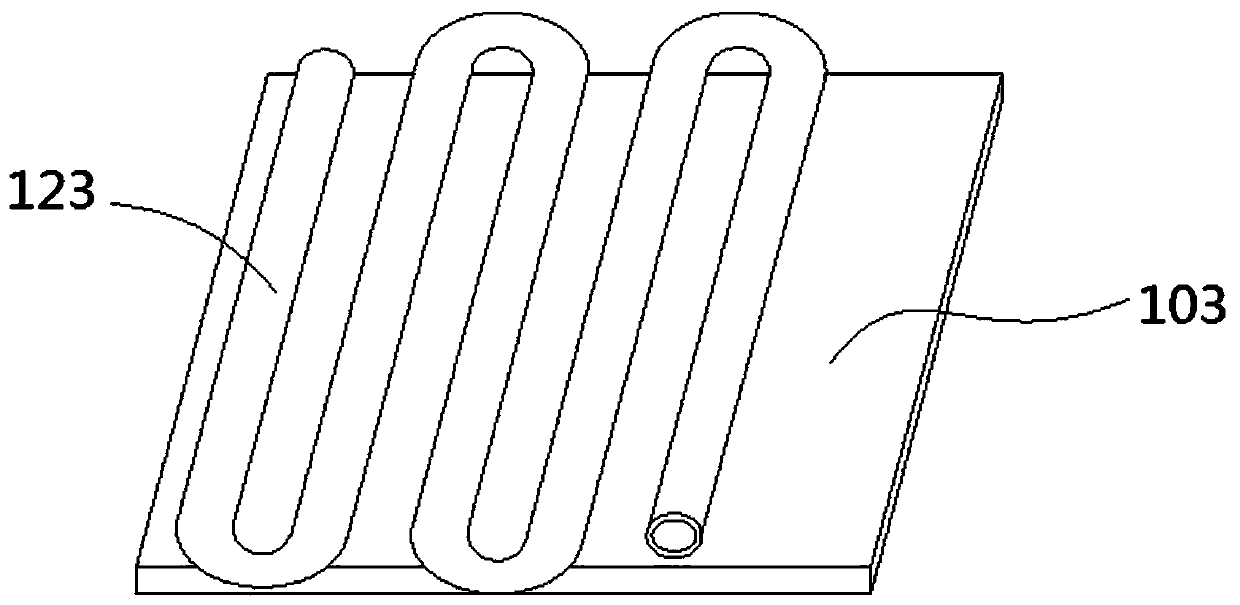

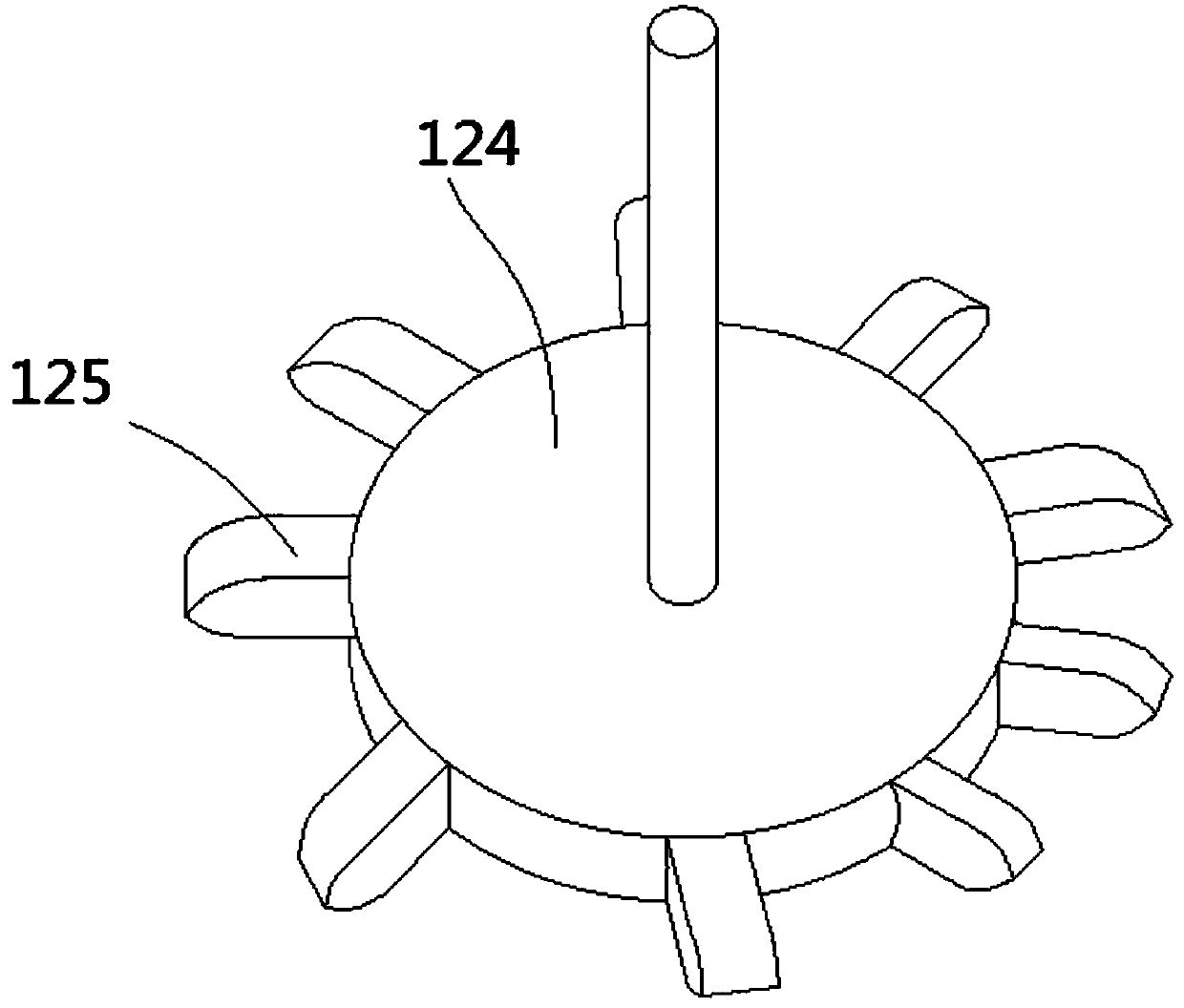

Vacuum incinerator device and operating method thereof

ActiveCN106091689AGuaranteed stabilityEasy to collectRemovable covers for furnacesSpinnerette packsTemperature controlControl system

The invention discloses a vacuum incinerator. The vacuum incinerator is a JZK-C well type vacuum incinerator and comprises a vacuum hearth, an incinerator cover opening and closing device, electric heating pipes, a waste collecting system, a vacuum pipeline anti-blocking device, a water spraying device, a water ring vacuum pump, a water backflow preventing device, a gas-water separator, a control system, a water circuit, an air circuit and the like, wherein the vacuum hearth is horizontally placed with an incinerator opening facing upwards and composed of an incinerator cover and a work room used for storing cleaned parts. The waste collecting system mainly comprises a waste collecting tank which is installed on the lower portion of the hearth. A hopper-shaped tray is arranged at the bottom of an inner cavity of the vacuum hearth. A discharging port of the tray is located over the waste collecting tank. Compared with the prior art, the vacuum incinerator is compact in structure, good in sealing performance and large in work space; the incinerator cover is opened and closed through two oil cylinders, the cover opening angle is larger than 90 degrees, and the opening and closing stability of the incinerator cover is guaranteed; waste can be collected conveniently, incineration and cleaning are conducted efficiently, and the situation of water backflow can be effectively prevented; and the automation level is high, temperature control is accurate, the working efficiency is improved, and the labor intensity is relieved.

Owner:JIANGSU XINLONG CHEM FIBER MACHINERY

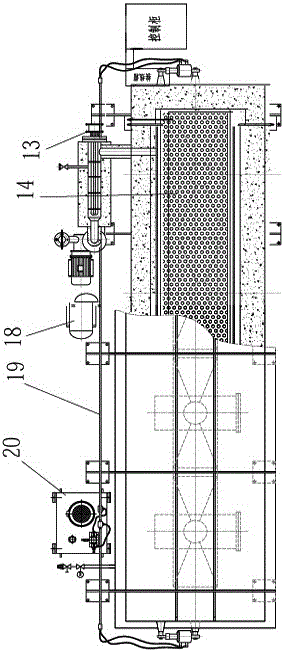

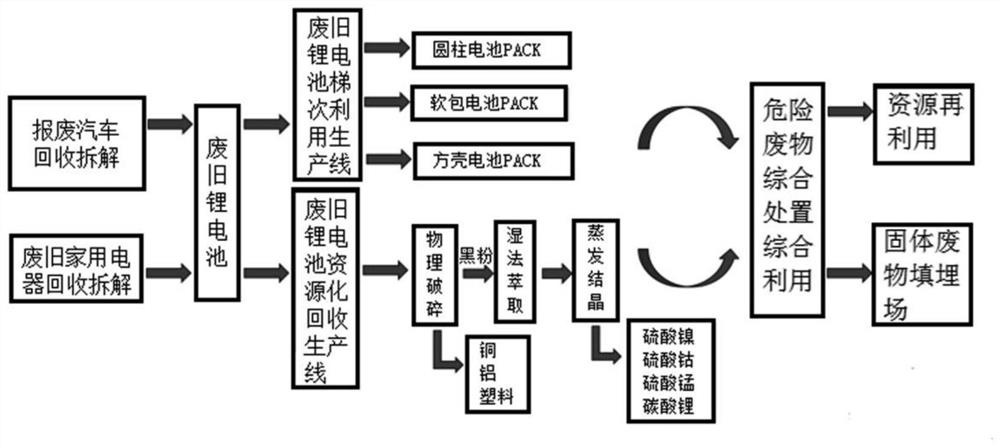

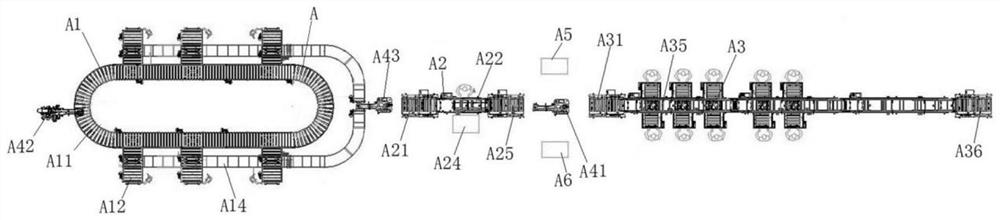

Waste battery recycling system and process thereof

ActiveCN113745685APerfect vacancyEnsure sustainable developmentWaste accumulators reclaimingBattery recyclingProcess engineeringEnvironmental engineering

The invention provides a waste battery recycling system and process, and the system comprises: a waste lithium battery echelon utilization production line for screening, screening, disassembling and capacity detection on waste lithium batteries are carried out, Pack assembling is carried out on lithium ion single batteries which can be used in an echelon manner; The waste lithium battery echelon utilization production line comprises a waste lithium battery disassembling system, a capacity grading system and a Pack recombination system; the waste lithium battery resource recycling production line is used for recycling lithium ion single batteries which cannot be utilized in an echelon mode and waste lithium ion single batteries generated in the running process of the waste lithium battery echelon utilization production line. And the system also includes a hazardous waste incineration disposal system used for incinerating hazardous wastes generated in the running process of the waste lithium battery echelon utilization production line and the waste lithium battery resource recycling production line. According to the invention, the disassembly and resource recovery of the waste battery and the incineration disposal of the waste battery which cannot be recovered are integrated, so that the environmental pressure of local solid waste stockpiling is solved.

Owner:派尔森环保科技有限公司

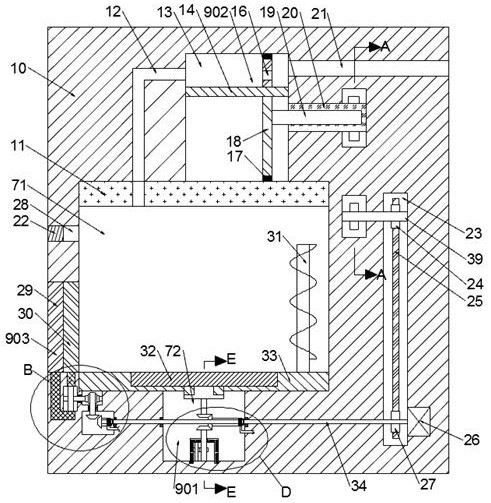

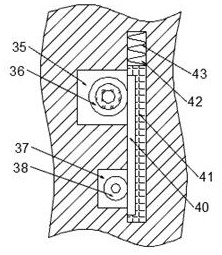

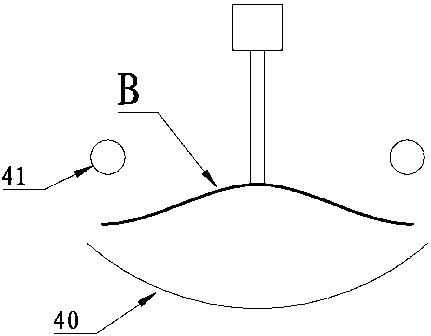

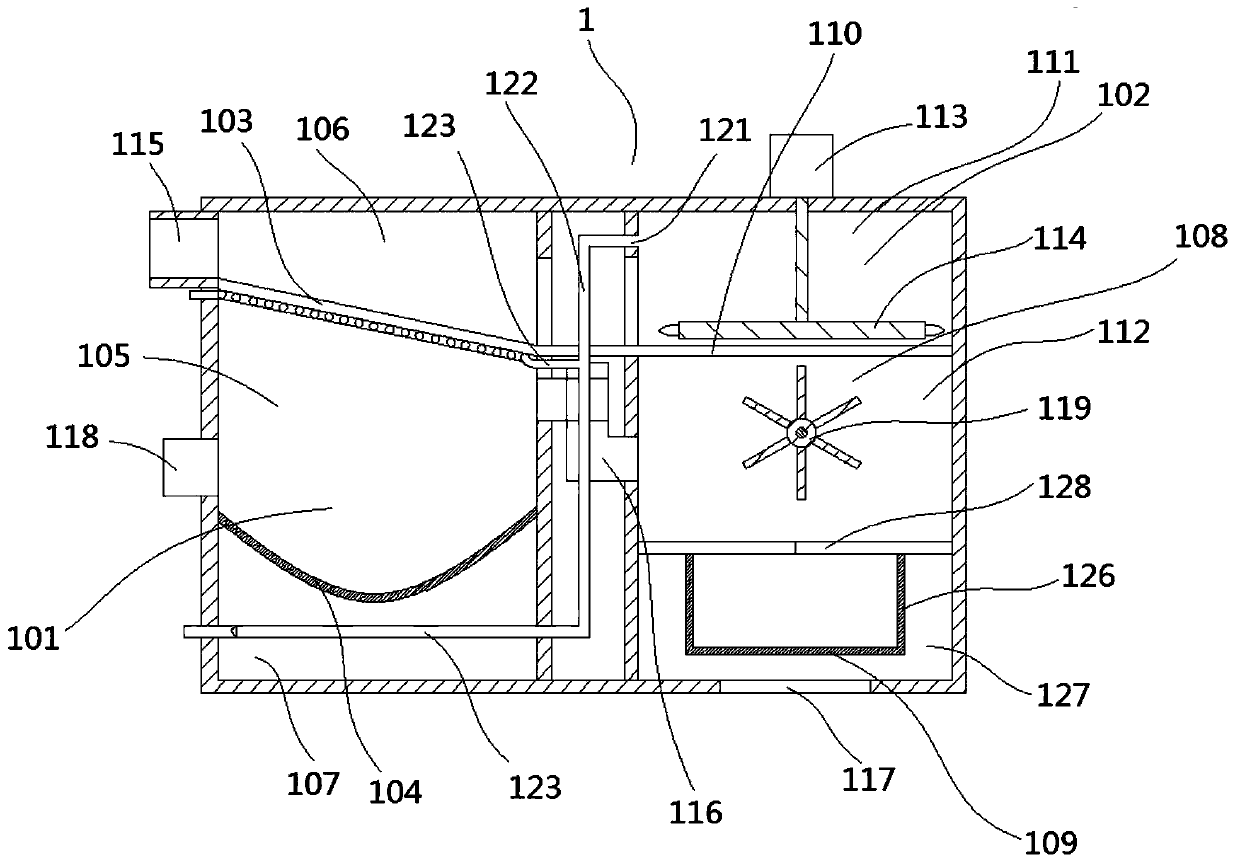

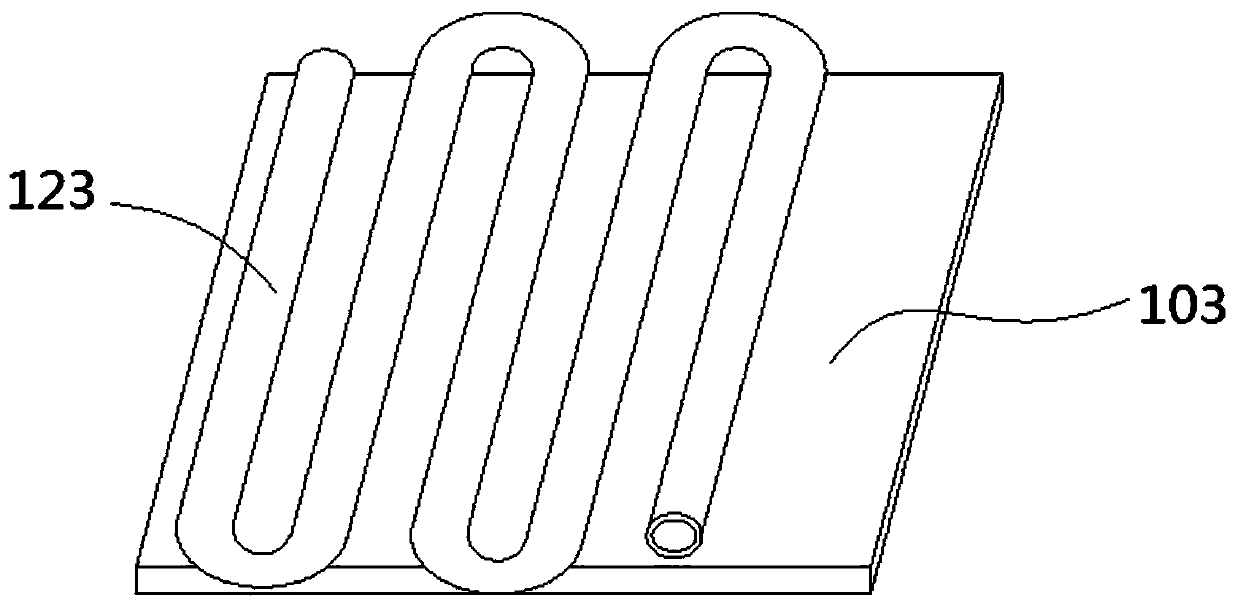

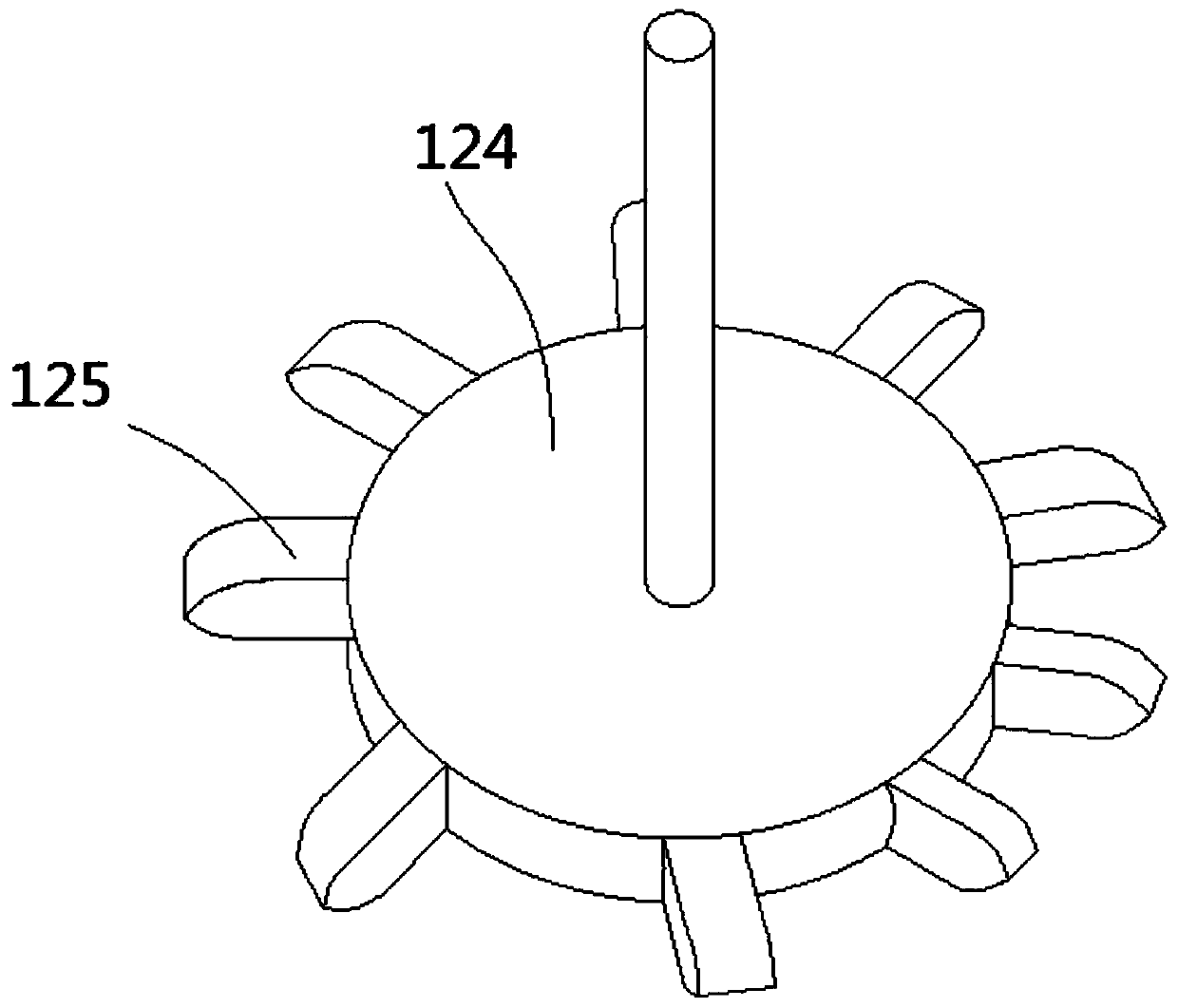

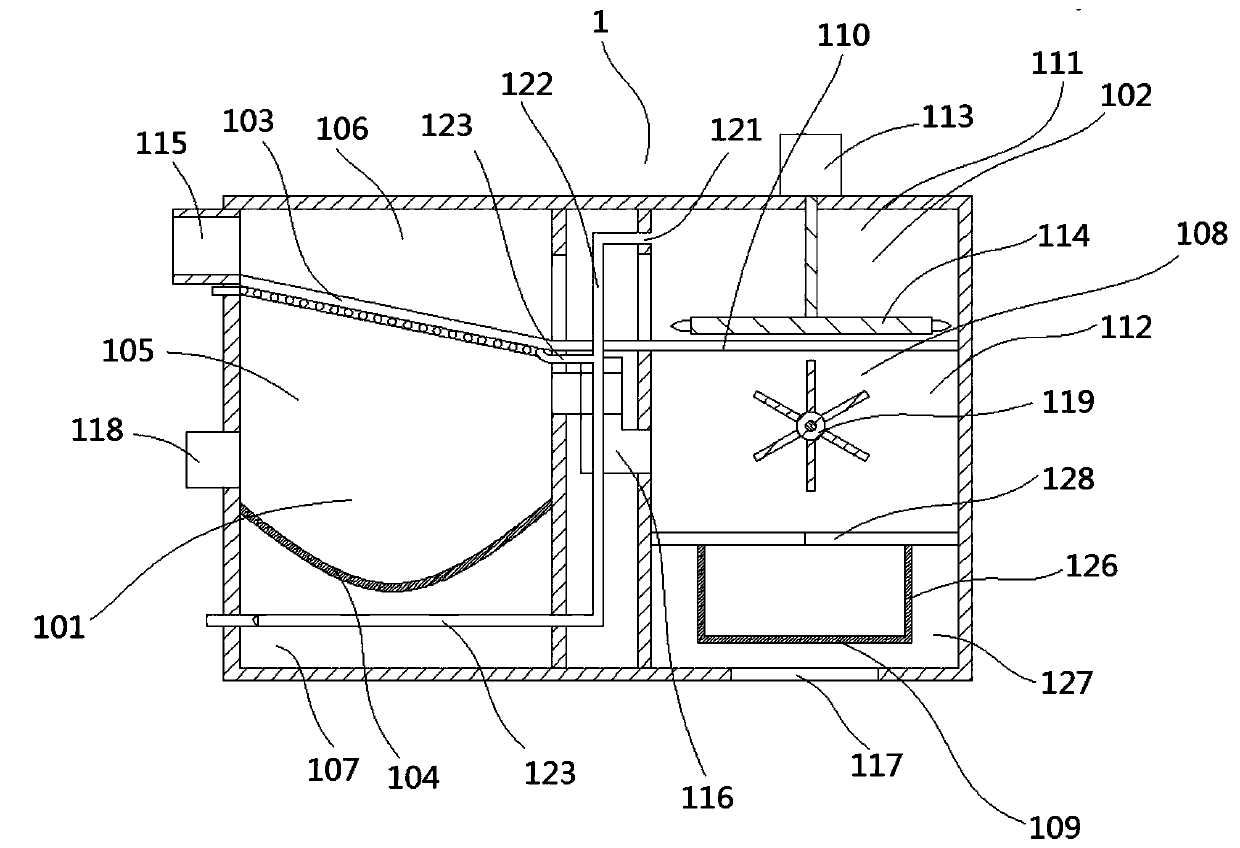

Green and environment-friendly garbage incineration equipment

InactiveCN111623351ABurn completelyIncineration firepowerIncinerator apparatusMechanical engineeringIncineration

The invention discloses green and environment-friendly garbage incineration equipment. The green and environment-friendly garbage incineration equipment comprises a machine body, an incineration cavity is arranged in the machine body, a heat insulation plate for heat insulation is fixedly arranged on the upper side wall body of the incineration cavity, and a middle rotary table is rotatably arranged on the lower side of the incineration cavity. According to the green and environment-friendly garbage incineration equipment, a driving device is arranged on the equipment, so that the incinerationgarbage accumulated in the incineration cavity can be more effectively classified by controlling the middle rotary table and side rotary tables to rotate in opposite directions, and the combustion ismore thorough; an air blowing device is arranged on the equipment, so that external air enters the incineration cavity to support combustion by changing the high-low air pressure in an air inlet cavity by driving a sliding plate, the incineration firepower is higher, and the garbage combustion is more efficient; and a switch device is arranged on the equipment and can be matched with the drivingdevice to enable a first sliding door and a second sliding door to be automatically opened, and the influence of high temperature on people is reduced accordingly.

Owner:叶周航

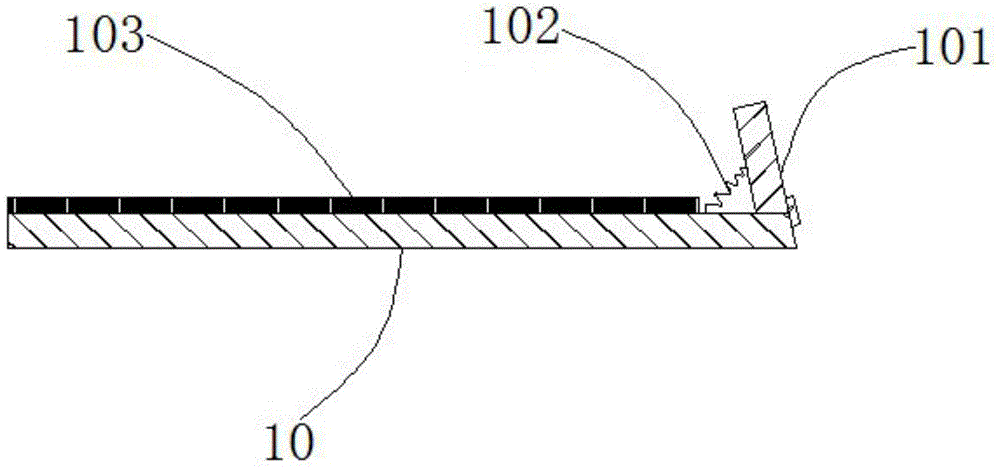

Incinerator with fixed fire grate

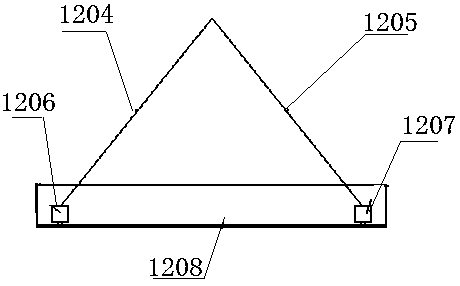

InactiveCN103994441AEnsure high constant temperature incineration demandEnsure high constant temperature incinerationIncinerator apparatusCombustion chamberMoisture

The invention belongs to the field of waste incineration devices and particularly relates to an incinerator with a fixed fire grate. The incinerator with the fixed fire grate is used for incinerating biomass materials such as straws and at least comprises a main combustion chamber, an air supply assembly and a smoke flue for guiding heat energy in the main combustion chamber out. The main combustion chamber is communicated with the smoke flue through a ventilation pipe, and a conveying and incinerating platform is arranged in the main combustion chamber and at least comprises a bearing plate and a stirring portion. The incinerator with the fixed fire grate further comprises a pushing portion, wherein an air return moisture removal cavity channel is arranged between the pushing portion and the main combustion chamber in a transition mode and forms a material conveying path for connecting the cavity of the main combustion chamber with the pushing portion, an air outlet is formed in the end of the air return moisture removal cavity channel and communicated with an external air draught fan, and the end of the air return moisture removal cavity channel and the pushing portion are positioned at the same end. The incinerator with the fixed fire grate is high in operation reliability and incineration efficiency, low in cost and capable of ensuring incineration at high and constant temperature and extracting and utilizing efficient heat energy of biomass fuel.

Owner:合肥康帕因设备技术有限公司

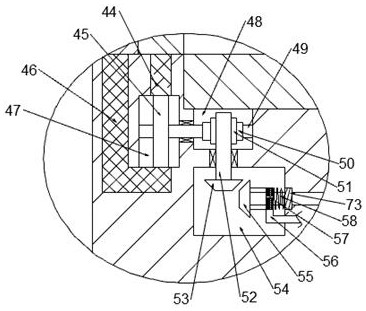

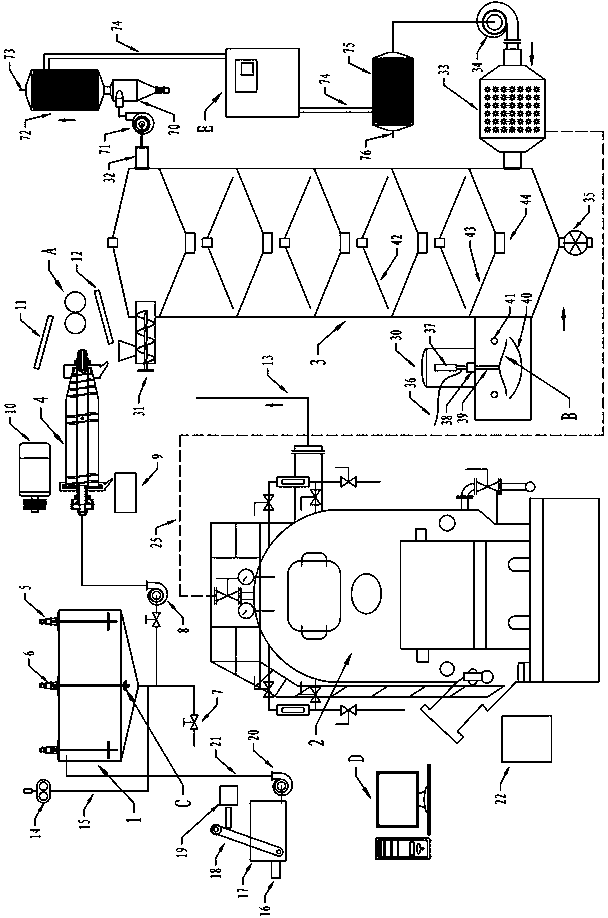

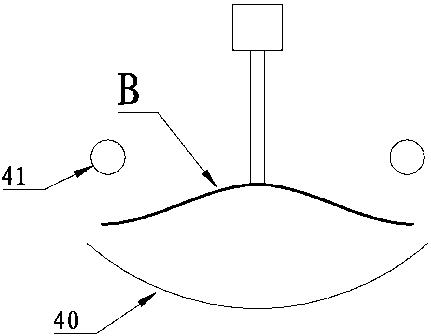

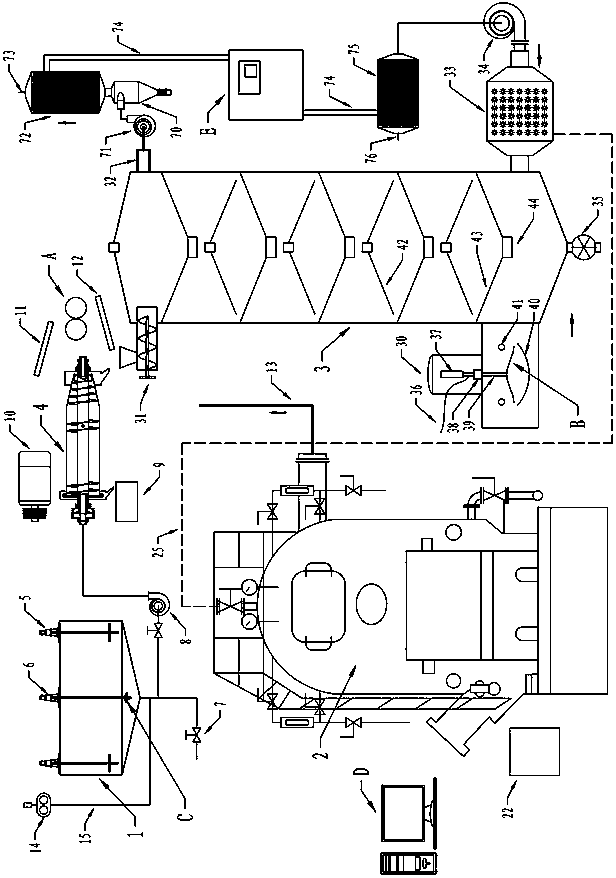

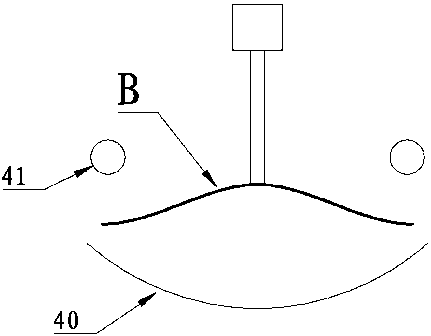

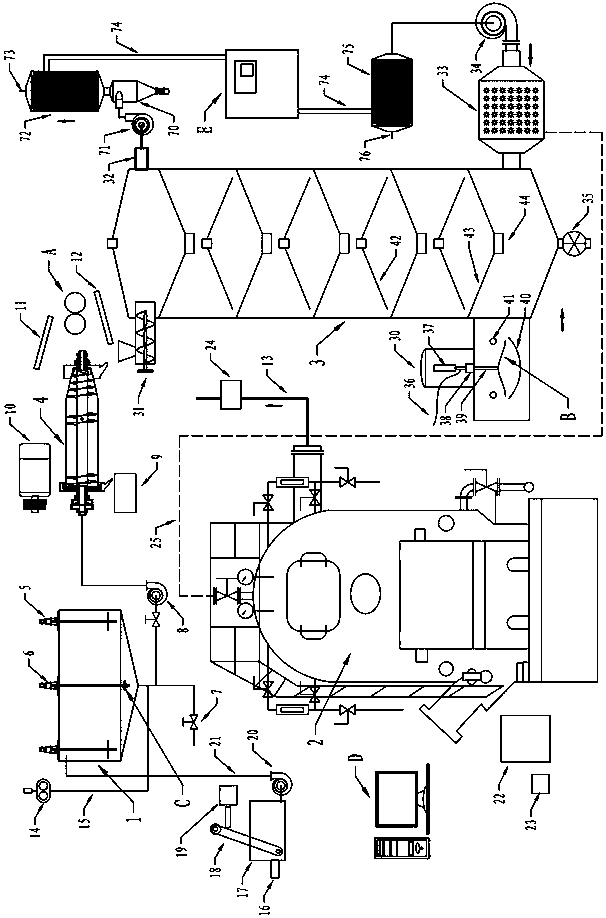

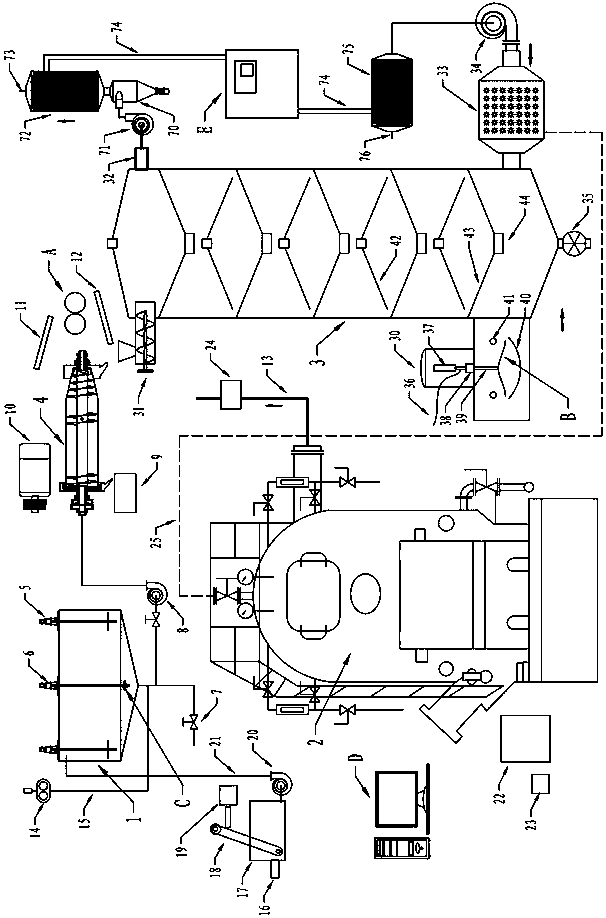

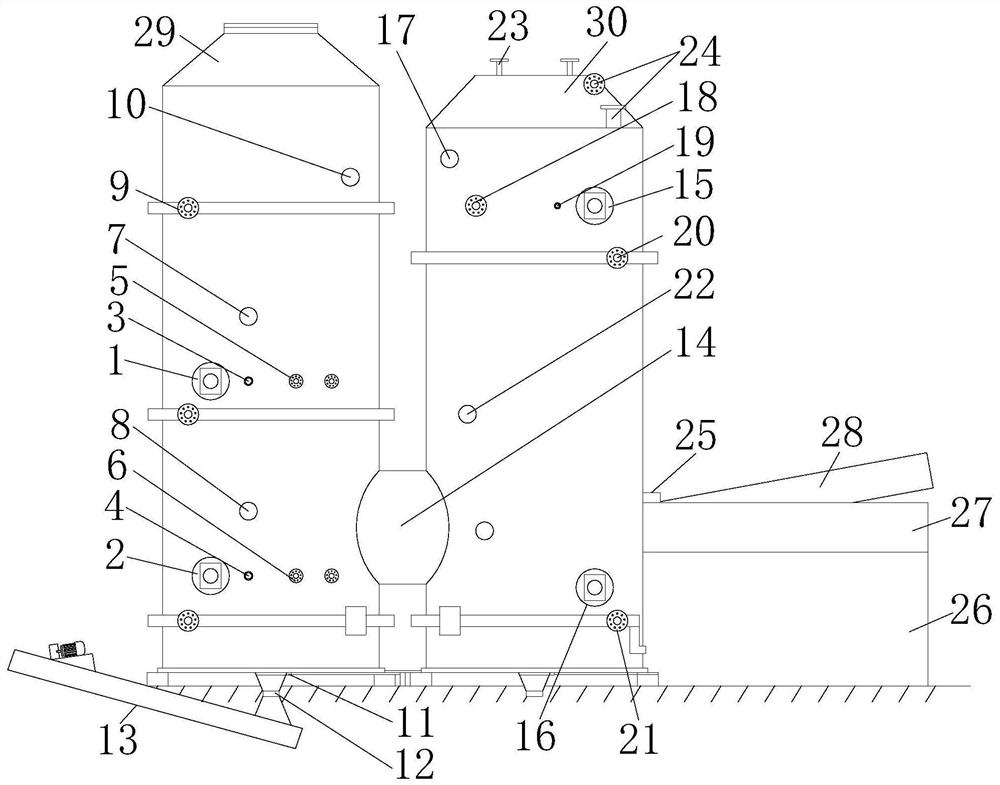

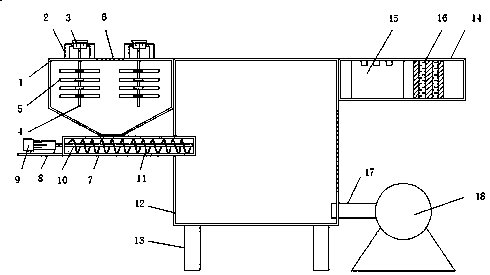

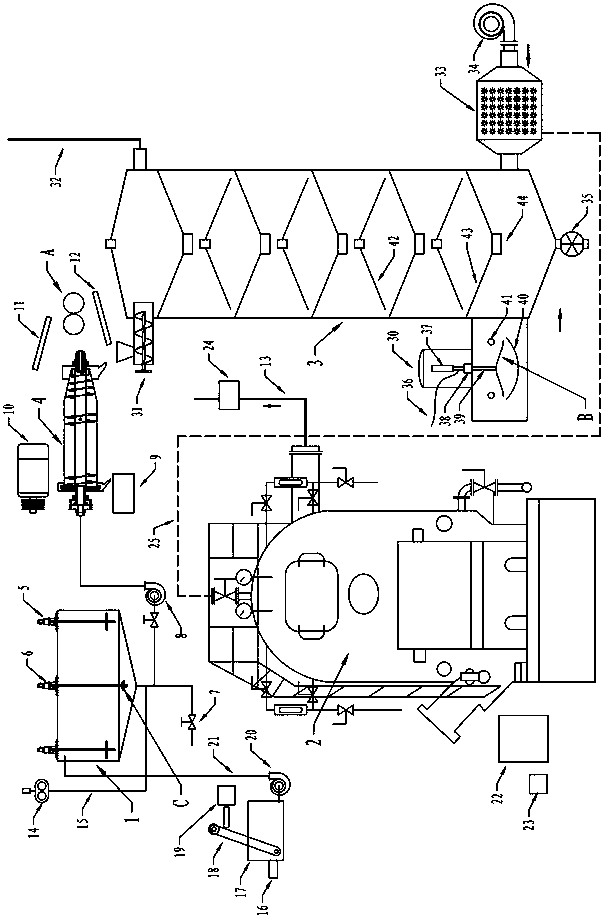

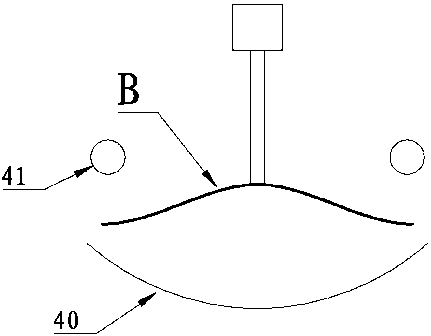

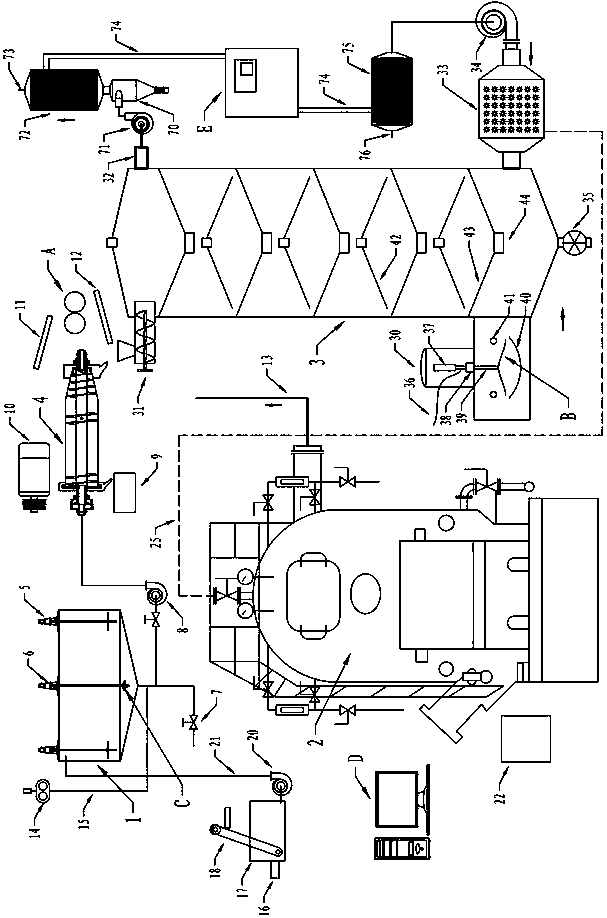

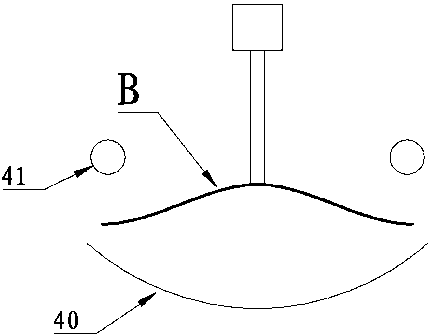

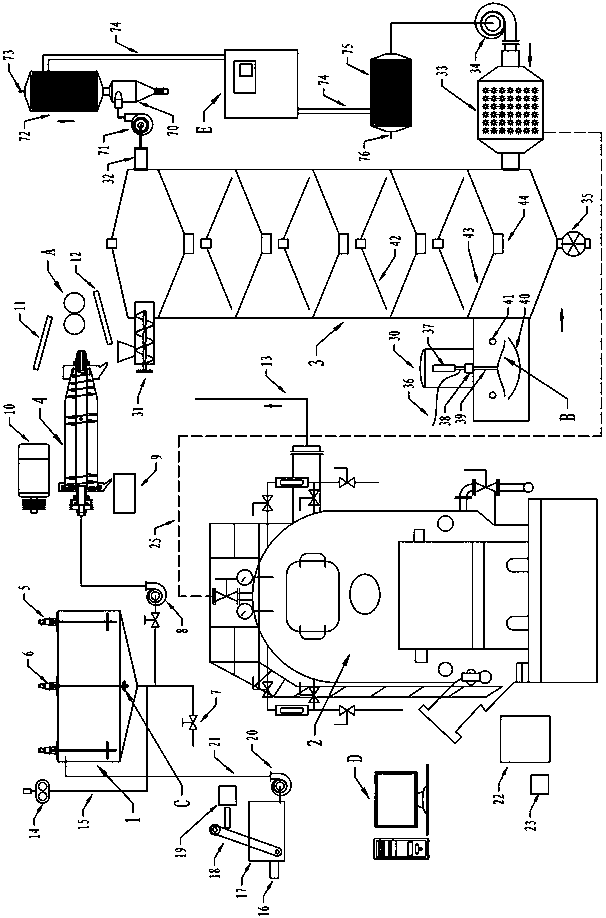

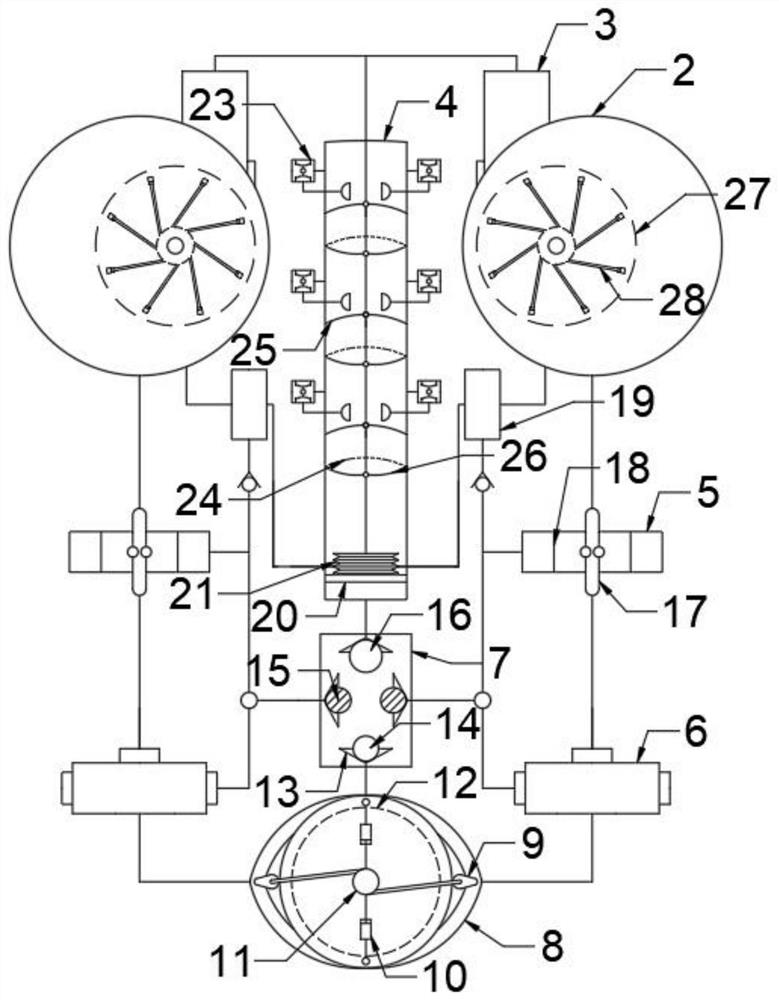

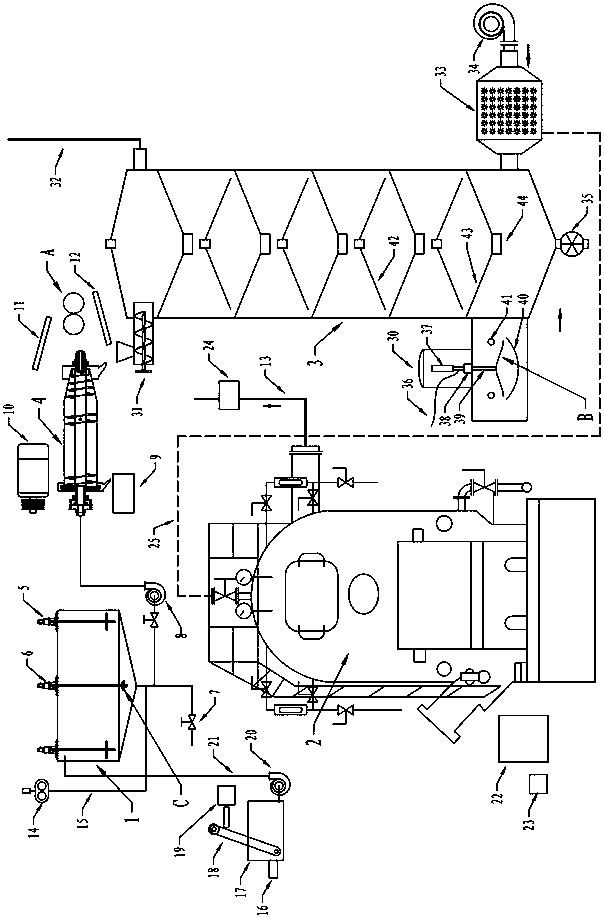

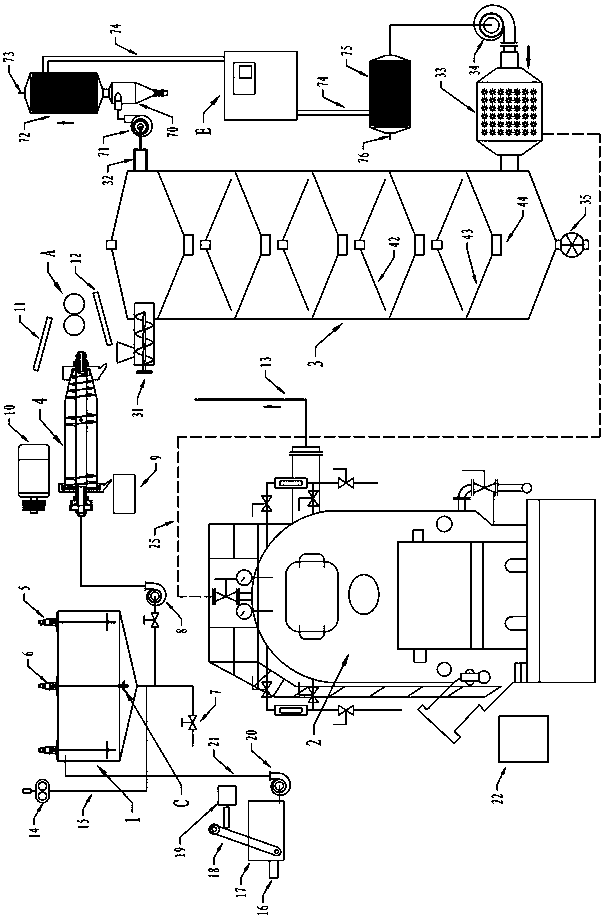

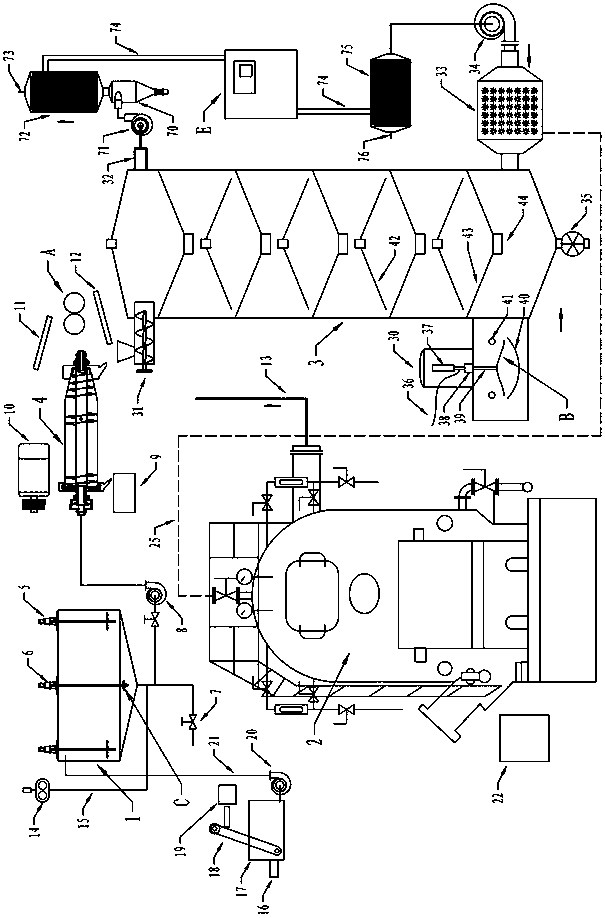

Municipal wastewater and garbage disposal device with tail heat utilizing function and centrifugal machine

InactiveCN107842858AContinuous monitoring of production dataRealize automated continuous processingShaking/oscillating/vibrating mixersTransportation and packagingComputer control systemBuffer tank

The invention discloses a municipal wastewater and garbage disposal device with a tail heat utilizing function and a centrifugal machine. The municipal wastewater and garbage disposal device comprisesa wastewater large tank, an incinerator, a countercurrent drying tower, sine rollers, a heat pump main unit and a computer control system. A municipal wastewater pipe is connected with a wastewater buffer tank which is internally provided with a grille residue salvaging machine, and the grille residue salvaging machine is connected with a centrifugal dewatering machine through a conveying pipeline. The wastewater buffer tank is connected with an inlet of the wastewater large tank through a wastewater pipe and a wastewater pump, and stirring devices and sine ultrasonic shock excitation stirrers are appropriately arranged in the wastewater large tank. The tapered bottom is connected with a roots blower, a bottom valve and a slurry pump through pipelines, and the slurry pump is sequentiallyconnected with the horizontal-type spiral centrifugal machine, a spiral air closing feeding machine and the countercurrent drying tower. An exhaust pipe of the drying tower is connected with a heat pump system, and the lower left portion of the heat pump system is provided with cosine plastic plate pulse gas explosion devices. The disposal device is controlled by a computer. The sine rollers, thecosine plastic plate pulse gas explosion devices and the sine ultrasonic shock excitation stirrers have the distinct characteristics and can reliably and synergistically complete municipal wastewaterand garbage disposal.

Owner:JISHOU UNIVERSITY

Incinerator

The invention provides a garbage incinerator. The garbage incinerator comprises an outer furnace wall, an outer furnace core and an inner furnace core which are sequentially arranged from outside to inside, wherein the outer furnace core and the inner furnace core are fixedly arranged on a base; the base, the outer furnace wall and the outer furnace core form an outer furnace chamber for combusting garbage; a garbage inlet and a fuel input channel are formed in the upper part of the outer furnace wall; a feeder is arranged between the outer furnace core and the outer furnace wall; a charging hole is formed in the upper part of the inner furnace core; a stirrer is arranged in the inner furnace core. The outer furnace chamber can be used for incinerating the garbage, and the inner furnace core can be used for roasting chemical waste materials which can be converted into ceramic raw materials; during the incineration of the garbage, industrial chemical waste materials generated in a production process of an aluminum product are roasted into ceramic preparation materials to achieve a waste recycling effect; moreover, conventional garbage incineration-based energy conversion activities are not affected, energy is fully utilized, and the garbage incinerator is energy-saving and emission-reducing.

Owner:惠州恒德远实业有限公司

Urban wastewater garbage treatment apparatus with tail heat utilization and roots blower

InactiveCN107746137AContinuous monitoring of production dataRealize automated continuous processingWater/sewage treatment by centrifugal separationSludge treatment by de-watering/drying/thickeningGas explosionCentrifuge

The invention discloses an urban wastewater garbage treatment apparatus with tail heat utilization and a roots blower. The urban wastewater garbage treatment apparatus comprises a sewage large groove,an incinerator, a countercurrent drying tower, a horizontal spiral centrifuge, a sine roller drum, a heat pump host computer and a computer control system, wherein a stirring device and a sine ultrasonic wave vibration exciting stirrer are appropriately arranged in the sewage large groove, the cone bottom is connected to a roots blower, a bottom valve and a mud pump through pipelines, the mud pump is sequentially connected to the horizontal spiral centrifuge, a spiral closed-air material feeding machine and the countercurrent drying tower, the tail gas pipe of the drying tower is connected toa heat pump system, the left-lower portion of the drying tower is provided with a cosine plastic disk pulse gas explosion device, and a treatment device is controlled by a computer. According to thepresent invention, the the sine roller drum, the cosine plastic disk pulse gas explosion gas device and the sine ultrasonic wave vibration exciting stirrer respectively have distinctive characteristics and can reliably and synergistically complete the treatment of urban wastewater and garbage.

Owner:JISHOU UNIVERSITY

Urban waste water and garbage treatment device with tail heat utilization function and tail gas purification function

InactiveCN107552545AContinuous monitoring of production dataRealize automated continuous processingSolid waste disposalMultistage water/sewage treatmentDetonationSlag

The invention discloses an urban waste water and garbage treatment device with a tail heat utilization function and a tail gas purification function. The device comprises a large sewage tank, an incinerator, a countercurrent drying tower, a heat pump host and a computer control system, wherein an urban waste water pipe is in connection with a waste water buffering tank; the waste water buffering tank is internally provided with a grating slag extractor; the waste water buffering tank is connected with an inlet of the large sewage tank through a pipeline and a pump; stirring devices and a sinusoidal ultrasonic vibration stirrer are arranged in the large sewage tank; a cone bottom is connected with a roots blower, a bottom valve and a mud pump through pipelines; the mud pump is sequentiallyconnected with the horizontal spiral centrifuge, a spiral closed air feeding machine and the countercurrent drying tower; a tail gas pipe of the drying tower is connected with a heat pump system; a cosine rubber disc pulse detonation device is arranged on the left lower part of the drying tower; a boiler tail gas pipe and a incineration tail gas treatment device are sequentially connected to theright upper part of the incinerator; and the treatment device is controlled by a computer. According to the urban waste water and garbage treatment device with the tail heat utilization function and the tail gas purification function, a sine roller, the cosine rubber disc pulse detonation device and the sinusoidal ultrasonic vibration stirrer have distinct characteristics and can be used for reliably and cooperatively finishing the treatment of the urban waste water and garbage.

Owner:JISHOU UNIVERSITY

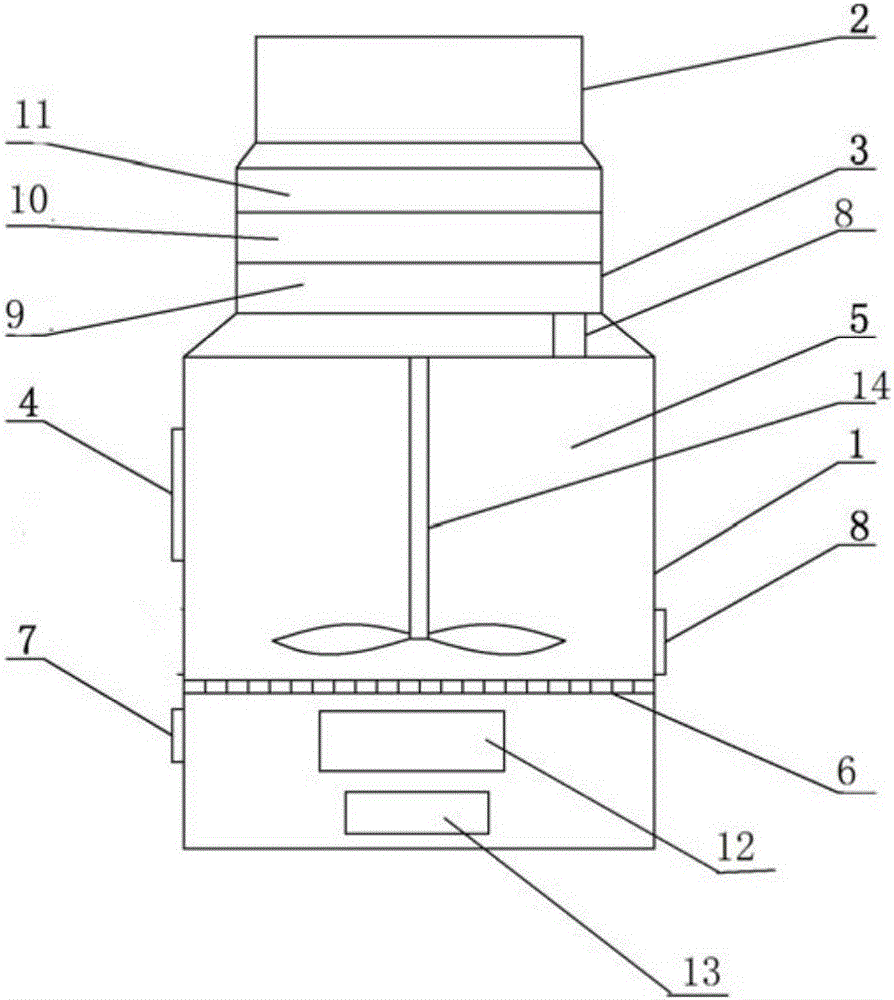

Waste incinerator provided with heat energy recovery device

InactiveCN105805752AEfficient incinerationTake advantage ofDispersed particle separationIncinerator apparatusThermal energyCombustion chamber

The invention discloses a waste incinerator provided with a heat energy recovery device. The waste incinerator provided with the heat energy recovery device comprises a waste incinerator body. The heat energy recovery device, a gas purification device, a liquid crystal display and a combustion chamber are arranged in the waste incinerator body. A waste inlet, a feeding port and an outlet are all formed in the combustion chamber. A grate is arranged in the combustion chamber. A first air hole is formed in the outer wall of the combustion chamber. Inlets and outlets are formed in the heat energy recovery device and the gas purification device correspondingly. An air duct is arranged in the combustion chamber. The outlet of the combustion chamber is connected with the inlet of the gas purification device. The outlet of the gas purification device is connected with the inlet of the heat energy recovery device. The gas purification device comprises an oil-water separator, a photocatalytic treatment device and an active carbon adsorption device, wherein the oil-water separator, the photocatalytic treatment device and the active carbon adsorption device are connected in sequence. The waste incinerator provided with the heat energy recovery device is simple in structure, convenient to use, high in heat energy recovery efficiency, and capable of saving energy and reducing emission.

Owner:JIANGSU MARITIME INST

Ultrasonic municipal wastewater and garbage treatment device with tail heat utilizing and exhaust purifying functions

InactiveCN107860007AContinuous monitoring of production dataRealize automated continuous processingShaking/oscillating/vibrating mixersTransportation and packagingComputer control systemCounter flow

The invention discloses an ultrasonic municipal wastewater and garbage treatment device with tail heat utilizing and exhaust purifying functions. The ultrasonic municipal wastewater and garbage treatment device with the tail heat utilizing and exhaust purifying functions comprises a large sewage tank, an incinerator, a counter flow drying tower, a heat pump host and a computer control system; a municipal wastewater pipe is connected with a wastewater buffering tank; a grille slag salvaging machine is arranged in the wastewater buffering tank; the wastewater buffering tank is connected with thelarge sewage tank through a pipeline; a stirring device and a sine ultrasonic wave exciter are arranged in the large sewage tank; a cone bottom is connected with a Roots blower, a bottom valve and amud pump through pipelines; the mud pump is connected with a horizontal spiral centrifugal machine, a spiral closed air feeding machine and the counter flow drying tower in sequence; and an exhaust pipe of the drying tower is connected with a heat pump system; a cosine plastic plate pulse aeration device is arranged at the lower left part of the counter flow drying tower; the upper right part of the incinerator is connected with an exhaust pipe of a boiler and an incineration exhaust treatment device in sequence; and the treatment device is controlled by a computer. The cosine plastic plate pulse aeration device and the sine ultrasonic wave exciter of the ultrasonic municipal wastewater and garbage treatment device with the tail heat utilizing and exhaust purifying functions have distinctcharacteristics, and can reliably and synergistically complete treatment of municipal wastewater and garbage.

Owner:JISHOU UNIVERSITY

Energy-saving and environment-friendly garbage incinerator

InactiveCN108119900AEfficient incinerationTake advantage ofIncinerator apparatusLiquid-crystal displayCombustion chamber

The invention discloses an energy-saving and environment-friendly garbage incinerator which comprises a garbage incinerator body. A heat energy recovery device, a gas purification device, a liquid crystal display screen and a combustion chamber are disposed in the garbage incinerator body. The combustion chamber is provided with a garbage inlet, a feeding port and an outlet, wherein the combustionchamber is internally provided with a grate, and the outer wall of the combustion chamber is provided with a first venting hole, the thermal energy recovery device and the gas purification device each are provided with an inlet and an outlet, an air flue is disposed in the combustion chamber, the outlet of the combustion chamber is connected with the inlet of the gas purification device, and theoutlet of the gas purification device is connected with the inlet of the thermal energy recovery device. The energy-saving and environment-friendly garbage incinerator is simple in structure and convenient to use, saves energy, reduces emission and can recycle excessive energy.

Owner:JIANGSU MARITIME INST

Vertical type incinerator capable of incinerating waste liquids, waste gases and solid waste simultaneously

The invention discloses a vertical type incinerator capable of incinerating waste liquids, waste gases and solid waste simultaneously. The vertical type incinerator comprises a connecting pipe, fire-observing windows, a first combustion mechanism, a second combustion mechanism, a feeding mechanism and discharging mechanisms. The first combustion mechanism comprises a second incinerator body. According to the vertical type incinerator capable of incinerating the waste liquids, waste gases and solid waste simultaneously, the discharging mechanisms are arranged on bottom positions of a first incinerator body and the second incinerator body, ash discharging is conducted by adopting a scraper slag discharging machine at the bottom, the operation is convenient, and trouble and hard work of manual labor are reduced; besides, burning ports are formed in the bottoms of the first incinerator body and the second incinerator body, solid waste can be incinerated while the waste liquids and waste gases are incinerated, and incineration diversity of the incinerator device is increased; through peculiar oxygen-supplementing wind ports, the solid waste is blown away and soars, the contact area of the solid waste and flames is increased, it is guaranteed that the solid waste combusts fully, and it is avoided that gas explosion occurs after certain concentration is reached by accumulated organicgases because of incomplete combustion of solid waste at the bottom; and the incinerator has the advantages of high-efficiency incineration and complete incineration.

Owner:宜兴市华瑞焚烧炉科技发展有限公司

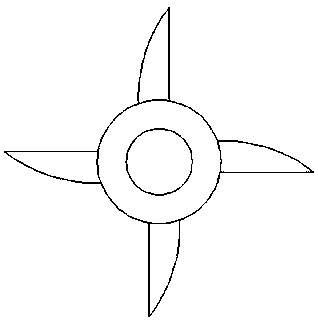

Environmentally-friendly waste incineration device

InactiveCN109751605AControl delivery volumeImprove combustion efficiencyIncinerator apparatusGrain treatmentsLitterEngineering

The invention relates to the technical field of environmentally-friendly equipment, and discloses an environmentally-friendly waste incineration device. The device comprises a material storing bucket,wherein the top part of the material storing bucket is fixedly connected to the bottom part of a fixing frame; a first motor is fixedly connected to the fixing frame, and an output shaft of the firstmotor is fixedly connected to the top part of a rotating rod; the bottom part of the rotating rod penetrates the top part of the material storing bucket and extends into the material storing bucket;blades are fixedly connected to the surface of the rotating rod; a feeding port is formed in the top part of the material storing bucket and is positioned at the right of the fixing frame; and the bottom part of the material storing bucket is fixedly connected to the top part of a feeding pipe. According to the device, the first motor which is fixedly connected to the fixing frame and the blades which are fixedly connected to the surface of the rotating rod are matched with a second motor which is fixedly connected to the top part of the supporting plate and a winch which is fixedly connectedto the surface of a rotating shaft to crush the wastes, and moreover, the waste feeding quantity can be controlled, so that the effect of improving the incineration efficiency is achieved.

Owner:江都区小纪镇恺胜体育用品厂

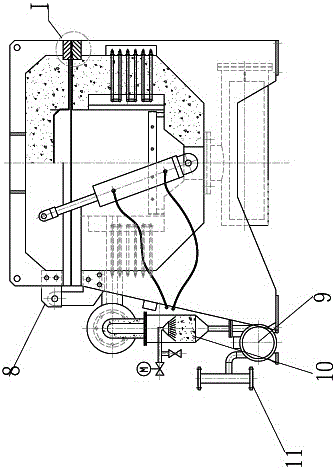

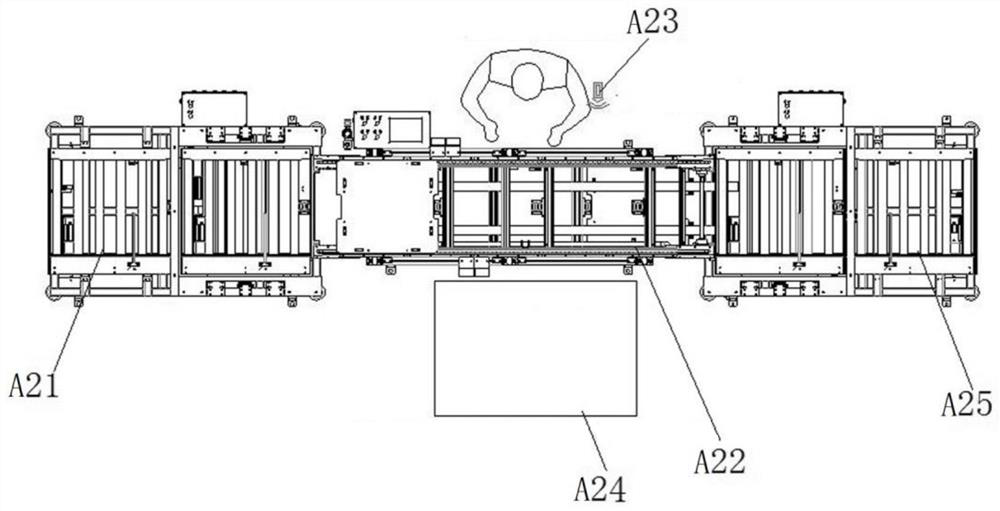

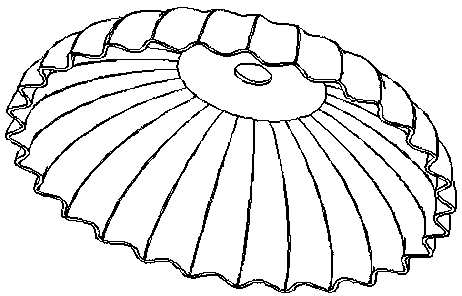

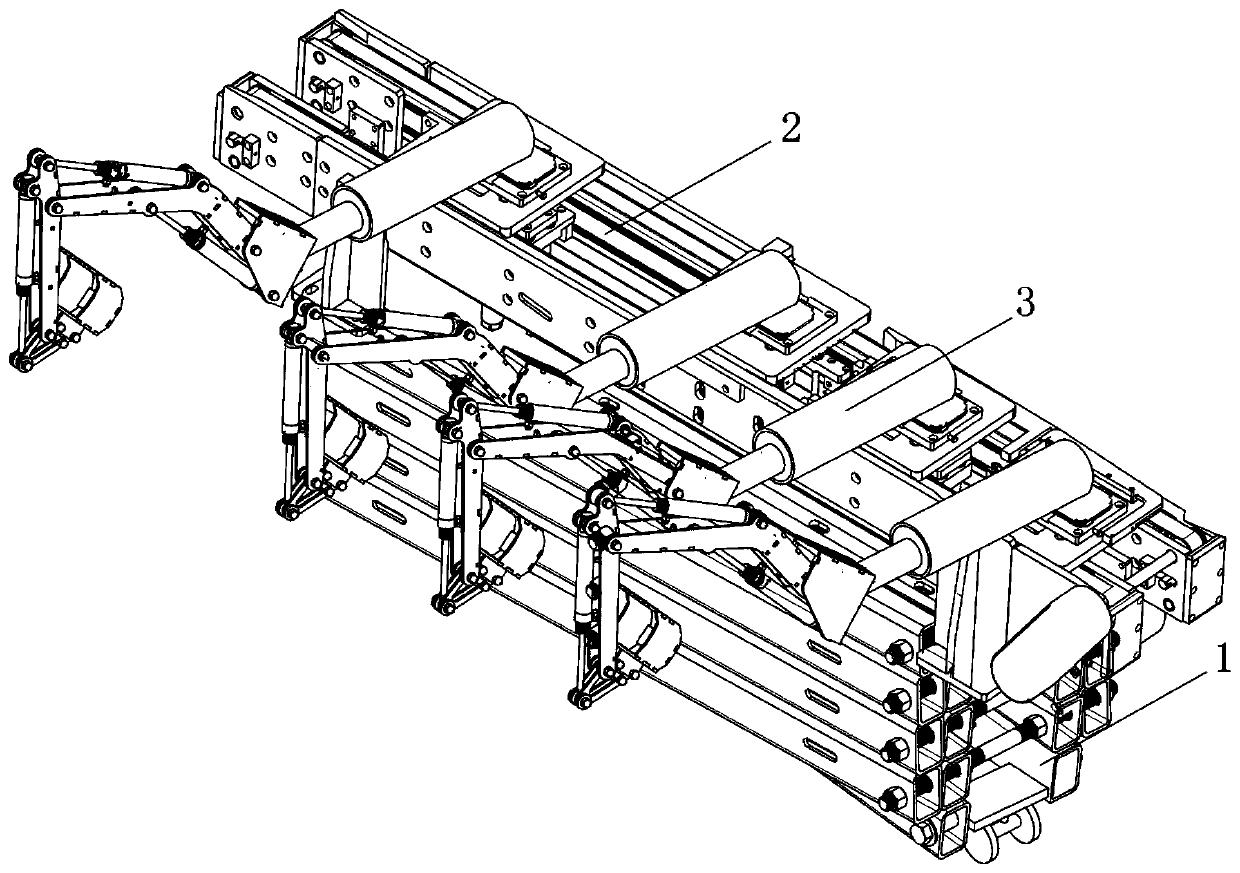

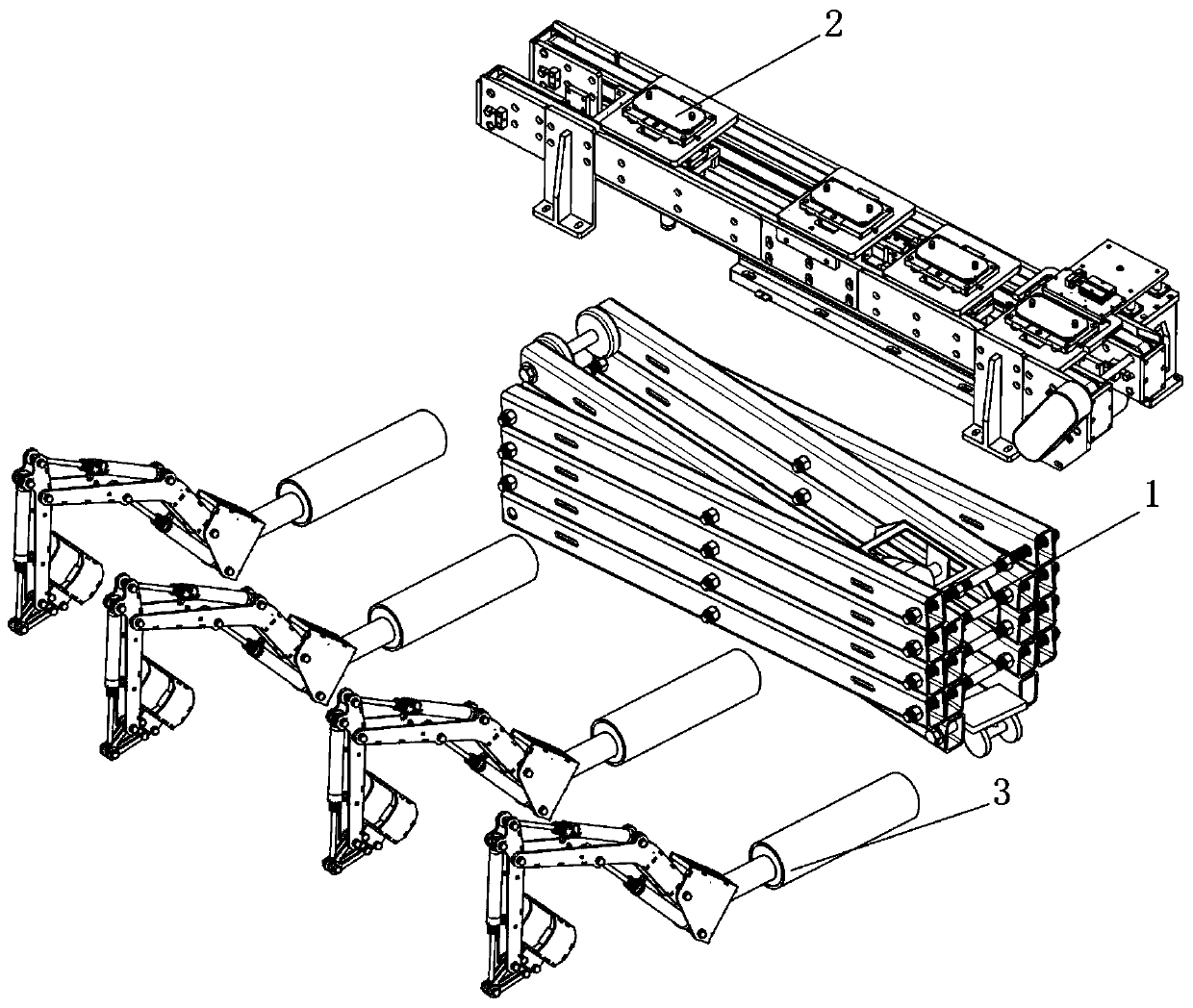

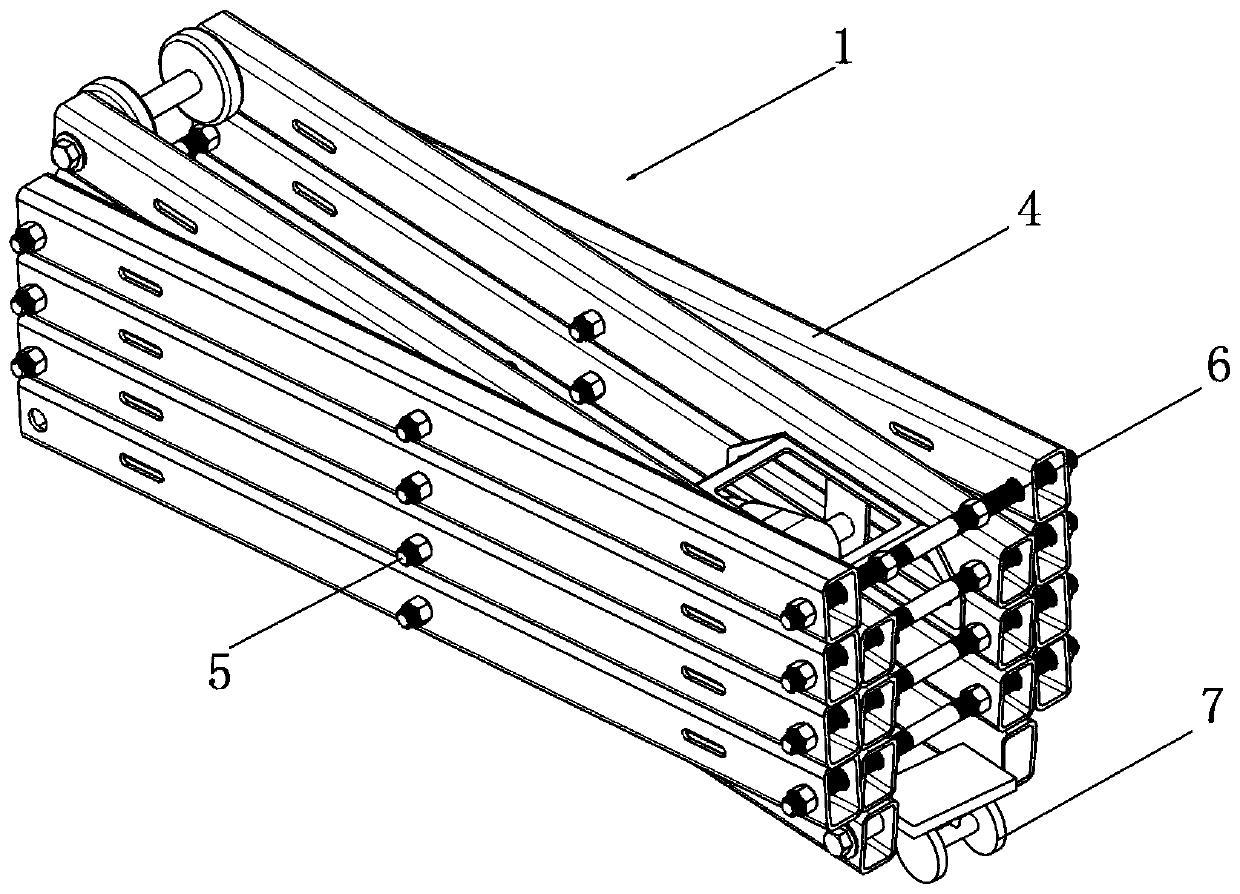

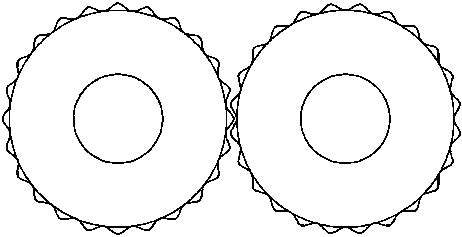

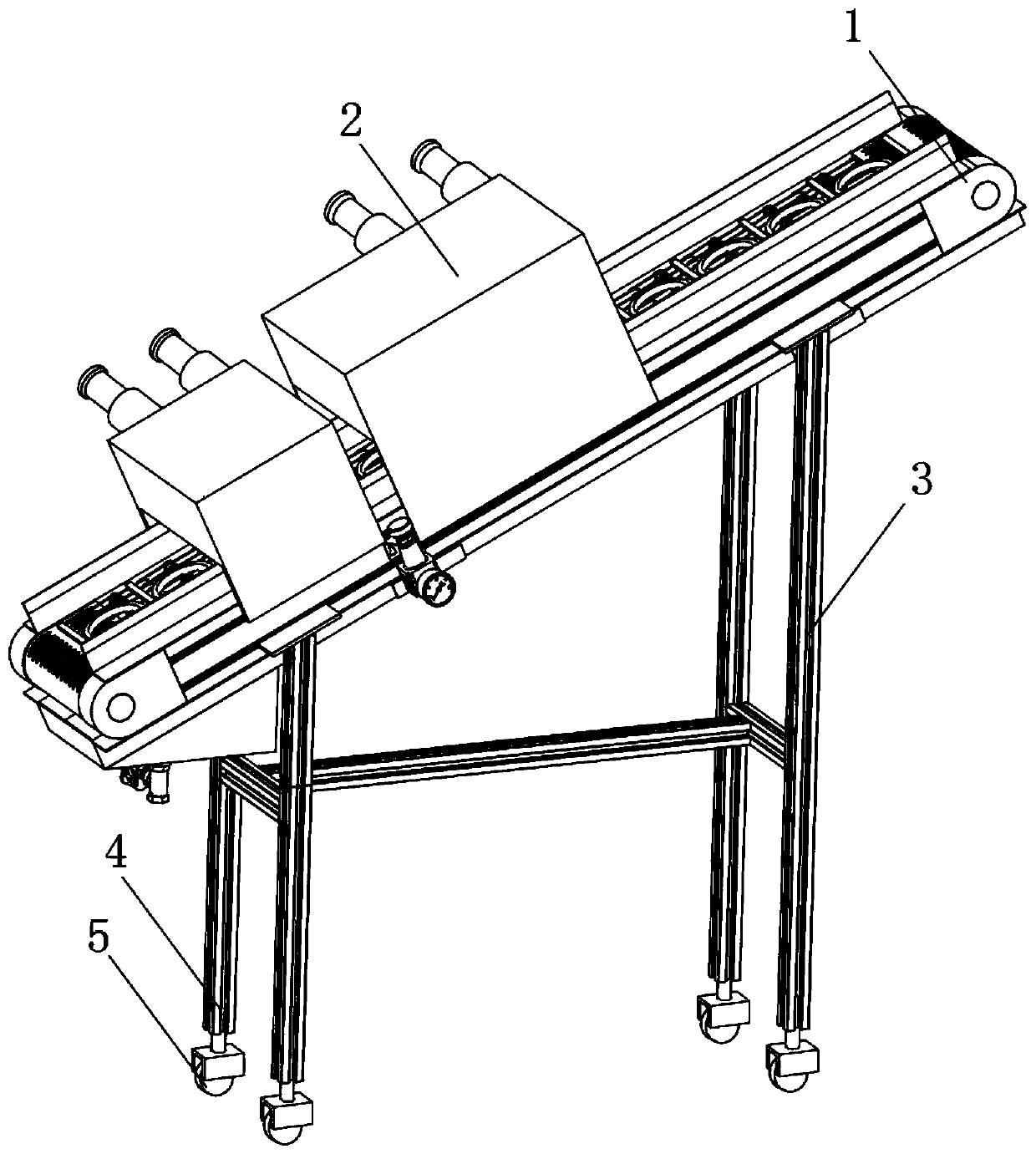

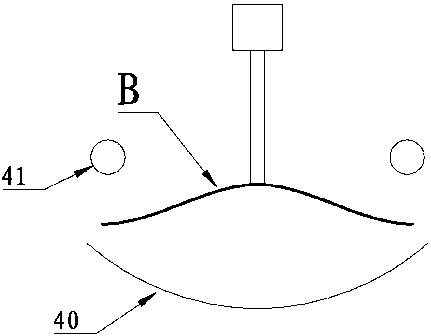

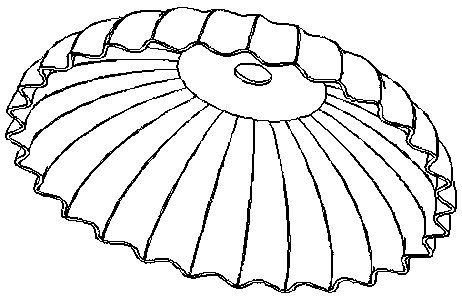

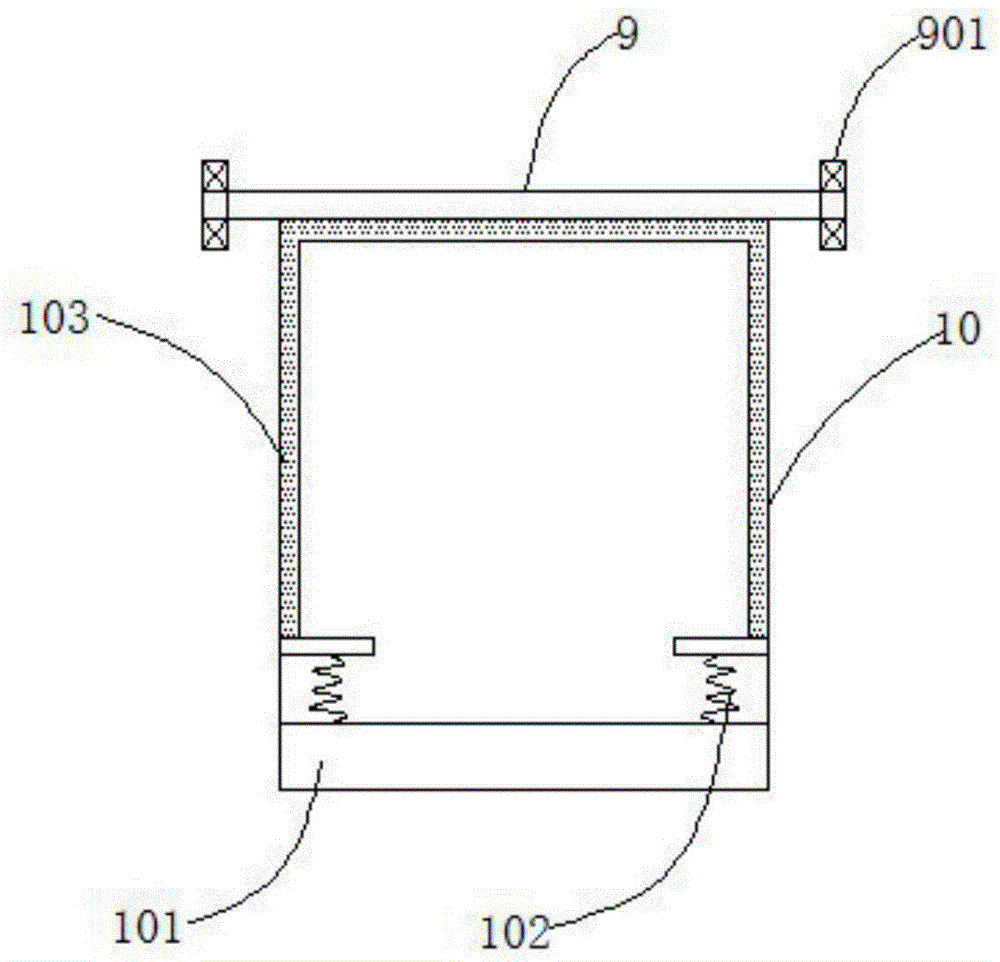

Feeding and filling device for garbage incineration

InactiveCN110631028AAvoid spillingHigh degree of automationIncinerator apparatusHydraulic cylinderLitter

The invention discloses a feeding and filling device for garbage incineration. The feeding and filling device for garbage incineration comprises a lifting and supporting platform, top trays and four swing grabbing disks. The four swing grabbing disks are arranged over the corresponding top trays. The two sides of the lifting and supporting platform are provided with a plurality of side lifting frames in parallel. First insertion shafts penetrate through the middle portions of the side lifting frames on the two sides of the lifting and supporting platform. The feeding and filling device for garbage incineration has the beneficial effects that third hydraulic cylinders on the swing grabbing disks drive filling hoppers through third hydraulic rods to turn downwards to dig waste. Moreover, fourth hydraulic cylinders drive V-shaped seats and the filling hoppers through fourth hydraulic rods to turn upwards to prevent the waste from being scattered from the filling hoppers. Afterwards, guidewheels drive the feeding and filling device to move to a filling port of a garbage incineration furnace. The filling hoppers are driven through the fourth hydraulic cylinders to turn over to topple the waste into the garbage incineration furnace to be incinerated and cleaned. The feeding and filling device for garbage incineration is high in operation automation degree and capable of saving timeand labor in the using process.

Owner:ANHUI SHENGYUN ENVIRONMENT PROTECTION GRP CO LTD

Pulse aeration-type device for treating wastewater and garbage and with purification of tail gas

InactiveCN107651787AFlexibleEfficient dryingWater/sewage treatment by centrifugal separationSludge treatment by de-watering/drying/thickeningSlagEngineering

The invention discloses a pulse aeration-type device for treating wastewater and garbage and with purification of tail gas. The pulse aeration-type device for treating the wastewater and garbage and with purification of the tail gas comprises a big sewage tank, an incinerator, a counter-current drying tower, a horizontal spiral centrifuge and a sine roller, wherein an urban wastewater pipe is connected with a wastewater buffer tank which is internally provided with a grille slag fetching machine, and the grille slag fetching machine is connected with a centrifugal dehydrator through conveying;the wastewater buffer tank is connected with the inlet of the big sewage tank through the wastewater pipe and a sewage pump, and the big sewage tank is provided with stirring devices and protruding-rib ultrasound excitation stirrers internally and appropriately; a cone base is connected with a Roots blower, a bottom valve and a mud pump through a pipeline, and the mud pump is connected to the horizontal spiral centrifuge, a spiral airlock feeder and the counter-current drying tower sequentially; the lower left part of the drying tower is provided with a cosine plastic-tray pulse aeration apparatus, and the upper right part of the incinerator is connected with a boiler flue gas pipe and a flue gas incinerating treatment device sequentially. According to the pulse aeration-type device for treating the wastewater and garbage and with purification of the tail gas, the sine roller, the cosine plastic-tray pulse aeration apparatus and the protruding-rib ultrasound excitation stirrers all have distinctive characteristics, and can complete treatment of the urban wastewater and garbage reliably and collaboratively.

Owner:JISHOU UNIVERSITY

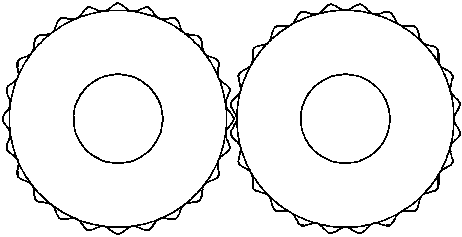

Ultrasonic municipal wastewater and garbage disposal device with tail heat utilization and slag dredger

InactiveCN107758951AContinuous monitoring of production dataRealize automated continuous processingMultistage water/sewage treatmentIncinerator apparatusSlagHeat pump

The invention discloses an ultrasonic urban wastewater garbage treatment device with tail heat utilization and slag removal machine, which comprises a large sewage tank, an incinerator, a countercurrent drying tower, a horizontal screw centrifuge, counter-rotating rollers, a heat pump host and a computer The control system, the urban waste water pipe is connected to the waste water buffer tank, the buffer tank is equipped with a grid slag remover, the grid slag remover is connected to the conveyor, the waste water buffer tank is connected to the inlet of the large sewage tank through the sewage pipe and the sewage pump, and the large sewage tank Appropriate amount of stirring device and sinusoidal ultrasonic excitation stirrer are installed, the bottom of the cone is connected with Roots blower, bottom valve and mud pump through pipelines, and the mud pump is connected with horizontal screw centrifuge, screw closed air feeder and countercurrent drying tower in turn, and the tail of the drying tower is The trachea is connected to the heat pump system, and the lower left part is equipped with a cosine rubber disc pulse explosion device, and the processing device is controlled by a computer. Treatment of waste water and garbage.

Owner:JISHOU UNIVERSITY

Ultrasonic-type municipal wastewater and garbage disposal device with tail heat utilizing function and pelletizer

InactiveCN107842859AContinuous monitoring of production dataRealize automated continuous processingIncinerator apparatusComputer control systemBuffer tank

The invention discloses an ultrasonic-type municipal wastewater and garbage disposal device with a tail heat utilizing function and a pelletizer. The ultrasonic-type municipal wastewater and garbage disposal device comprises a wastewater large tank, an incinerator, a countercurrent drying tower, counter rotating rollers, a heat pump main unit and a computer control system. A municipal wastewater pipe is connected with a wastewater buffer tank which is internally provided with a grille residue salvaging machine and connected with an inlet of the wastewater large tank through a pipeline and a pump. Stirring devices and sine ultrasonic shock excitation stirrers are appropriately arranged in the wastewater large tank, and the tapered bottom is connected with a roots blower, a bottom valve anda slurry pump through pipelines. The slurry pump is sequentially connected with a horizontal-type spiral centrifugal machine, a spiral air closing feeding machine and the countercurrent drying tower.An exhaust pipe of the drying tower is connected with a heat pump system, and the lower left portion of the heat pump system is provided with cosine plastic plate pulse gas explosion devices. An ash outlet of the incinerator is sequentially connected with the buffer tank and the pelletizer, and the disposal device is controlled by a computer. The cosine plastic plate pulse gas explosion devices and the sine ultrasonic shock excitation stirrers have the distinct characteristics and can reliably and synergistically complete municipal wastewater and garbage disposal.

Owner:JISHOU UNIVERSITY

Solid garbage incineration device with adjustable oxygen concentration

PendingCN113108286AImprove incineration efficiencyEfficient incinerationIncinerator apparatusPistonMechanical engineering

The invention discloses a solid garbage incineration device with an adjustable oxygen concentration, comprising a fixed frame and characterized in that purification mechanisms are arranged on the two sides of the top end of the fixed frame. An incineration mechanism is welded to the lower portions of the purification mechanisms; a combustion-supporting mechanism is arranged under the top end of the fixed frame; the bottom end of the combustion-supporting mechanism is in through connection with an adjusting mechanism; the lower end of the adjusting mechanism is in through connection with a scattering mechanism; the two ends of the scattering mechanism are in through connection with a distinguishing mechanism; the top end of the distinguishing mechanism is in through connection with a limiting mechanism; a discharge port is formed in the scattering mechanism; a torsional spring is sleeved with the discharge port; the two ends of the torsional spring are connected with movable blocks through bearings; cylinders are arranged at the upper and lower ends of the discharge port; pistons are slidably sleeved into the cylinders; and a connecting rod is welded to one end of each piston. The device has the characteristics of efficient incineration, overheat protection and efficiency improvement through classified incineration.

Owner:邱国伦

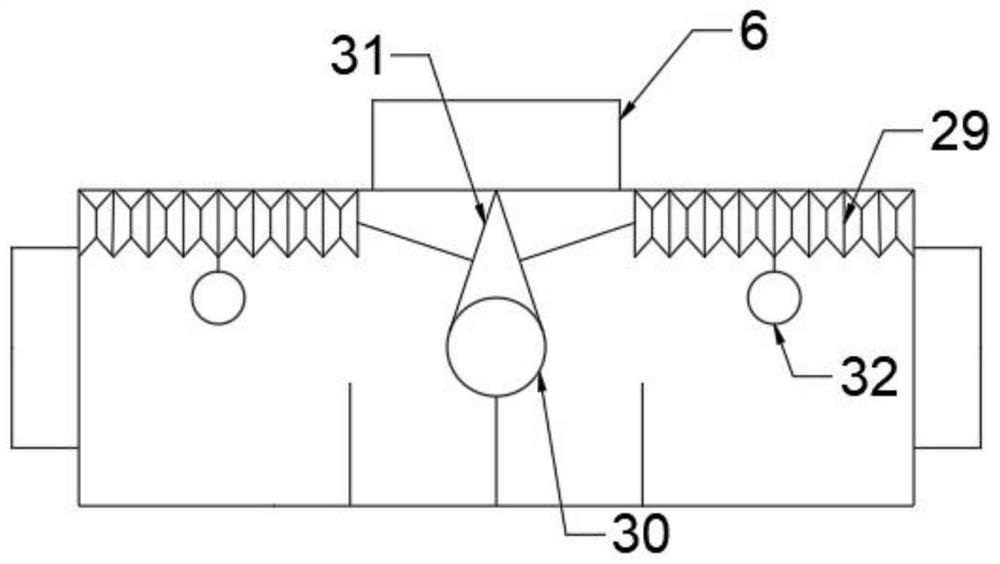

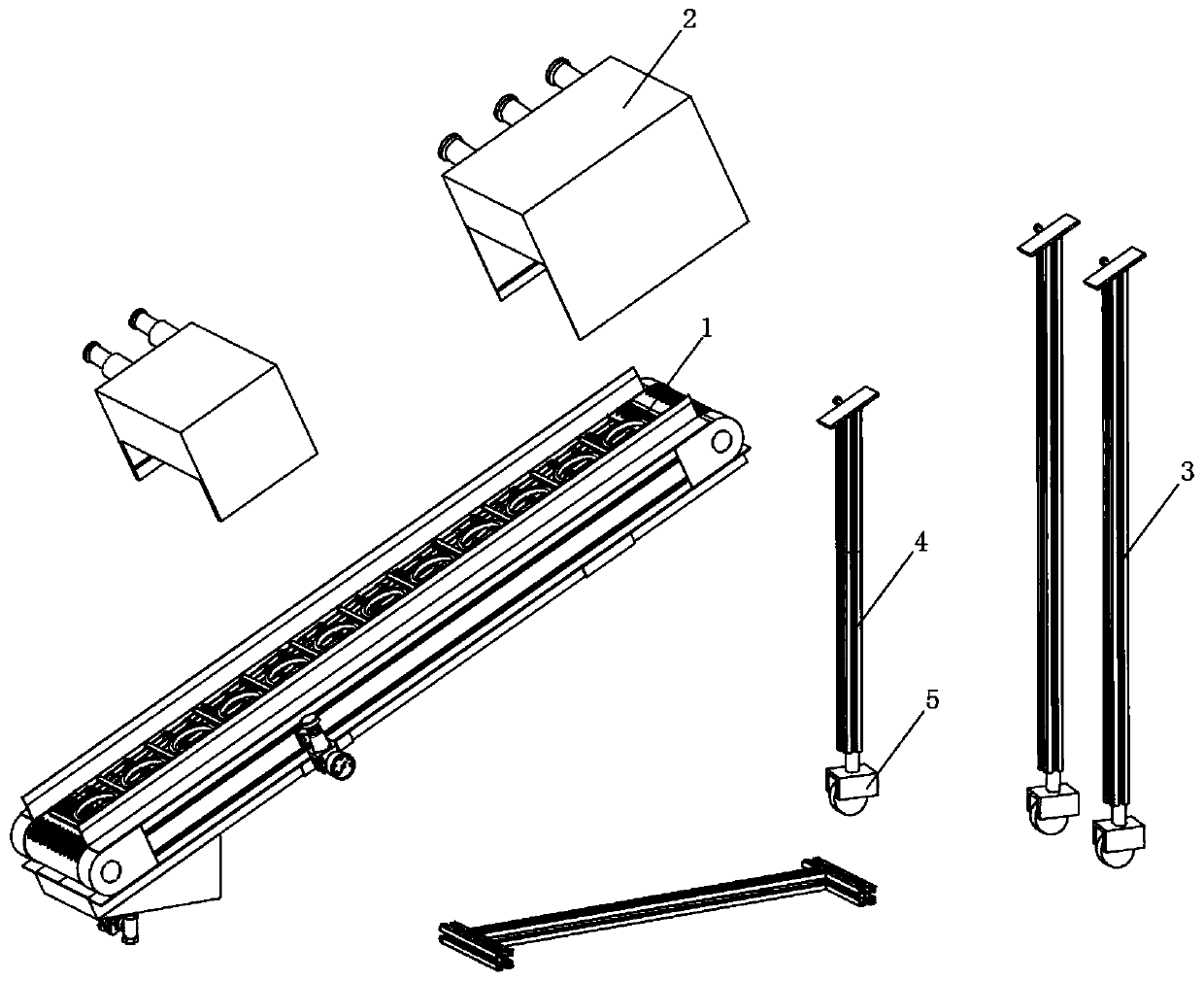

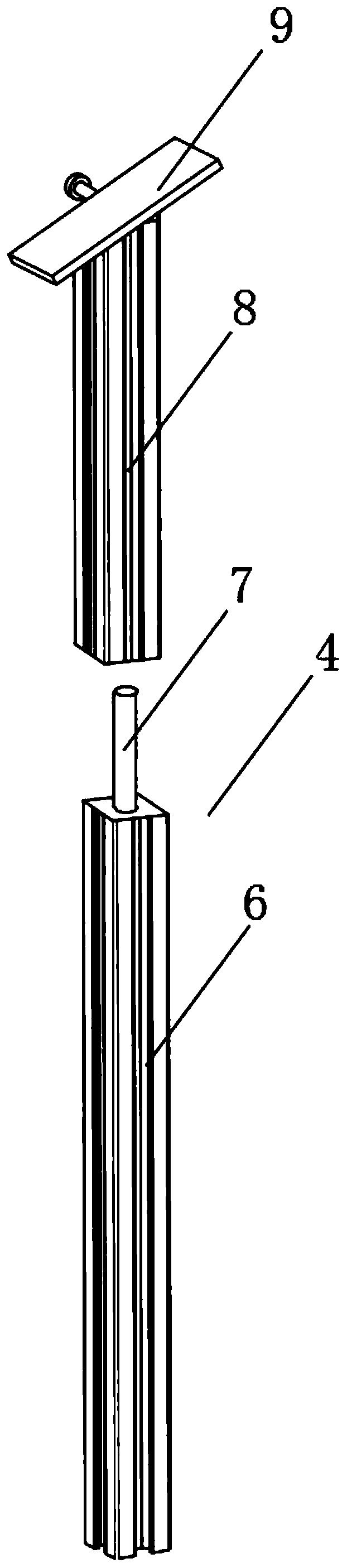

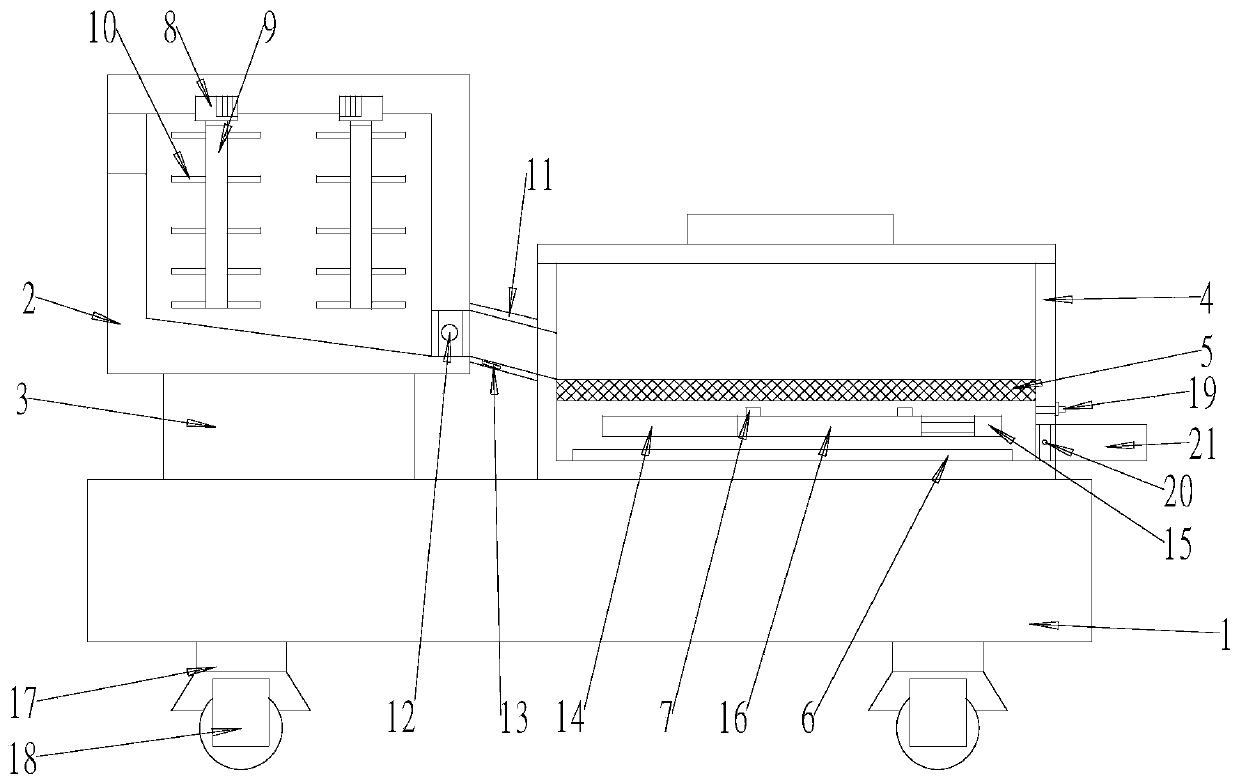

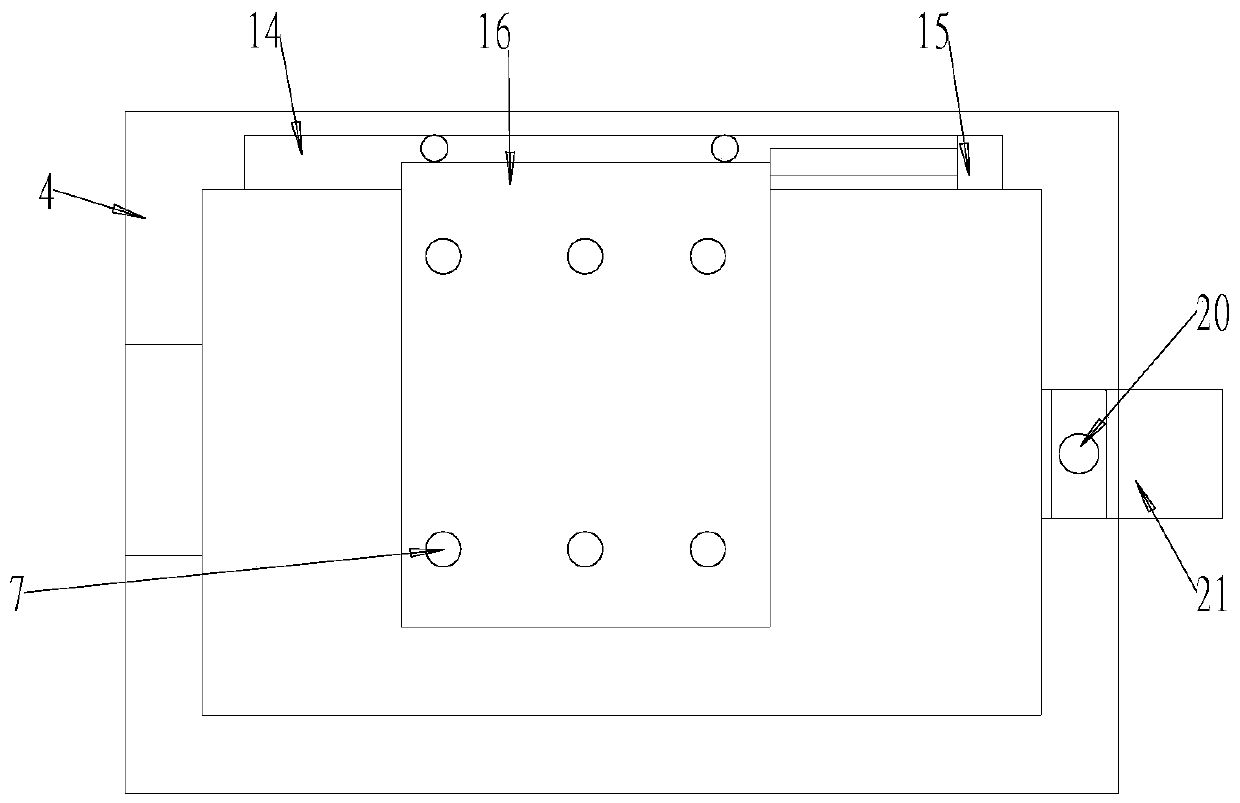

Wind strengthening device for garbage incineration

InactiveCN110645590AIncinerate completelyEfficient incinerationBlast-producing apparatusIncinerator apparatusProcess engineeringHydraulic ram

The invention discloses a wind strengthening device for garbage incineration. The device comprises a conveying base, a sliding table, a first supporting table and a second supporting table, wherein the sliding table sleeves above the conveying base, the first supporting table is arranged at one end below the conveying base, the second supporting table is arranged at the other end below the conveying base, and a first hydraulic oil cylinder is vertically arranged below the second supporting table. The device has the beneficial effects that the first hydraulic oil cylinder on the second supporting table drives the sliding table to move up and down to adjust the height through a first telescopic rod, on the one hand, it is guaranteed that the position where a blowing platform on the device performs air blowing on garbage waste in an incinerator so as to strengthen combustion is more accurate and suitable, and on the other hand, when the device performs air blowing strengthening on the garbage in the incinerator, it is guaranteed that the device can flexibly adjust movable type to work, the work coverage of the device is wider and more comprehensive, the garbage is burned more completely and efficiently, and the device can adapt to garbage incinerators with different heights and shapes for air blowing and strengthening combustion.

Owner:ANHUI SHENGYUN ENVIRONMENT PROTECTION GRP CO LTD

Board waste harmless treatment system for printing

InactiveCN110779021AEasy to operateLow costIndirect carbon-dioxide mitigationIncinerator apparatusEnvironmental engineeringWaste material

The invention discloses a board waste harmless treatment system for printing. The system involves an operating table, and a crushing mechanism and an incinerating mechanism which are arranged on the operating table; the crushing mechanism comprises a crushing chamber, a bottom frame, a crushing part and a conveying part; the bottom frame is arranged at the left end of the upper surface of the operating table; the crushing chamber is arranged on the upper surface of the bottom frame; the crushing part is arranged inside the crushing chamber; the conveying part is arranged at the lower end of the side surface of the crushing chamber; and the incinerating mechanism is used for incinerating crushed plates.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

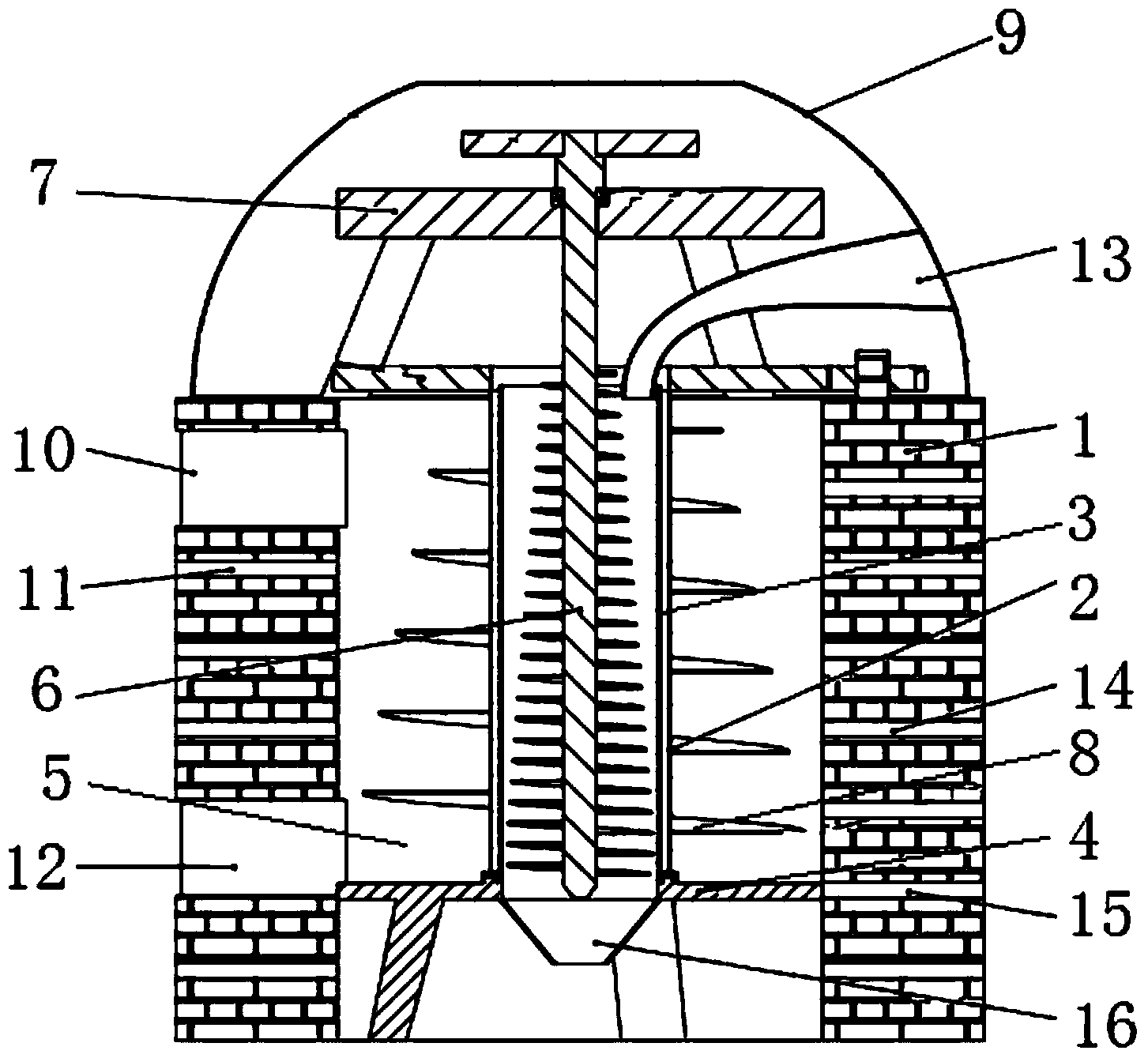

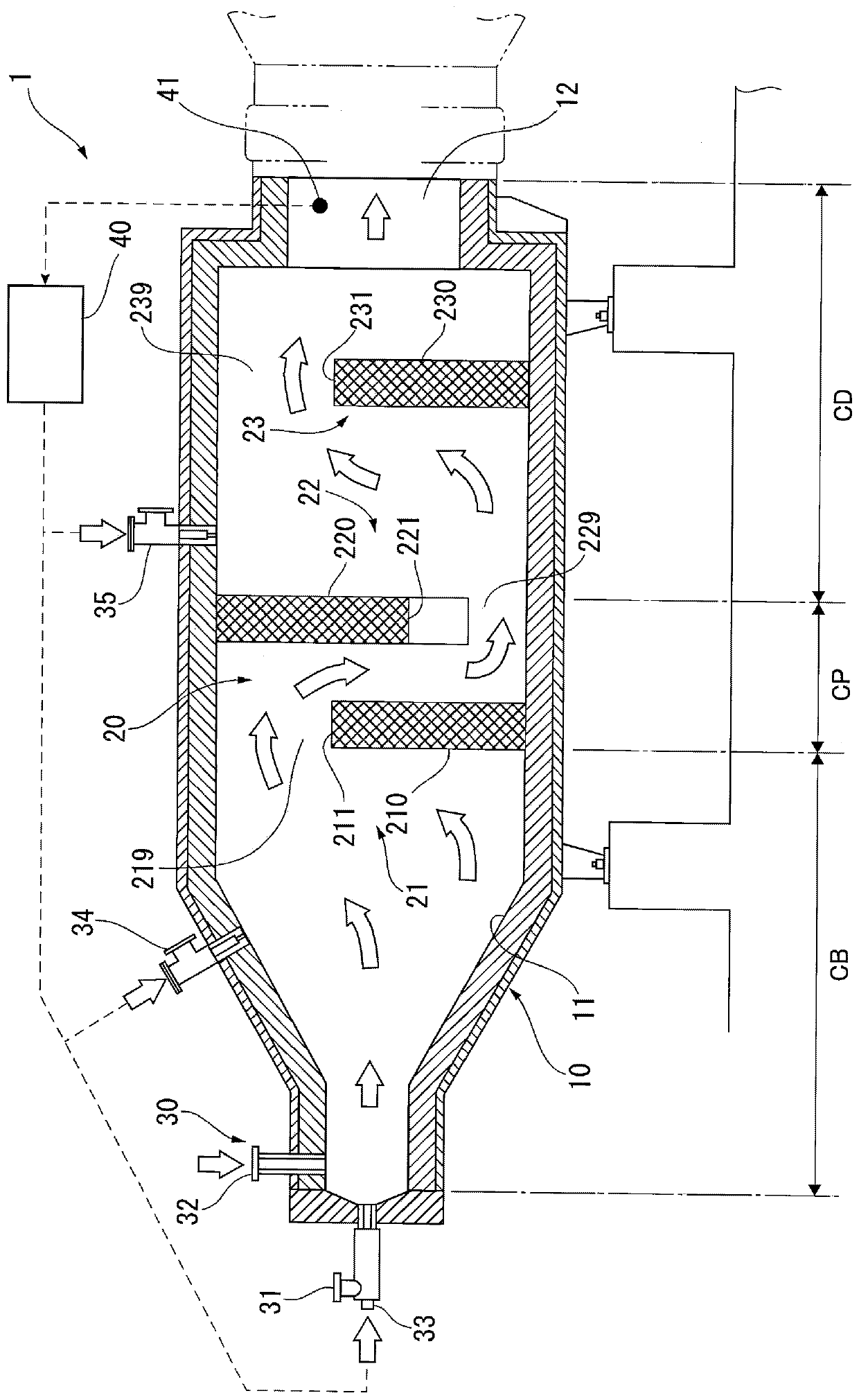

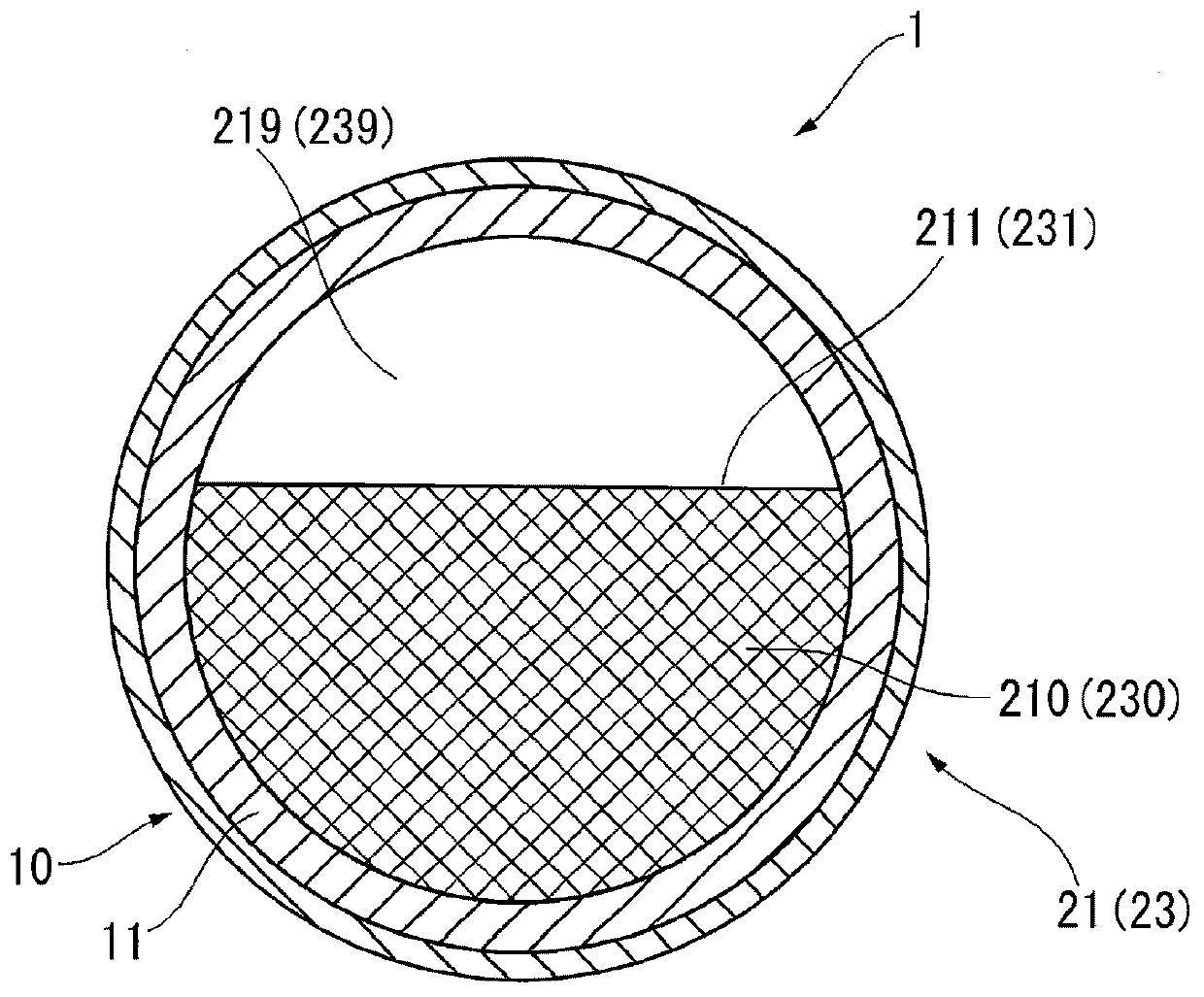

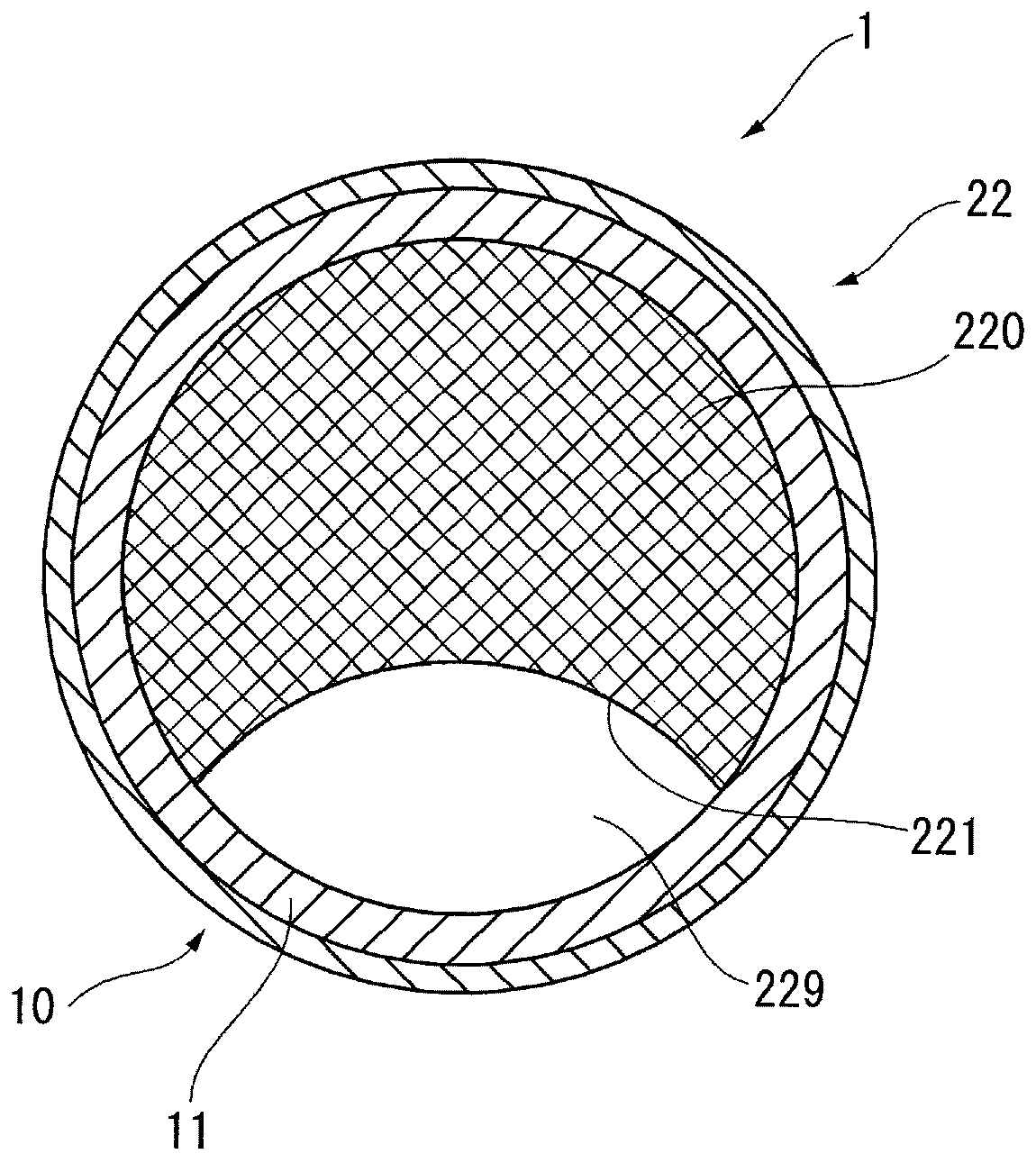

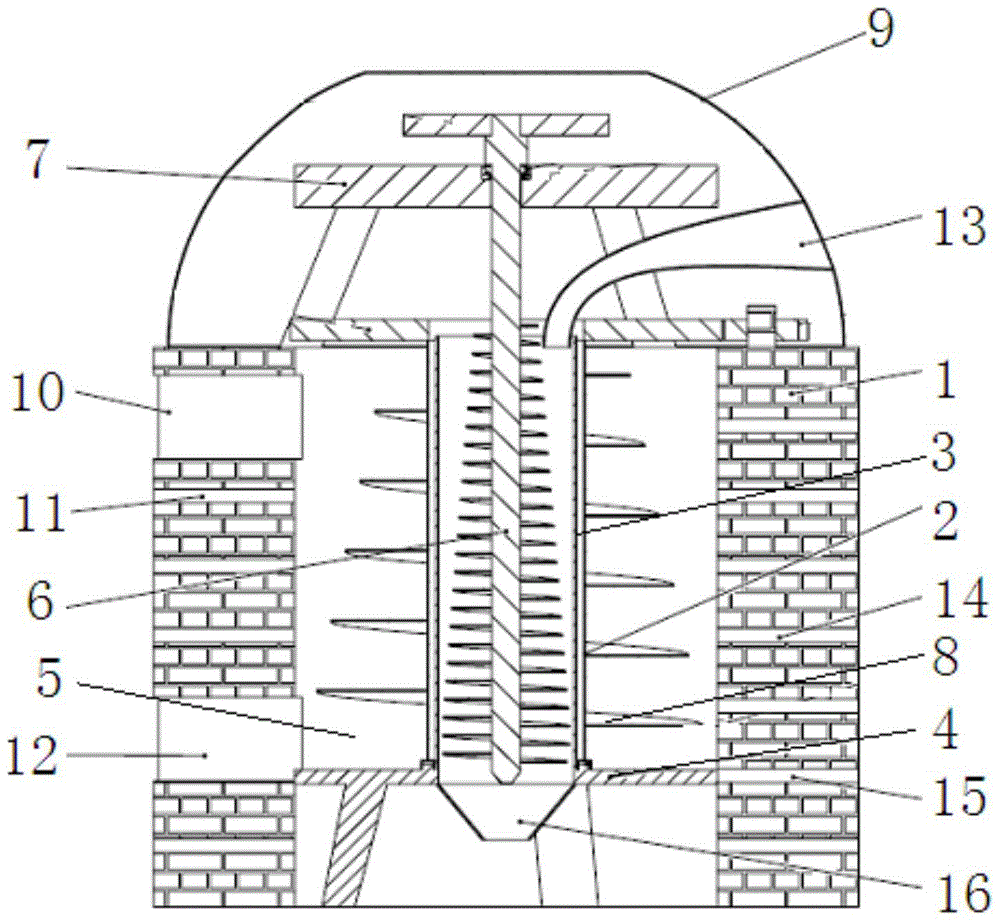

Nitrogen-containing waste liquid combustion furnace and its denitrification method

ActiveCN108167843BPrevent incomplete denitrificationPrevent outflowIncinerator apparatusCombustion chamberBrick

The utility model relates to a nitrogenous waste liquid burning furnace and a denitration method. The nitrogenous waste liquid burning furnace is provided with a horizontal type furnace body (10), ofwhich the inner surface made of bricks (11) and the extending direction is horizontal, and a separation structure (20) which divides the interior of the furnace body (10) into a combustion chamber (CB) on the upstream side and a denitration chamber (Cd) at the downstream side, wherein the separation structure (20) comprises a plurality of baffles (21, 22 ) which are arranged along the extending direction and having opening parts (219,229) formed in the part of the edges, and the opening parts (219,229) of adjacent baffles (21, 22 ) are formed on the opposite sides.

Owner:NIPPON STEEL & SUMIKIN ENG CO LTD +1

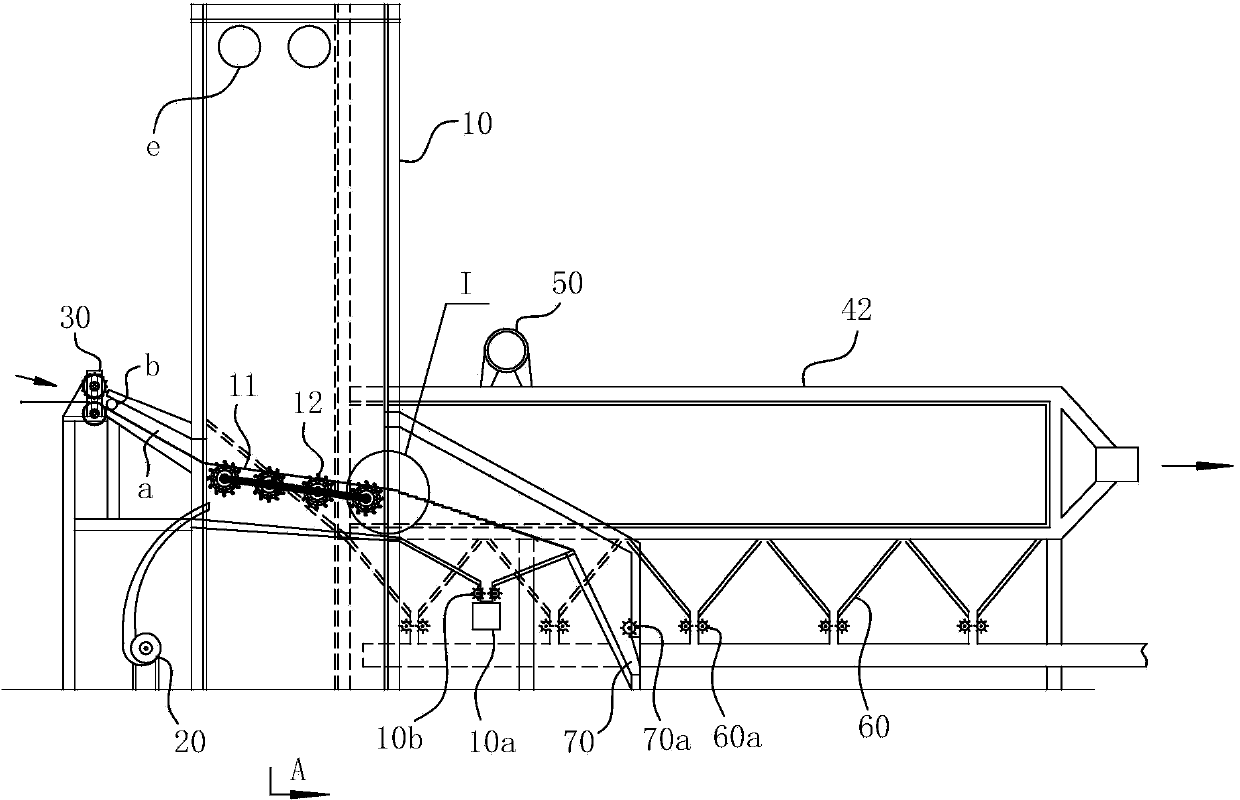

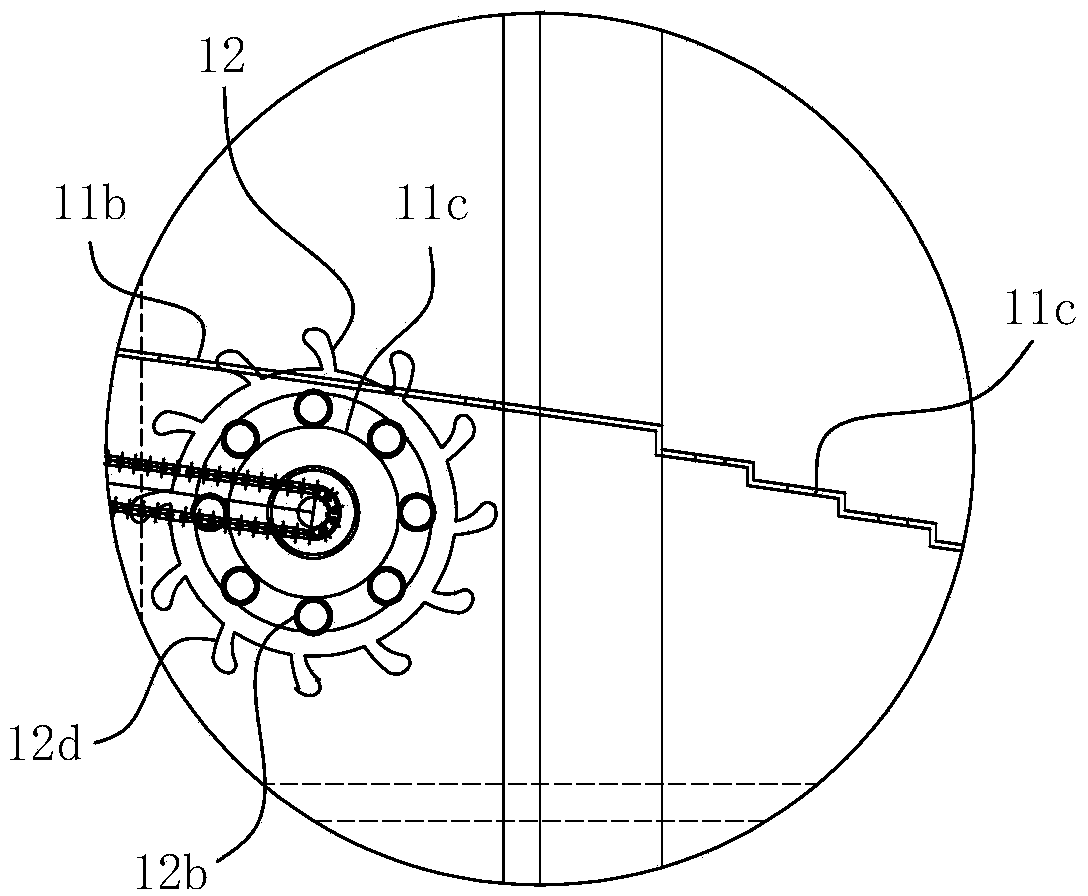

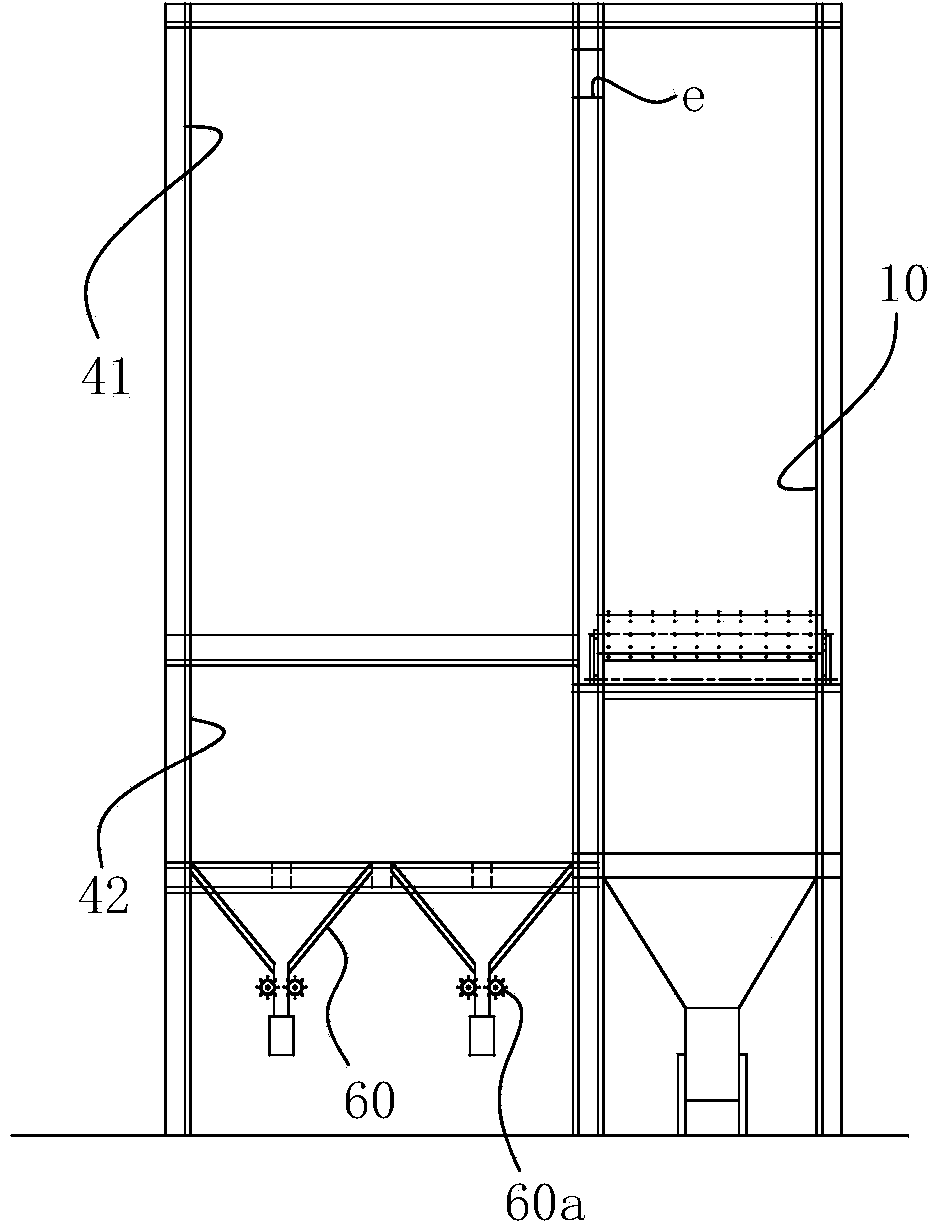

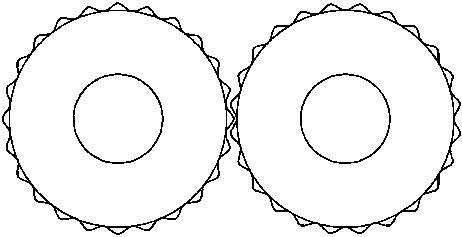

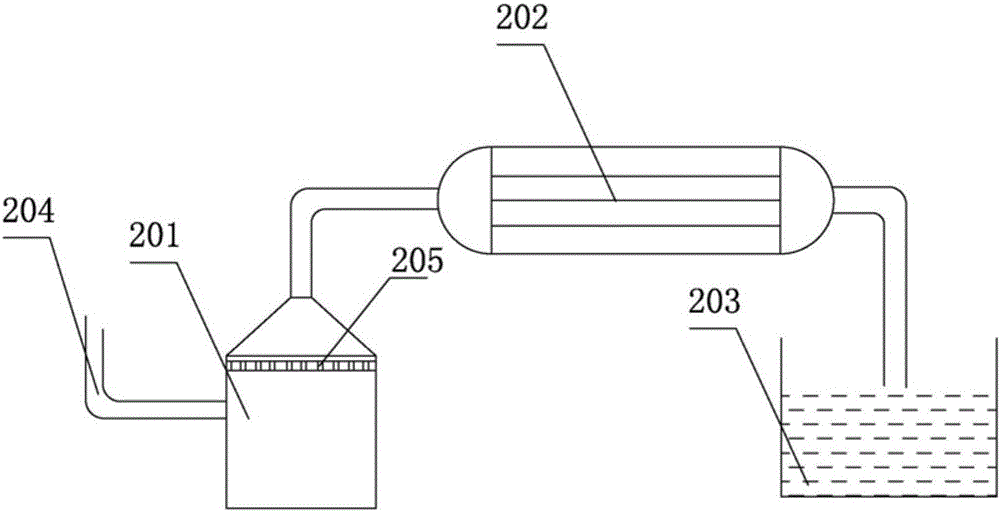

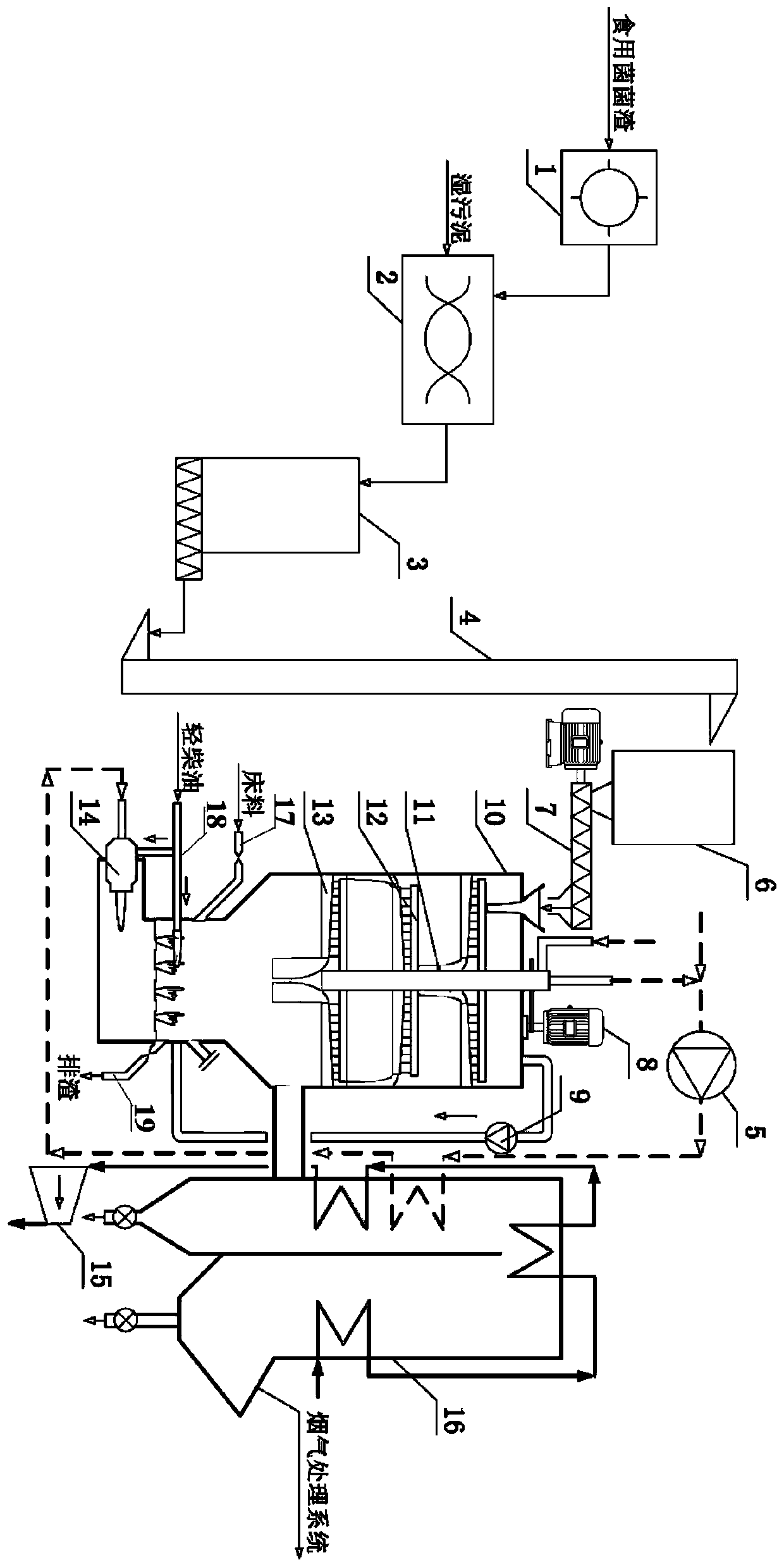

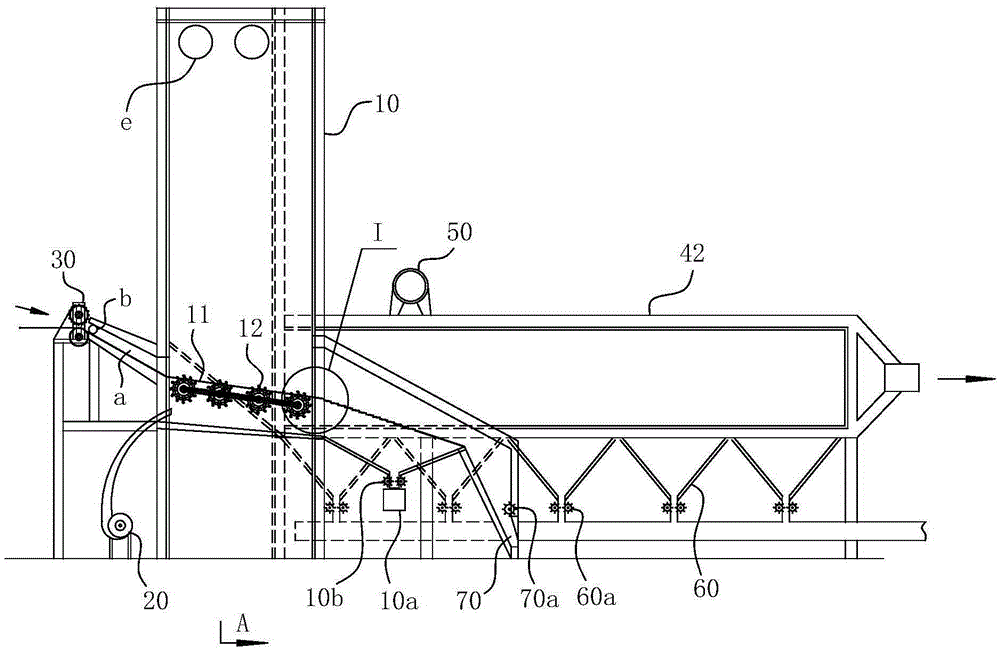

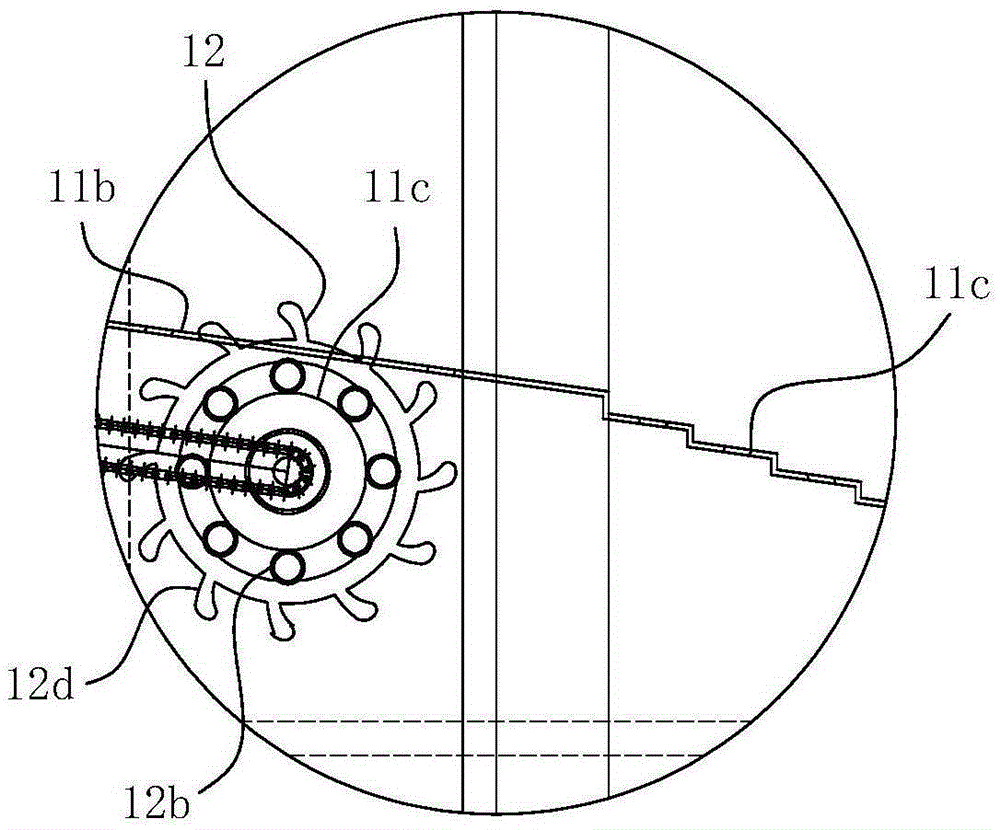

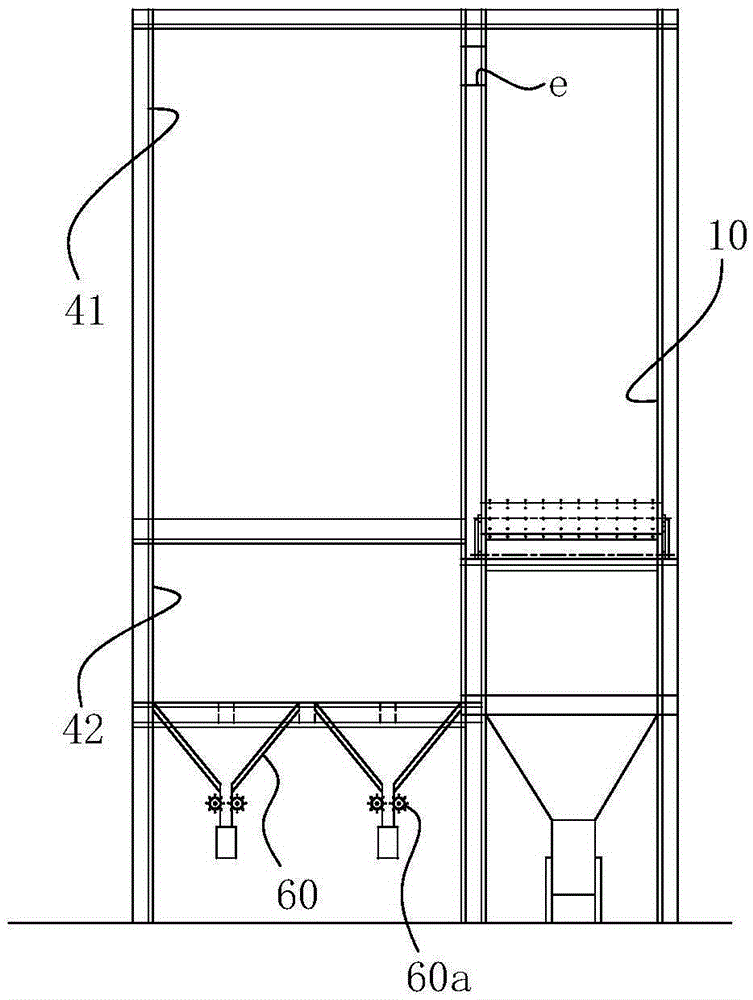

A low calorific value sludge and edible fungus residue co-incineration system and process

ActiveCN107420914BEfficient incinerationAchieving self-sustaining incinerationIncinerator apparatusCombined combustion mitigationSludgeCogeneration

The invention discloses a collaborative incineration system and technology for sludge with a low heat value and edible fungus dregs. The incineration system sequentially comprises a feeding treating system, a storing and conveying system, an incineration and waste heat boiler system and a turbine power generation system; the incineration and waste heat boiler system comprises an incinerator and a waste heat boiler, wherein the incinerator is composed of multiple layers of grate furnaces on the upper portion and a fluidized bed on the lower portion; and the turbine power generation system comprises a back pressure type turbine and a steam pipeline, wherein the steam pipeline is heated by the waste heat boiler. The collaborative incineration system and technology for the sludge with the low heat value and the edible fungus dregs have the following advantages that the incinerator combines the advantages of multiple layers of the grate furnaces and the fluidized bed, and therefore the heat utilization efficiency is greatly improved; the wet sludge with the low heat value is collaboratively treated by means of the waste edible fungus dregs with a high heat value, and therefore the purpose of treating waste with another waste is achieved; combined heat and power generation is conducted through a back pressure type turbine unit, and therefore heat is efficiently utilized; the whole system does not need additional fuel, and therefore self-maintaining incineration and external heat supply are achieved.

Owner:张国闽

Ultrasonic municipal wastewater and garbage treatment device with tail gas purification function

InactiveCN107626720AEfficient dryingEfficient incinerationSolid waste disposalMultistage water/sewage treatmentGratingWastewater

The invention discloses an ultrasonic municipal wastewater and garbage treatment device with a tail gas purification function. The ultrasonic municipal wastewater and garbage treatment device comprises a sewage large groove, an incinerator, a counter-current drying tower, a horizontal spiral centrifugal machine and a contra-rotation roller. A municipal wastewater pipe is connected with a wastewater buffer groove. A grating submerged chain conveyor is arranged in a buffer groove and is connected with a centrifugal dehydrator through conveying. The wastewater buffer groove is connected with an inlet of the sewage large groove through a pipeline and a sewage pump. A stirring device and a sine ultrasonic shock excitation stirrer are properly arranged in the sewage large groove. A cone bottom is connected with a Roots blower, a bottom valve and a slurry pump through a pipeline. The slurry pump is sequentially connected with the horizontal spiral centrifugal machine, a spiral closed air feeding machine and the counter-current drying tower. The upper right portion of the drying tower is provided with a tail gas pipe, and the lower left portion of the drying tower is provided with a cosineglue disc pulse gas explosion device. The upper right portion of the incinerator is sequentially connected with a boiler tail gas pipe and an incineration tail gas treatment device. According to theultrasonic municipal wastewater and garbage treatment device, the cosine glue disc pulse gas explosion device and the sine ultrasonic shock excitation stirrer both have distinct characteristics, and treatment of municipal wastewater and garbage can be achieved reliably and cooperatively.

Owner:李军飞

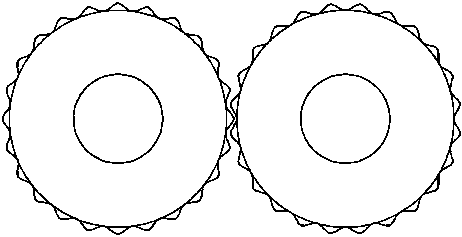

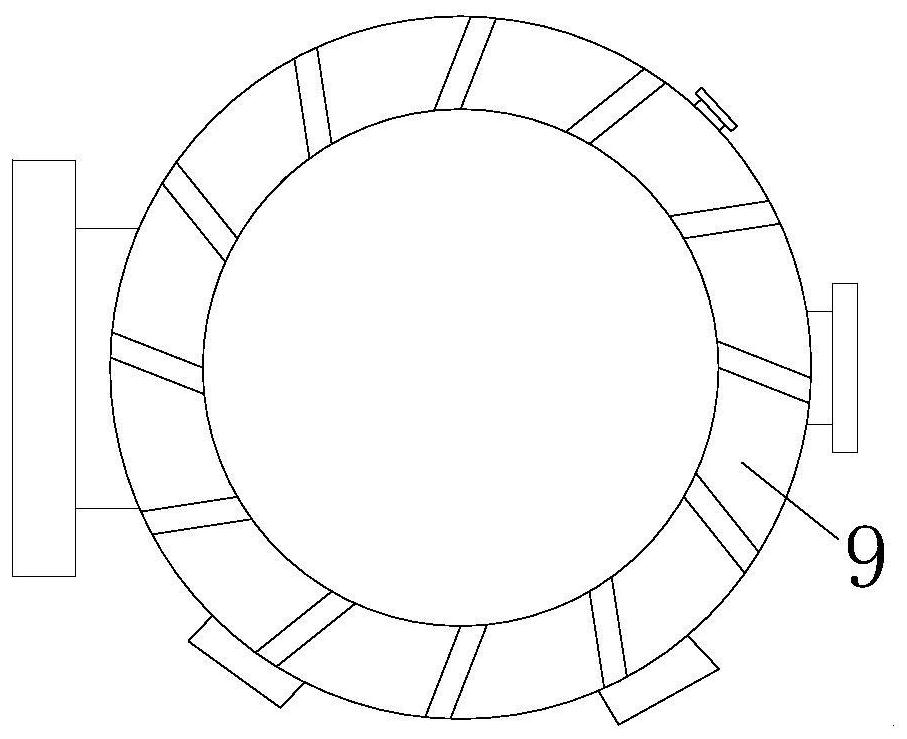

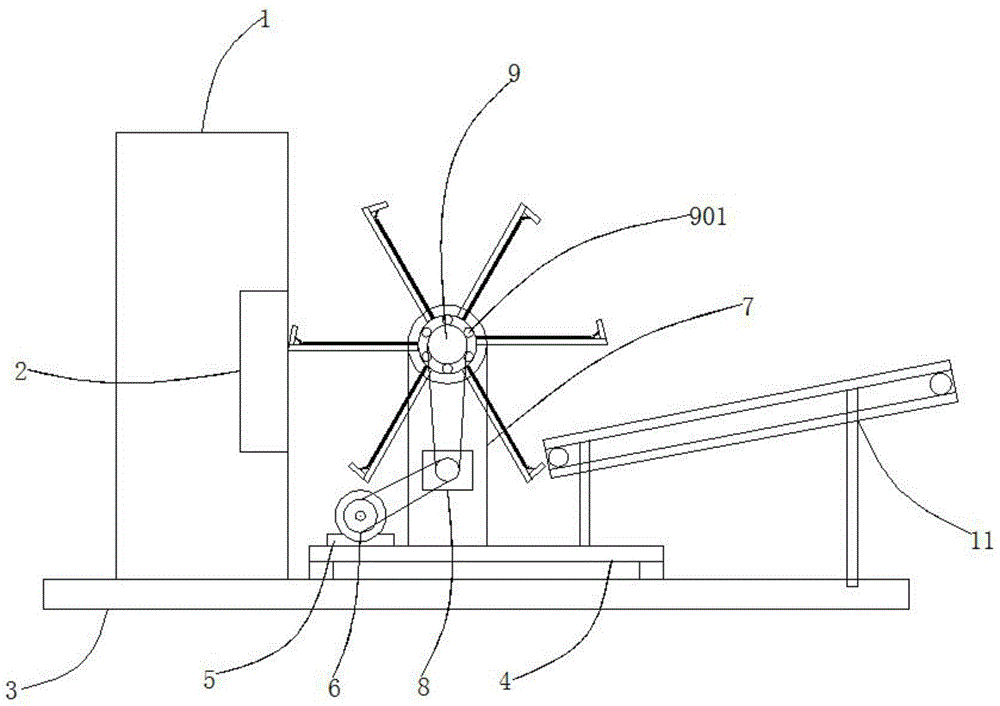

Rotary continuous feeding device

The invention discloses a rotary continuous feeding device. The rotary continuous feeding device comprises a furnace stack, a feeding opening and a working platform, and is characterized by comprising a rack, a motor, a driving wheel, a support frame, a reducer, a rotating shaft, partitions and a conveyor, wherein the rack is located at the top of the working platform; the motor is located on the right side of the top of the rack, and the motor and the rack are in threaded connection; the driving wheel penetrates the rotating shaft of the motor, and the driving wheel and the rotating shaft of the motor are in rotational connection; the support frame is located in the center of the top of the rack, and the support frame and the rack are in threaded connection; the reducer is located on the right side of the support frame, and the reducer and the support frame are in threaded connection; the rotating shaft is located in the center of the support frame, and the rotating shaft and the support frame are in rotational connection; the partitions are located on the side wall of the rotating shaft and are a plurality of rectangular iron plates, and the partitions and the rotating shaft are in welded connection; and the conveyor is located on the front side of the top of the working platform, and the conveyor and the working platform are in threaded connection.

Owner:池州中宏运环保设备有限公司

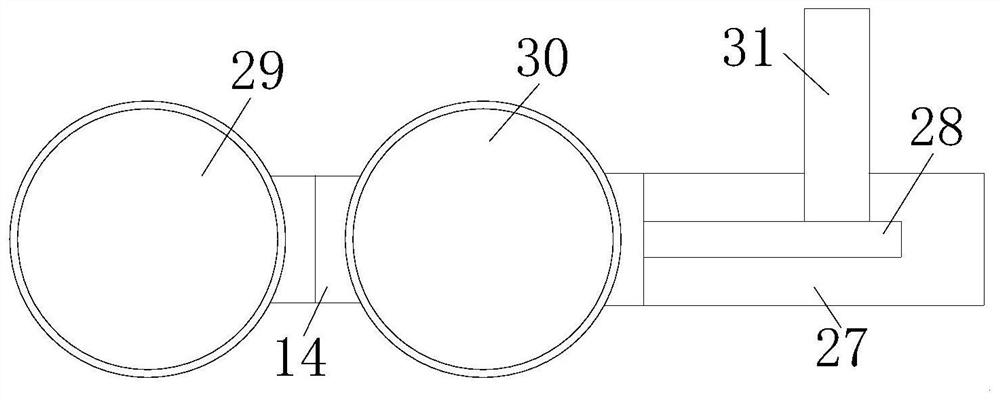

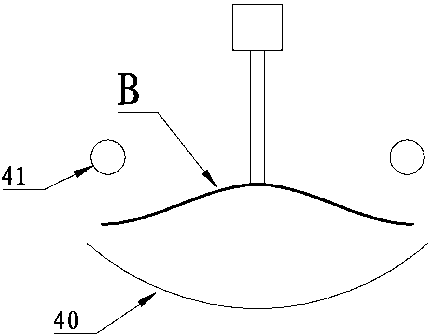

Sine roller type municipal wastewater and garbage disposal device with tail heat utilization and centrifugal machine

InactiveCN107758949AEfficient dryingEfficient incinerationSludge treatment by de-watering/drying/thickeningSolid waste disposalSlagBuffer tank

The invention discloses a sinusoidal roller type municipal wastewater treatment device with tail heat utilization and a centrifuge, which includes a large sewage tank, an incinerator, a countercurrent drying tower, a horizontal spiral centrifuge, a sinusoidal roller and a heat pump host, and the city The waste water pipe is connected to the waste water buffer tank, and the buffer tank is equipped with a grille slag extractor, which is connected to the centrifugal dehydrator through conveying, and the waste water buffer tank is connected to the inlet of the large sewage tank through the sewage pipe and the sewage pump. Set up a stirring device and a sinusoidal ultrasonic excitation agitator. The bottom of the cone is connected to the Roots blower, the bottom valve and the mud pump through the pipeline. Connected to the heat pump system, the sinusoidal roller and the sinusoidal ultrasonic excitation agitator of the present invention have distinctive features, and can reliably and cooperatively complete the treatment of urban wastewater and garbage.

Owner:梁金秀

A fixed grate incinerator

InactiveCN103994441BEnsure high constant temperature incineration demandEnsure high constant temperature incinerationIncinerator apparatusCombustion chamberMoisture

The invention belongs to the field of waste incineration devices and particularly relates to an incinerator with a fixed fire grate. The incinerator with the fixed fire grate is used for incinerating biomass materials such as straws and at least comprises a main combustion chamber, an air supply assembly and a smoke flue for guiding heat energy in the main combustion chamber out. The main combustion chamber is communicated with the smoke flue through a ventilation pipe, and a conveying and incinerating platform is arranged in the main combustion chamber and at least comprises a bearing plate and a stirring portion. The incinerator with the fixed fire grate further comprises a pushing portion, wherein an air return moisture removal cavity channel is arranged between the pushing portion and the main combustion chamber in a transition mode and forms a material conveying path for connecting the cavity of the main combustion chamber with the pushing portion, an air outlet is formed in the end of the air return moisture removal cavity channel and communicated with an external air draught fan, and the end of the air return moisture removal cavity channel and the pushing portion are positioned at the same end. The incinerator with the fixed fire grate is high in operation reliability and incineration efficiency, low in cost and capable of ensuring incineration at high and constant temperature and extracting and utilizing efficient heat energy of biomass fuel.

Owner:合肥康帕因设备技术有限公司

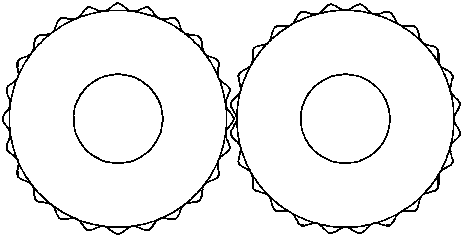

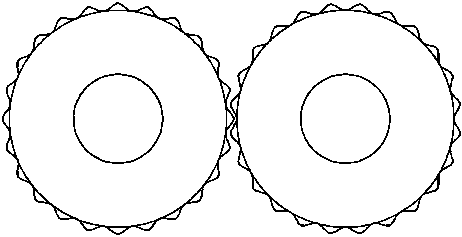

An environment-friendly energy saving and emission reduction system

ActiveCN109869723BCrushed fullyReduce consumptionIncinerator apparatusWater storageEnvironmental engineering

The invention relates to an energy conservation and emission reduction system, and discloses an environment-friendly type energy conservation and emission reduction system. An incinerator of the environment-friendly type energy conservation and emission reduction system comprises a pretreatment chamber and an incineration chamber. The pretreatment chamber is sequentially divided into a large-particle trash chamber, a dust trash chamber and a water storage chamber from top to bottom. The incineration chamber comprises an incineration cavity and a fuel cavity. The incineration cavity is dividedinto a large particle incineration cavity and a dust incineration cavity. A stirring and smashing paddle is arranged in the incineration cavity. An induced draft fan communicating with the dust trashchamber and the dust incineration cavity is arranged on the side wall of the dust trash chamber. A trash smashing device comprises a roller and crushing bodies distributed on the left side and the right side of the roller correspondingly. Each crushing body comprises a crushing block used in cooperation with the outer side wall of the roller for conducting trash crushing. The width of a trash crushing cavity is gradually decreased from top to bottom. According to the environment-friendly type energy conservation and emission reduction system, by means of the structural design of the incinerator and the trash smashing device, the incineration efficiency and the incineration sufficiency can be increased to a great extent, the incineration time can be sufficiently shortened, the fuel consumption and the slag discharge amount can be reduced, and the effects of energy conservation and emission reduction can be achieved.

Owner:浙江绿创新拓建筑规划设计有限公司

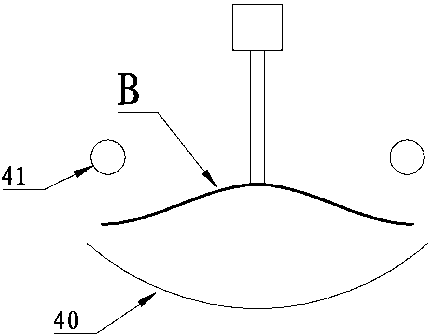

A garbage disposal device with energy-saving and emission-reducing functions

ActiveCN109882857BCrushed fullyEfficient incinerationIncinerator apparatusSlagEnvironmental engineering

The invention relates to a waste disposal device, and discloses a waste disposal device with the functions of energy saving and emission reduction. The waste disposal device comprises a waste crushingdevice (2) comprising a crushing shell (201), and the crushing shell (201) is internally provided with a roller (204) arranged longitudinally, and crushing bodies (205) arranged on the right and leftsides of the roller (204) separately; each crushing body (205) comprises a crushing block (207) matched with the outside wall of the roller (204) for crushing wastes, and the roller (204) and the side faces, close to the roller (204), of the right and left crushing blocks (207) form a waste crushing cavity (208) jointly; and the width of the crushing block (207) is increased from top to bottom gradually so that the width of the waste crushing cavity (208) is decreased from top to bottom gradually. According to the waste disposal device, through design of the waste crushing device, wastes canbe crushed more thoroughly, so that the waste incineration efficiency is higher, and the fuel consumption is reduced; the combustion is more thorough, and slag emission is reduced; and the effects ofenergy saving and emission reduction are achieved fully.

Owner:HEFEI REYAO ENVIRONMENTAL PROTECTION BUILDING MATERIAL TECH

Pulse gas explosion type municipal wastewater and garbage treatment device with tail heat utilization and centrifuge

InactiveCN107763635AEfficient dryingEfficient incinerationMultistage water/sewage treatmentIncinerator apparatusSlagBuffer tank

The invention discloses a pulse gas explosion type municipal wastewater and garbage treatment device with tail heat utilization and a centrifuge. The pulse gas explosion type municipal wastewater andgarbage treatment device comprises a large sewage tank, an incinerator, a counter-current drying tower, the horizontal spiral centrifuge, a sine roller and a heat pump host. A municipal wastewater pipe is connected with a wastewater buffer tank. A grid slag catcher is arranged in the buffer tank. The grid slag catcher is connected with a centrifugal dehydrator through conveying. The wastewater buffer tank is connected with an inlet of the large sewage tank through a sewage pipe and a sewage pump. An appropriate number of mixing devices and a protruding rib ultrasonic wave shock excitation mixer are arranged in the large sewage tank. A conical bottom is connected with a Roots blower, a bottom valve and a mud pump through a pipeline. The mud pump is sequentially connected with the horizontalspiral centrifuge, a spiral airlock feeding machine and the countercurrent drying tower. A tail gas pipe of the drying tower is connected with a heat pump system. A cosine plastic disc pulse gas explosion device is arranged on the lower left portion of the drying tower. According to the pulse gas explosion type municipal wastewater and garbage treatment device, the sine roller, the cosine plasticdisc pulse gas explosion device and the protruding rib ultrasonic wave shock excitation mixer all have the distinctive features and can reliably cooperate with one another to complete the municipal wastewater and garbage treatment.

Owner:杨瑞琪

Incinerator

ActiveCN103982899BEfficient incinerationTake advantage ofIncinerator apparatusEngineeringChemical waste

The invention provides a garbage incinerator. The garbage incinerator comprises an outer furnace wall, an outer furnace core and an inner furnace core which are sequentially arranged from outside to inside, wherein the outer furnace core and the inner furnace core are fixedly arranged on a base; the base, the outer furnace wall and the outer furnace core form an outer furnace chamber for combusting garbage; a garbage inlet and a fuel input channel are formed in the upper part of the outer furnace wall; a feeder is arranged between the outer furnace core and the outer furnace wall; a charging hole is formed in the upper part of the inner furnace core; a stirrer is arranged in the inner furnace core. The outer furnace chamber can be used for incinerating the garbage, and the inner furnace core can be used for roasting chemical waste materials which can be converted into ceramic raw materials; during the incineration of the garbage, industrial chemical waste materials generated in a production process of an aluminum product are roasted into ceramic preparation materials to achieve a waste recycling effect; moreover, conventional garbage incineration-based energy conversion activities are not affected, energy is fully utilized, and the garbage incinerator is energy-saving and emission-reducing.

Owner:惠州恒德远实业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com