An environment-friendly energy saving and emission reduction system

An energy-saving, emission-reducing, and environmentally-friendly technology that is applied to combustion types, lighting and heating equipment, and incinerators. Efficient effect of slag discharge and waste incineration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

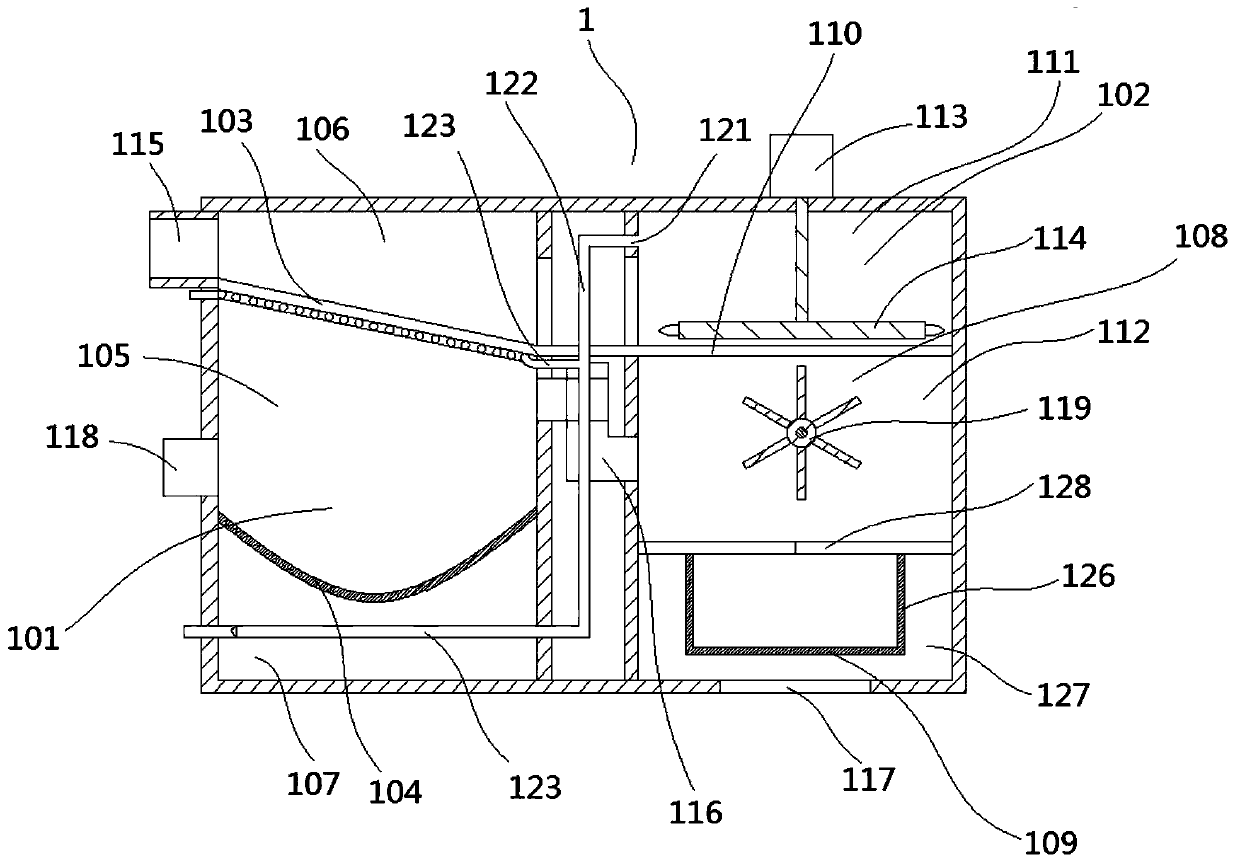

[0034] An environment-friendly energy-saving and emission-reduction system, including an incinerator 1, and a garbage crushing device 2, which is arranged before the incinerator 1, so that the garbage can be pulverized and ground before entering the incinerator 1, so as to ensure that the subsequent incinerator 1 sufficiency of incineration.

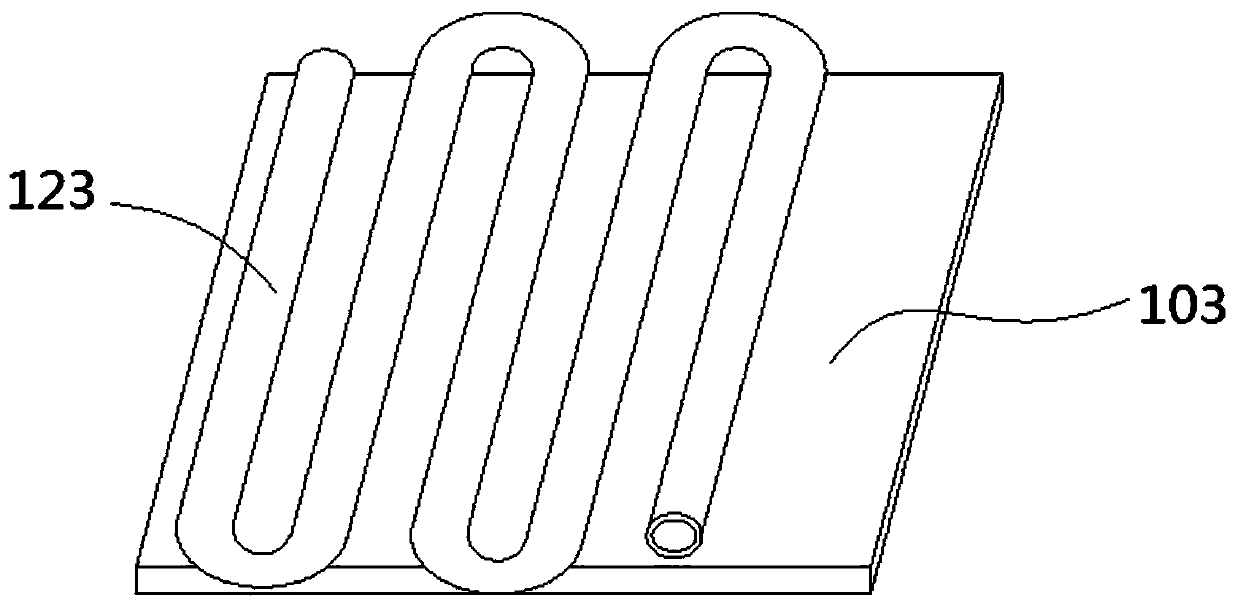

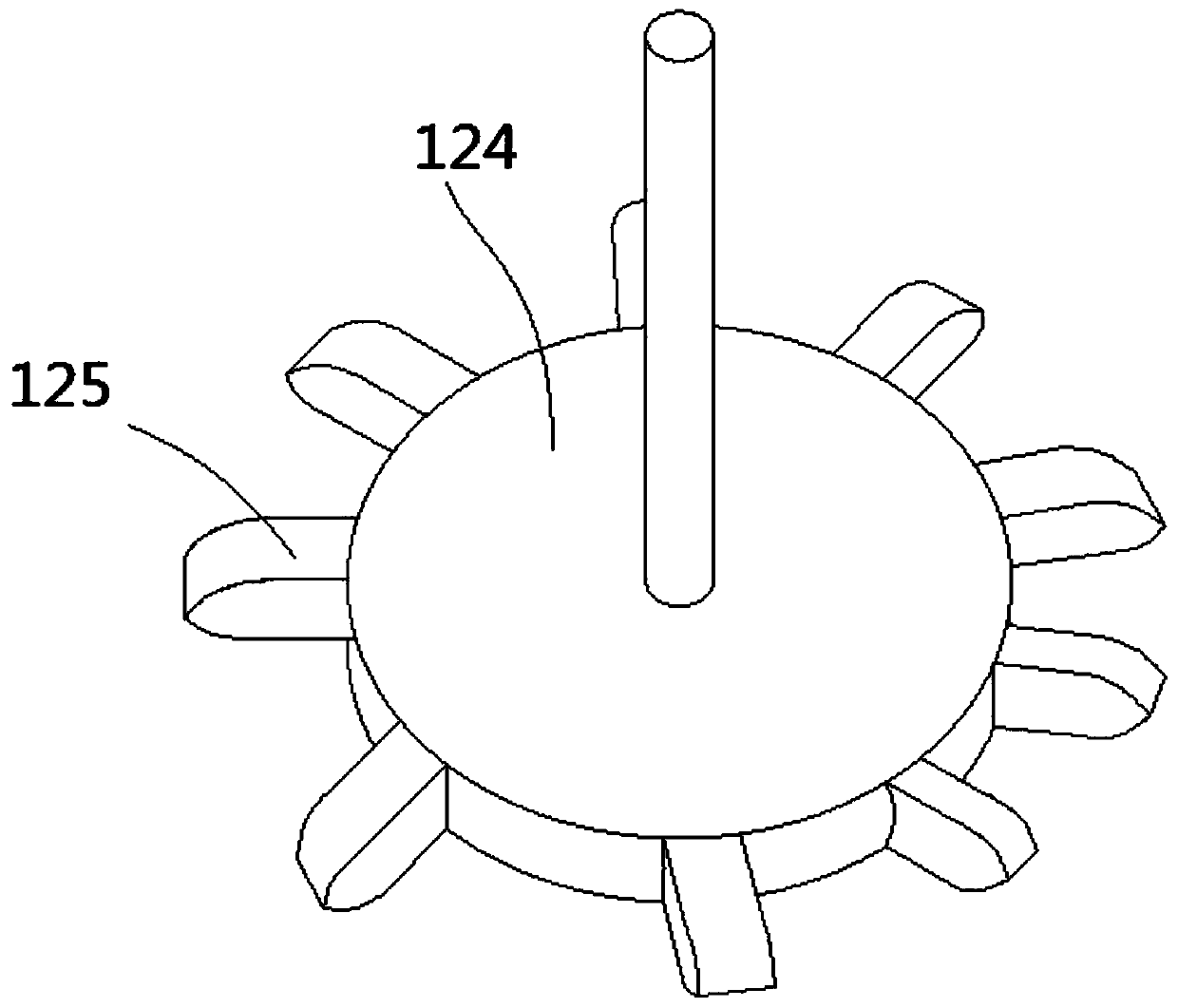

[0035] Such as figure 1 As shown, the incinerator 1 in the system has a special structural design, which includes a pretreatment chamber 101 and an incineration chamber 102. The first filter plate 103 and The arc-shaped aluminum plate 104 sunken downwards, the first filter plate 103 and the arc-shaped aluminum plate 104 separate the pretreatment chamber 101 into a large particle garbage chamber 106, a dust garbage chamber 105 and a water storage chamber 107 successively from top to bottom; Incineration chamber 102 Including the upper incineration chamber 108 and the lower fuel chamber 109, a horizontally arranged second filter plate 110...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com