A low calorific value sludge and edible fungus residue co-incineration system and process

A technology of edible fungus and low calorific value, applied in incinerators, combustion types, combustion methods, etc., can solve problems such as deterioration of the surrounding environment, bacterial reproduction, waste of agricultural resources, etc., and achieve efficient use of heat and improve heat utilization efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

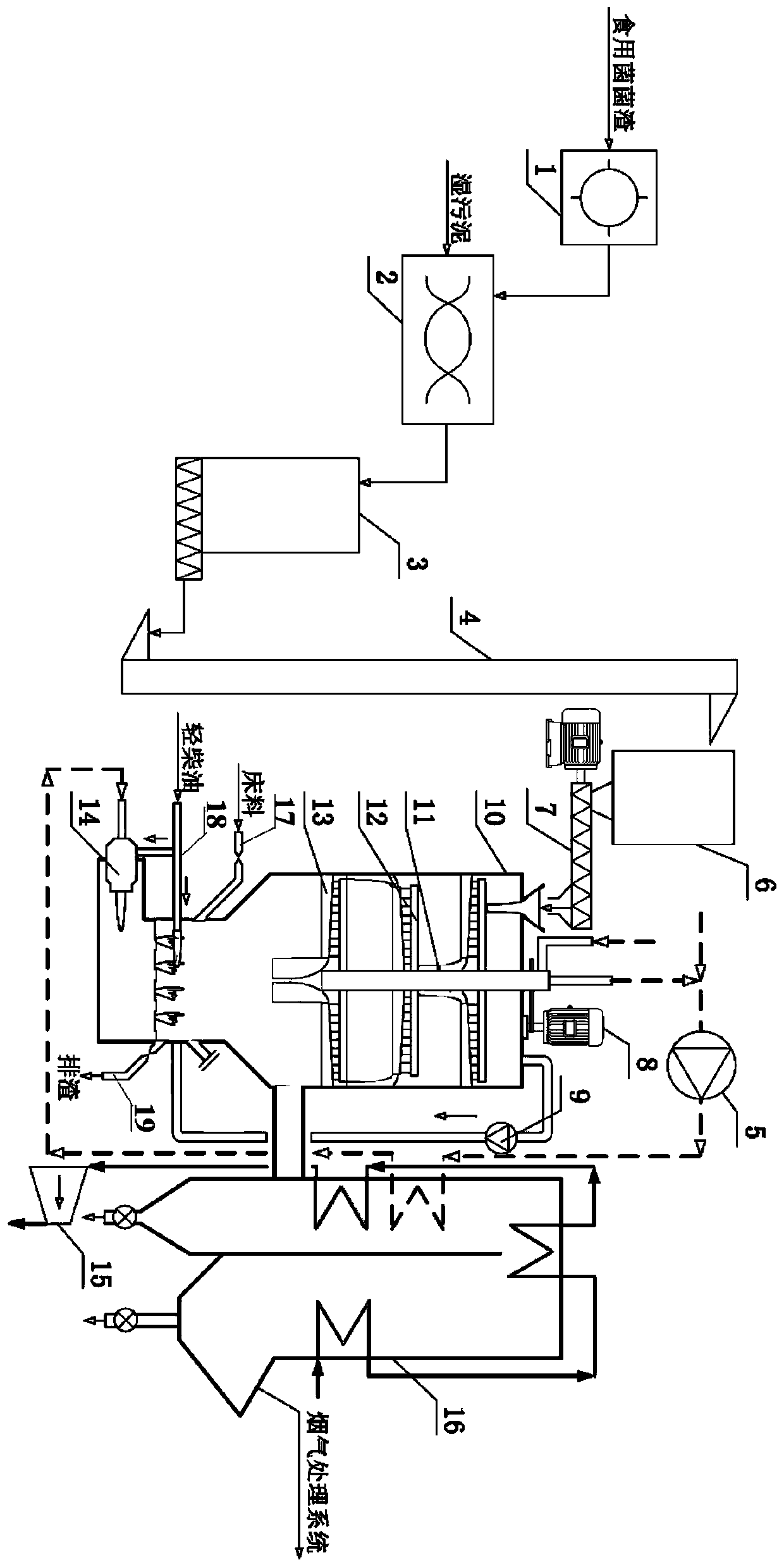

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

[0023] as attached figure 1 The low calorific value sludge and edible fungus slag co-incineration system shown, from front to back, includes the pretreatment of edible fungus slag and the feed treatment system for mixing edible fungus slag and wet sludge, used for The storage and transportation system for the storage and transportation of edible fungus residue and wet sludge mixture, the incineration and waste heat boiler system for incinerating the mixture and recovering the heat of high-temperature furnace gas, and the back pressure steam turbine for power generation system.

[0024] The incineration and waste heat boiler system includes an incinerator 10 and a waste heat boiler 16 connected to the incinerator 10. The high temperature furnace gas generated by the incinerator 10 enters the waste heat boiler 16, and the waste heat boiler 16 recovers the heat of the hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com