Incinerator with fixed fire grate

A technology for fixing grate and incinerator, applied in incinerators, combustion methods, combustion types, etc., can solve the problems of aggravating the cost, difficulty and unbalance of straw incineration, and ensure efficient heat extraction and utilization effect and operation reliability. The effect of high and high incineration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

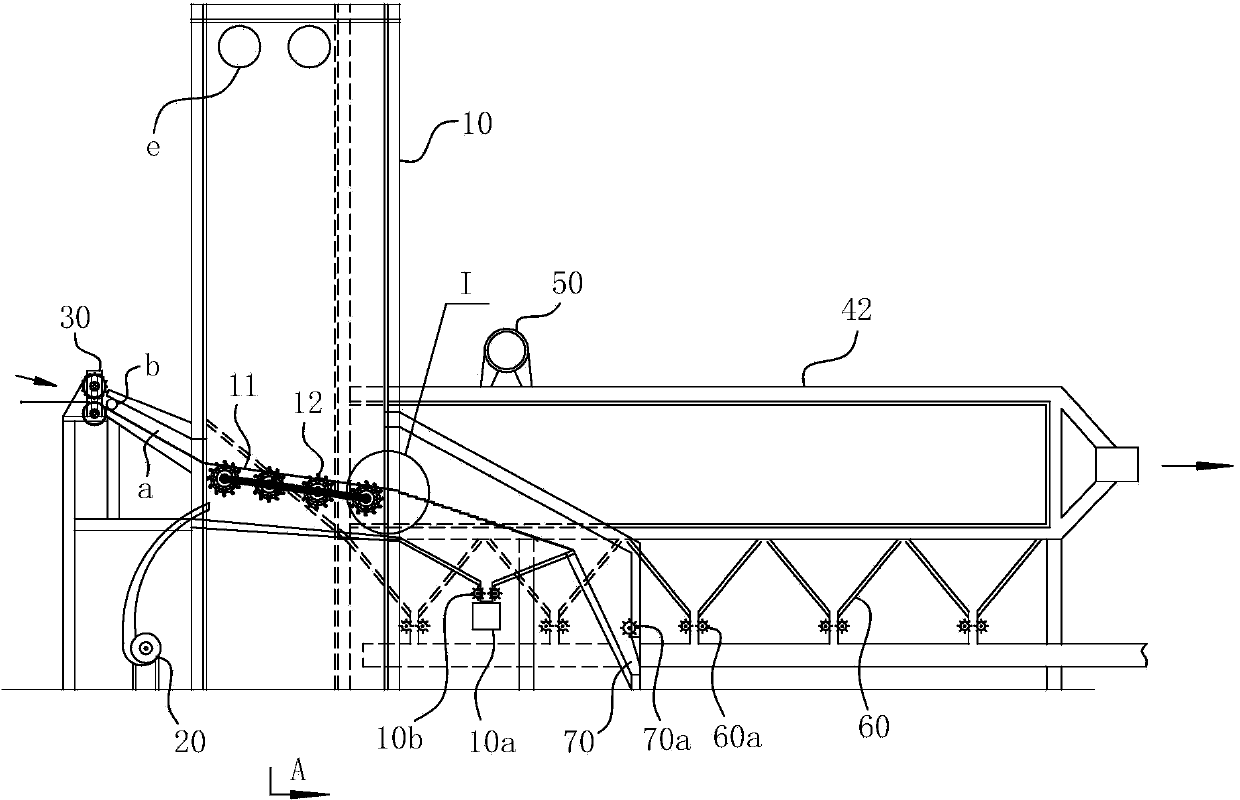

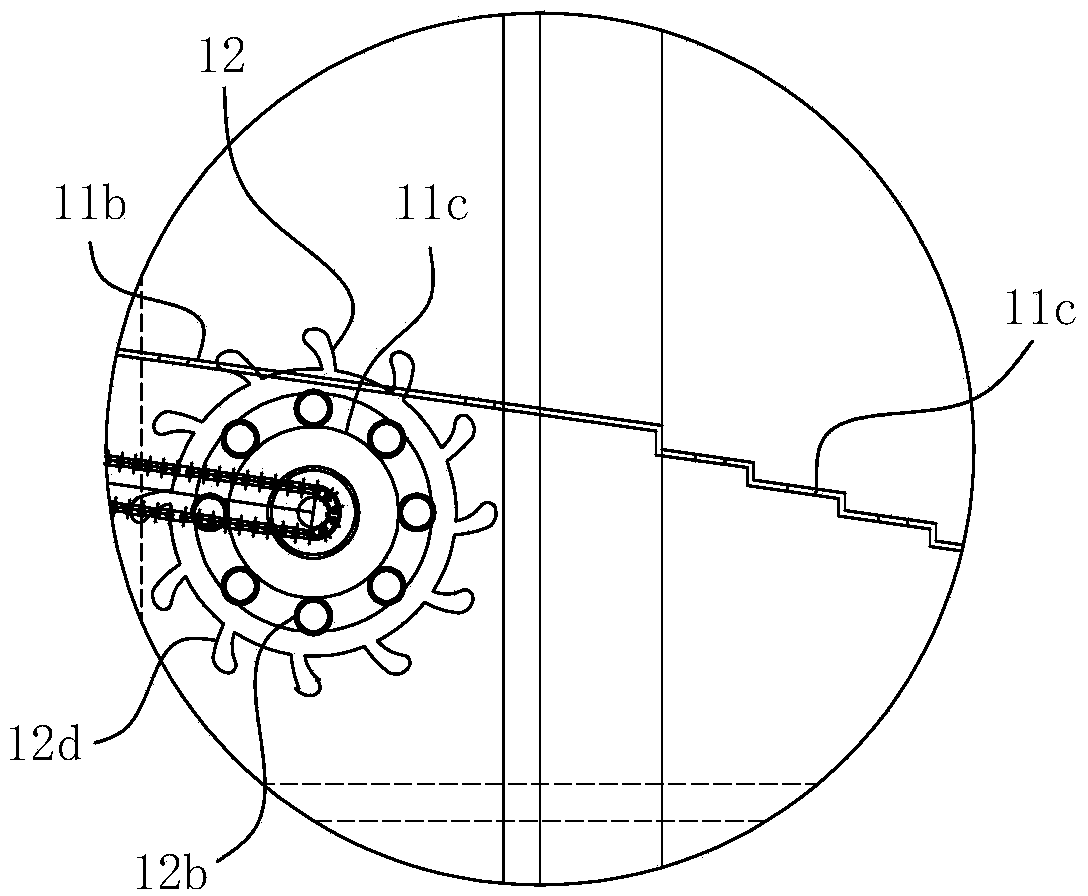

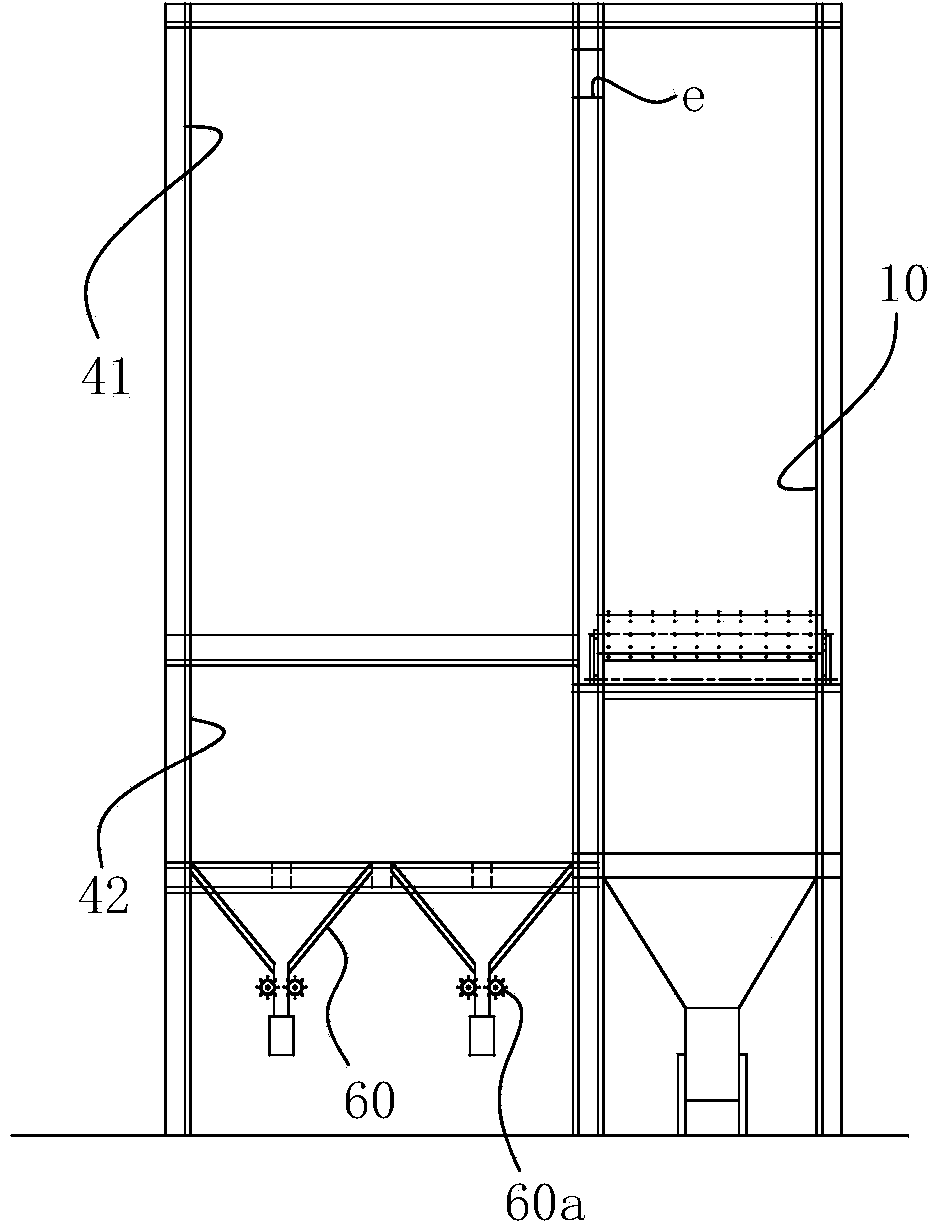

[0041] For ease of understanding, combined here Figure 1-8 Specifically set forth the component structure of the present invention and its specific work flow:

[0042] Concrete structure of the present invention, refer to Figure 1-8 As shown, it includes at least a fixed plate structure fire grate (that is, a loading plate 11) that is equipped with a stirring portion that has a conveying capacity; Compression molding function: the ash accumulation unit 70 is arranged at the discharge end of the bearing plate 11, so as to ensure the ability to collect and remove the burned ash. Such as Figure 1-2 and Figure 4 and Figure 6 As shown, the entire bearing plate 11 presents a knuckle and inclined surface structure with a high feed end and a low discharge end. The load plate 11 is divided into a moisture removal section 11a, a combustion section 11b, a burnout section 11c and ash slag by its working sections. The cooling section 11d, wherein the moisture discharge section 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com