Patents

Literature

39results about How to "Reliable travel" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

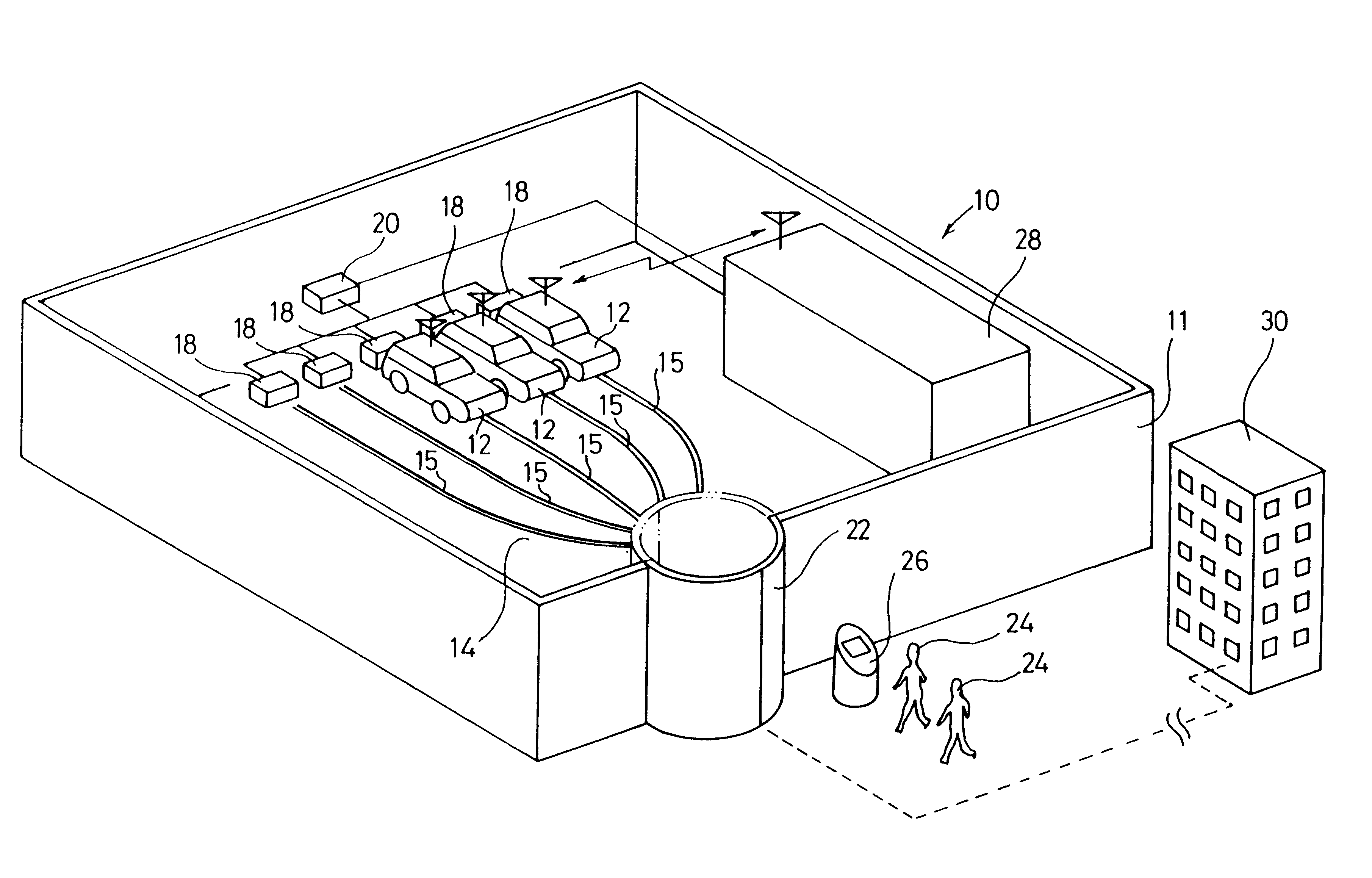

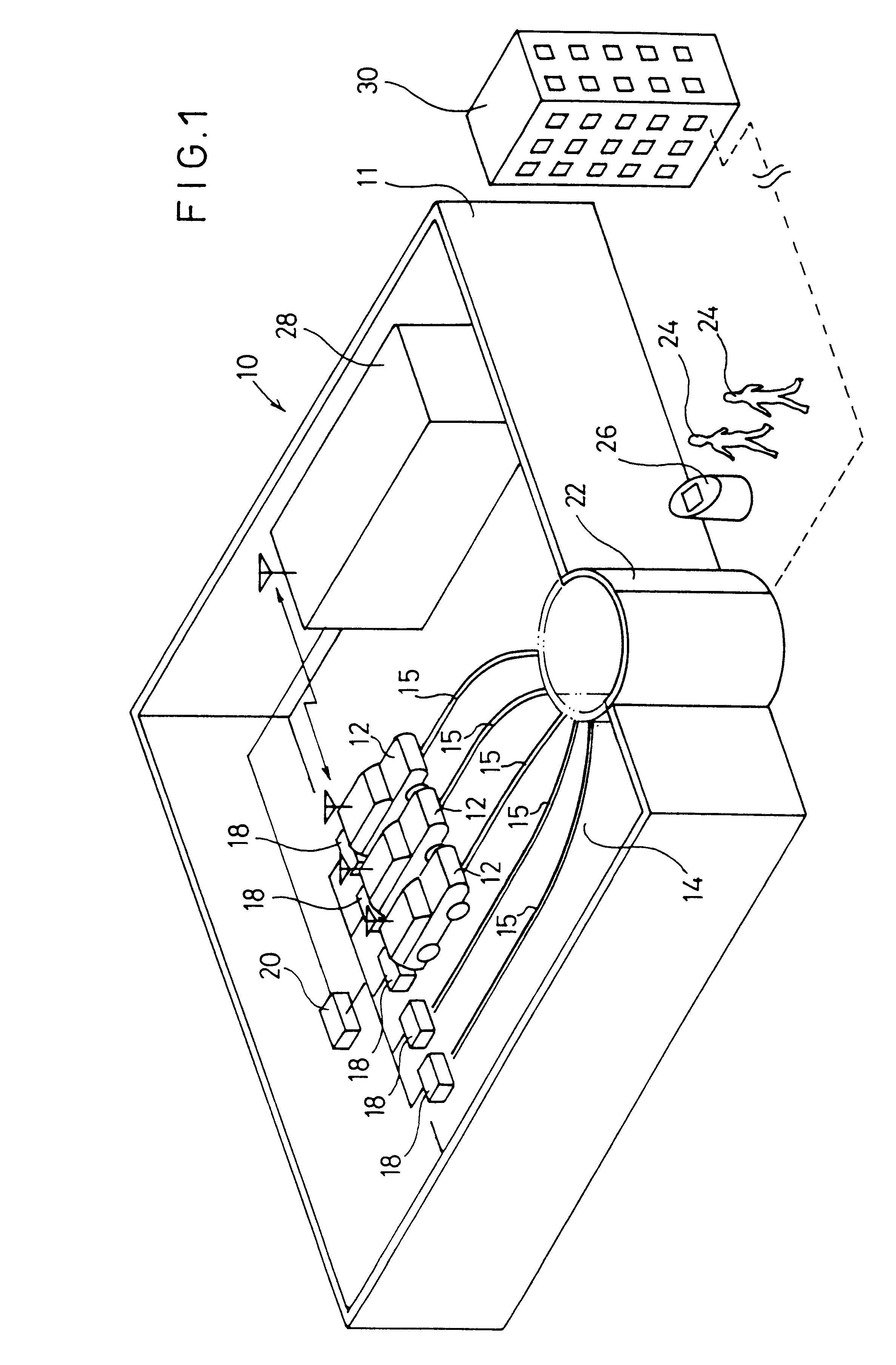

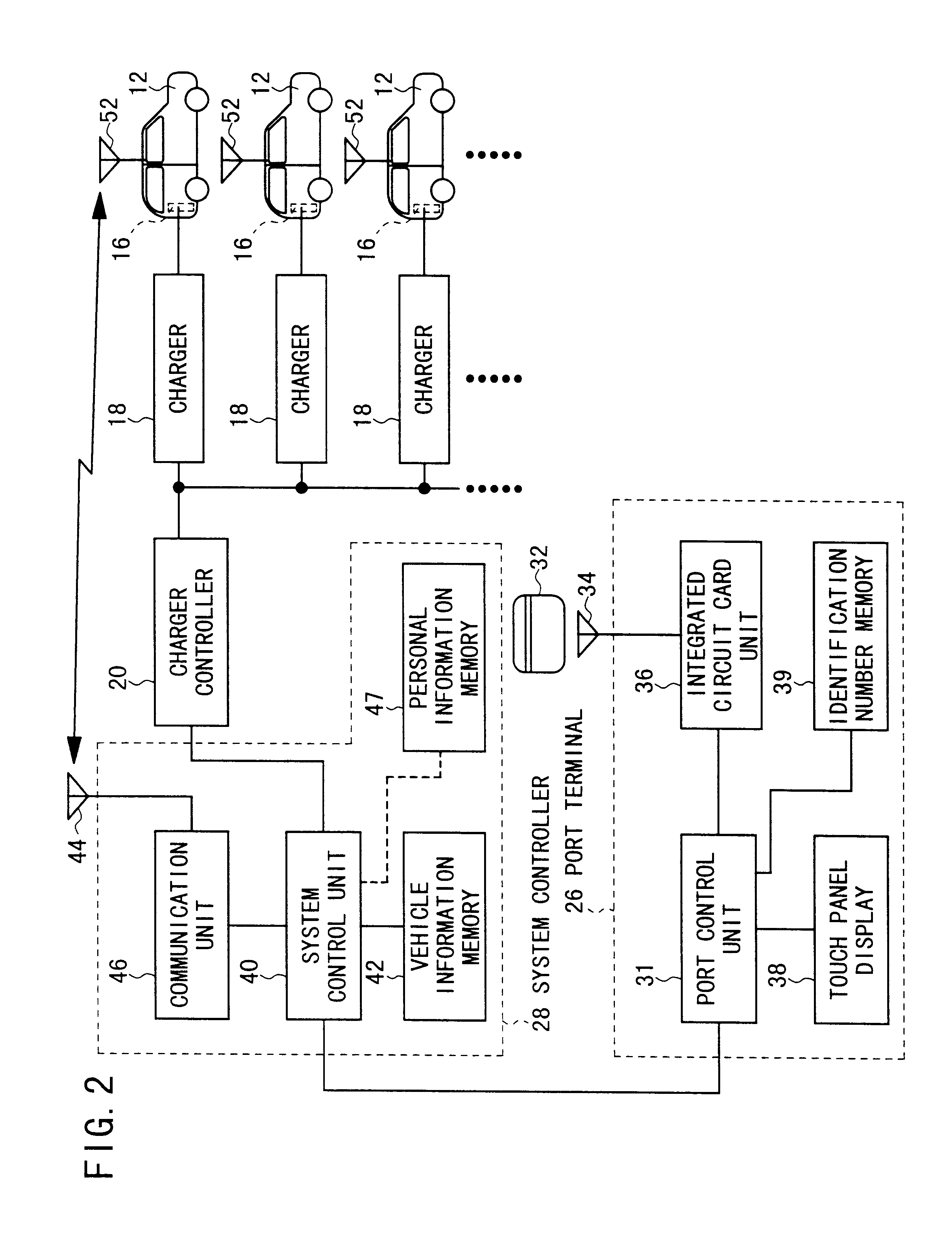

Electric vehicle sharing system

InactiveUS6181991B1Efficient supplyReliable travelVehicle testingRegistering/indicating working of vehiclesTouch panelElectrical battery

When a user enters a destination using a touch panel display unit, a system control unit calculates a predicted travel distance from a present position to the destination, determines an electric vehicle having a remaining battery capacity required to travel the calculated predicted travel distance, and supplies the determined electric vehicle to the user.

Owner:HONDA MOTOR CO LTD

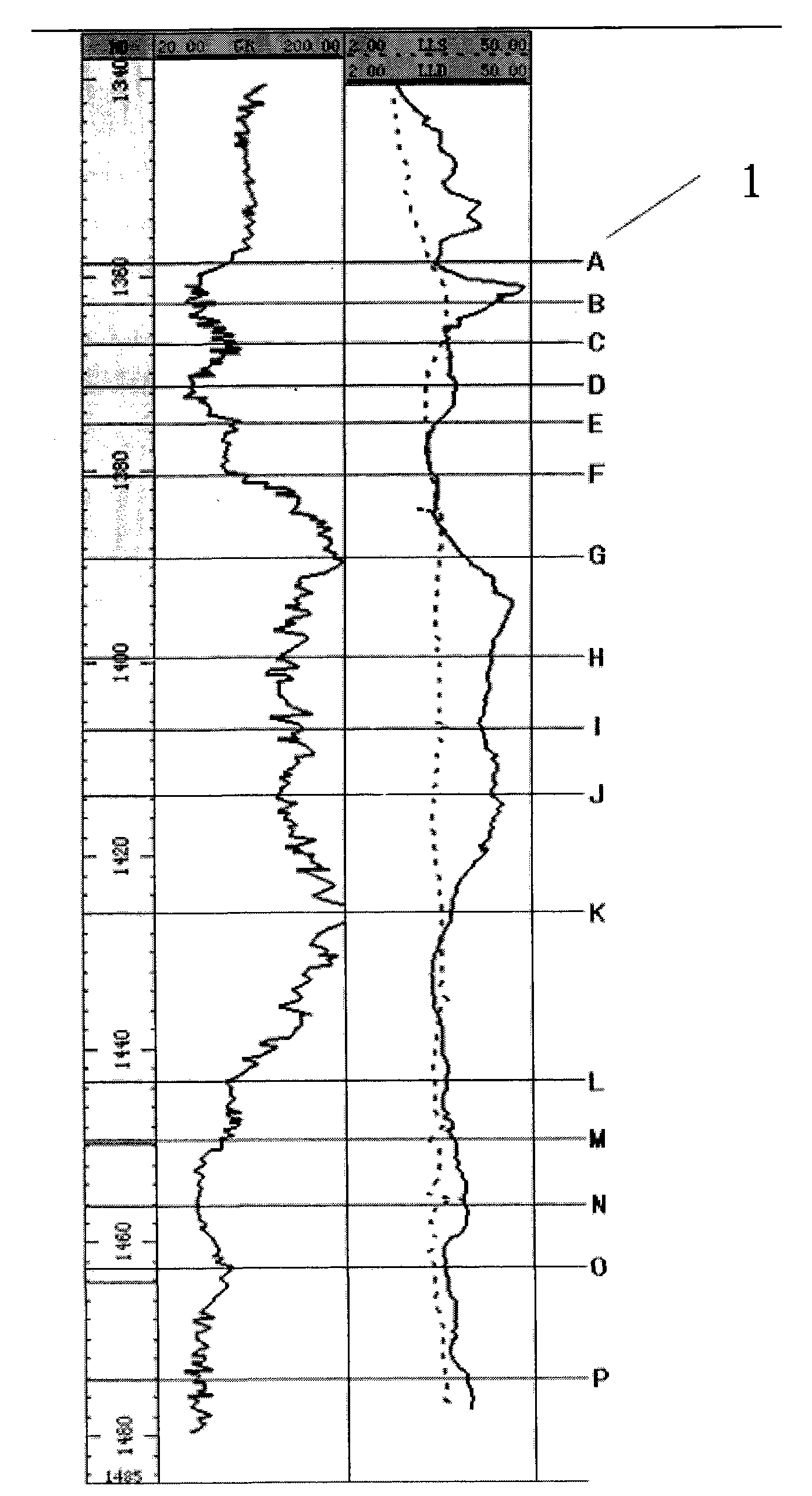

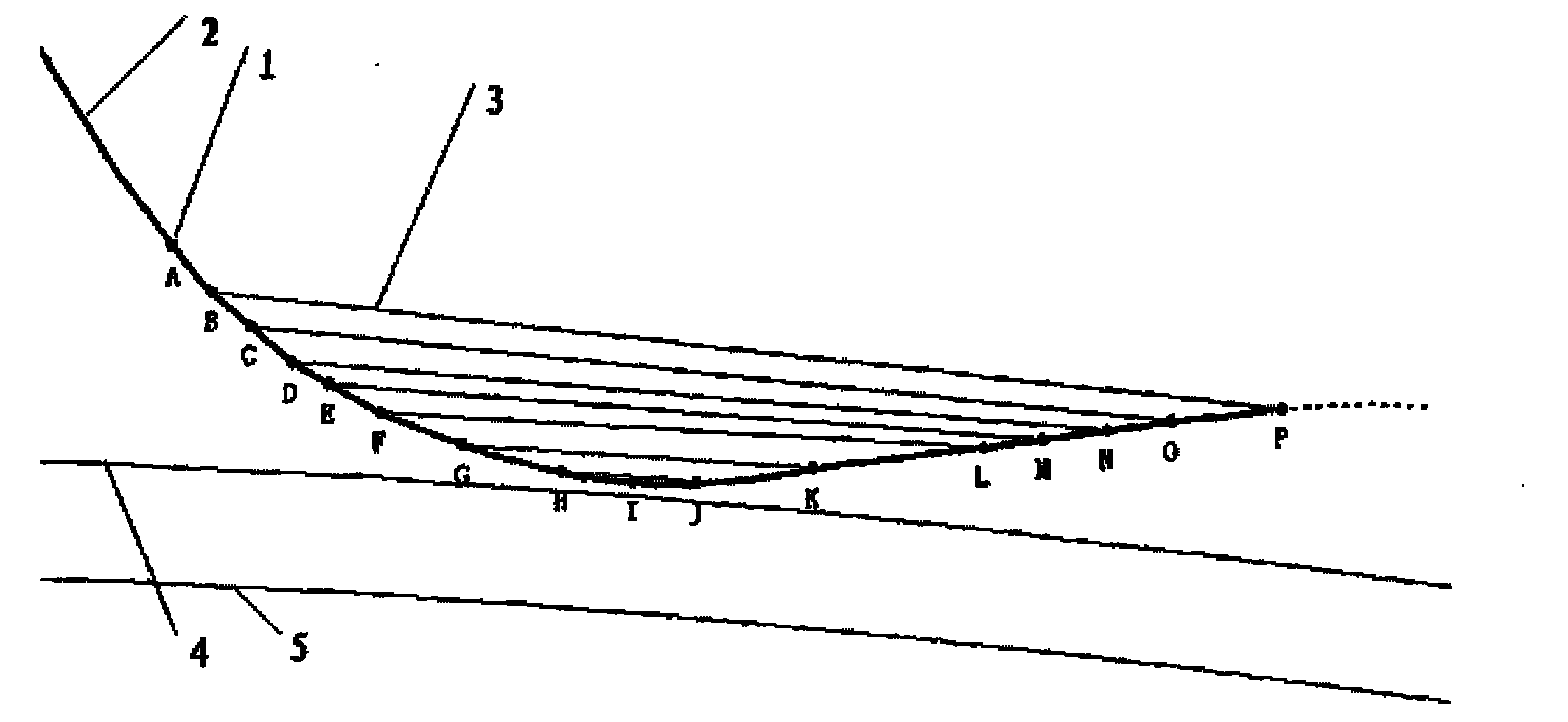

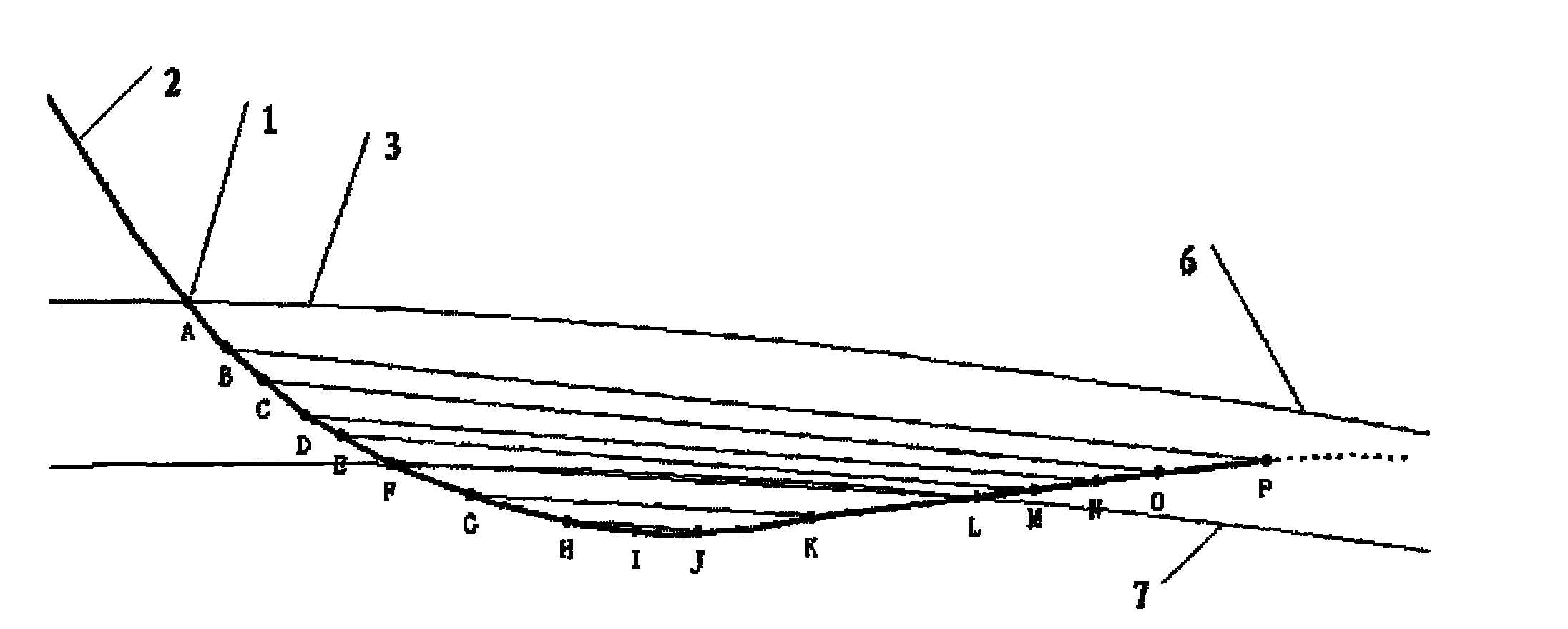

Horizontal well logging while drilling geo-steering method

The invention discloses a horizontal well logging while drilling geo-steering method, and relates to the technical field of drilling, exploration and development of petroleum, natural gas and the like, in particular to a logging while drilling geo-steering method suitable for the drilling process of a horizontal section of a horizontal well. The method is characterized by comprising the following steps of: interpreting and making a logging curve graph and a well track profile graph by using real-time data obtained by logging while drilling and measurement while drilling, defining logging curve marking points on the logging curve graph and marking on the well track profile graph, further defining symmetrical marking points, analyzing and interpreting the symmetrical marking points to obtain the average formation dip and formation dip variation trend of each section of a well track, and redrawing a top boundary and a bottom boundary of a target layer by combining drilling points of the top boundary and the bottom boundary of the target layer; and predicting the altitude depth of a drill position according to the last measuring point, and determining the actual position of a drill in the target layer to provide a basis for next-step geo-steering decision making.

Owner:邱世军

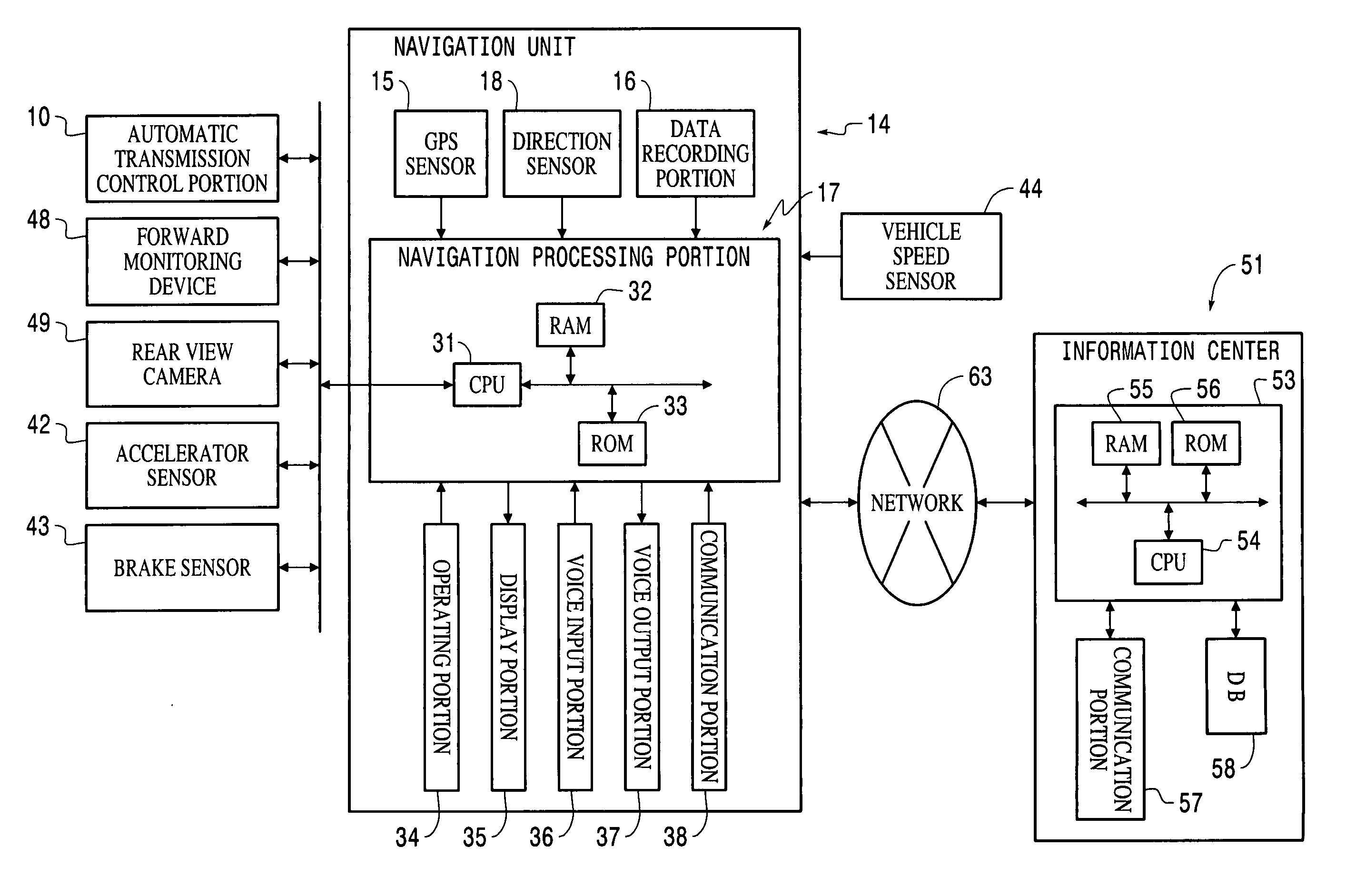

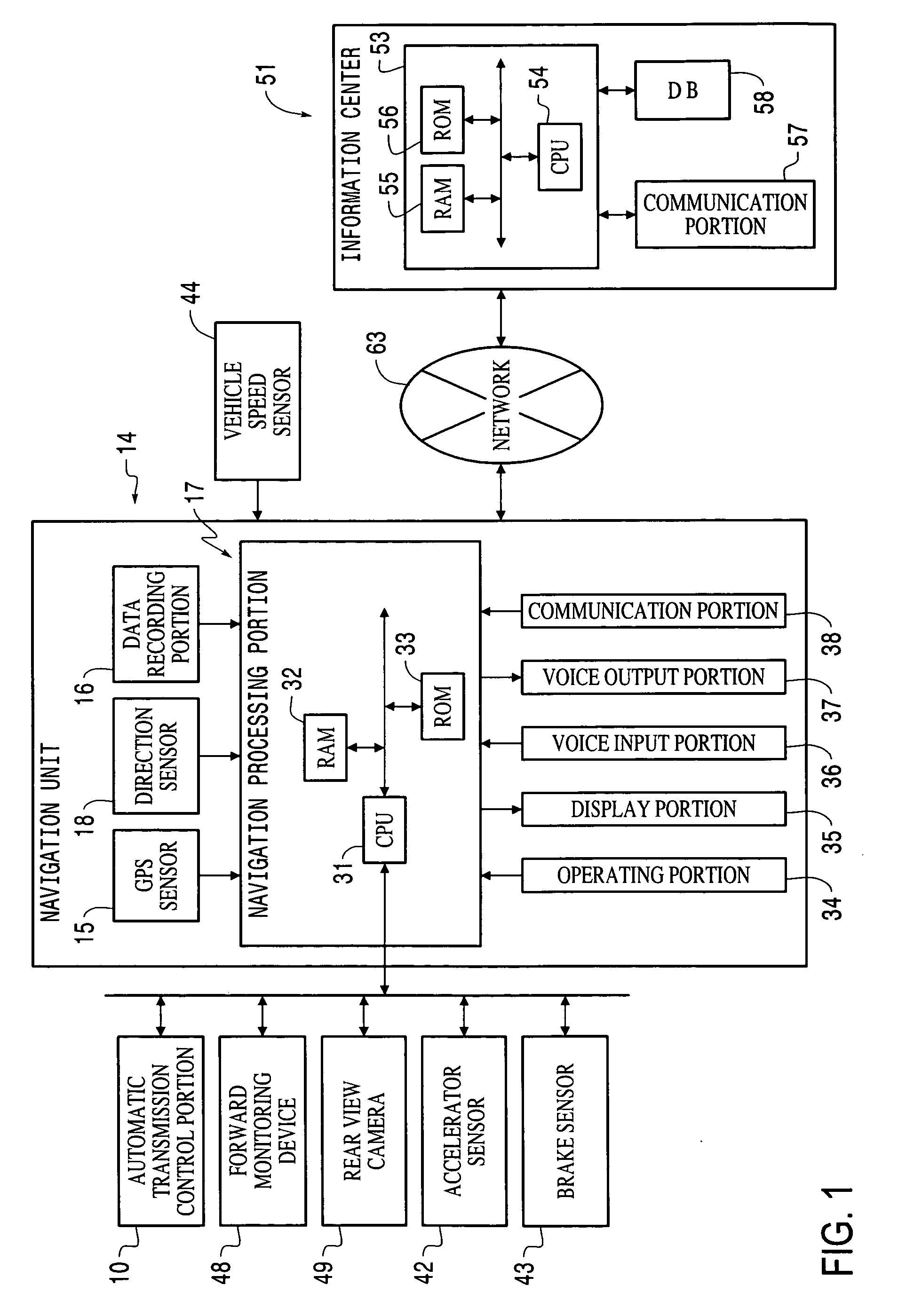

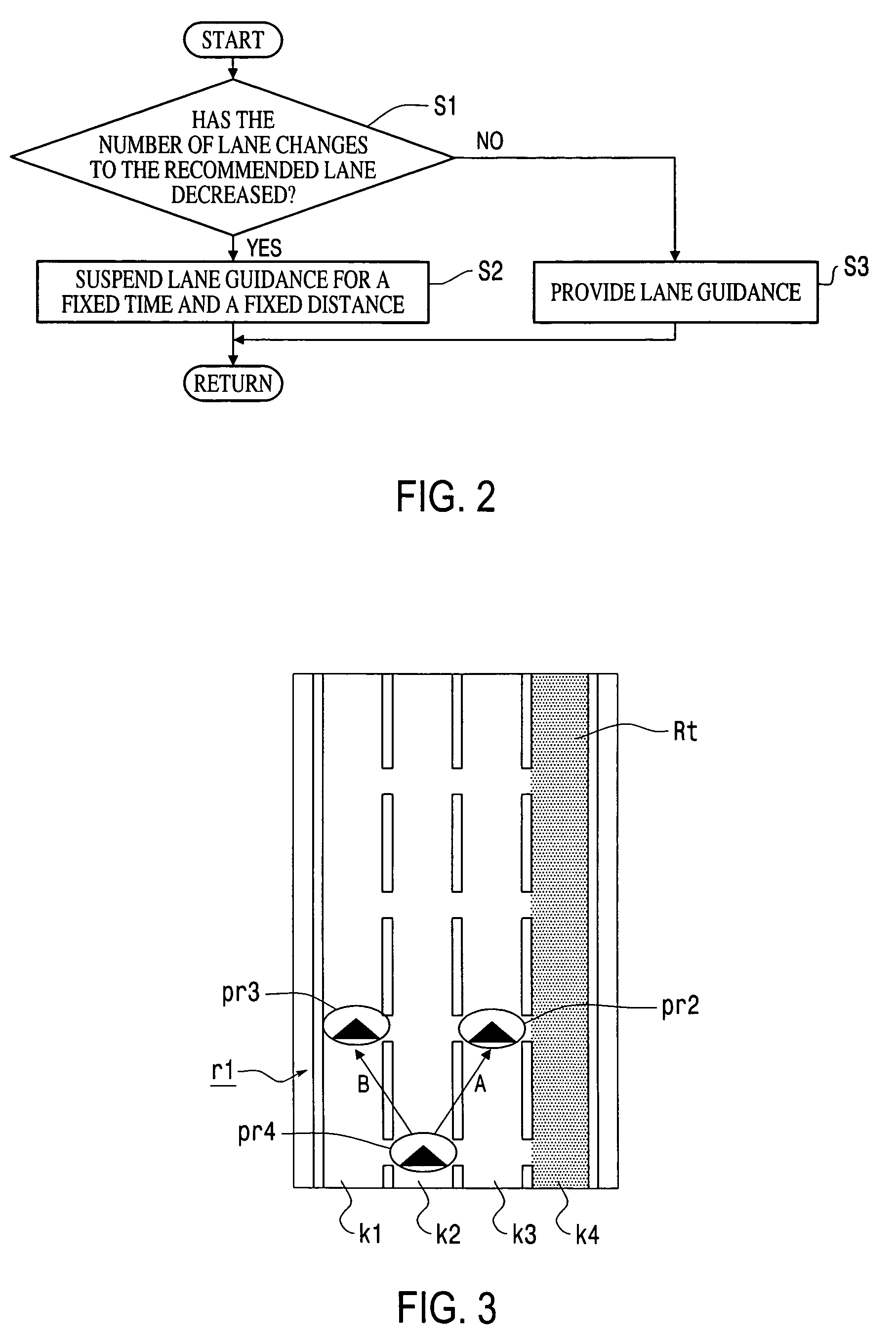

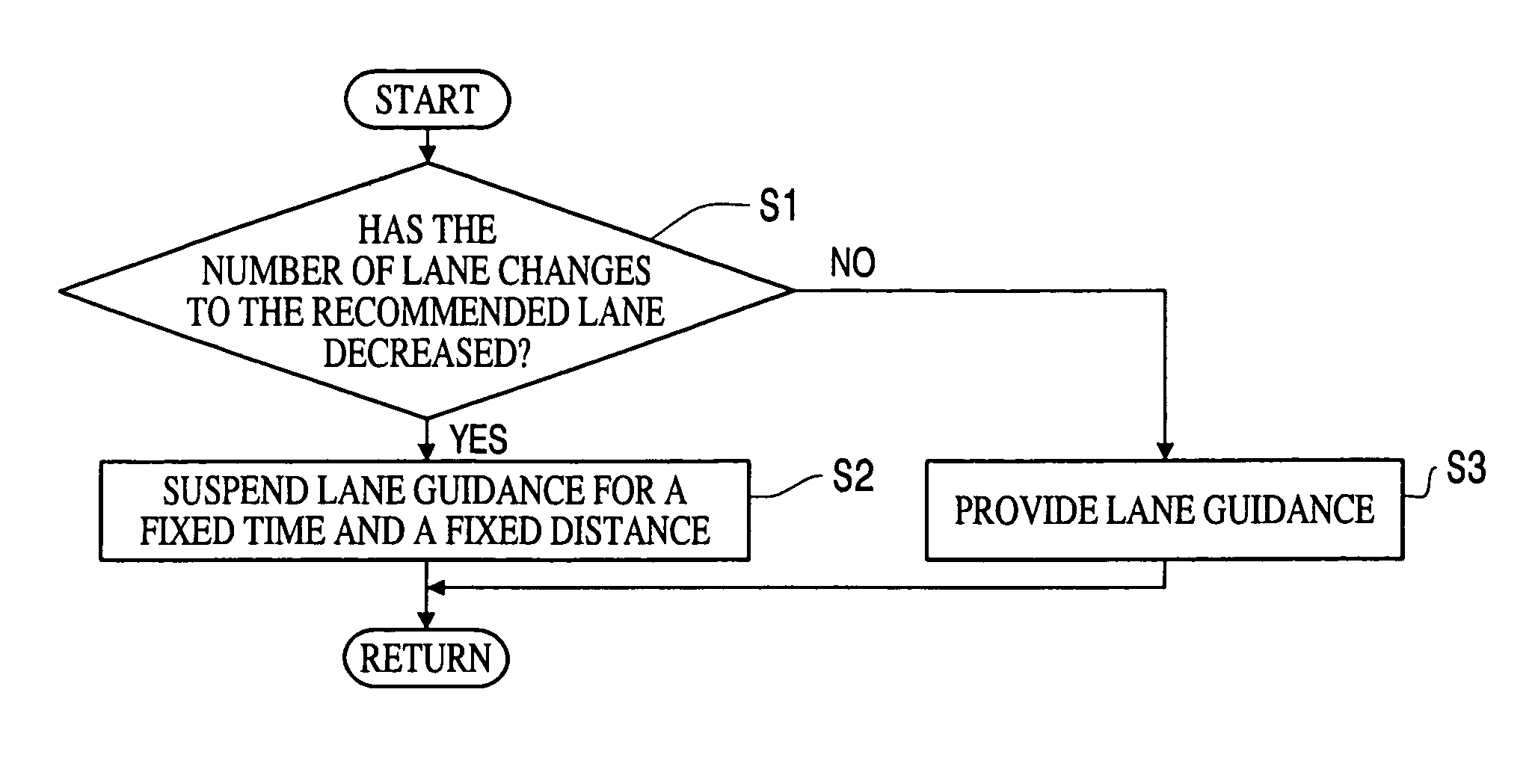

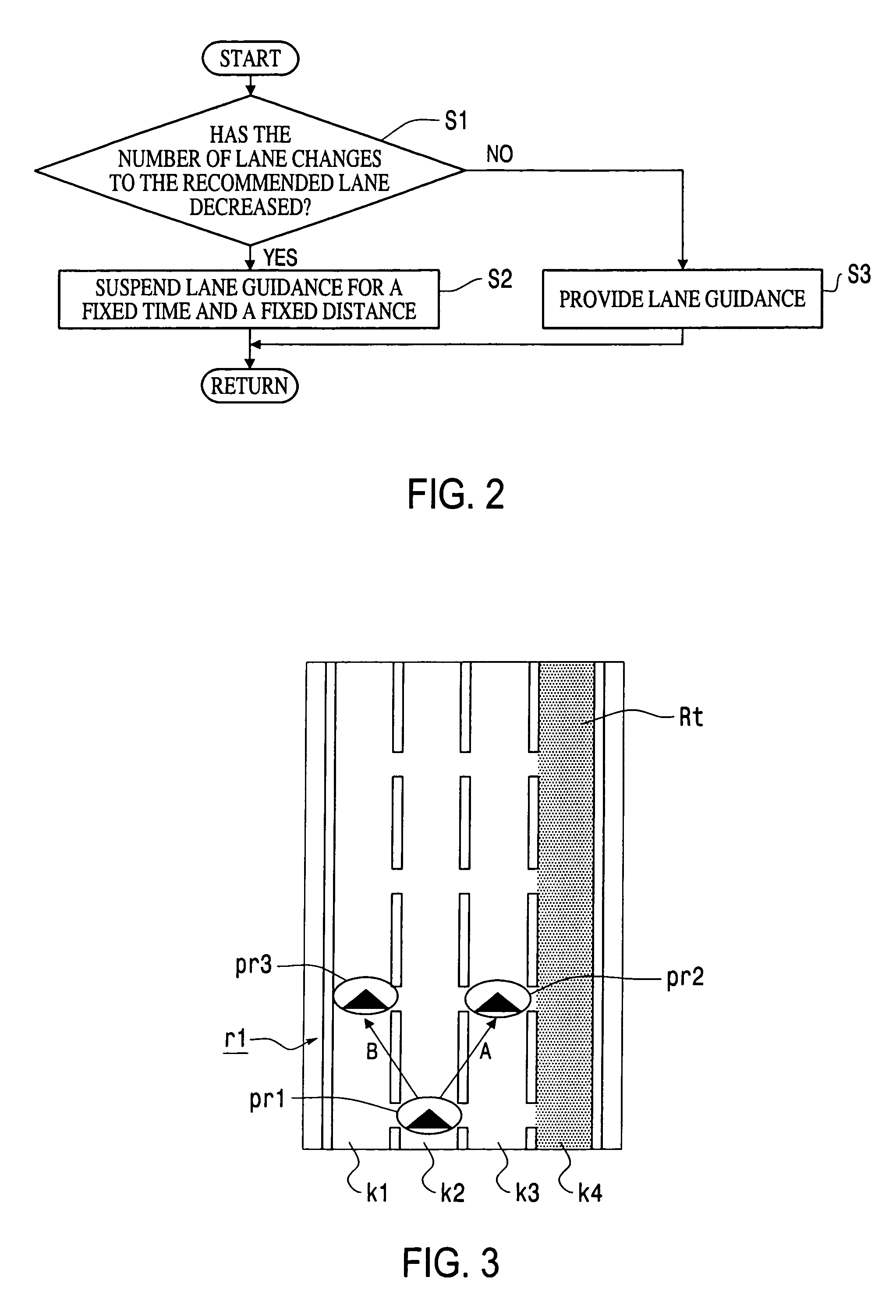

Route guidance systems, methods, and programs

InactiveUS20070124072A1Reliable travelAnalogue computers for vehiclesInstruments for road network navigationGuidance systemComputer science

Systems, methods, and programs search for a route to a destination and set a recommended travel lane, based on the searched for route. The systems, methods, and programs provide lane guidance to lead the vehicle into the recommended lane. The systems, methods, and programs receive a current position of the vehicle and determine a movement direction of the vehicle, based on the received current position and the recommended lane. The systems, methods, and programs determine whether to provide lane guidance based on the movement direction of the vehicle.

Owner:AISIN AW CO LTD

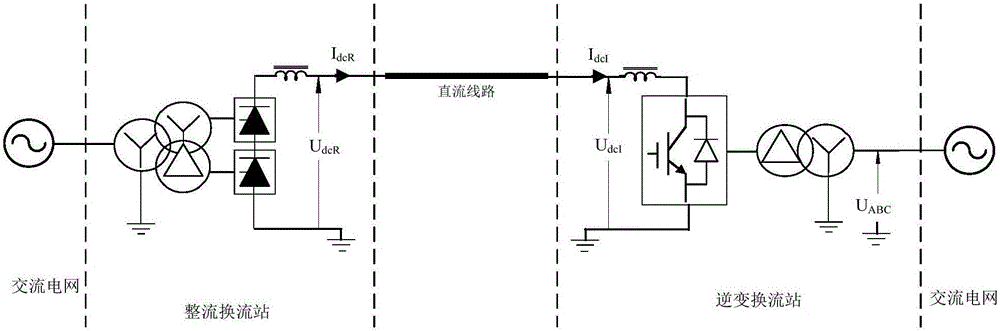

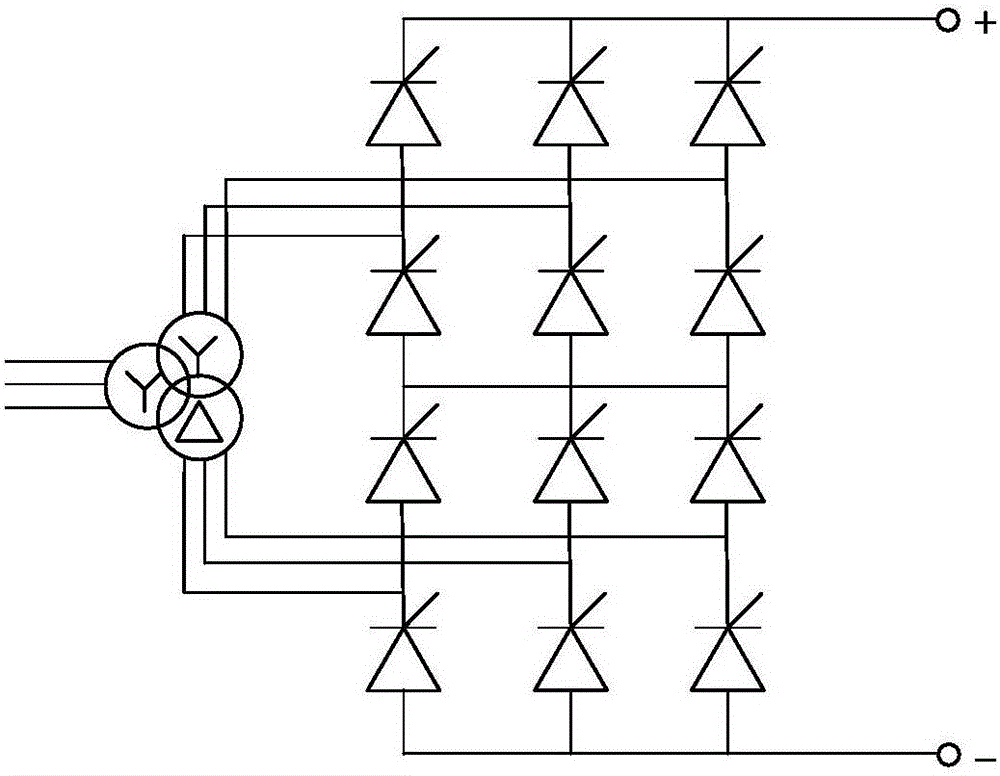

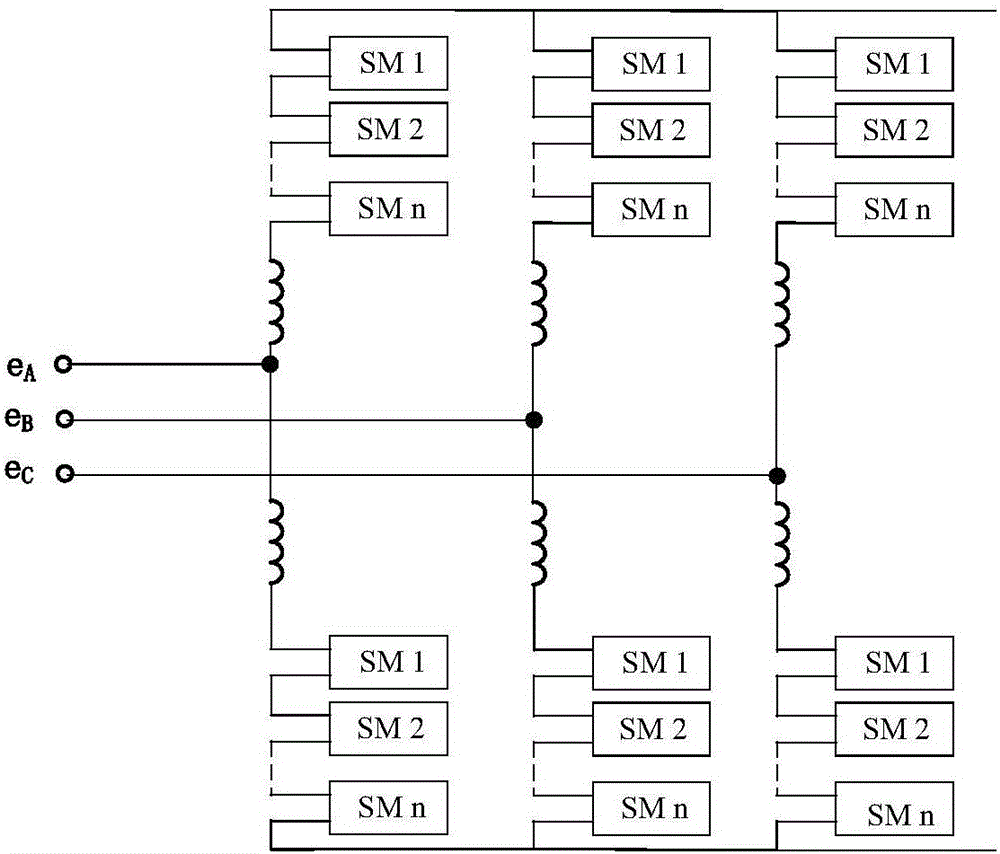

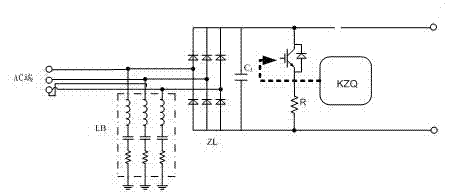

Method for handling failure of alternating current side of invertor side of mixed-type direct current transmission system

InactiveCN106058826AGet back up and running quicklySmooth return to operationEmergency protective circuit arrangementsElectric power transfer ac networkHybrid typeCapacitance

This invention discloses a method for handling failure of alternating current side of invertor side of mixed-type direct current transmission system. The method is characterized by comprising the following steps: steps1, detect whether a serious failure is happened in an alternating current network of the invertor side; if so, enter the step 2; the serious failure means that the failure happened in the network of the invertor side makes the positive sequence voltage of the connection part of an inversion converter station and the alternating current network less than 0.6 time of a rated voltage; step2, shift the phase of a rectification converter station to an inversion state; in other words, adjust the trigger angle of a converter valve of a thyristor of the rectifier side to be greater than 90 degrees; and step 3, the voltage source type converter of the inversion converter station triggers a single-phase valve in three phases to run straightly and simultaneously locks the other two phases of valves. By adoption of this method, the mixed-type direct current transmission system can safely and reliably pass through the serious failure of the alternating current network of the invertor side; the overvoltage of the inner capacitor of the voltage source type converter and the overvoltage of the direct current side can be limited; and after the failure of alternating current network is cleared, the mixed-type direct current transmission system can be resumed quickly and steadily.

Owner:NR ELECTRIC CO LTD +1

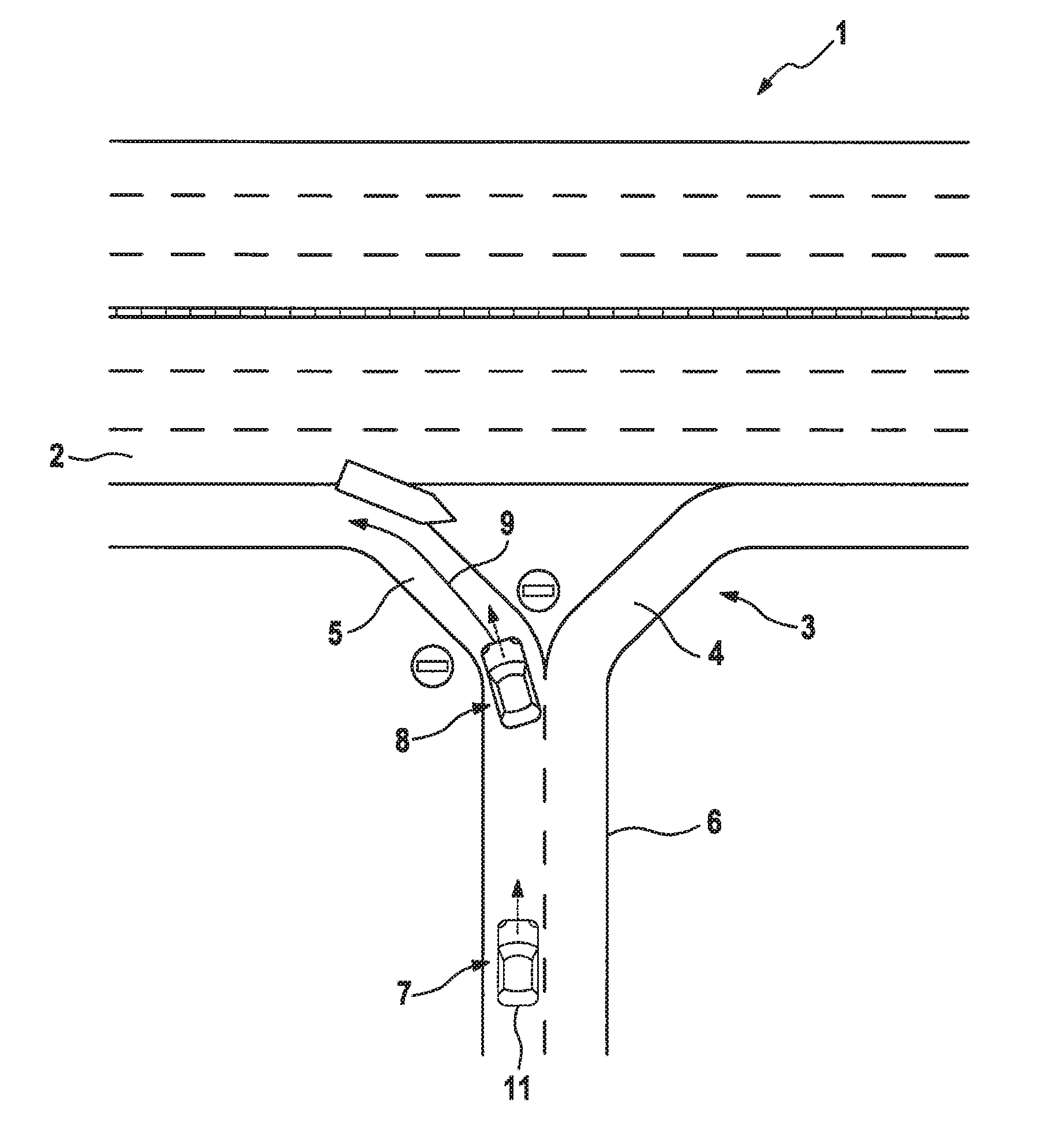

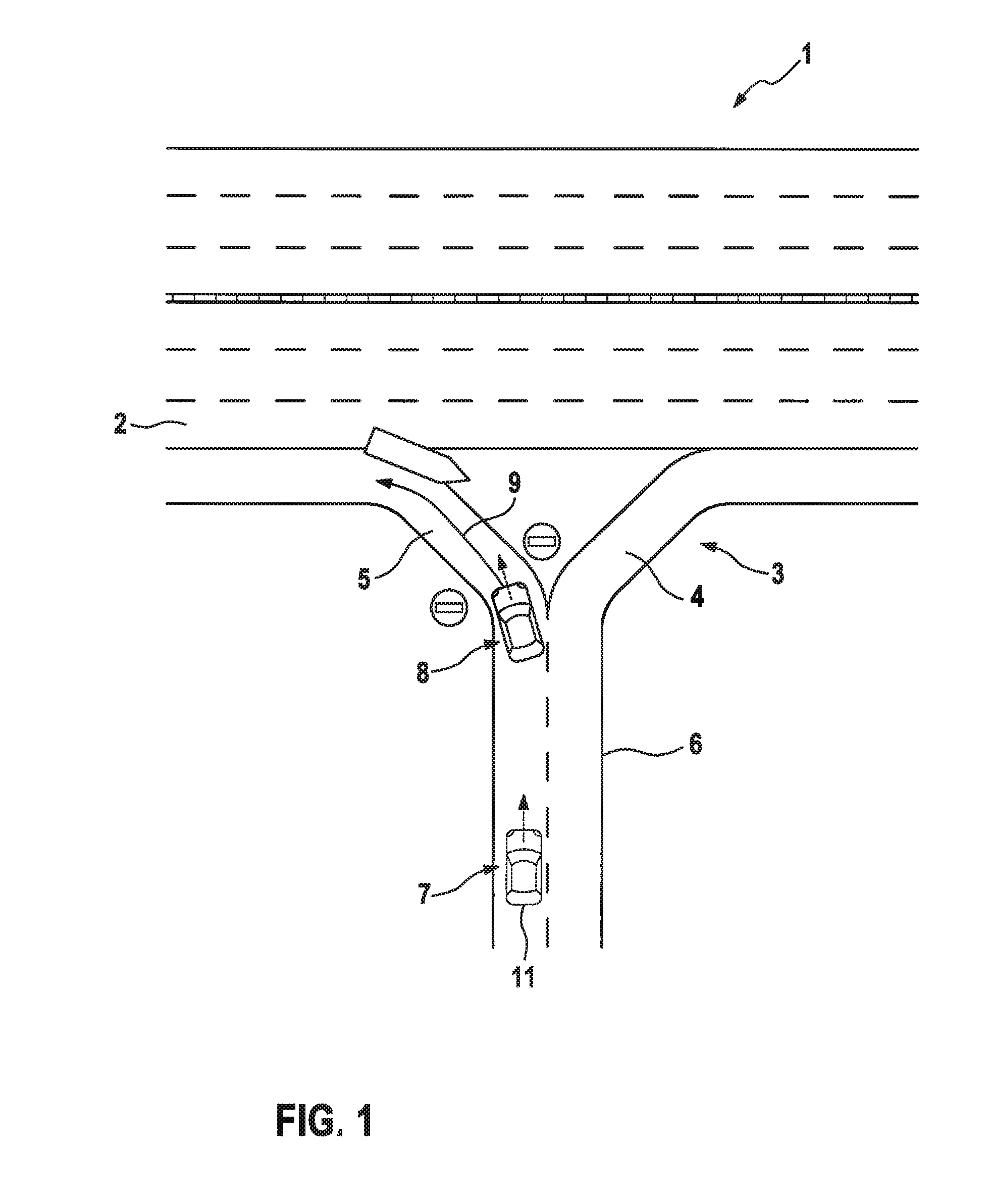

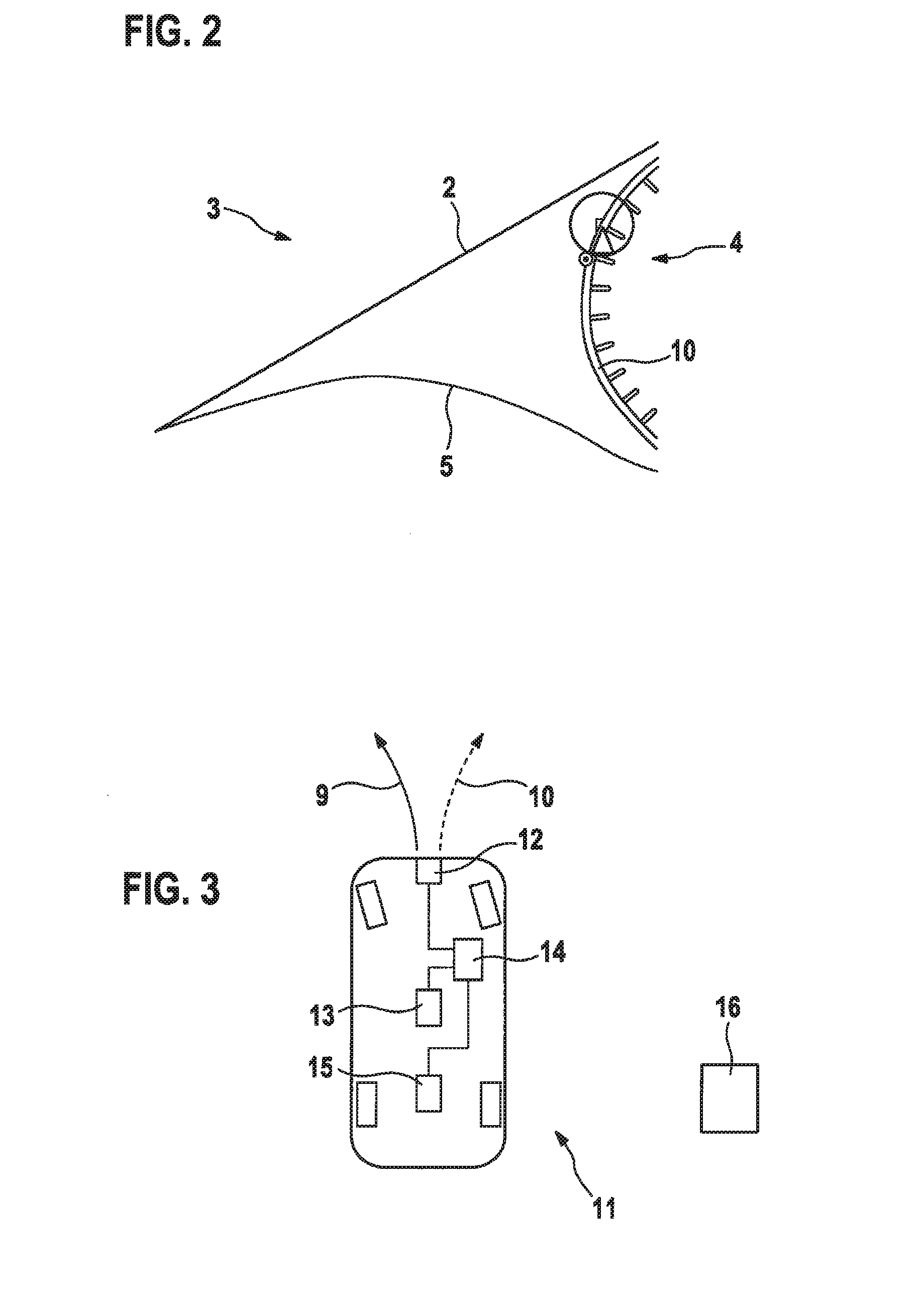

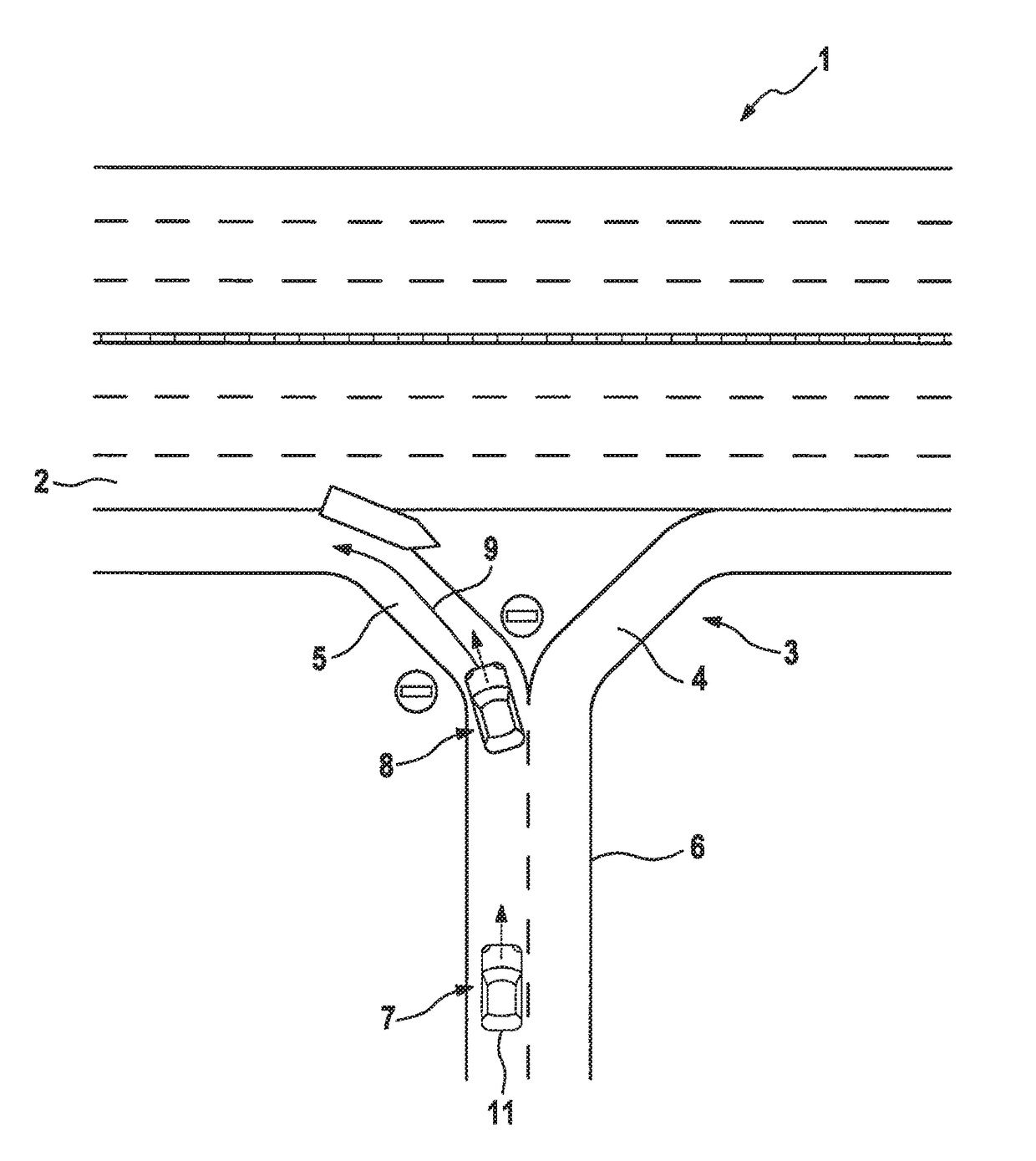

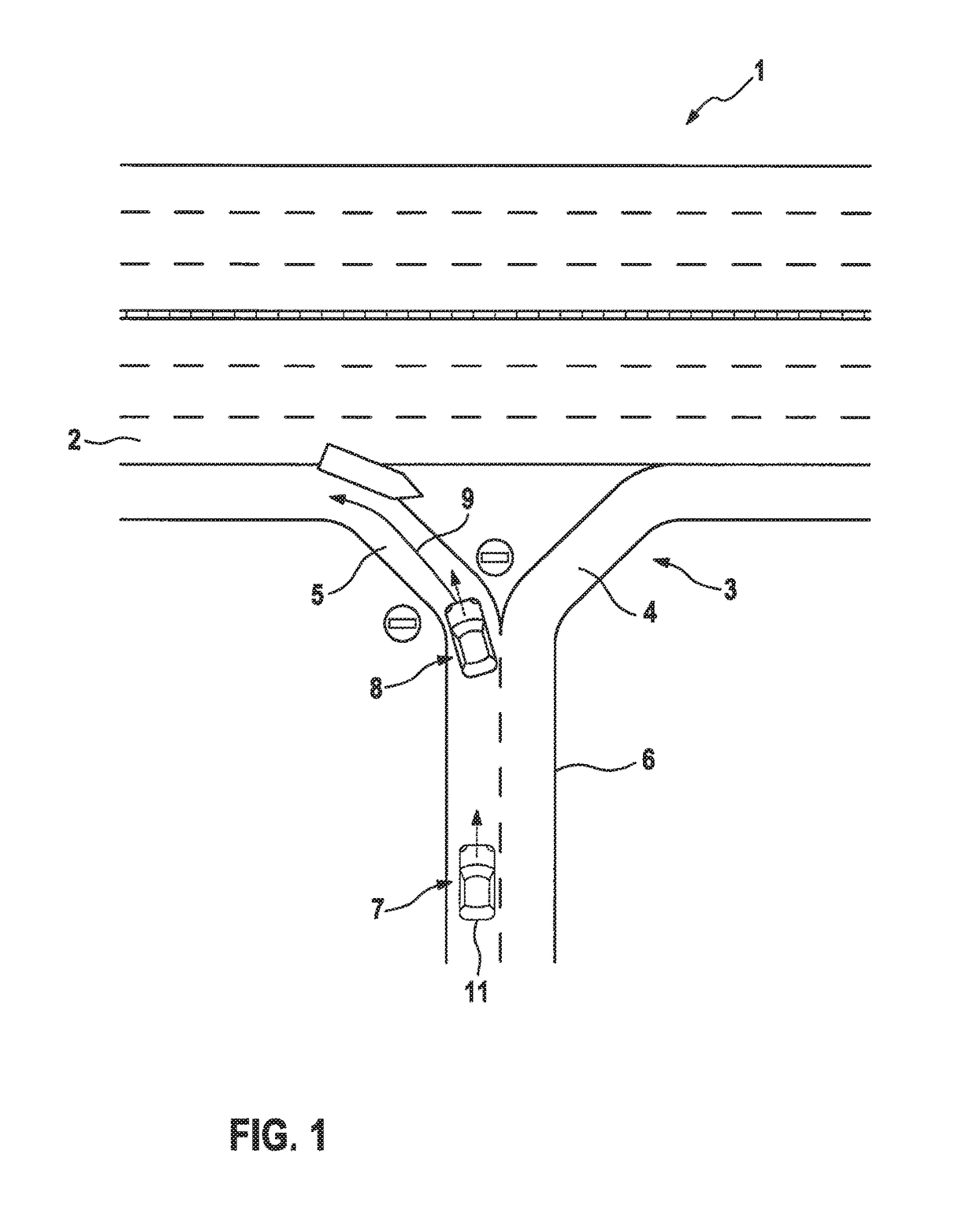

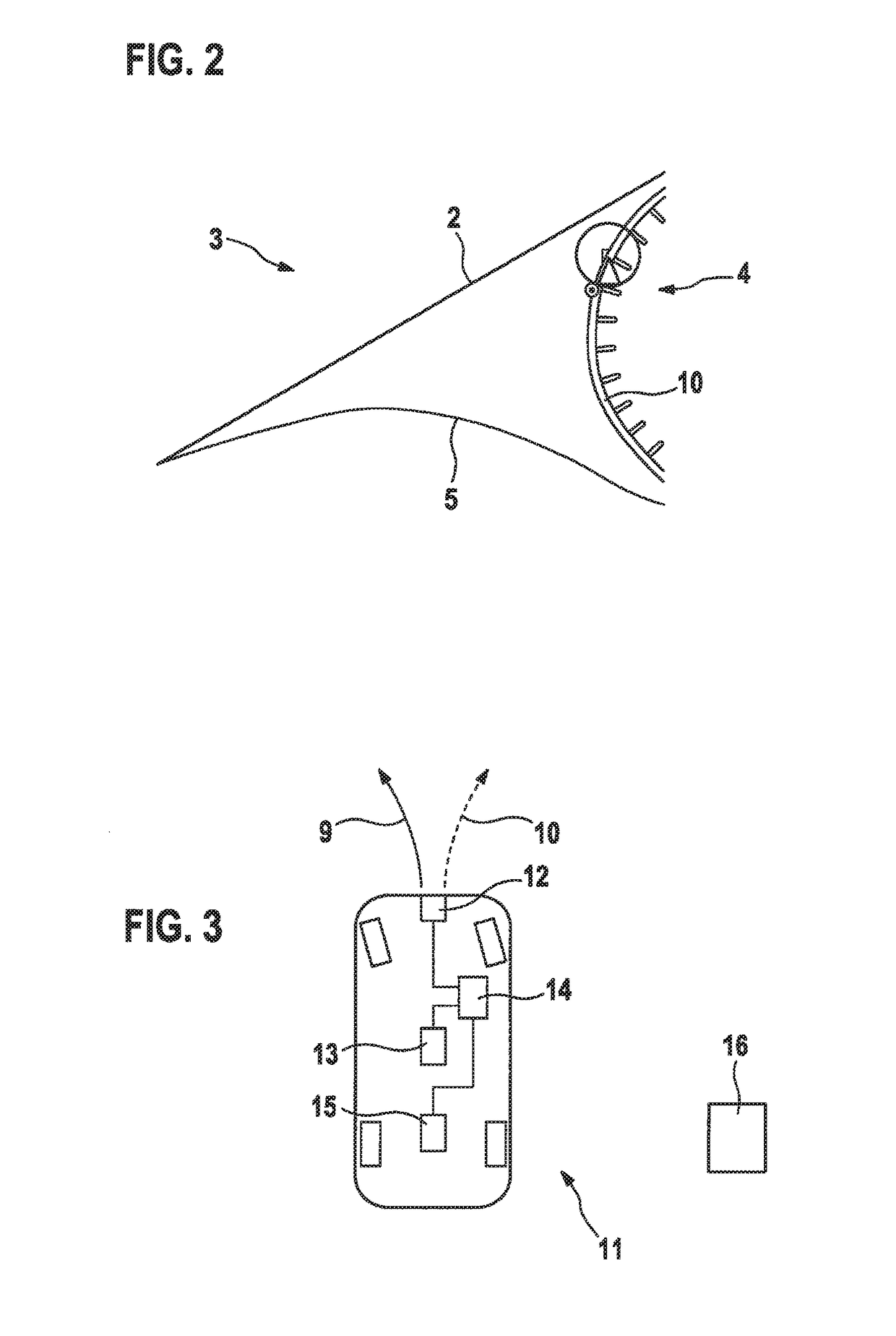

Method and control and detection device for determining the plausibility of a wrong-way travel of a motor vehicle

ActiveUS20160203716A1Solid foundationImprove reliabilityRoad vehicles traffic controlNavigation instrumentsSimulationLimit value

A method for determining the plausibility of a wrong-way travel of a motor vehicle when entering a directional roadway, in which at least one item of curve information of a current travel path of the motor vehicle is detected, at least one item of curve information of a permitted travel path is ascertained, a deviation between the detected item of curve information and the ascertained item of curve information is determined, and a wrong-way travel is plausibilized if a deviation exists or if a limit value for a deviation is breached. A control and detection device for determining the plausibility of a wrong-way travel of a motor vehicle when entering a directional roadway, includes an arrangement for detecting at least one item of curve information of a current travel path of the motor vehicle; an arrangement for ascertaining at least one item of curve information of a permitted travel path; an arrangement for determining a deviation between the detected item of curve information and the ascertained item of curve information; and an arrangement for determining the plausibility of a wrong-way travel if a deviation exists for when a limit value for a deviation is breached.

Owner:ROBERT BOSCH GMBH

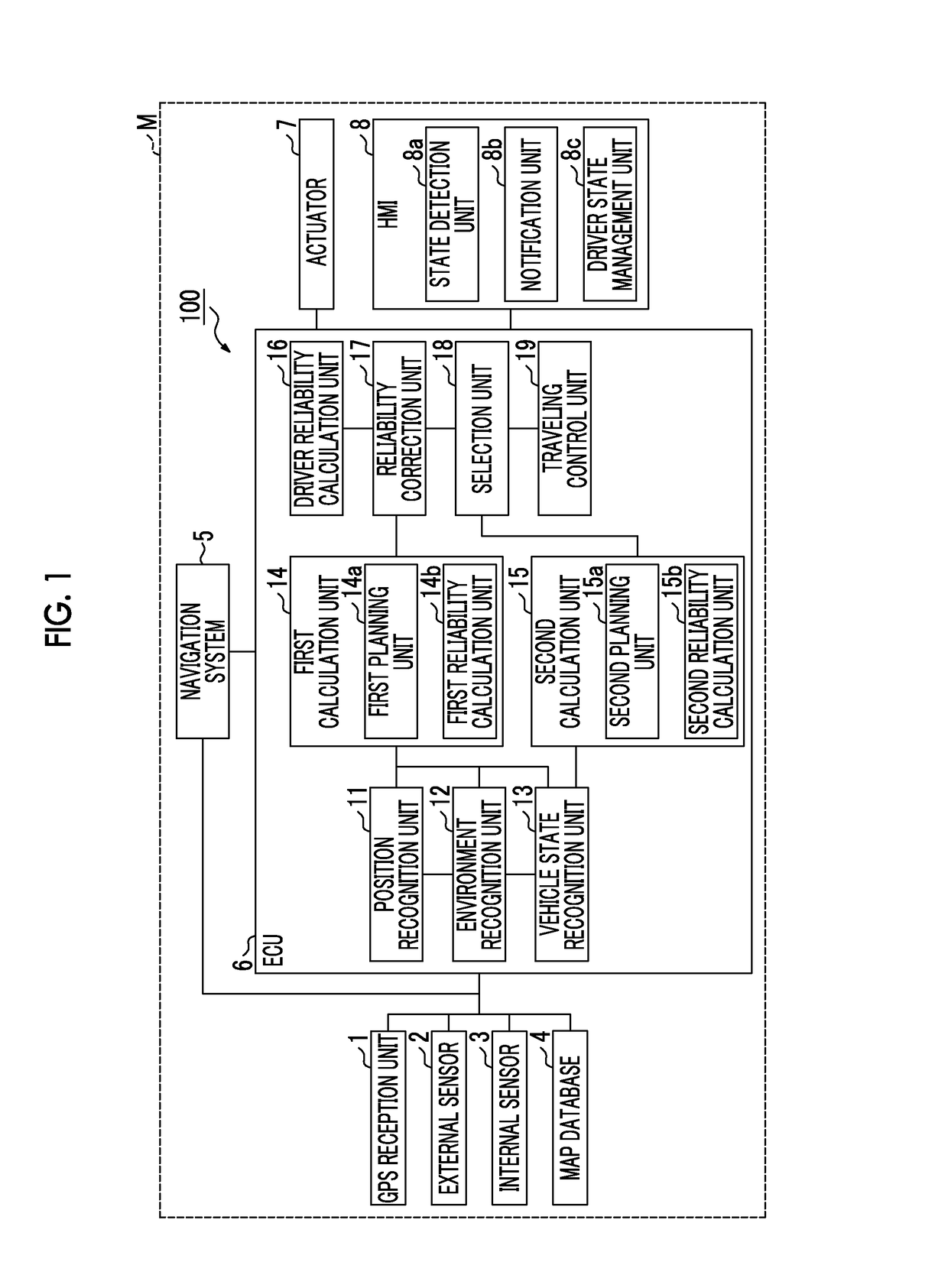

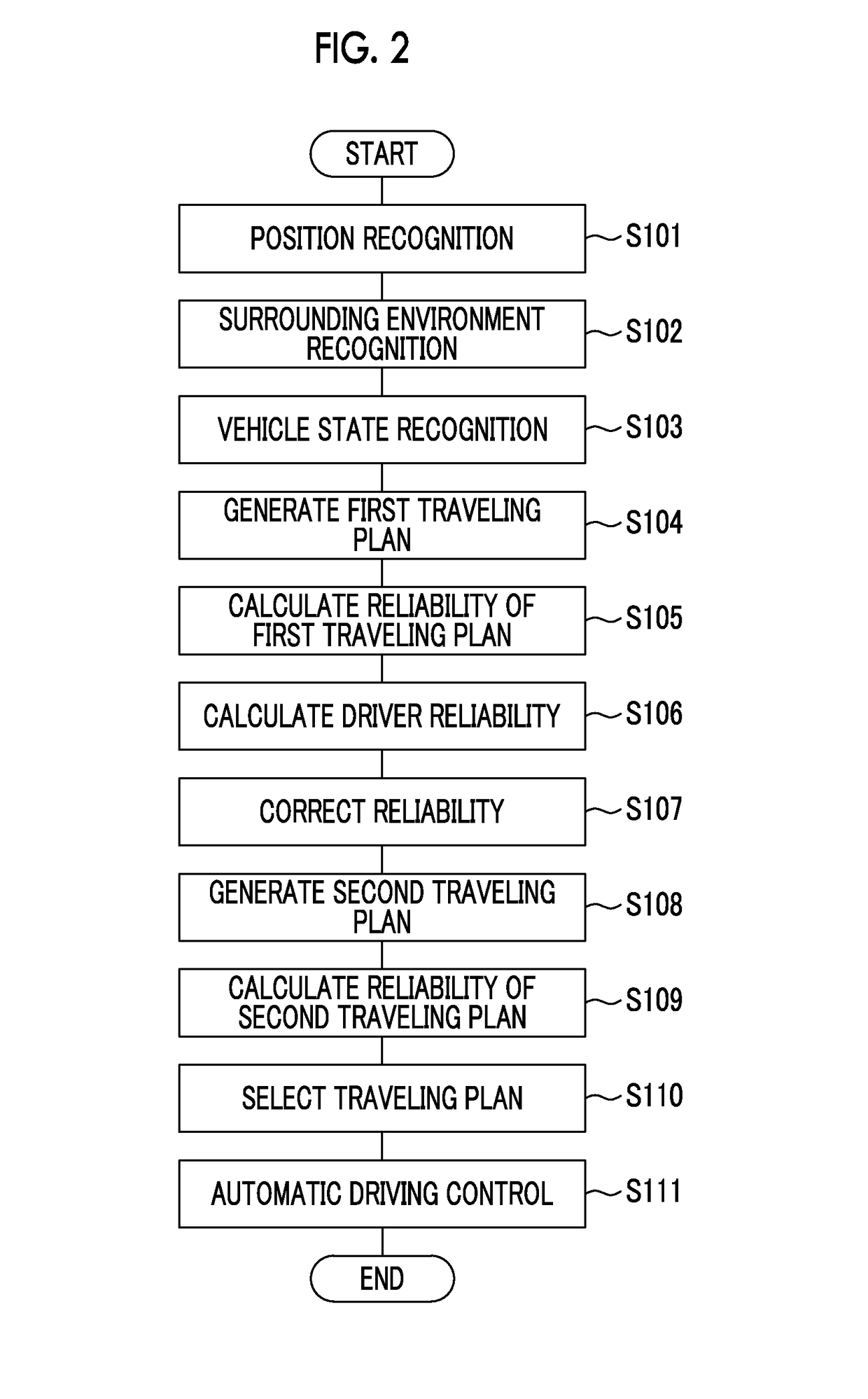

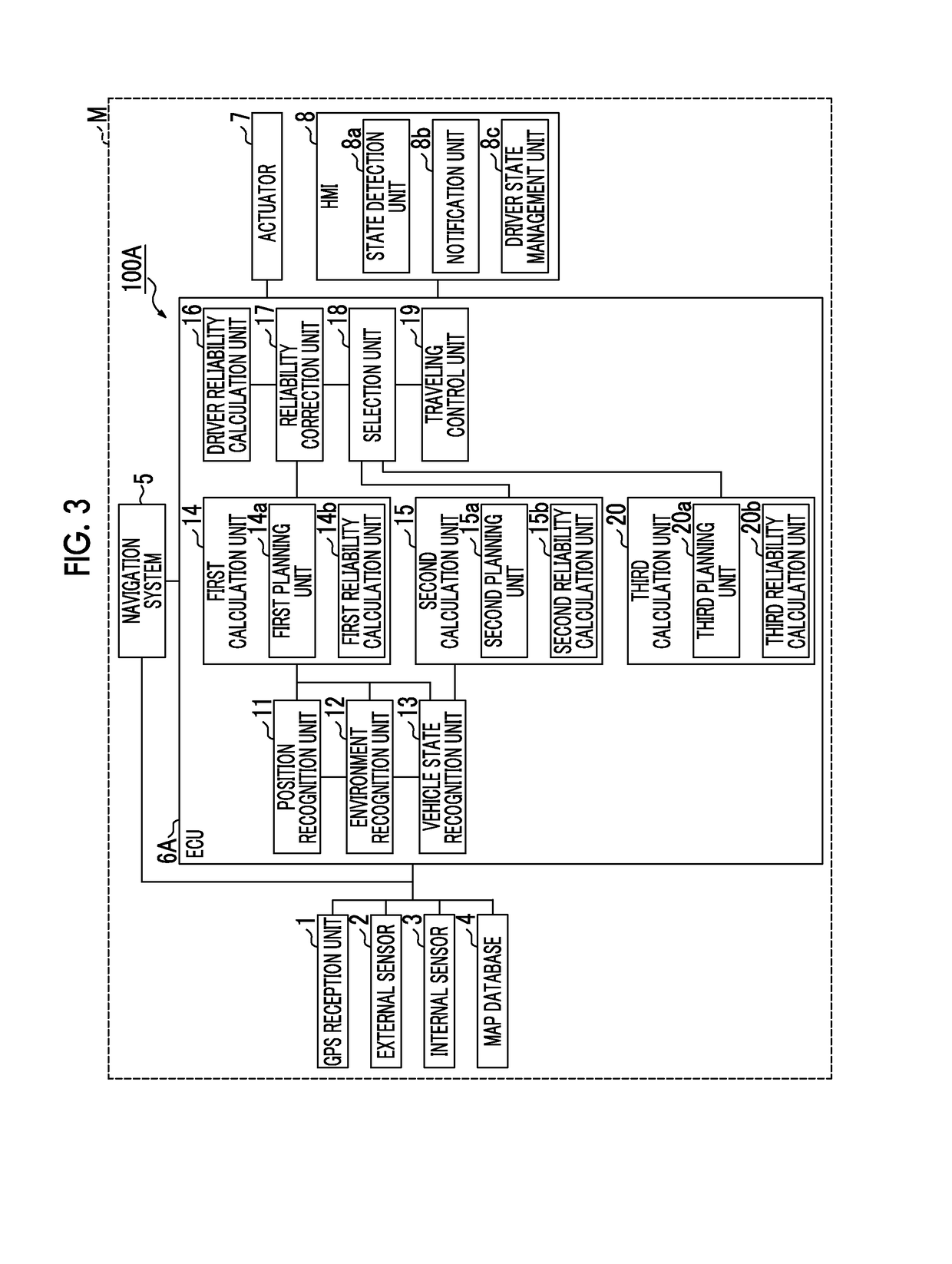

Automatic driving system

ActiveUS20170261984A1Avoid difficult choicesSecure long timeAutonomous decision making processExternal condition input parametersActuatorAutopilot

An automatic driving system includes an actuator and an electronic control unit. The electronic control unit is configured to recognize a position, a surrounding environment, a state of the vehicle. The electronic control unit is configured to generate a first traveling plan based on the recognized position, the recognized surrounding environment, and the recognized state of the vehicle and calculate reliability of the first traveling plan. The electronic control unit is configured to generate a second traveling plan of the vehicle based on one or two of the recognized position, the recognized surrounding environment, and the recognized state of the vehicle and calculate reliability of the second traveling plan. The electronic control unit is configured to select a traveling plan having the higher reliability out of the first traveling plan and the second traveling plan, and control the traveling of the vehicle by the actuator.

Owner:TOYOTA JIDOSHA KK

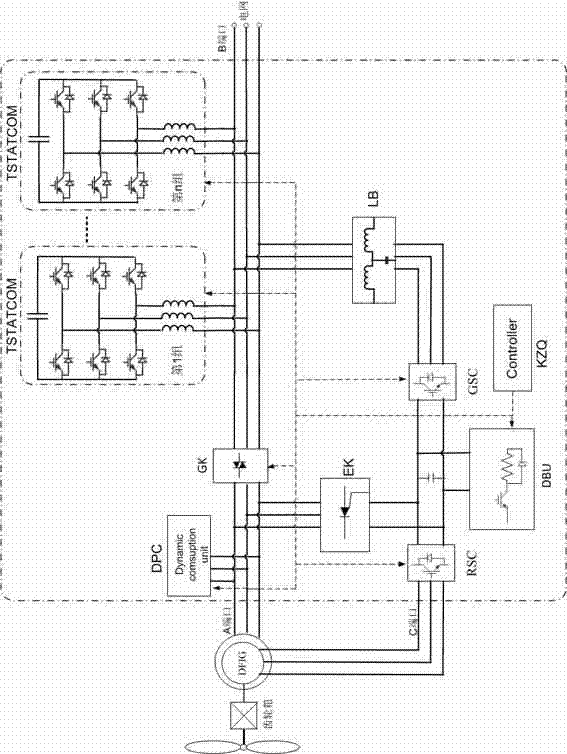

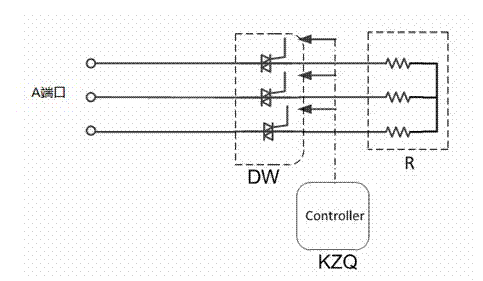

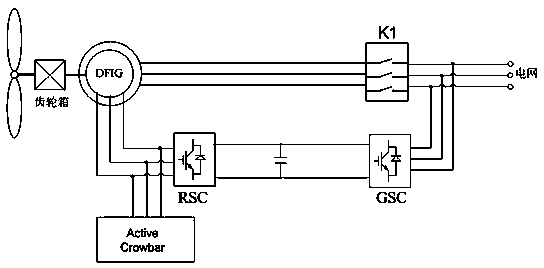

DVR (Dynamic Voltage Restorers)-based low-voltage ride through support device of wind generating set

InactiveCN102447266AAvoid distortionExtended service lifeSingle network parallel feeding arrangementsReactive power adjustment/elimination/compensationVIT signalsPower inverter

The invention relates to a DVR (Dynamic Voltage Restorers)-based low-voltage ride through support device of a wind generating set, consisting of a DVR, an active power release circuit, a network-side reactive current injection inverter and a controller, wherein the DVR is provided with a port A, a port B and a port C, wherein the port A is connected with the output end of the wind generating set, the port B is connected with a grid, a filter input side of the DVR is connected to a main loop in a serial connection mode, an output side of an H bridge inverter is the port C, and a direct-current capacitor is arranged in the port C; the reactive current injection inverter is provided with a port AC and a port DC, wherein the port AC is connected with the port B of the DVR, and a direct-current bus capacitor is arranged at the port DC; a stator Crowbar is provided with a port AC and a port DC, wherein the port AC is connected with the port A of the DVR, and the direct-current bus capacitor is arranged at the port DC; and a working state of the DVR is controlled by a triggering signal sent by the controller.

Owner:NANJING JUNENG ELECTRICAL CONTROL AUTOMATION EQUIP

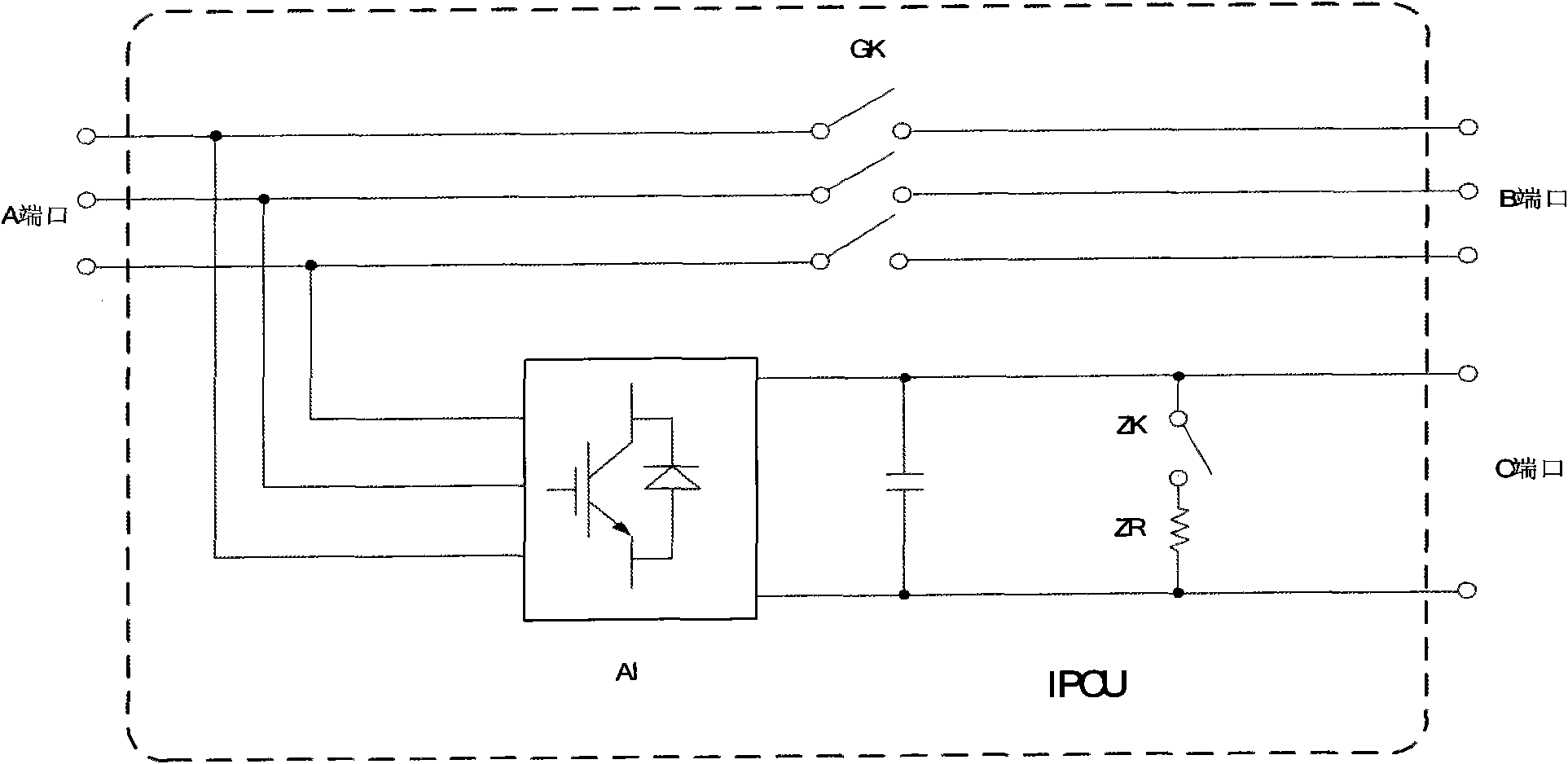

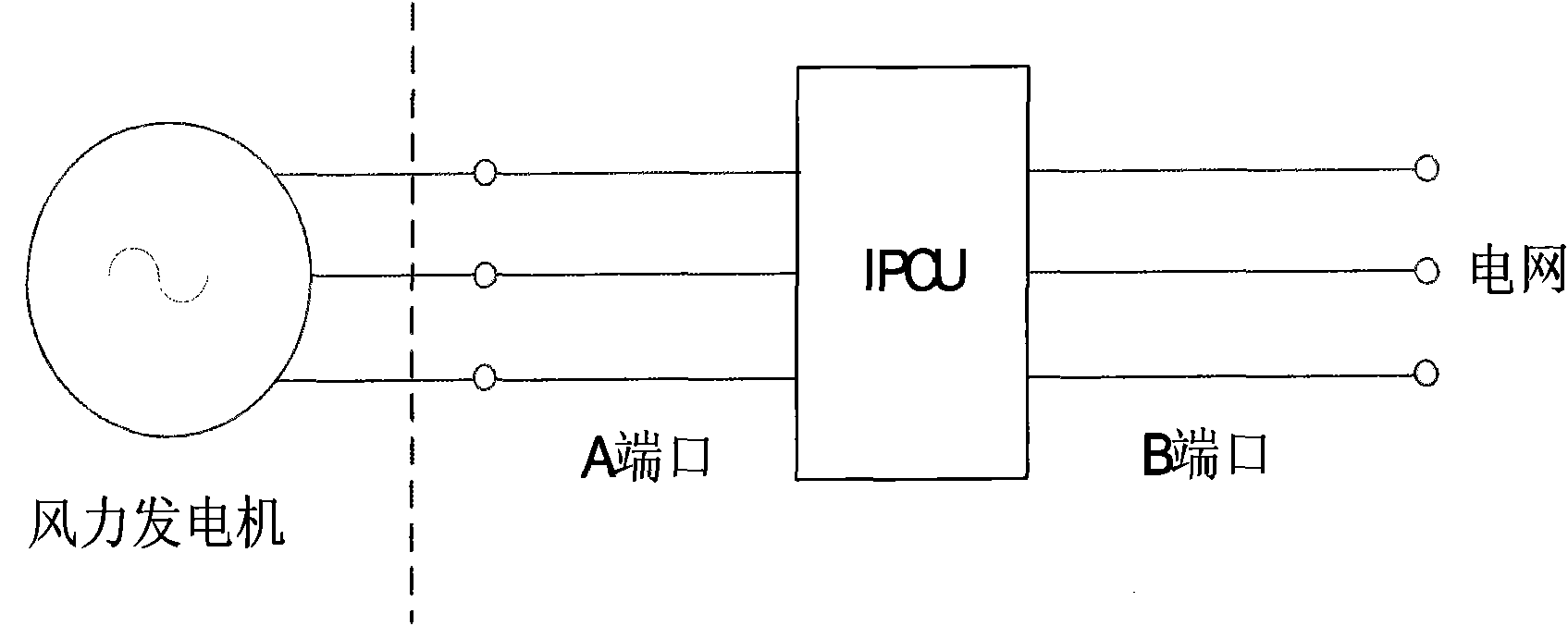

Intelligent power control unit for low voltage ride through and application thereof

InactiveCN102055207APerfect low voltage ride through capabilityReliable travelTransistorPower network operation systems integrationStator voltageBridge type

The invention relates to an intelligent power control unit (IPCU) for low voltage ride through, which comprises a port A, a port B, a port C, a built-in auxiliary frequency converter for stabilizing stator voltage at the moment of ride through and for providing reactive power, and a controllable active load for absorbing active power; a high speed switch is arranged between the port A and the port B; the built-in auxiliary frequency converter is arranged between the port A and the port C; and the built-in auxiliary frequency converter and the controllable active load are sequentially connected between the port A and the port C in series or connected with the controllable active load from the port A through a three-phase bridge-type rectifier, so that the branch circuit of the built-in auxiliary frequency converter is connected with that of the controllable active load in parallel. When the IPCU is used, the port A is connected with the stator winding of a wind generating set, the port B is connected with the power network, and the port C is connected with the DC bus of an external auxiliary frequency converter.

Owner:NANJING HIGH DRIVE ELECTROMECHANICAL AUTOMATION EQUIP CO LTD

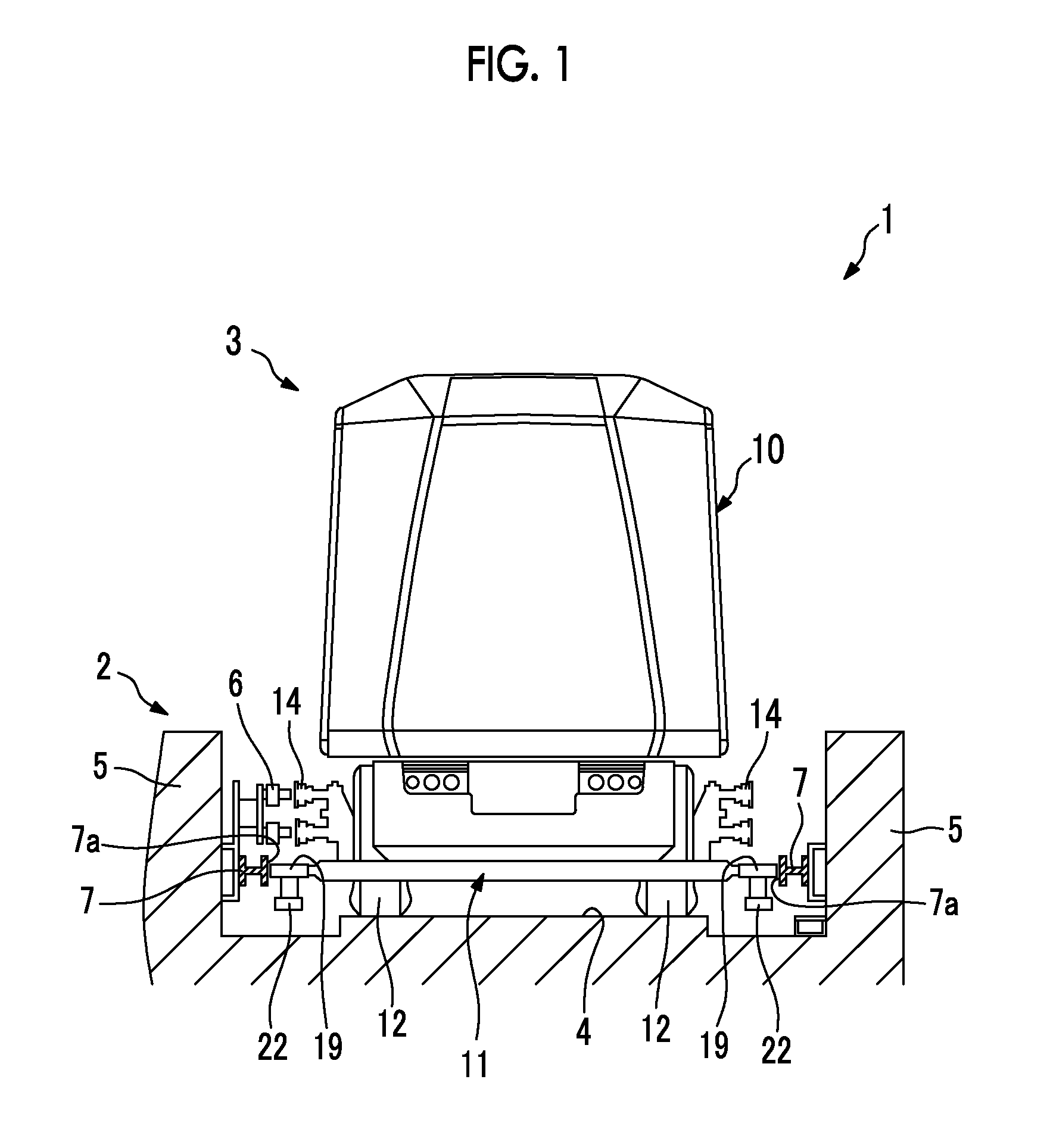

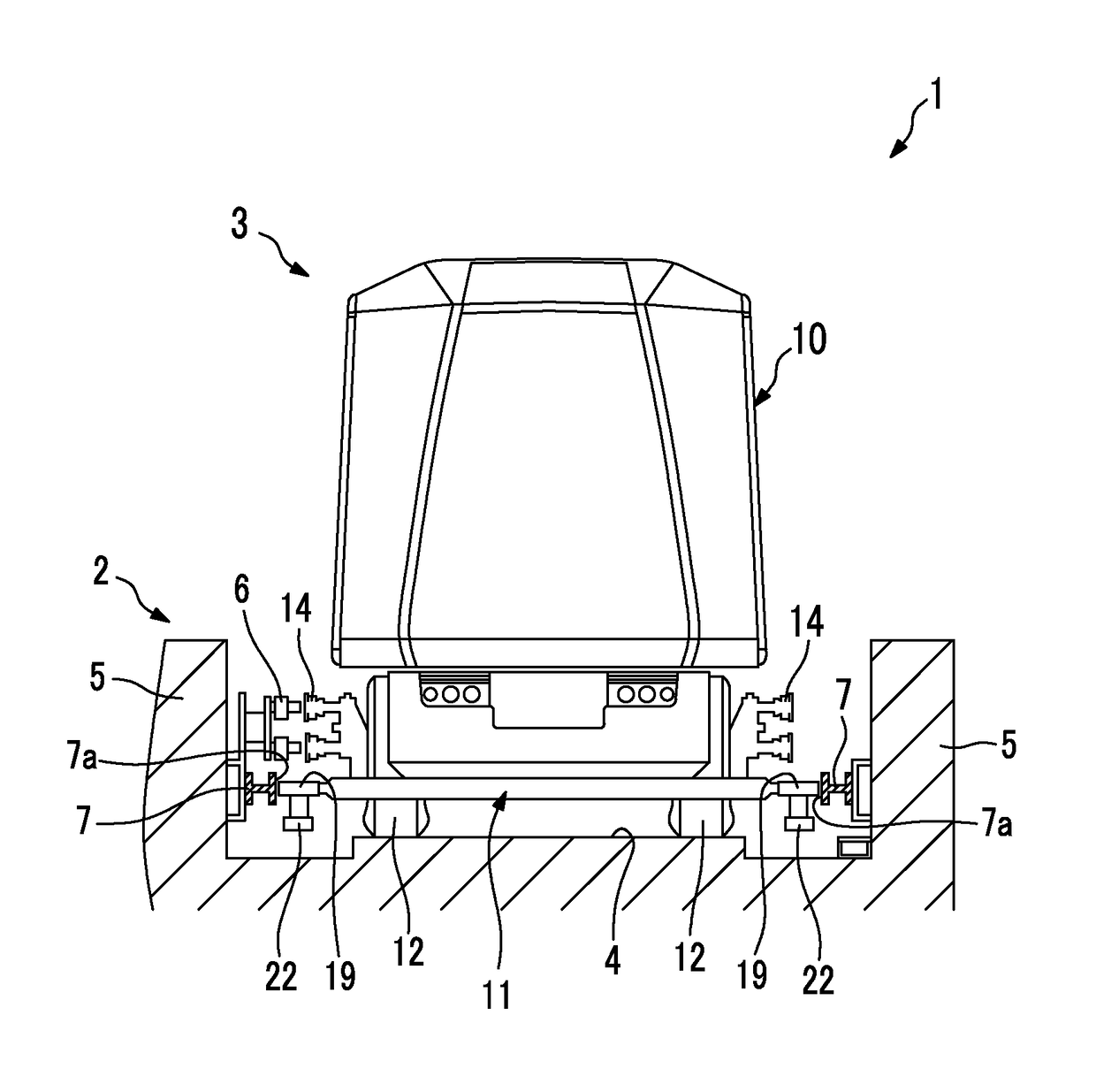

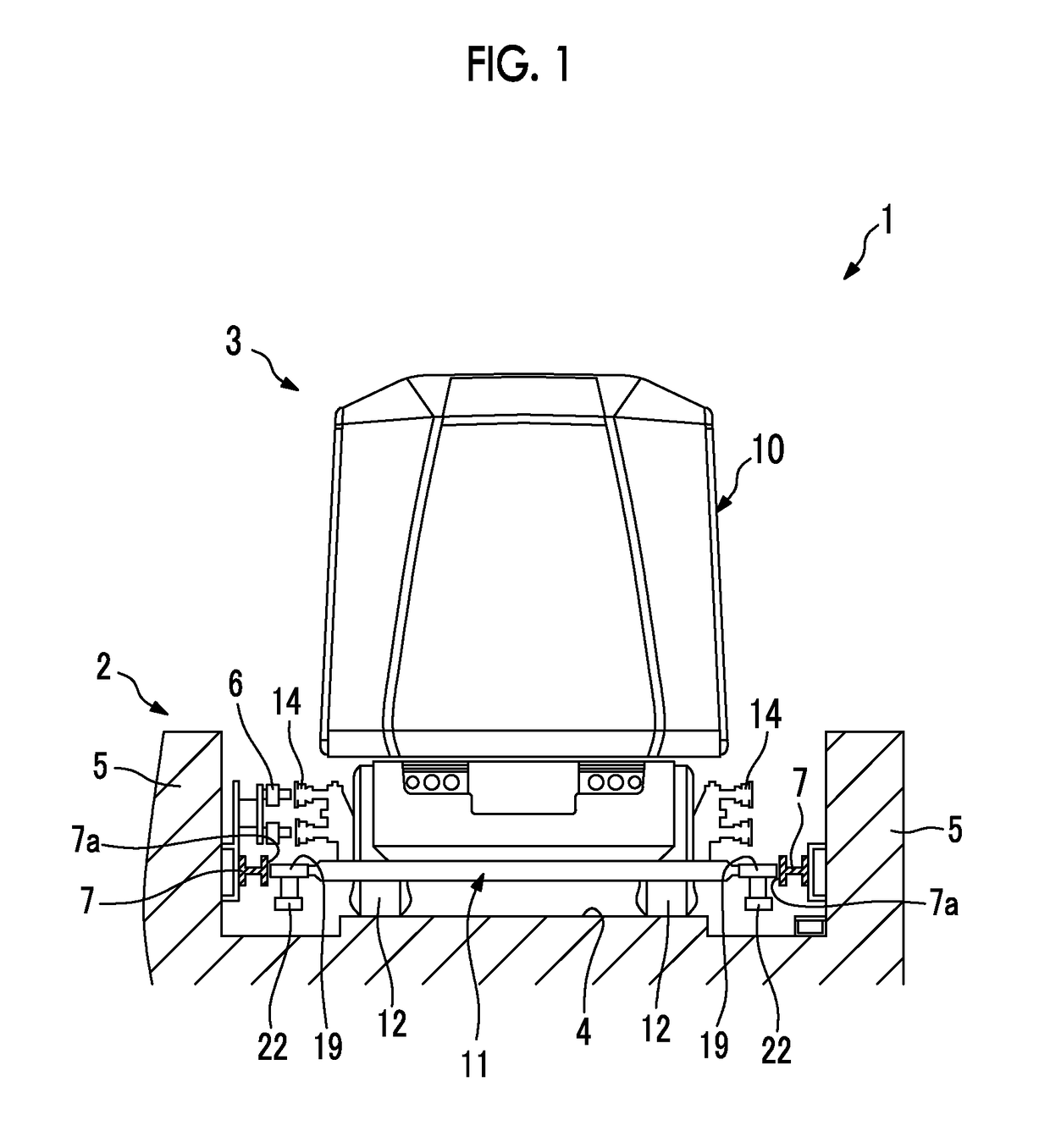

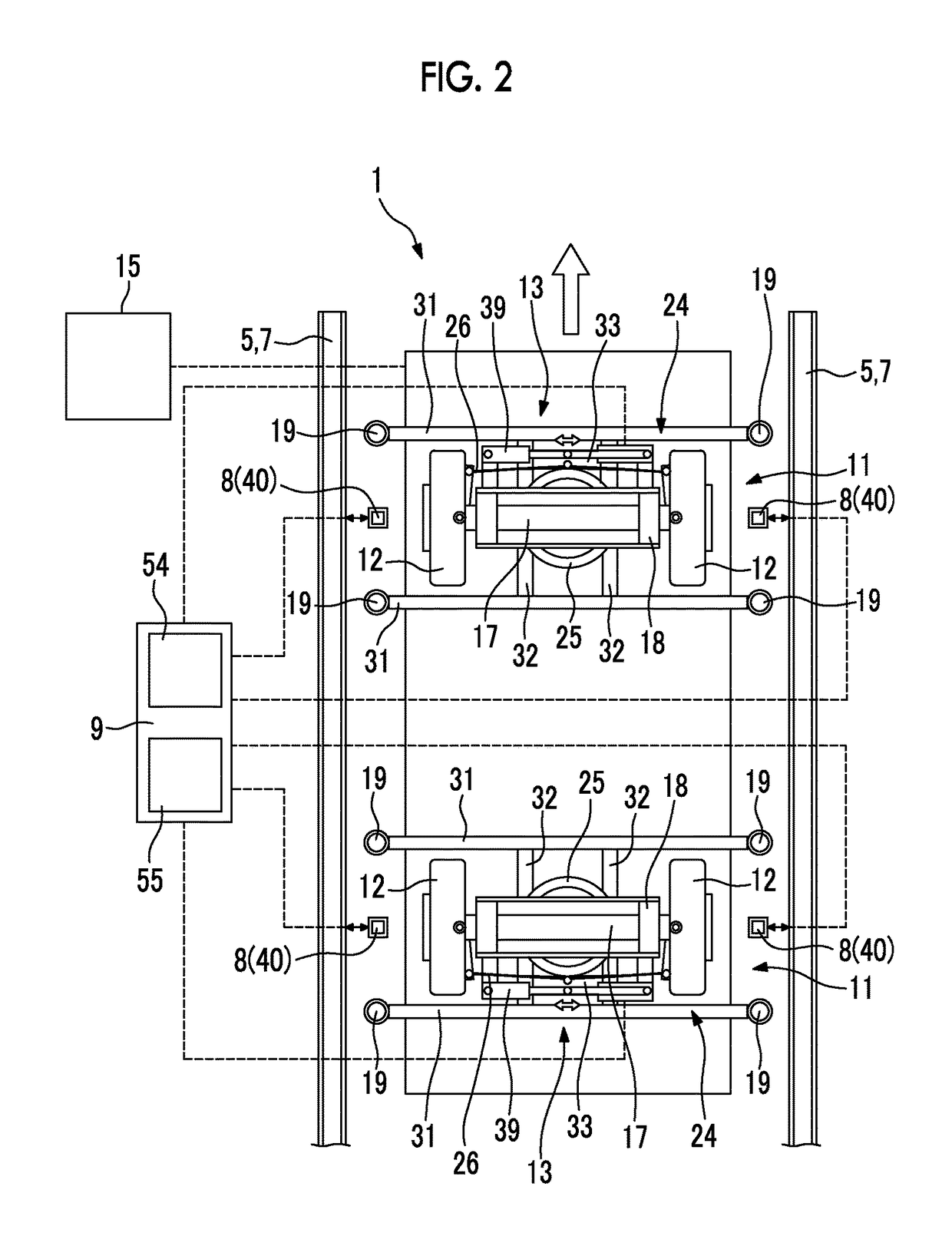

Vehicle and track transportation system

ActiveUS20150314796A1Reliable travelEasy to controlMonorailsAutomatic systemsLocation detectionRoad surface

A vehicle includes running wheels traveling on traveling road surfaces of tracks; a pair of position detection parts disposed at an interval in a width direction that output signals by detecting a distance from measured objects; a control unit controlling the amount of steering of the running wheels according to the signals from the position detection parts; and a steering mechanism steering the running wheels via the control unit. Each of the position detection parts outputs a signal having characteristics such that the output increases as the distance from the measured objects increases while an output change ratio is decreased in a range wherein the distance from the measured objects is not less than a predetermined value, and is configured such that, when the distance between one position detection part and the measured object is decreased, the distance between the other position detection part and the measured object is increased.

Owner:MITSUBISHI HEAVY IND ENG LTD

Route guidance systems, methods, and programs

InactiveUS8335641B2Reliable travelAnalogue computers for vehiclesInstruments for road network navigationGuidance systemComputer science

Systems, methods, and programs search for a route to a destination and set a recommended travel lane, based on the searched for route. The systems, methods, and programs provide lane guidance to lead the vehicle into the recommended lane. The systems, methods, and programs receive a current position of the vehicle and determine a movement direction of the vehicle, based on the received current position and the recommended lane. The systems, methods, and programs determine whether to provide lane guidance based on the movement direction of the vehicle.

Owner:AISIN AW CO LTD

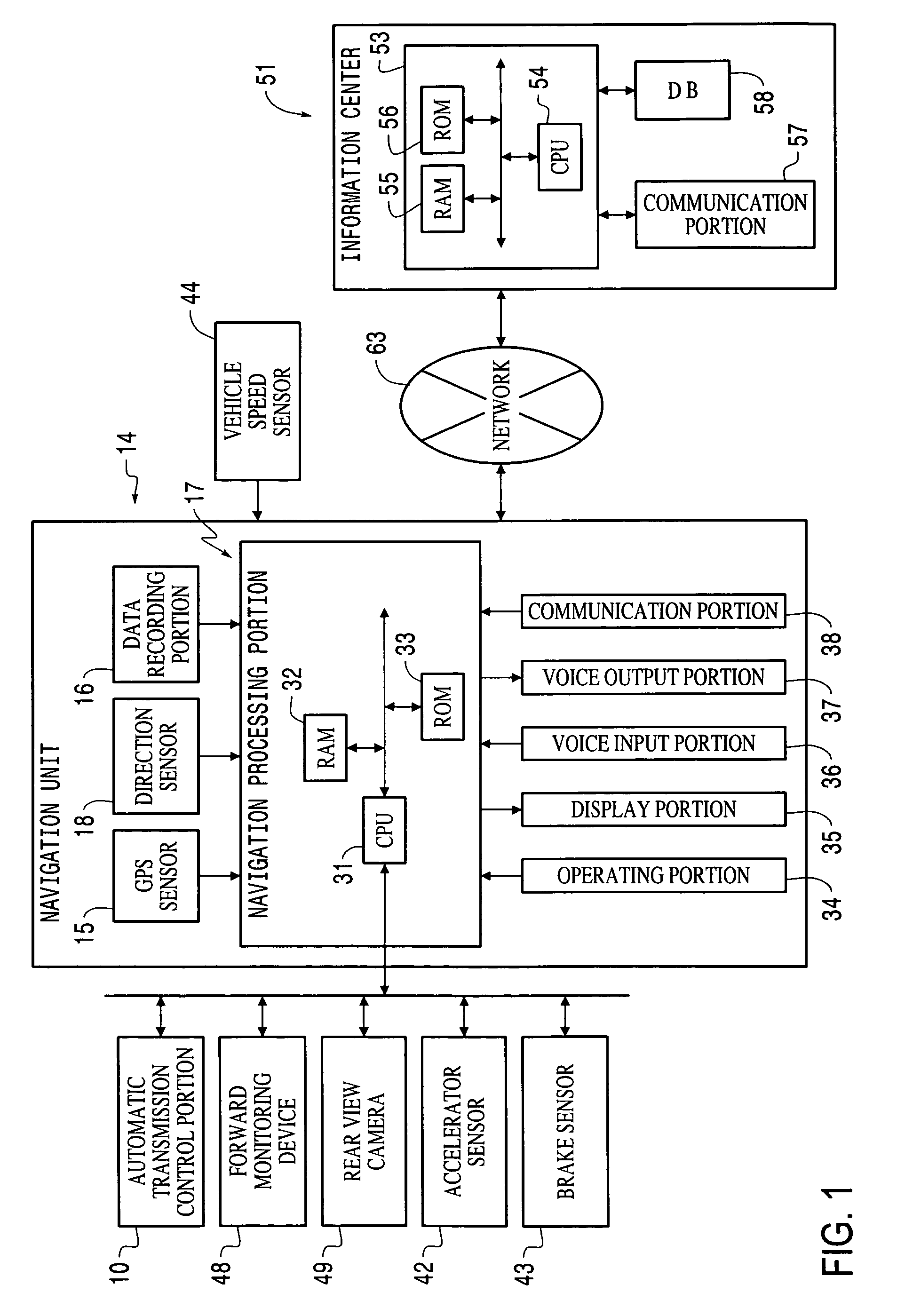

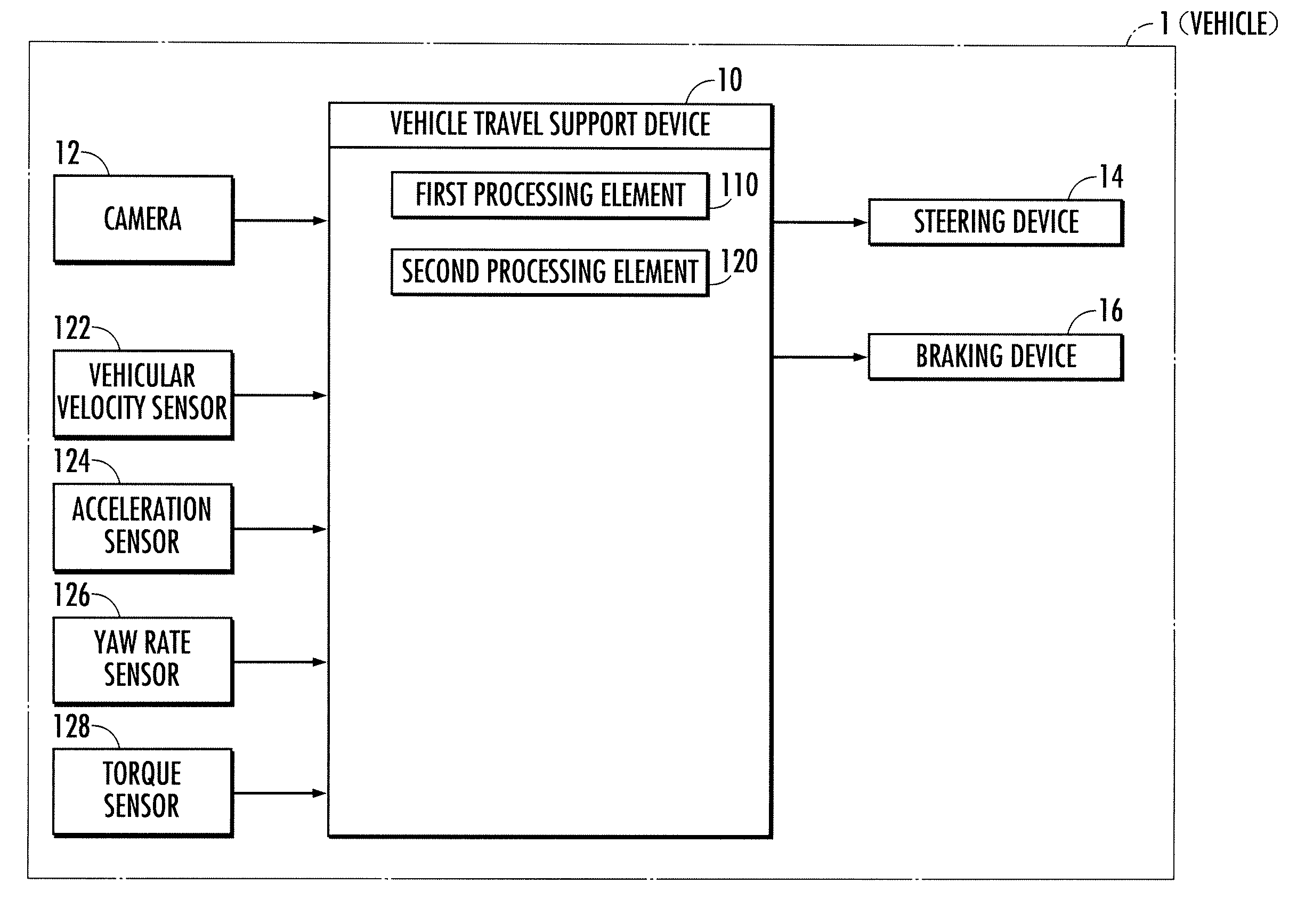

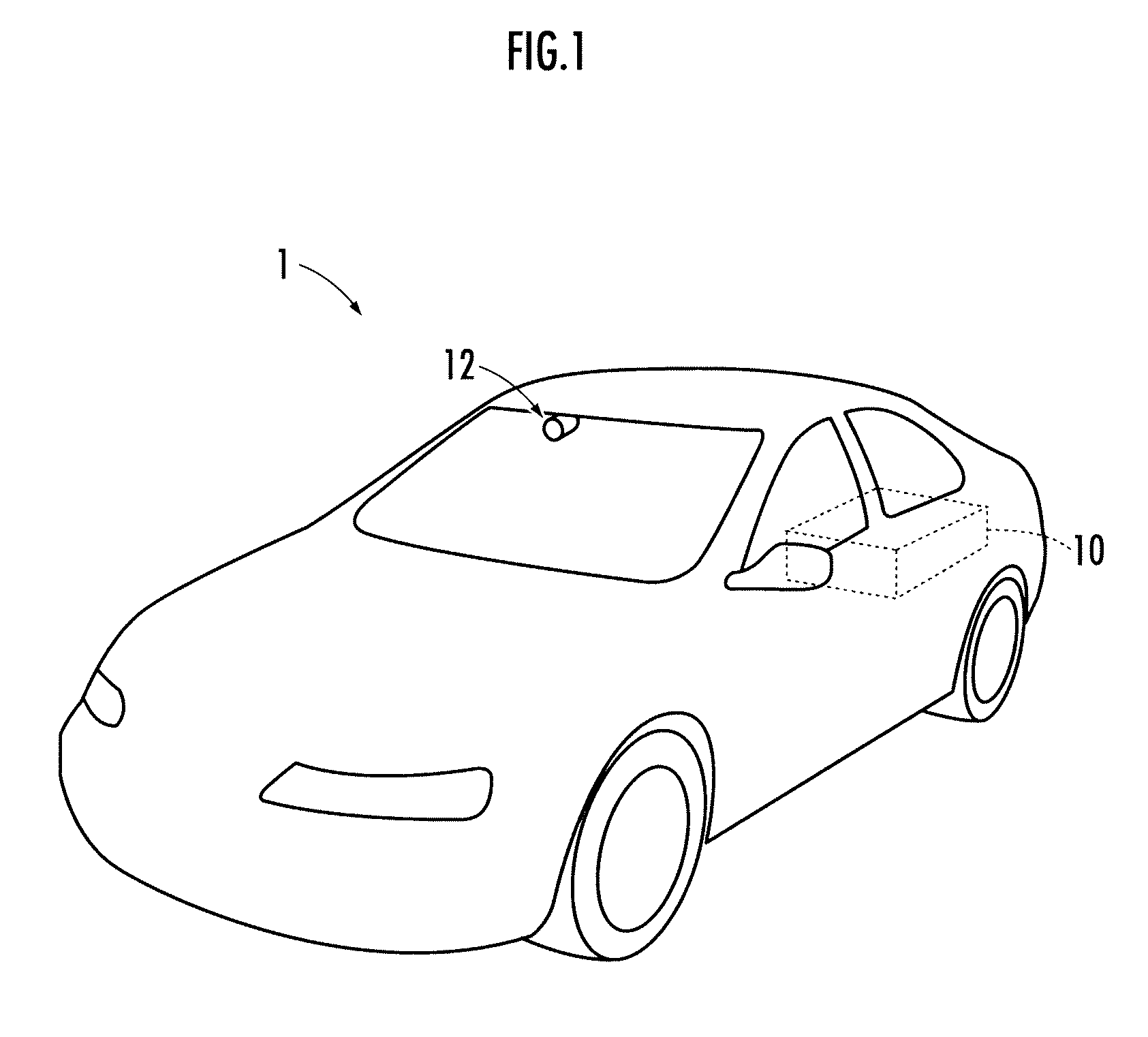

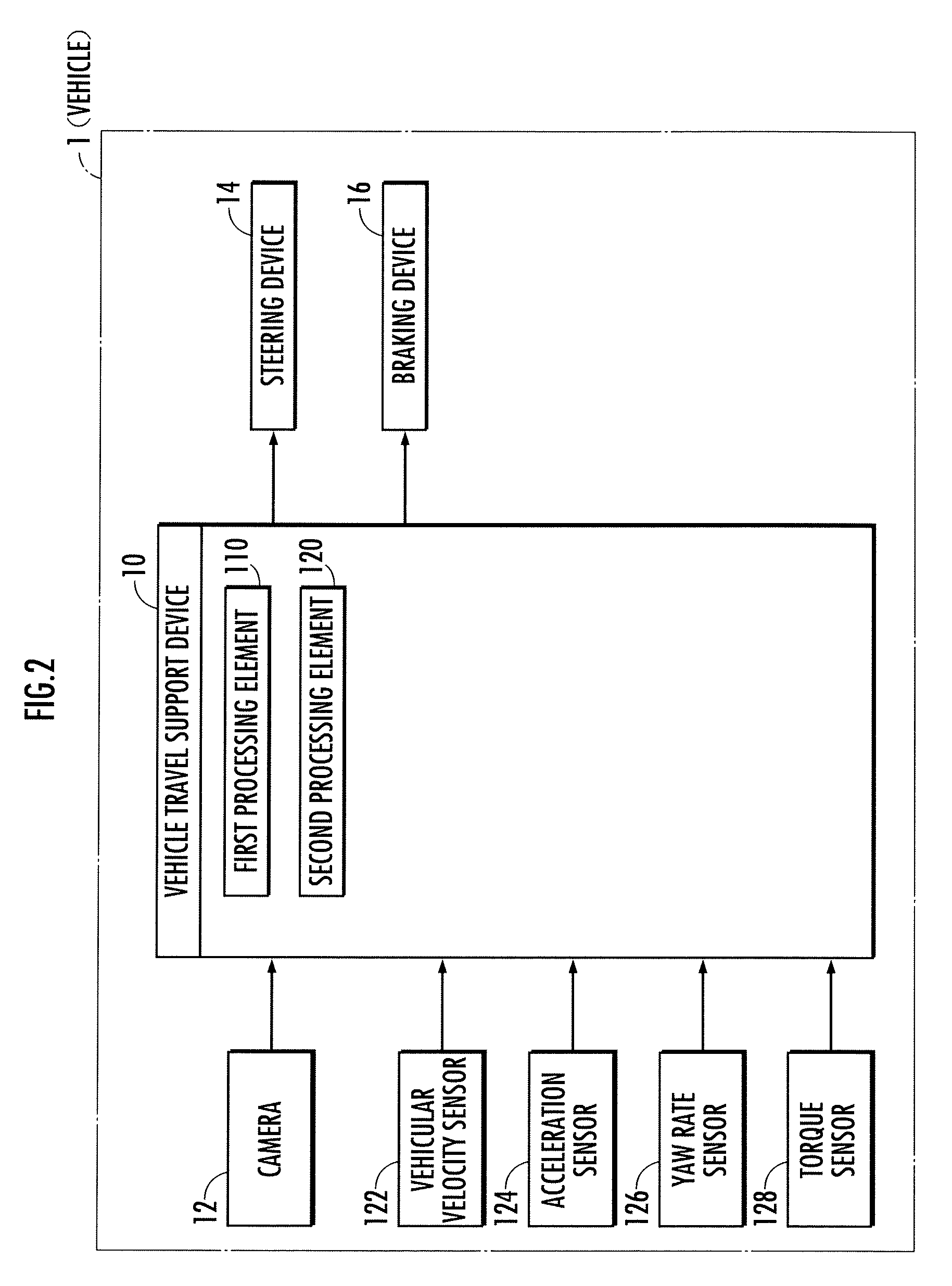

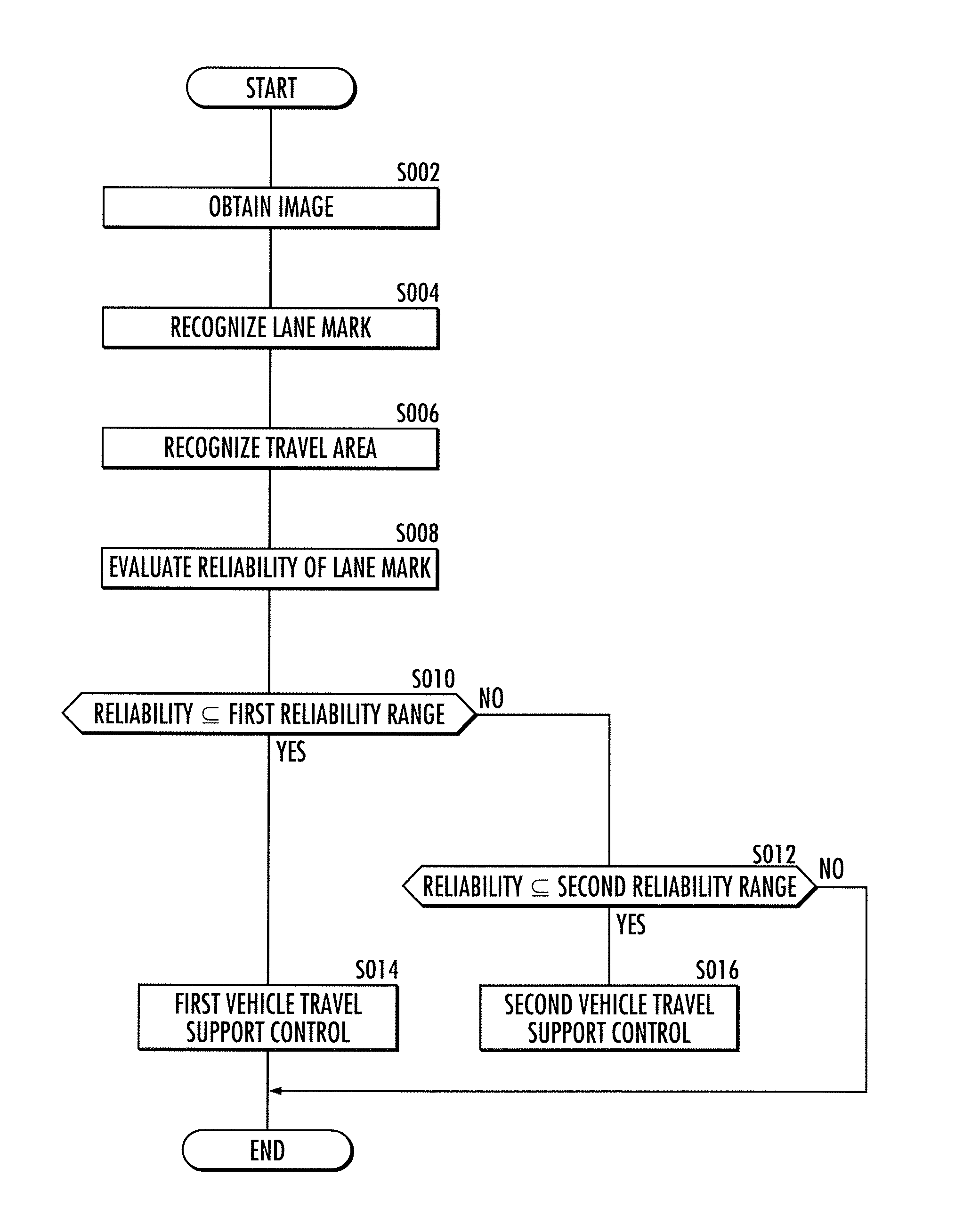

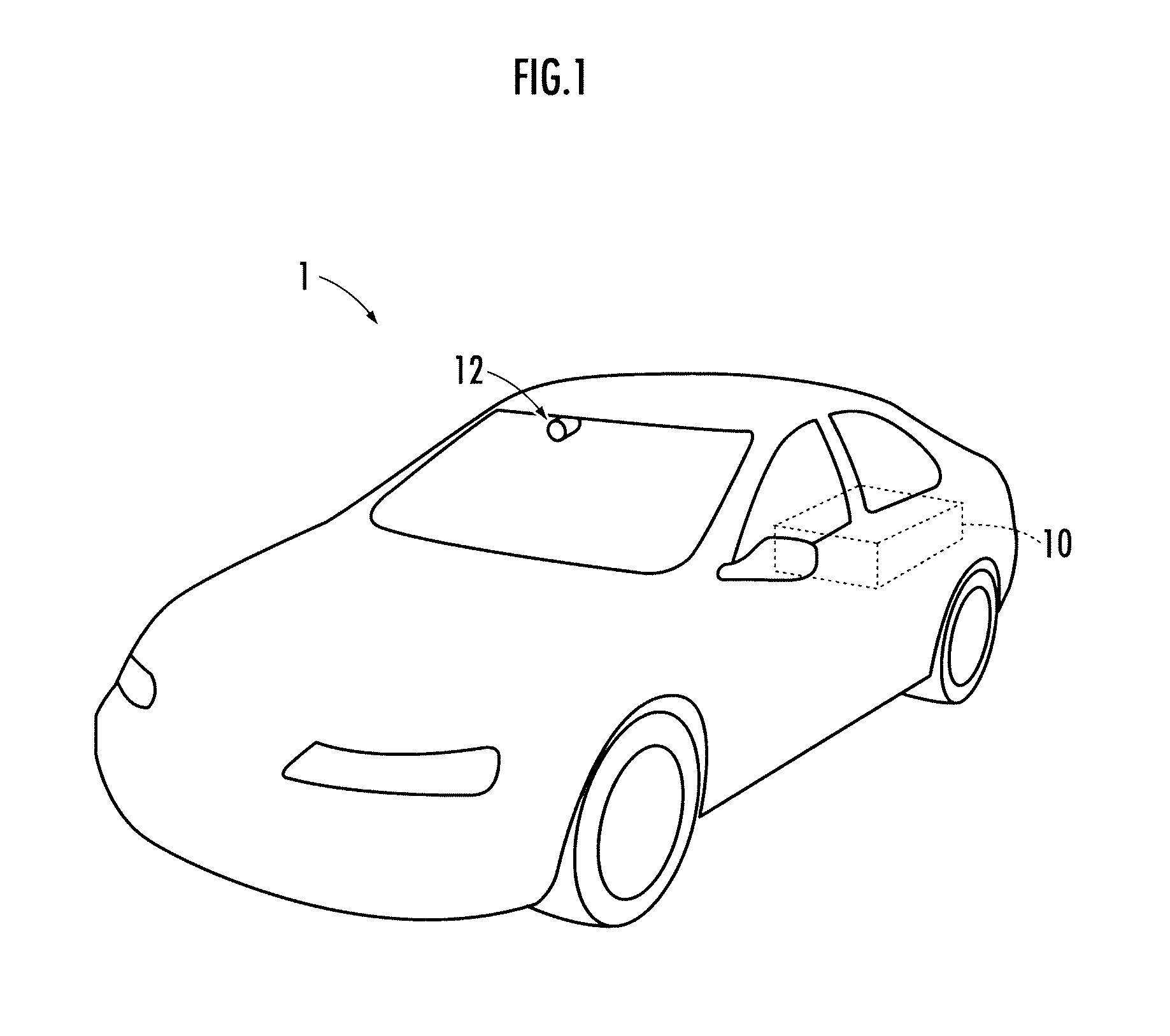

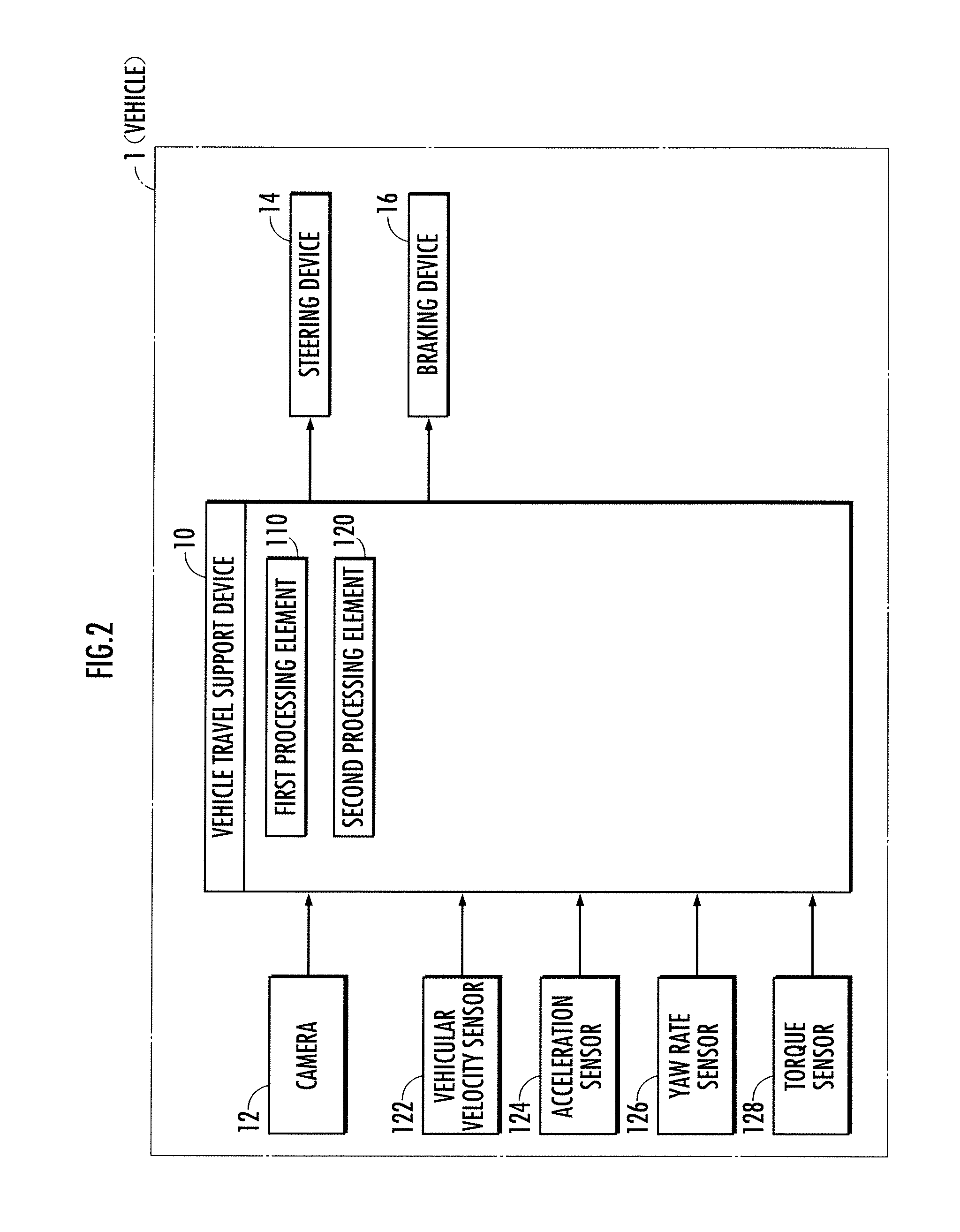

Vehicle travel support device, vehicle, and vehicle travel support program

ActiveUS20100332050A1Continuous operationImprove reliabilityDigital data processing detailsAnti-collision systemsEngineeringDependability

Owner:HONDA MOTOR CO LTD

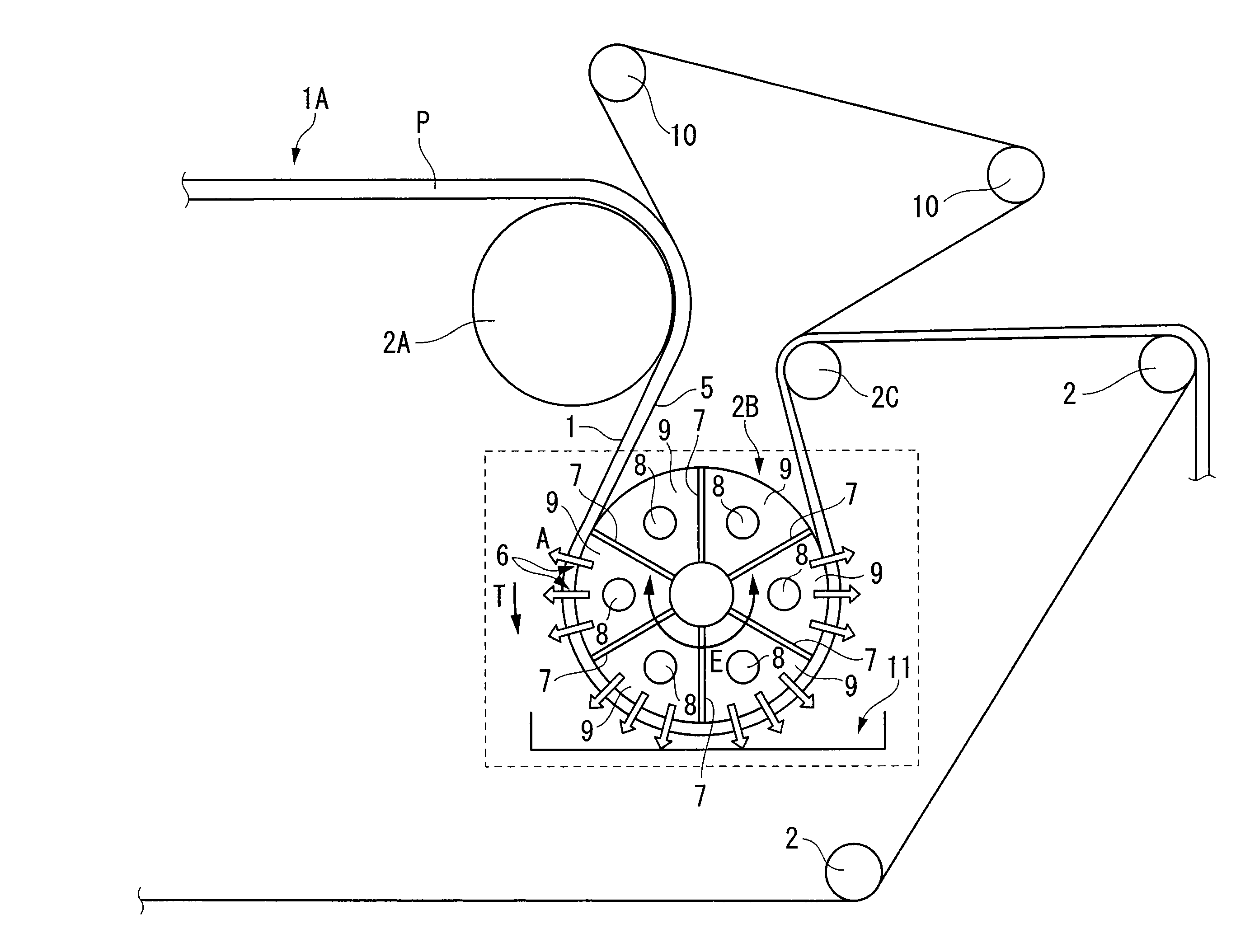

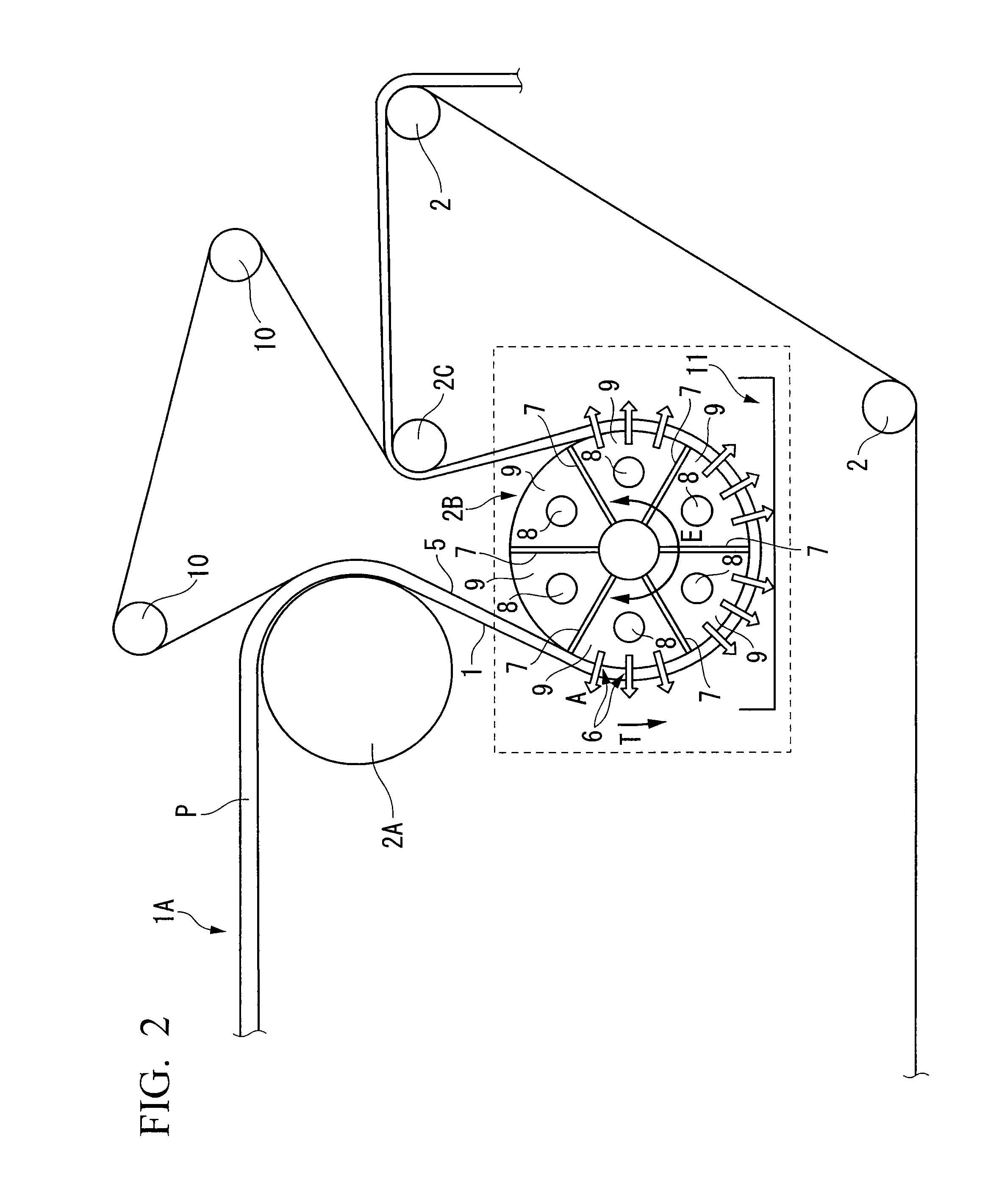

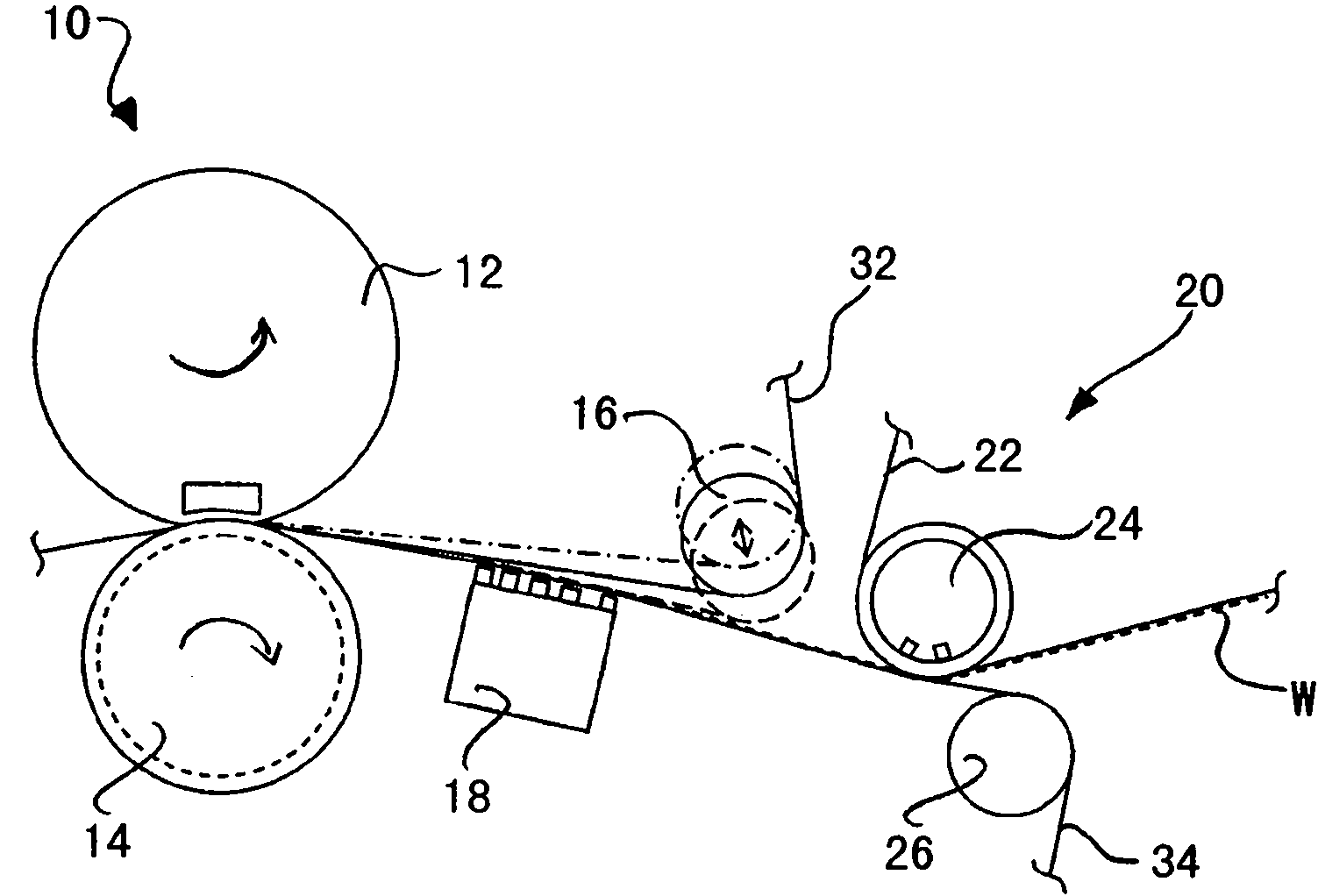

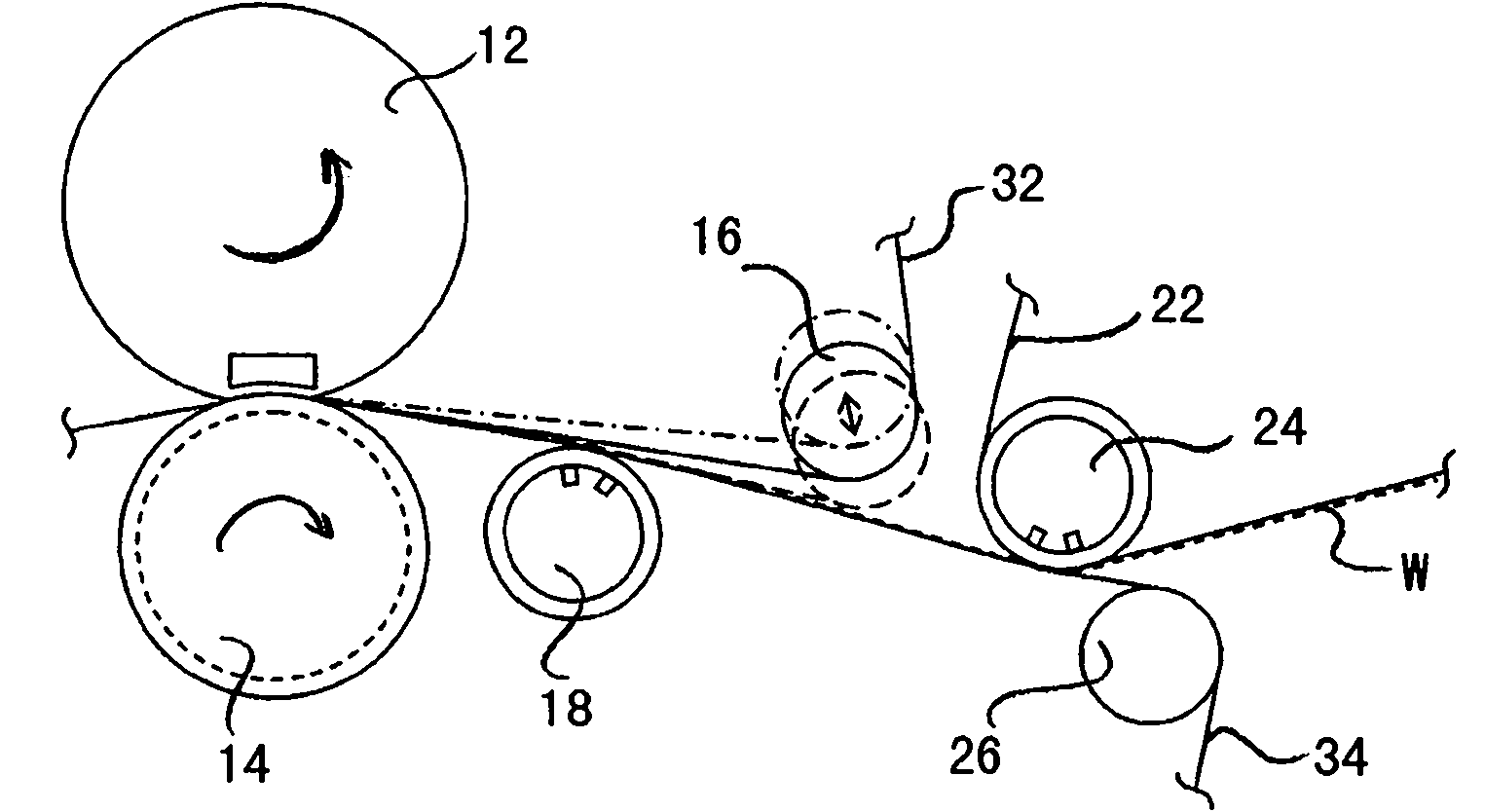

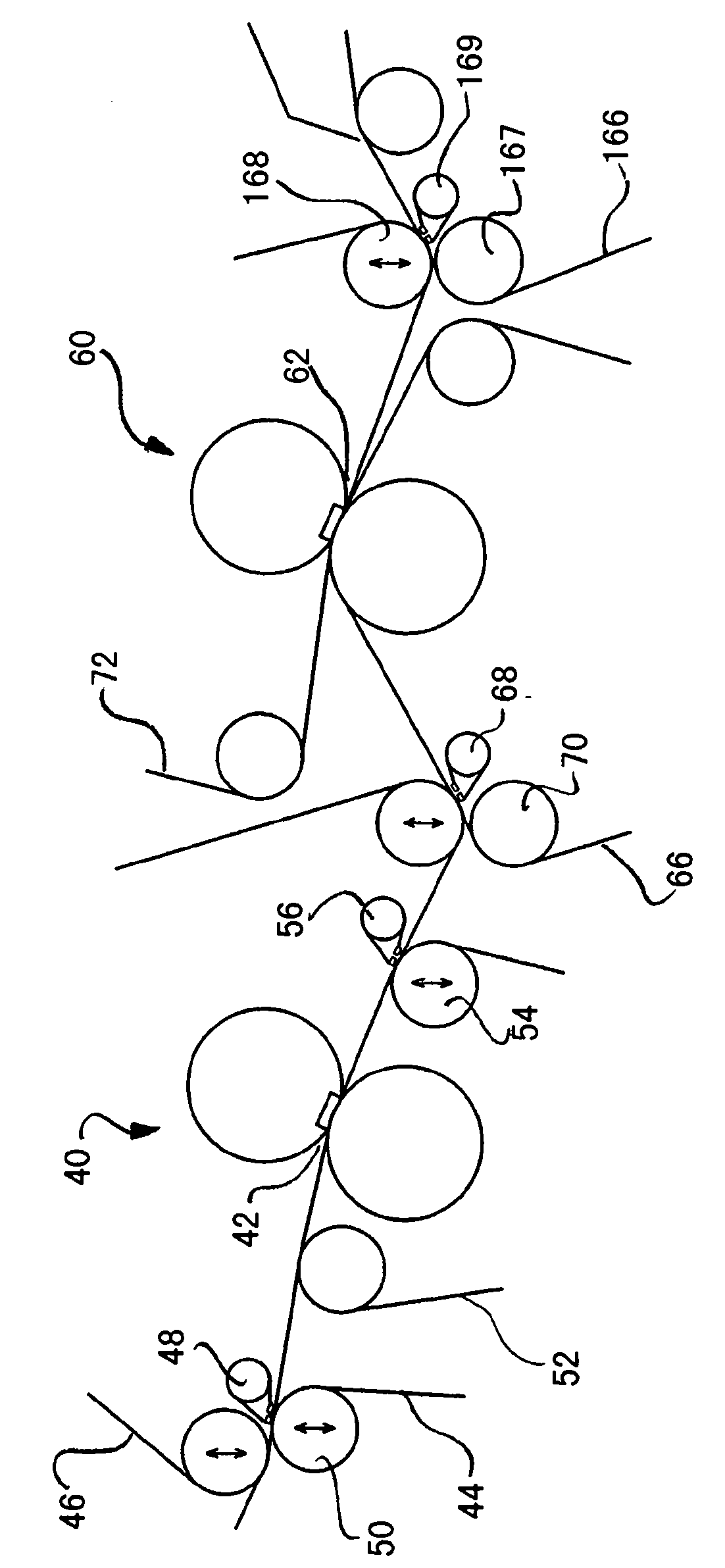

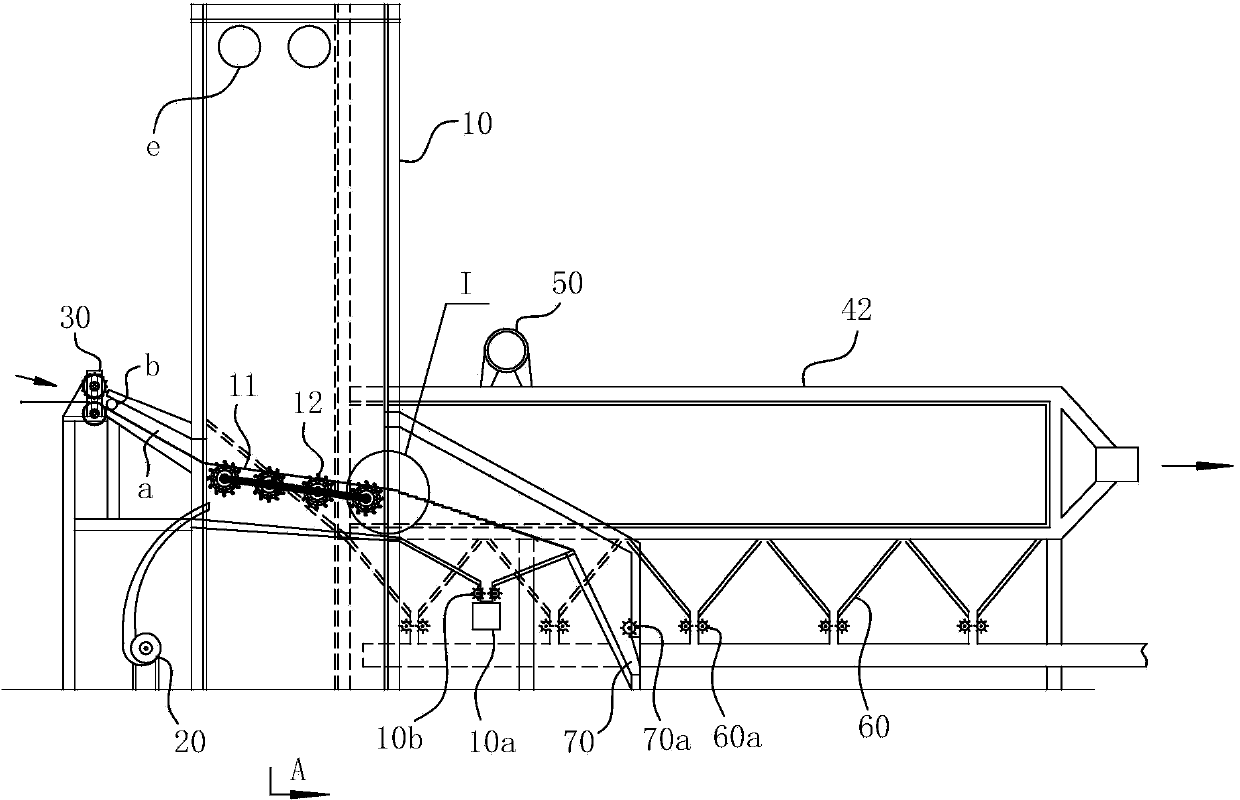

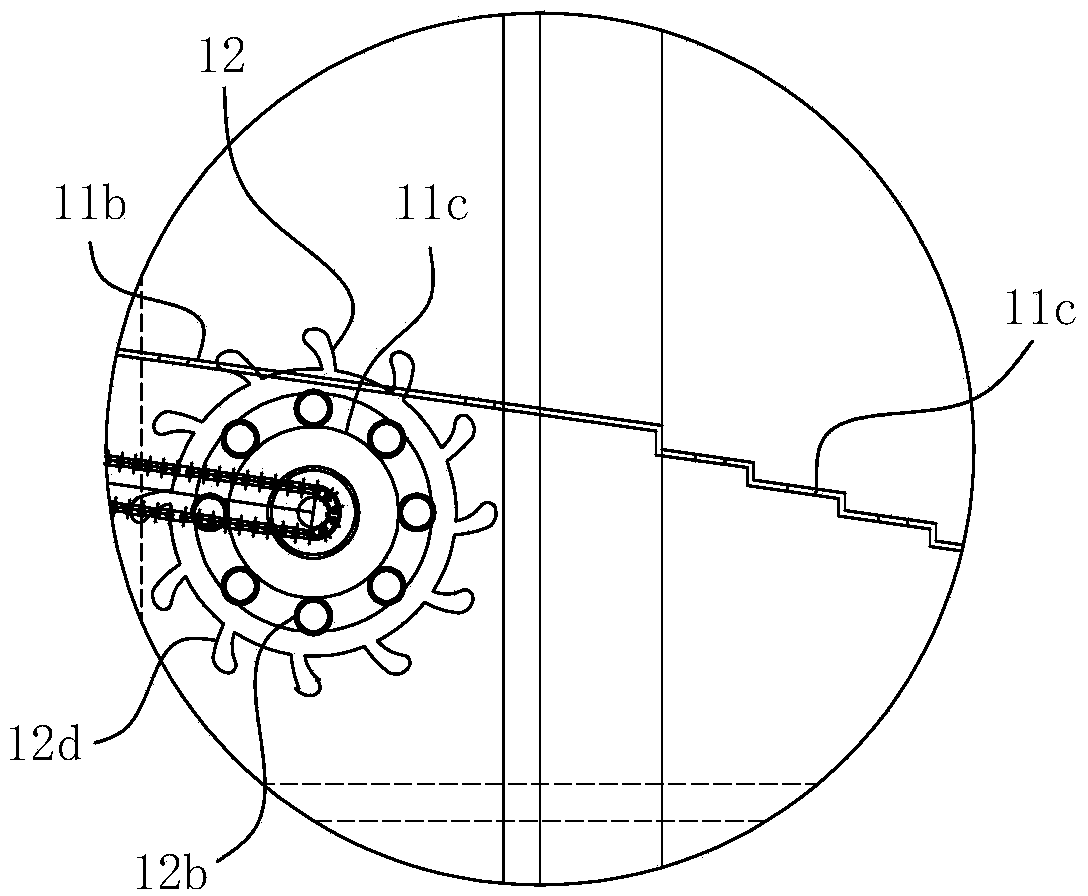

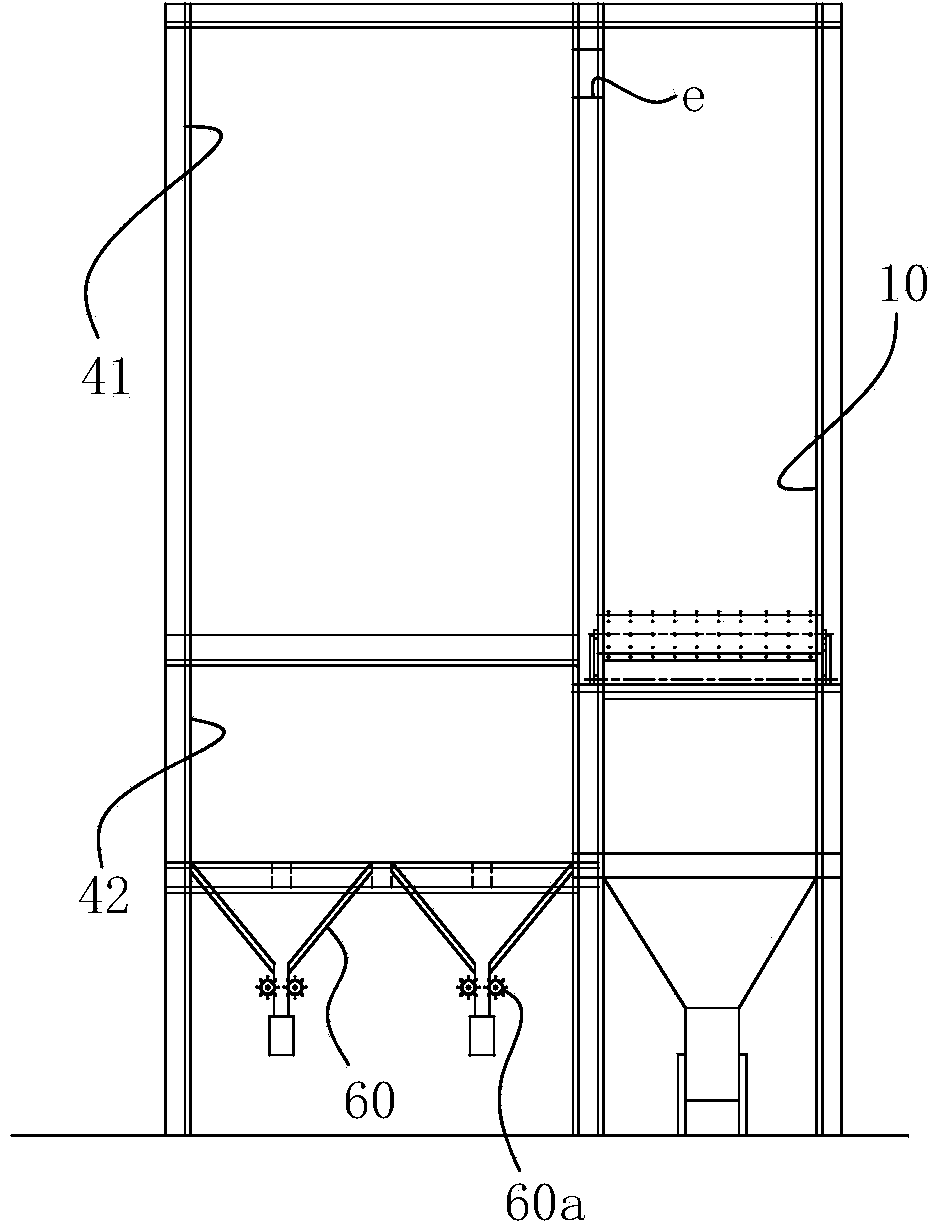

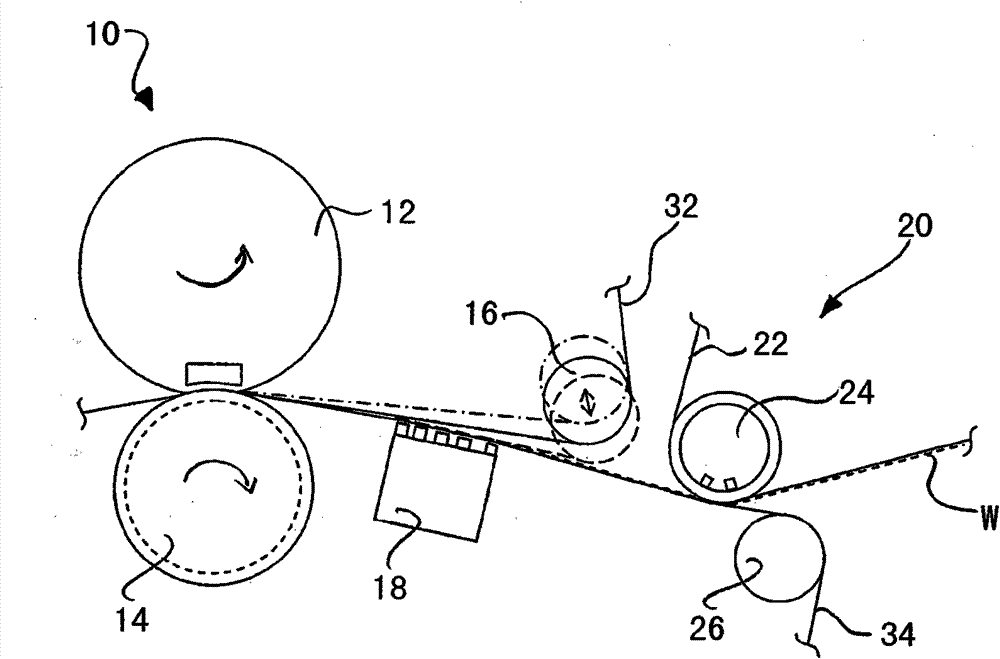

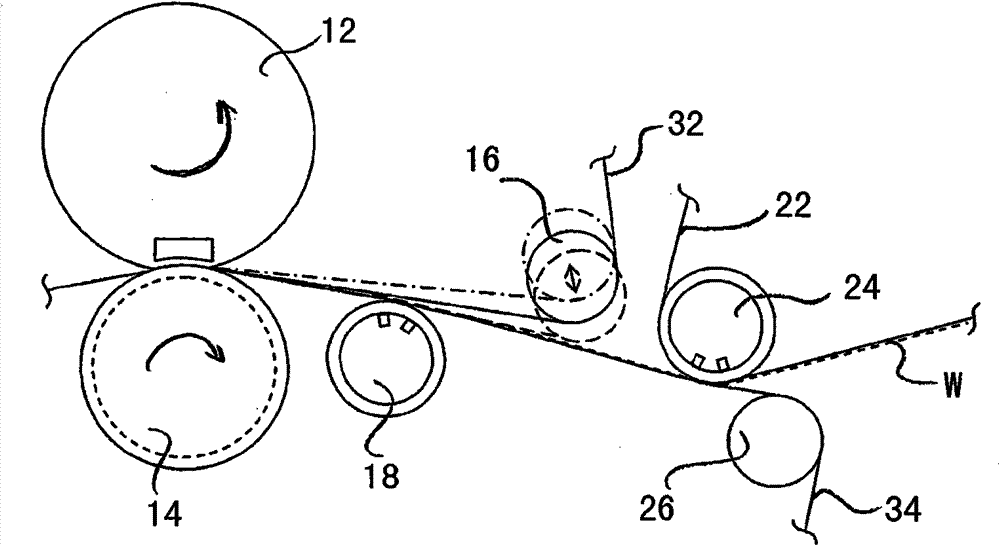

Solid-Liquid Separating Device, Filtering Apparatus, and Solid-Liquid Separating Method

ActiveUS20110036769A1Effective squeezeComponents is relatively effectiveFiltration circuitsPressesEngineeringMaterial supply

A solid-liquid separating apparatus is provided with: a separating roll which has a substantially cylindrical shape with a plurality of through holes, which penetrate between an inner surface and an outer surface in radial direction thereof, and is rotatable in circumferential direction thereof; and a pair of separating filter cloths which is endless belts capable of traveling in a rotation direction of the separating roll and are wound around the outer circumference of the separating roll so as to overlap each other, wherein a material supplied between the pair of filter cloths is squeezed by being rolled together with the pair of filter cloths therebetween on the outer circumference of the separating roll, and the material is dehydrated by ventilating via each through hole.

Owner:TSUKISHIMA KIKAI CO LTD

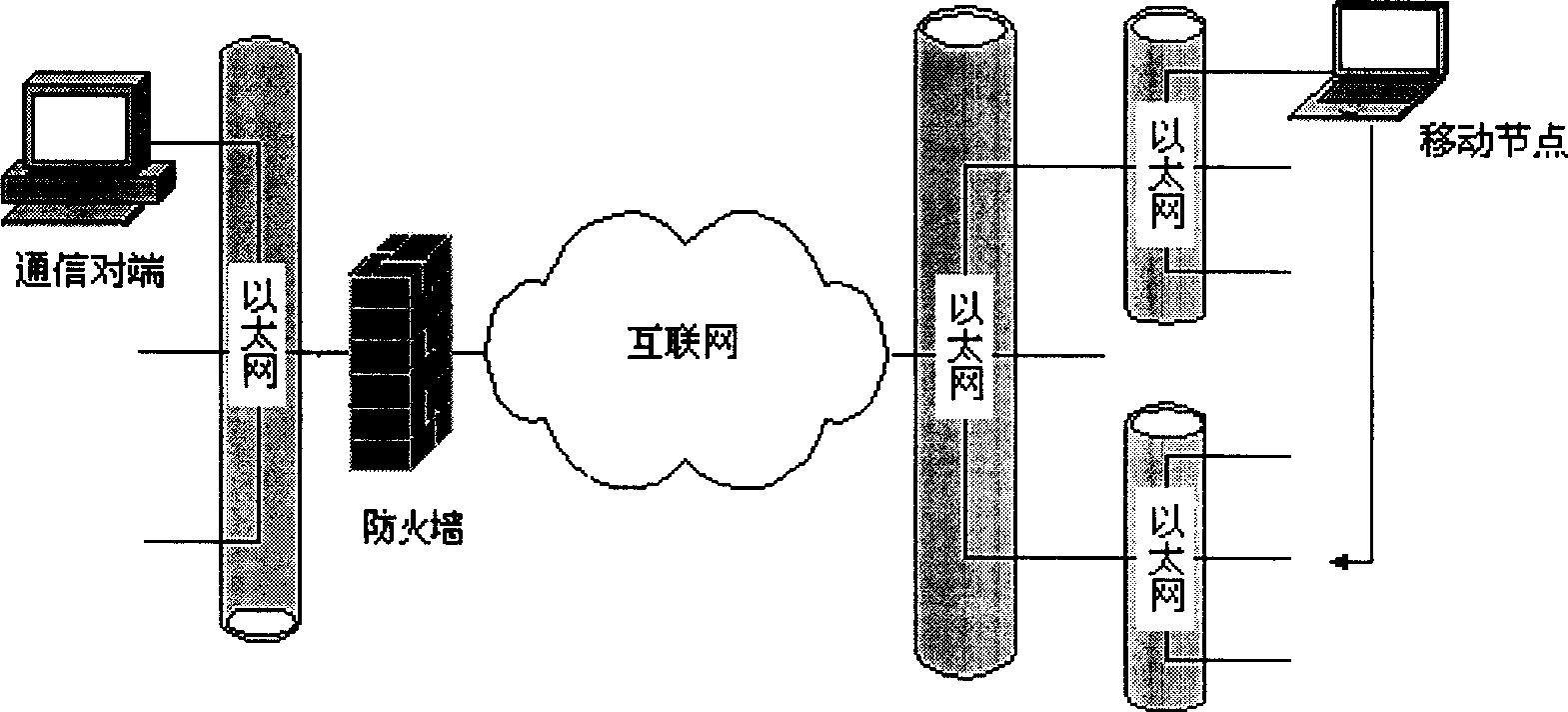

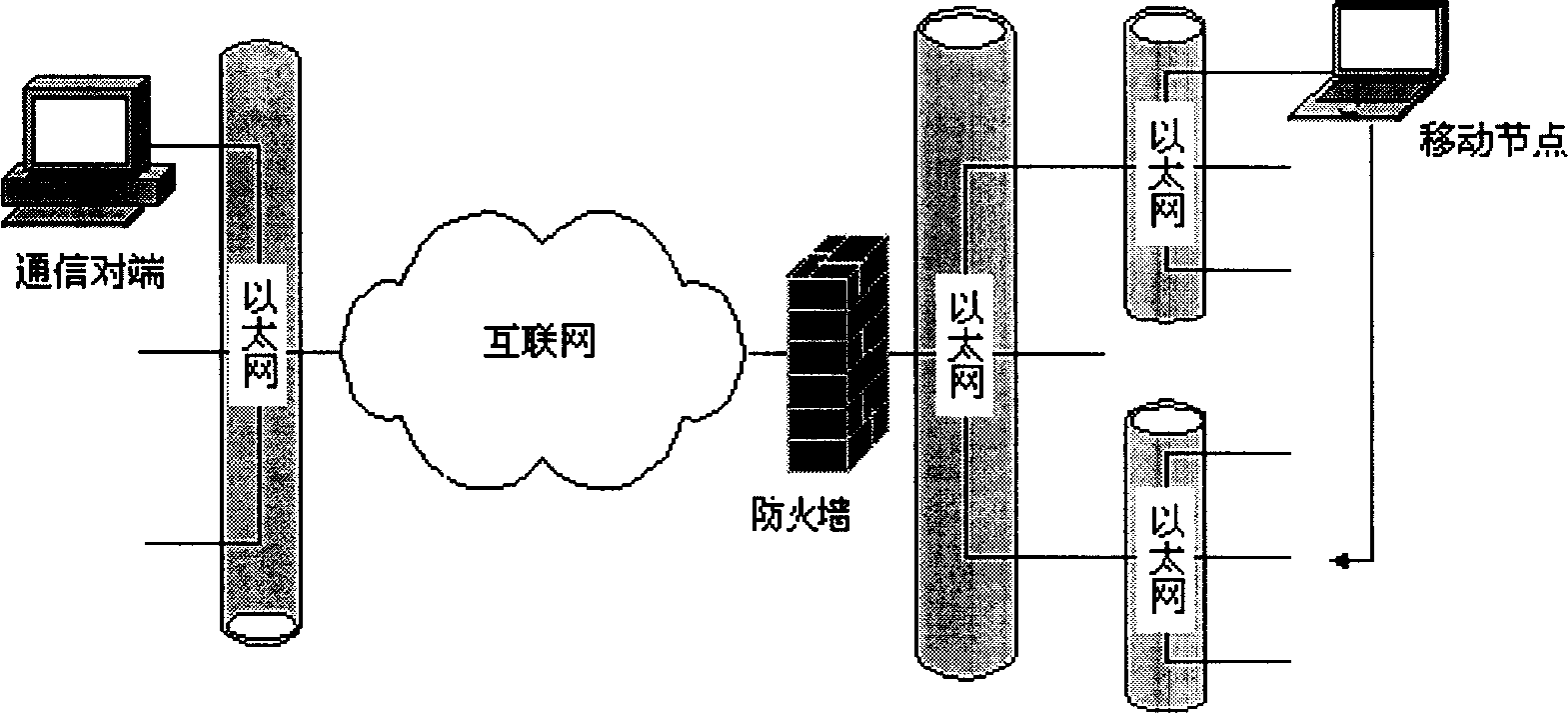

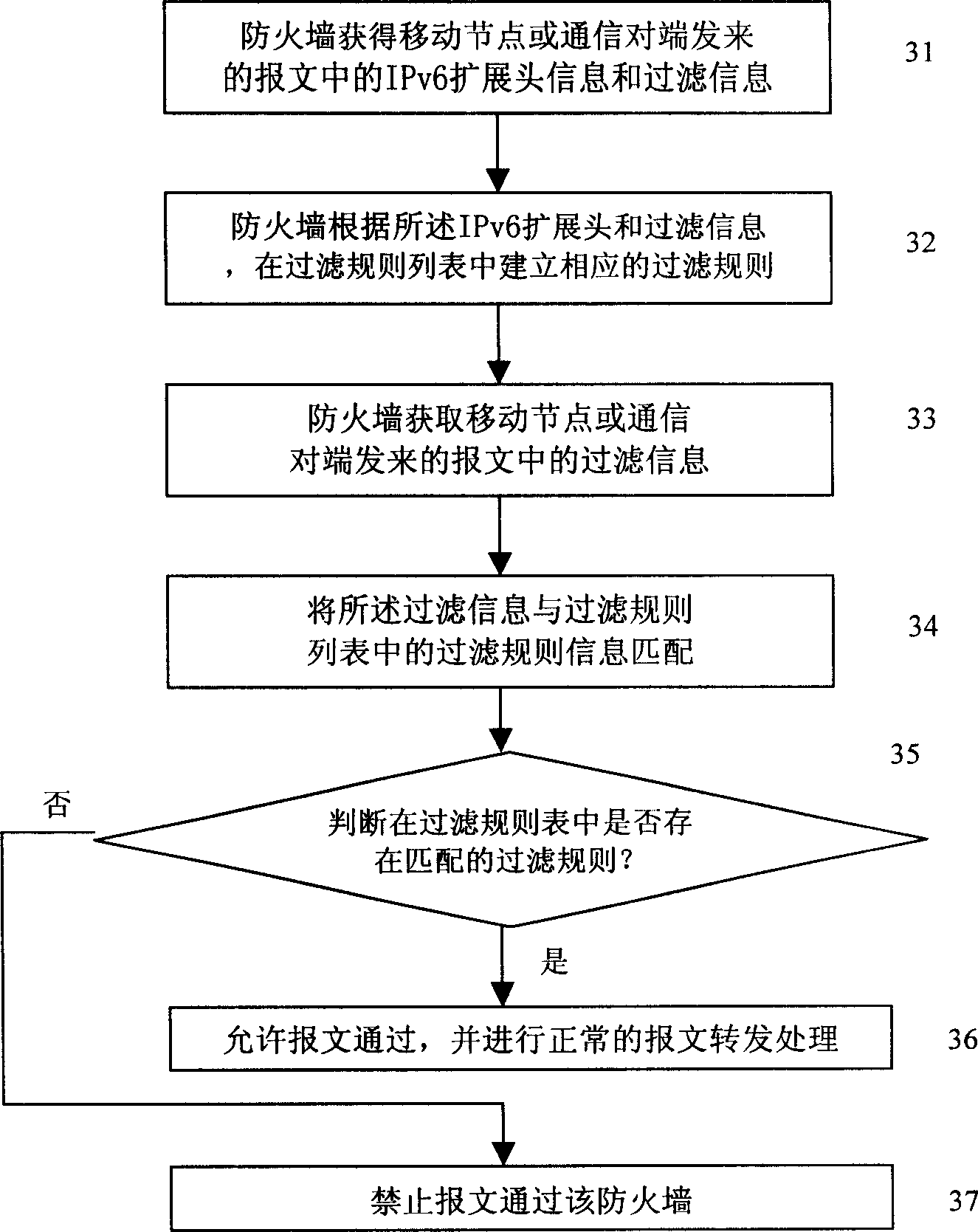

Method for realizing mobile IPv6 message crossing firewall

InactiveCN1838632AReliable travelAdd supportWireless network protocolsData switching networksFiltering rulesWorld Wide Web

Owner:GLOBAL INNOVATION AGGREGATORS LLC

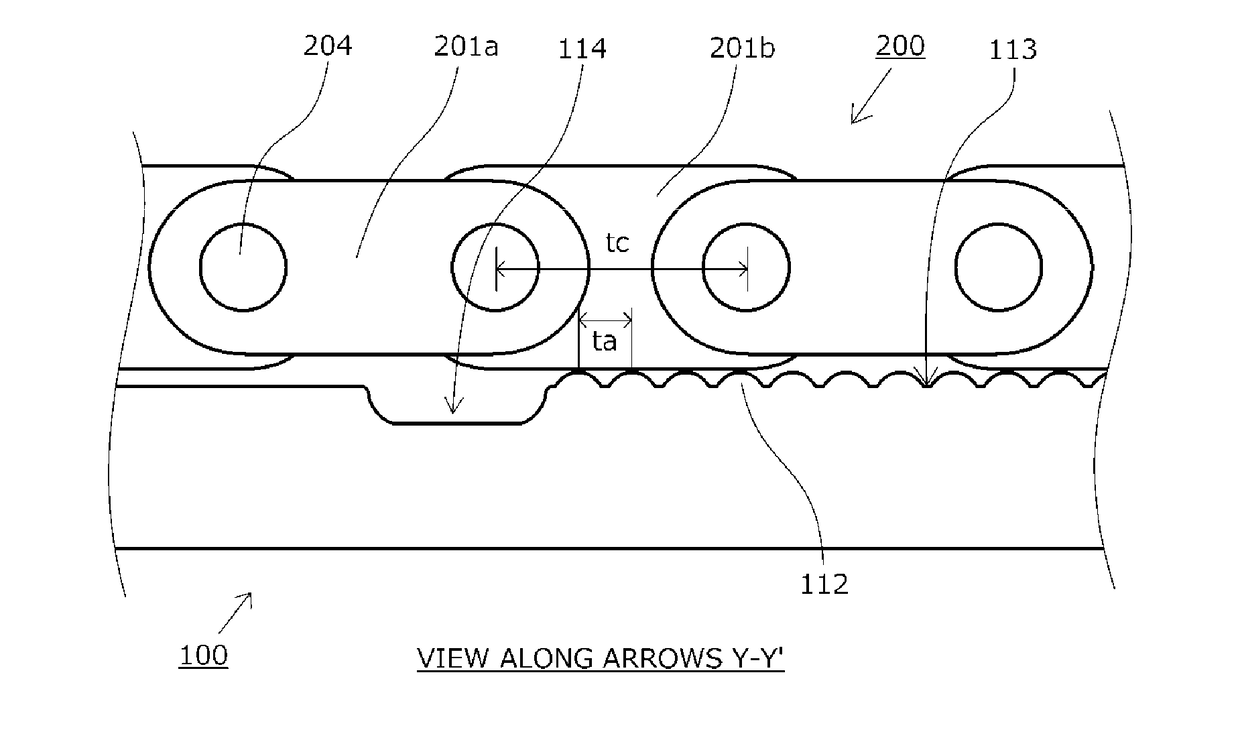

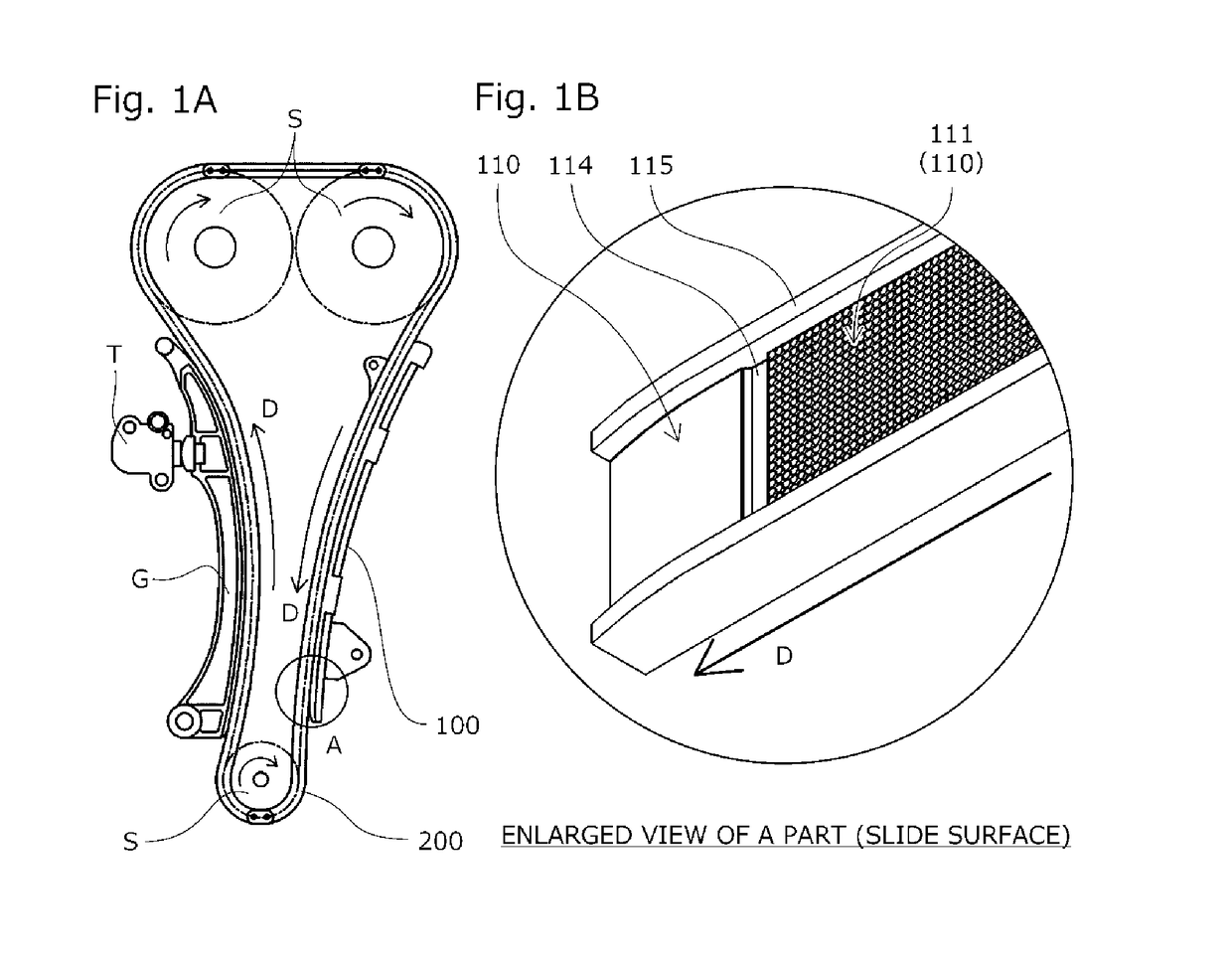

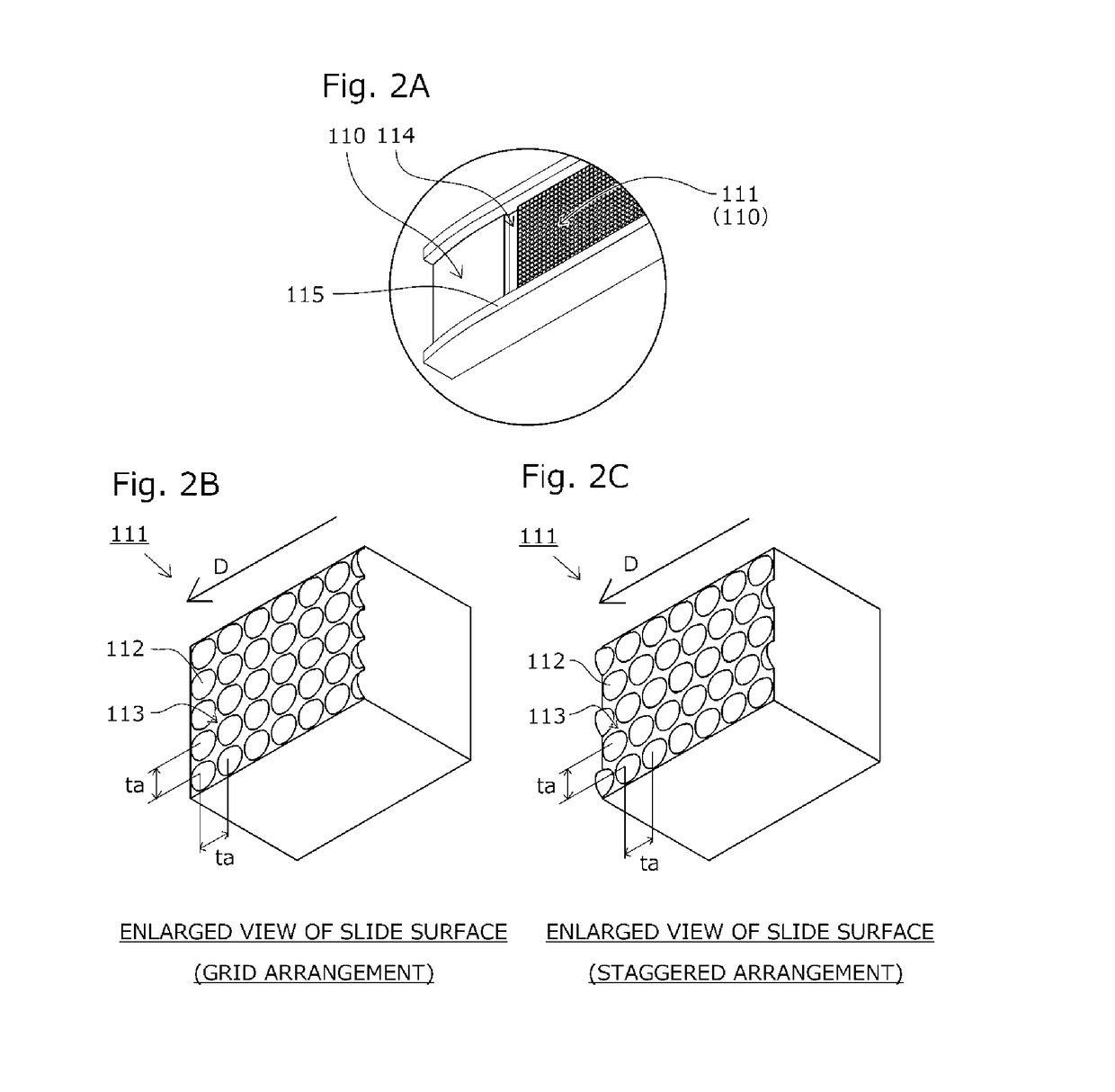

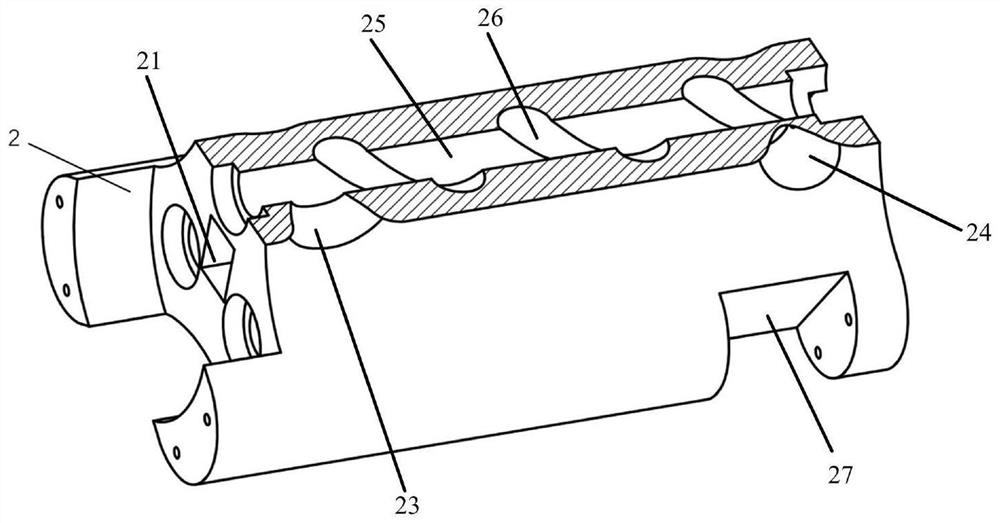

Guide shoe

A guide shoe is provided, which exhibits a lower level of slide resistance between a chain and a slide surface at the time of the sliding of the chain, is able to keep a sufficient lubricant on the slide surface even at the time of the starting of an engine, and produces less noise and wear. The guide shoe includes: a slide surface that slidably guides a link plate of a traveling chain; and a plurality of guide protrusions provided on the slide surface, the guide protrusions protruding in a vertical direction from the slide surface, wherein each of front surfaces of the guide protrusions is formed to have a convex curved surface at least from a part thereof on an upstream side to a top part thereof in a chain traveling direction.

Owner:TSUBAKIMOTO CHAIN CO

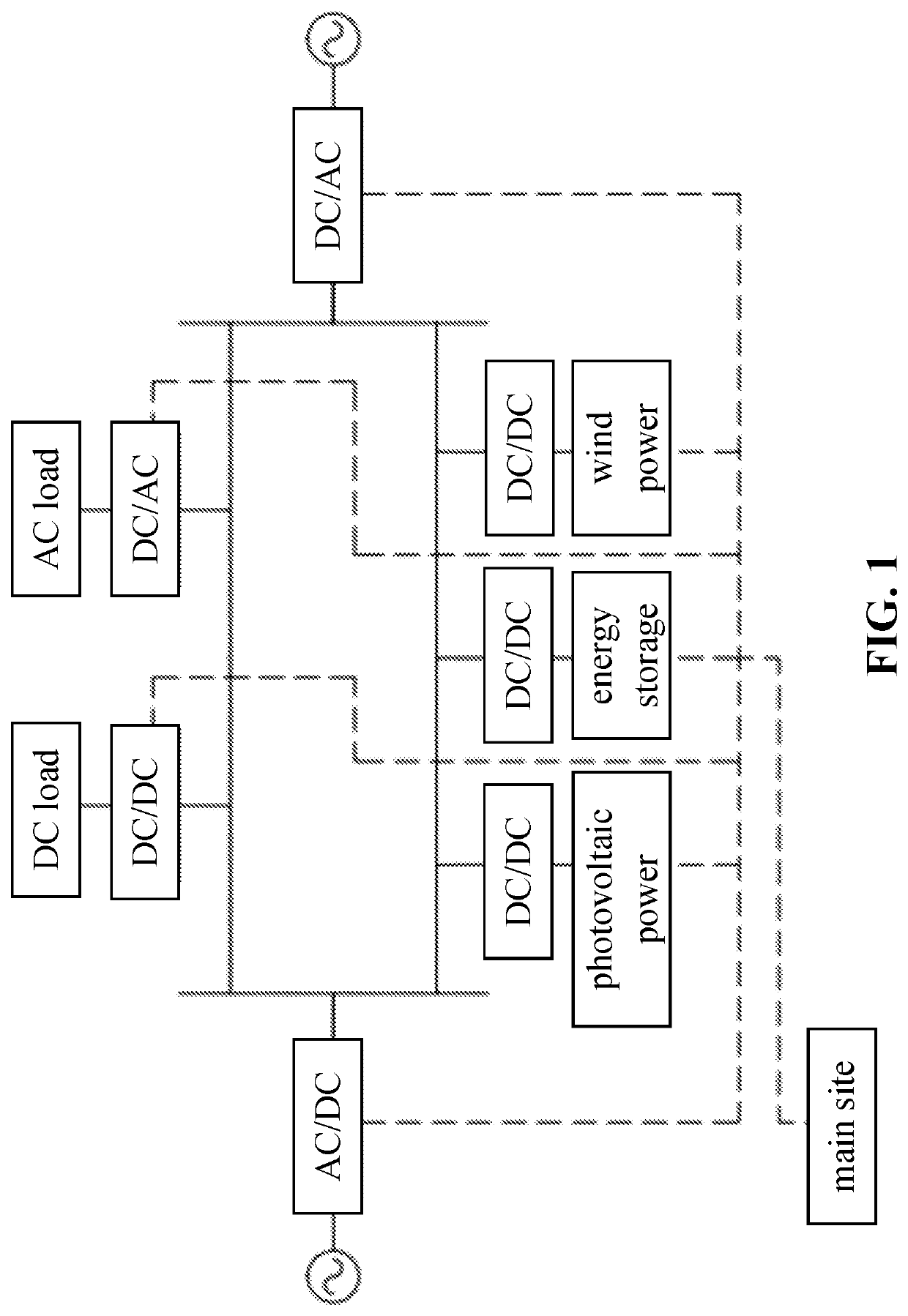

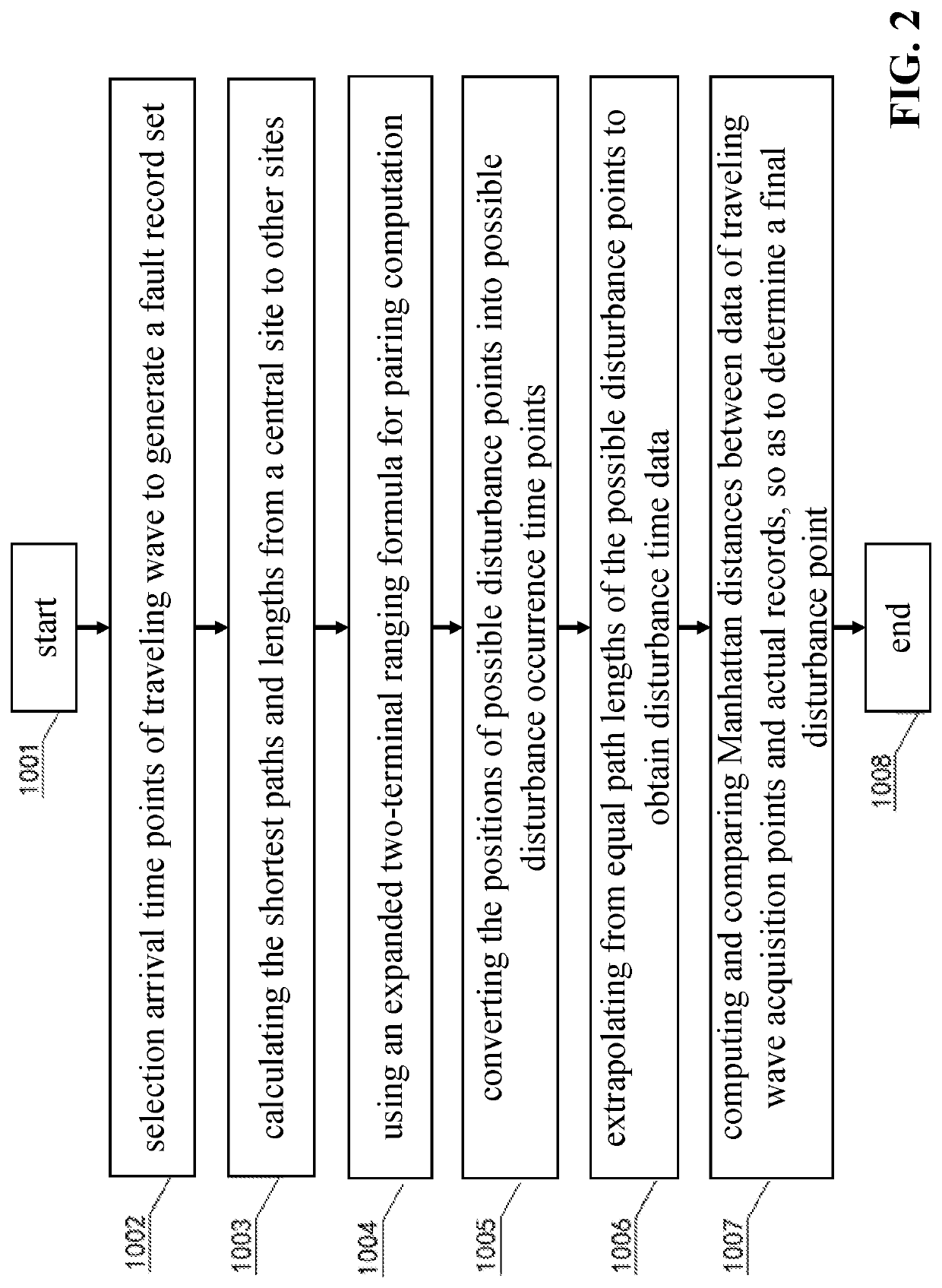

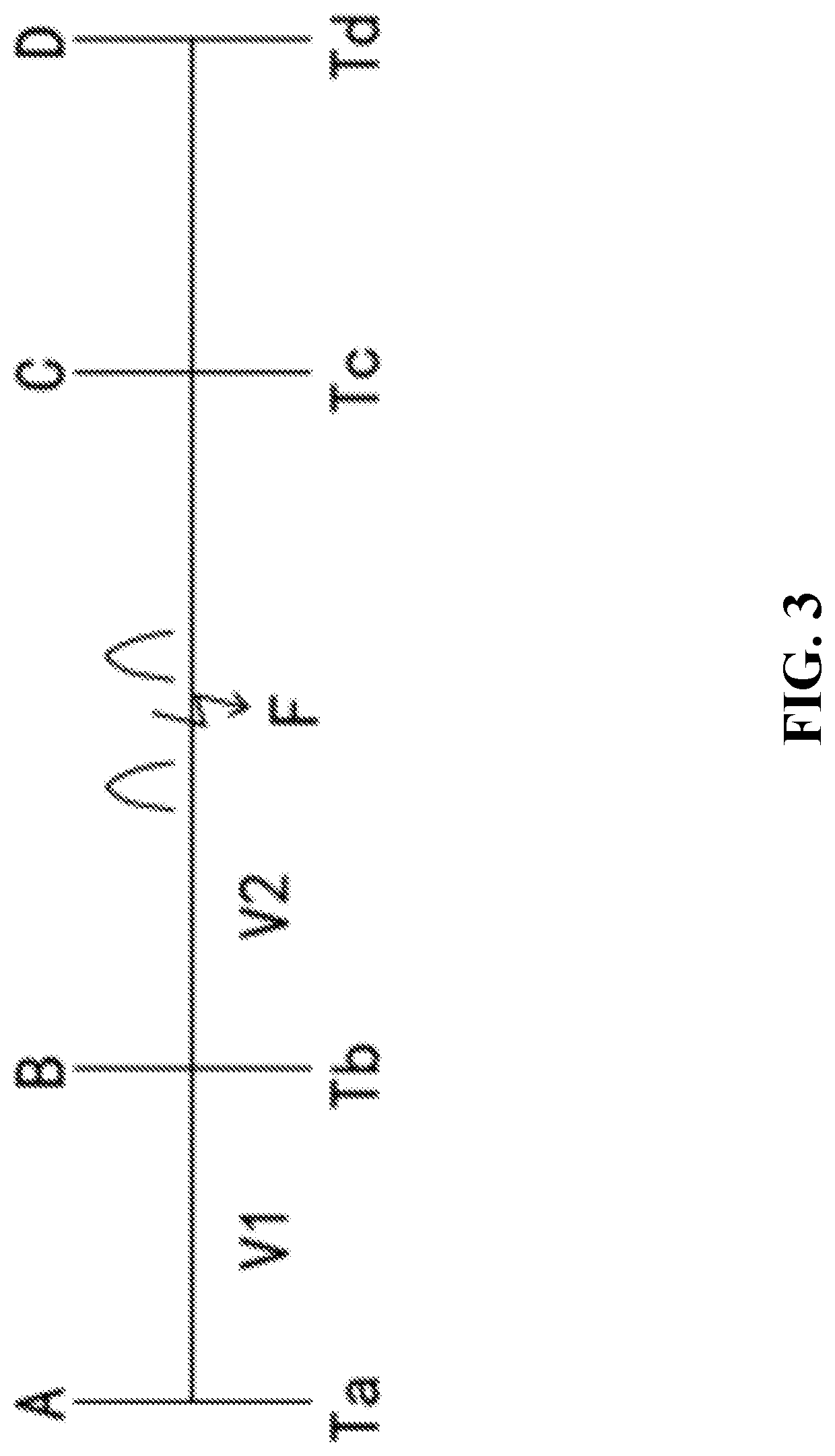

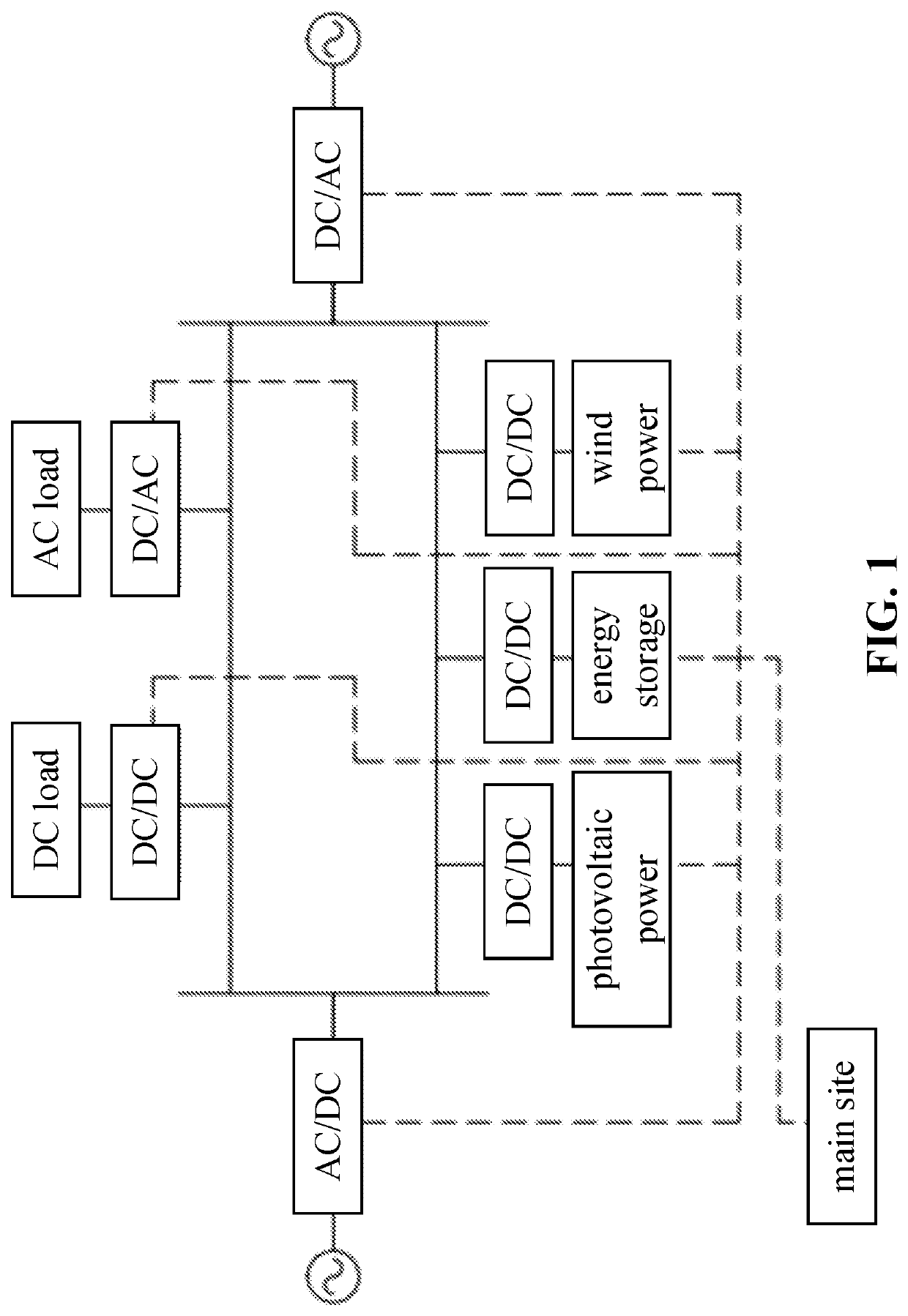

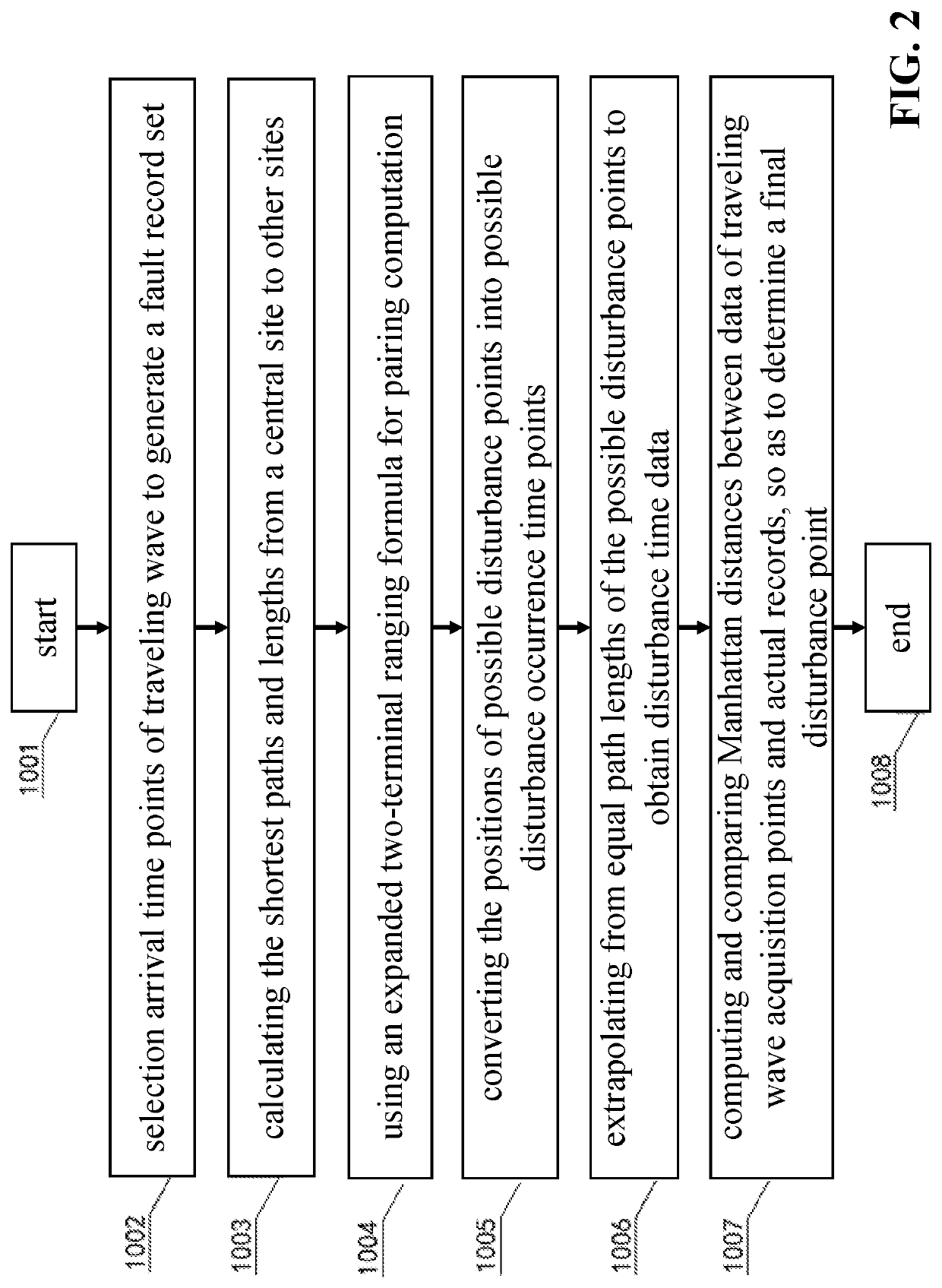

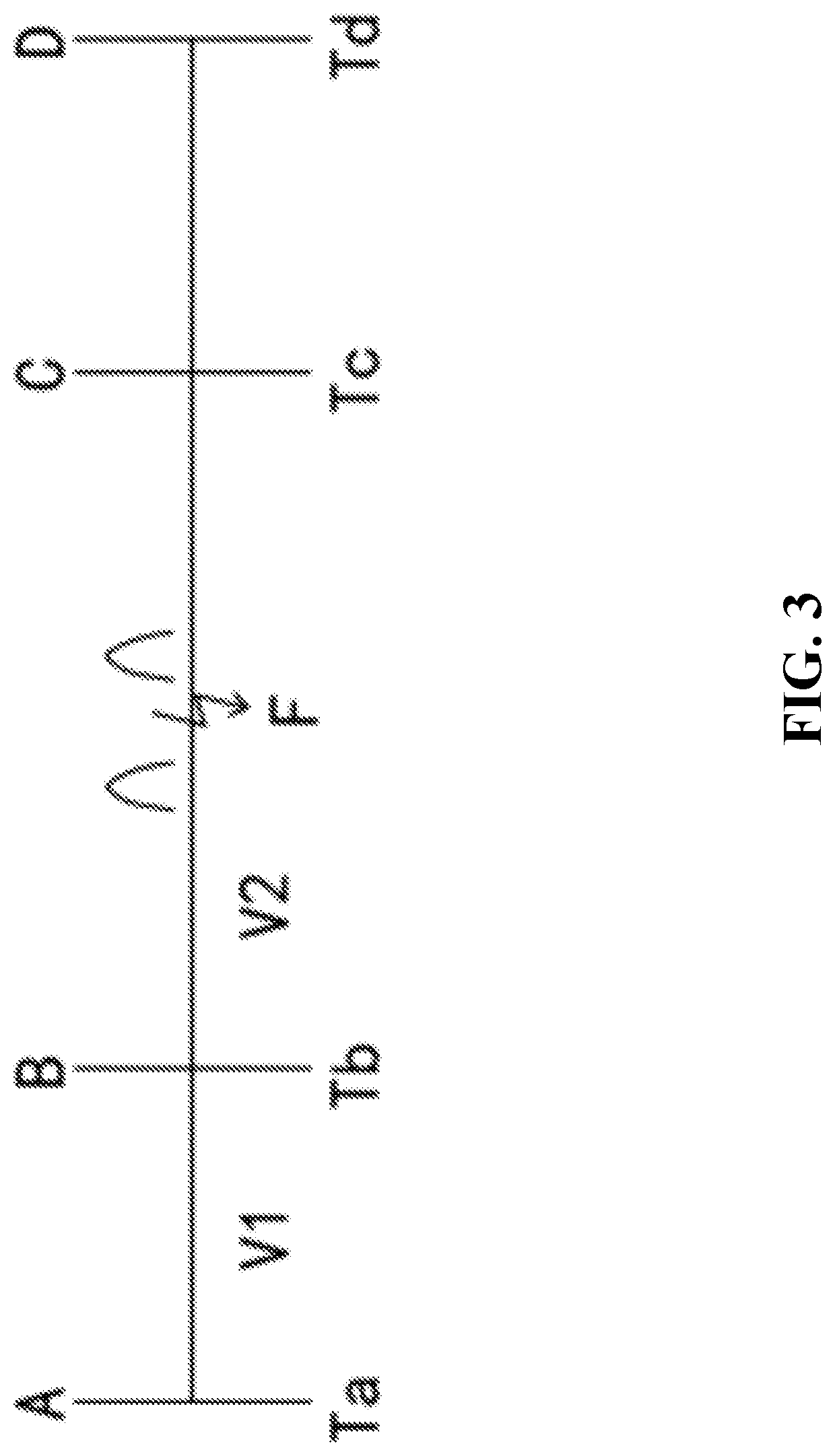

Method for fault location to multi-terminal traveling wave in direct current distribution line

ActiveUS20210156899A1Inhibition rangeImprove reliabilityFault location by conductor typesFault location by pulse reflection methodsPath lengthEngineering

A method for fault location to multi-terminal traveling wave in a direct current distribution line, which belongs to the field of power line fault ranging and location technology. The method includes a main site and a plurality of acquisition points installed into the distribution line and includes steps as follows. Step 1001: collecting and uploading a traveling wave signal by each of the acquisition points after a fault occurs in the line; step 1002: generating a fault record set; step 1003: computing the shortest paths from a central site to other sites and their lengths; step 1004: using expanded two-terminal traveling wave ranging principle for pairing computation; step 1005: converting positions of possible disturbance points into possible disturbance occurrence time points; step 1006: extrapolating from equal path lengths of the possible disturbance points to obtain disturbance time data; and step 1007: determining a final disturbance point.

Owner:SHANDONG UNIV OF TECH

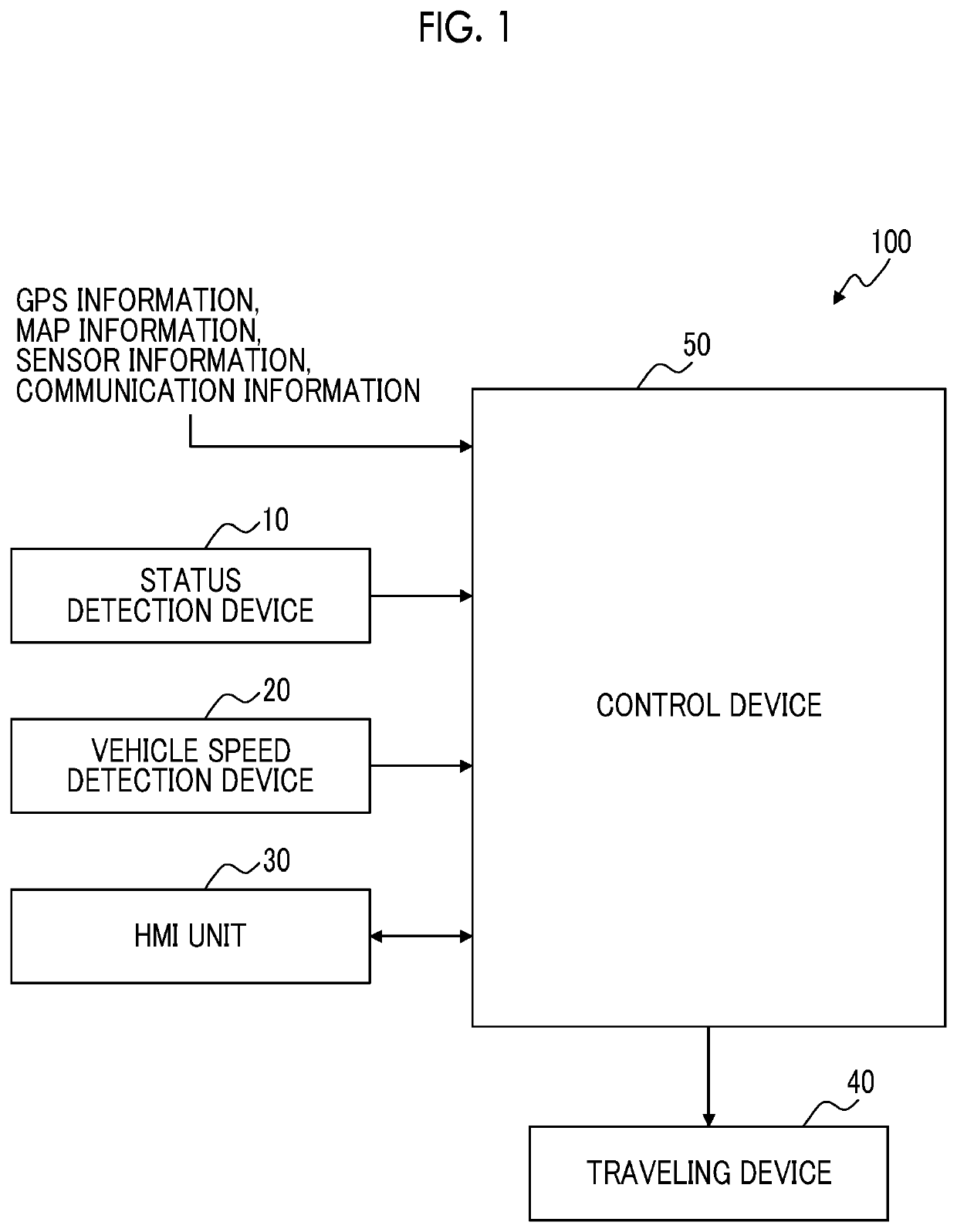

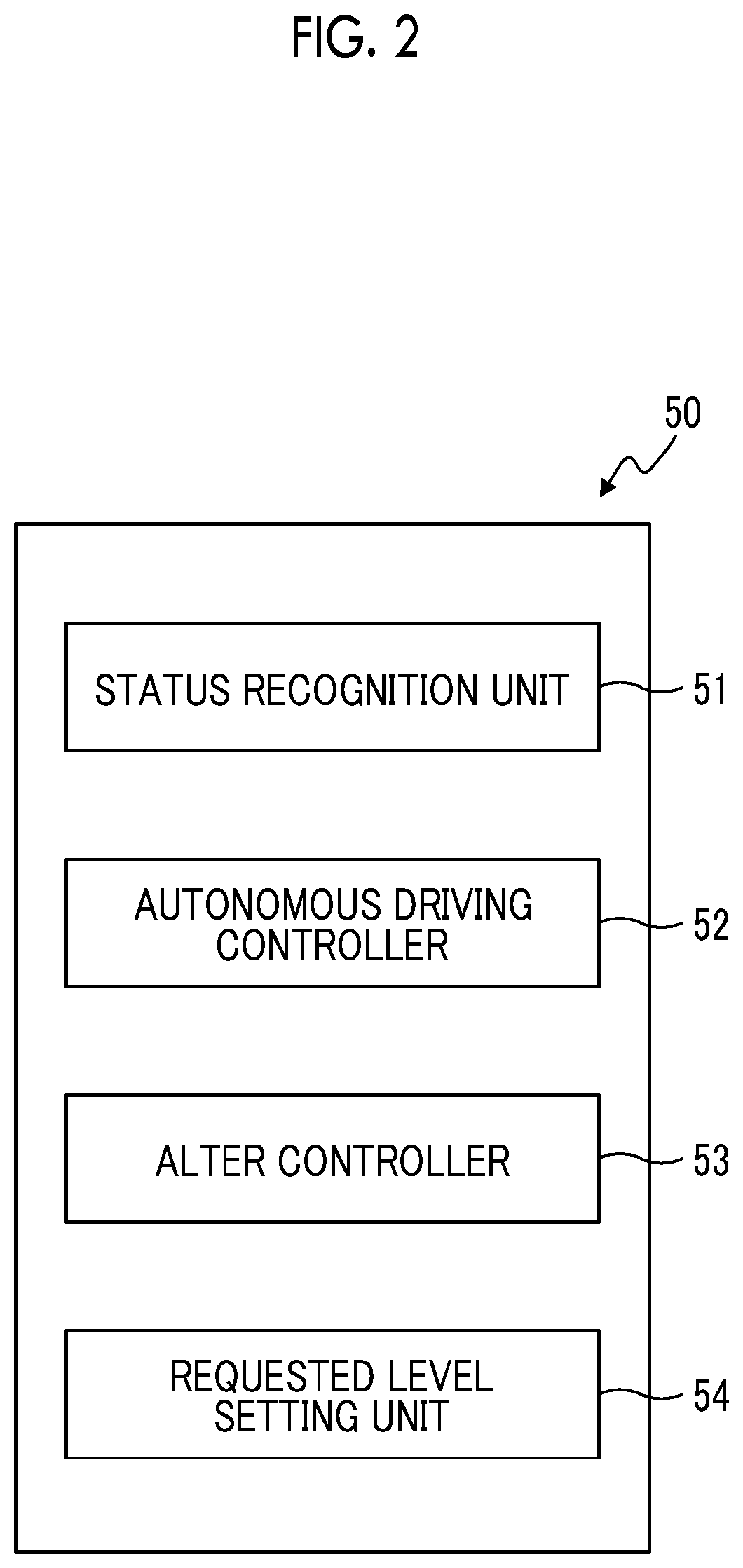

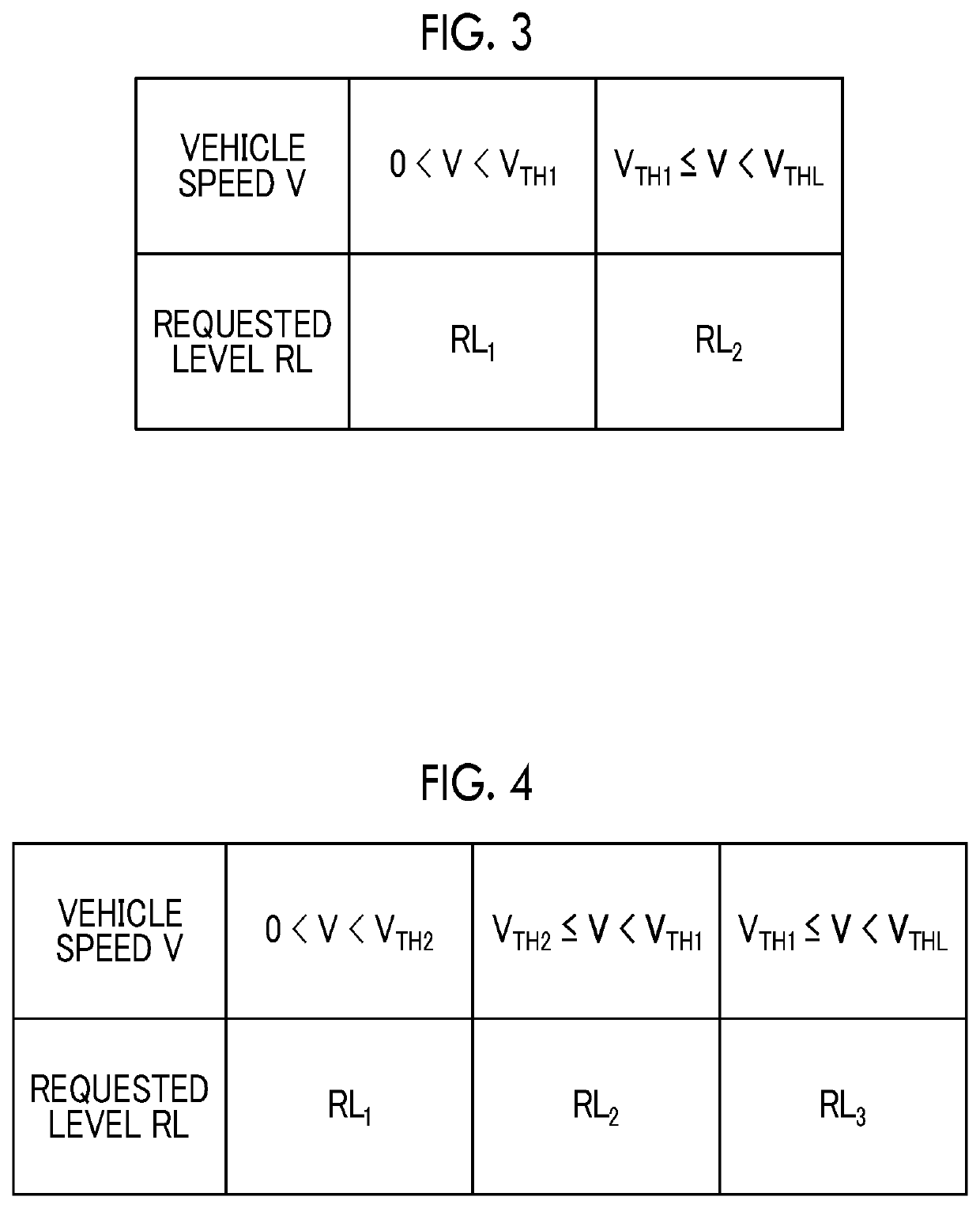

Vehicle control system

InactiveUS20200317228A1Improve convenienceConvenient travelExternal condition input parametersVehicle cleaningDriver/operatorControl system

A control device includes a status recognition unit, an autonomous driving controller, an alert controller, and a requested level setting unit. The status recognition unit recognizes a status of a driver. The autonomous driving controller executes autonomous driving control. The alert controller executes an alert control. The requested level setting unit sets a requested level. The autonomous driving controller prohibits the execution of the autonomous driving control in a case where the requested level is equal to or higher than an actual level. The requested level setting unit sets the requested level in each of at least two divided vehicle speed ranges. The requested level set in a relatively low vehicle speed range is lower than the requested level set in a relatively high vehicle speed range.

Owner:TOYOTA JIDOSHA KK

Electric vehicle sharing system

InactiveUS6181991B2Efficient supplyReliable travelVehicle testingRegistering/indicating working of vehiclesSimulationCar sharing

When a user enters a destination using a touch panel display unit, a system control unit calculates a predicted travel distance from a present position to the destination, determines an electric vehicle having a remaining battery capacity required to travel the calculated predicted travel distance, and supplies the determined electric vehicle to the user.

Owner:HONDA MOTOR CO LTD

Vehicle travel support device, vehicle, and vehicle travel support program

ActiveUS8306700B2Continuous operationImprove reliabilityDigital data processing detailsAnti-collision systemsEngineeringDependability

Owner:HONDA MOTOR CO LTD

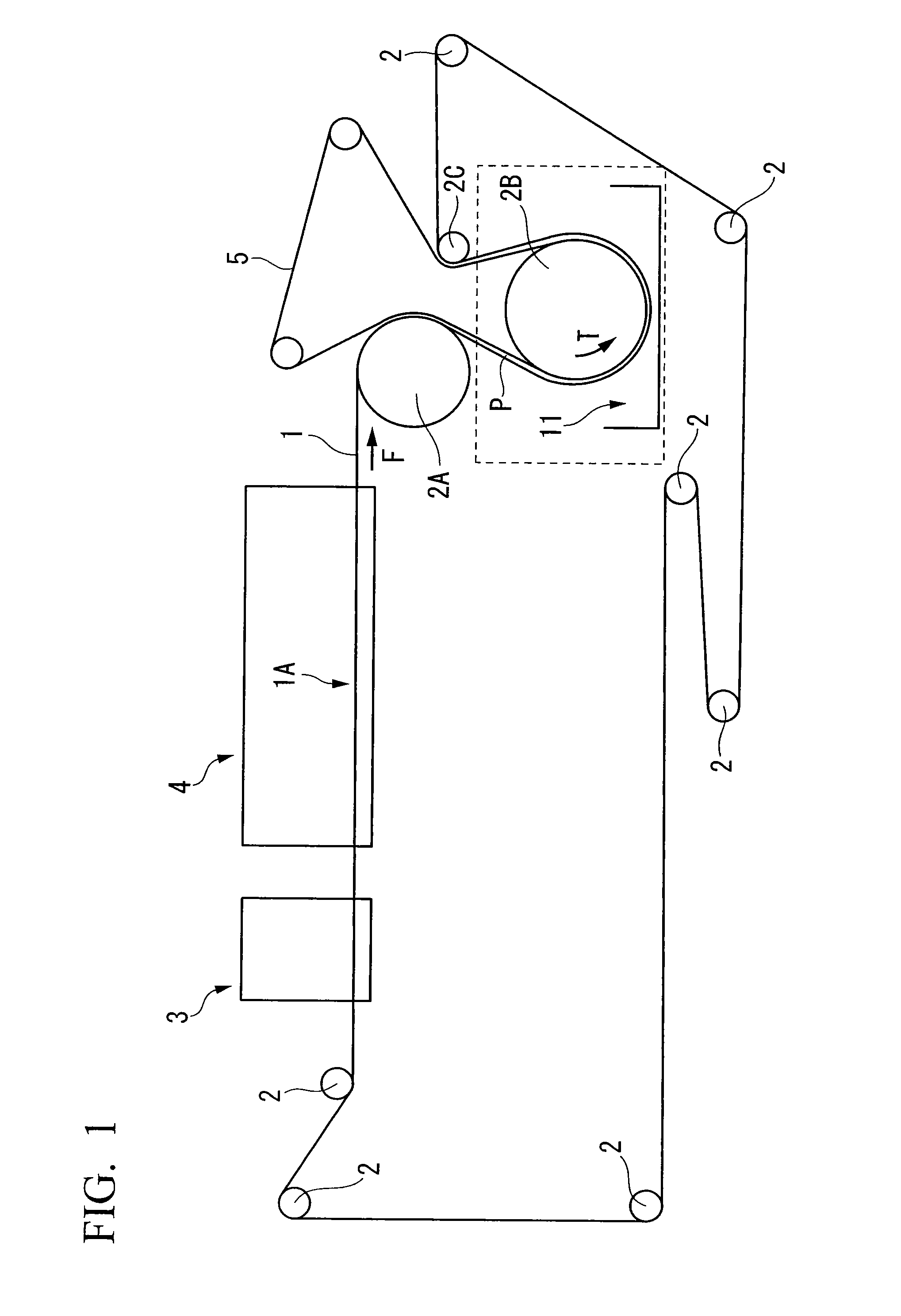

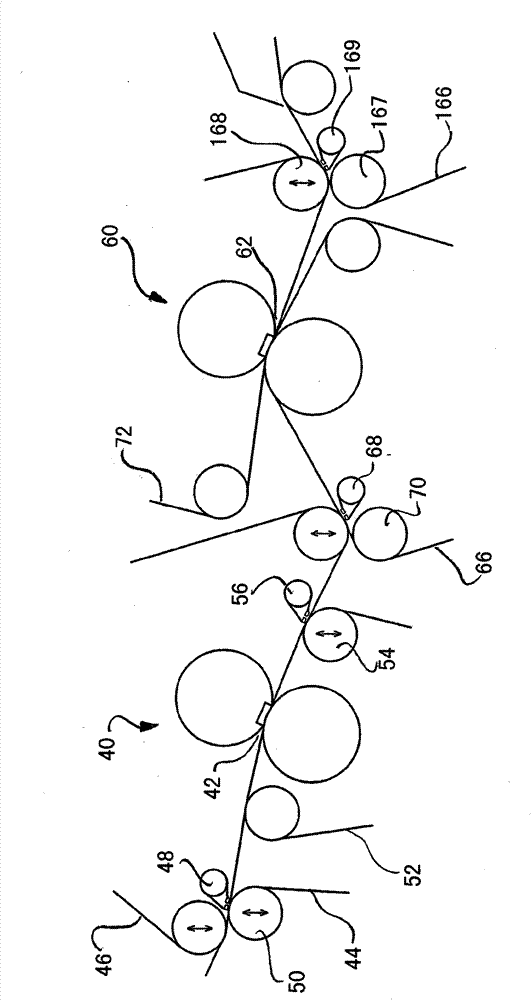

Method and device for transferring a paper web from a supporting woven fabric to another

ActiveCN101868578AReliable travelSolve wear and tearMachine wet endPress sectionStructural engineeringIndustrial engineering

The invention provides a device for transferring a paper web from a supporting woven fabric to another. The device comprises a fabric at least on both sides of the paper web; a suction unit for detaching the paper web from a first fabric and adhering the paper web to a second fabric; and a guide roller located on one side of the paper web and the fabric, opposite to the suction unit. The fabric peeled off from the paper web is transferred continuously by the guide roller. The suction unit is composed of a transferring suction box. The transferring suction box is provided with a cover having one or more suction slots or one or more rows of discrete openings transversely extending along the paper web. The transferring suction box is arranged close to the guide roller, so that one row of discrete openings transversely extending along the paper web is located at the following positions relative to the guide roller. Namely, the row of discrete openings is at a position, wherein the surface of the guide roller begins to diverge away from the direction of fabric on the side of the transferring suction box. The at least one slot or the at least one row of openings below the fabric is extending over a width which is greater than the width of the paper web.

Owner:VALMET CHINA CO LTD

Method and control and detection device for determining the plausibility of a wrong-way travel of a motor vehicle

ActiveUS9767686B2Improve robustness and reliabilityReliable travelInstruments for road network navigationAnti-collision systemsMobile vehicleSimulation

A method for determining the plausibility of wrong-way travel of a motor vehicle when entering a directional roadway, including detecting at least one curve information item of a current travel path, ascertaining at least one curve information item of a permitted travel path, determining a deviation between the detected and ascertained curve information items, and plausibilizing a wrong-way travel if a deviation exists or a deviation limit value is breached. A control / detection device for determining the plausibility of wrong-way travel when entering a directional roadway, includes an arrangement for detecting at least one curve information item of a current travel path; an arrangement for ascertaining at least one curve information item of a permitted travel path; an arrangement for determining a deviation between detected and ascertained curve information items; and an arrangement for determining the plausibility of wrong-way travel if a deviation exists or a deviation limit value is breached.

Owner:ROBERT BOSCH GMBH

Incinerator with fixed fire grate

InactiveCN103994441AEnsure high constant temperature incineration demandEnsure high constant temperature incinerationIncinerator apparatusCombustion chamberMoisture

The invention belongs to the field of waste incineration devices and particularly relates to an incinerator with a fixed fire grate. The incinerator with the fixed fire grate is used for incinerating biomass materials such as straws and at least comprises a main combustion chamber, an air supply assembly and a smoke flue for guiding heat energy in the main combustion chamber out. The main combustion chamber is communicated with the smoke flue through a ventilation pipe, and a conveying and incinerating platform is arranged in the main combustion chamber and at least comprises a bearing plate and a stirring portion. The incinerator with the fixed fire grate further comprises a pushing portion, wherein an air return moisture removal cavity channel is arranged between the pushing portion and the main combustion chamber in a transition mode and forms a material conveying path for connecting the cavity of the main combustion chamber with the pushing portion, an air outlet is formed in the end of the air return moisture removal cavity channel and communicated with an external air draught fan, and the end of the air return moisture removal cavity channel and the pushing portion are positioned at the same end. The incinerator with the fixed fire grate is high in operation reliability and incineration efficiency, low in cost and capable of ensuring incineration at high and constant temperature and extracting and utilizing efficient heat energy of biomass fuel.

Owner:合肥康帕因设备技术有限公司

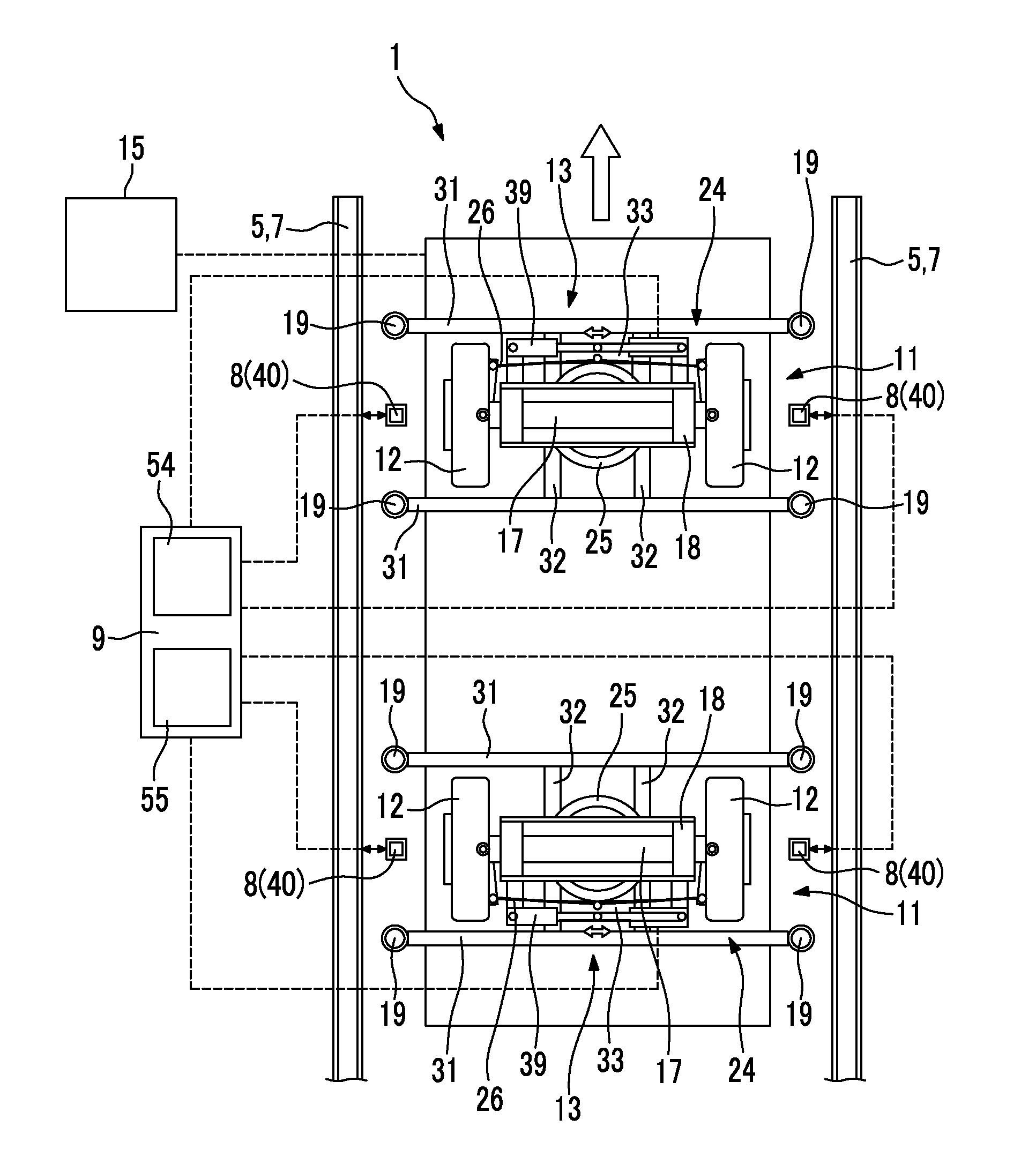

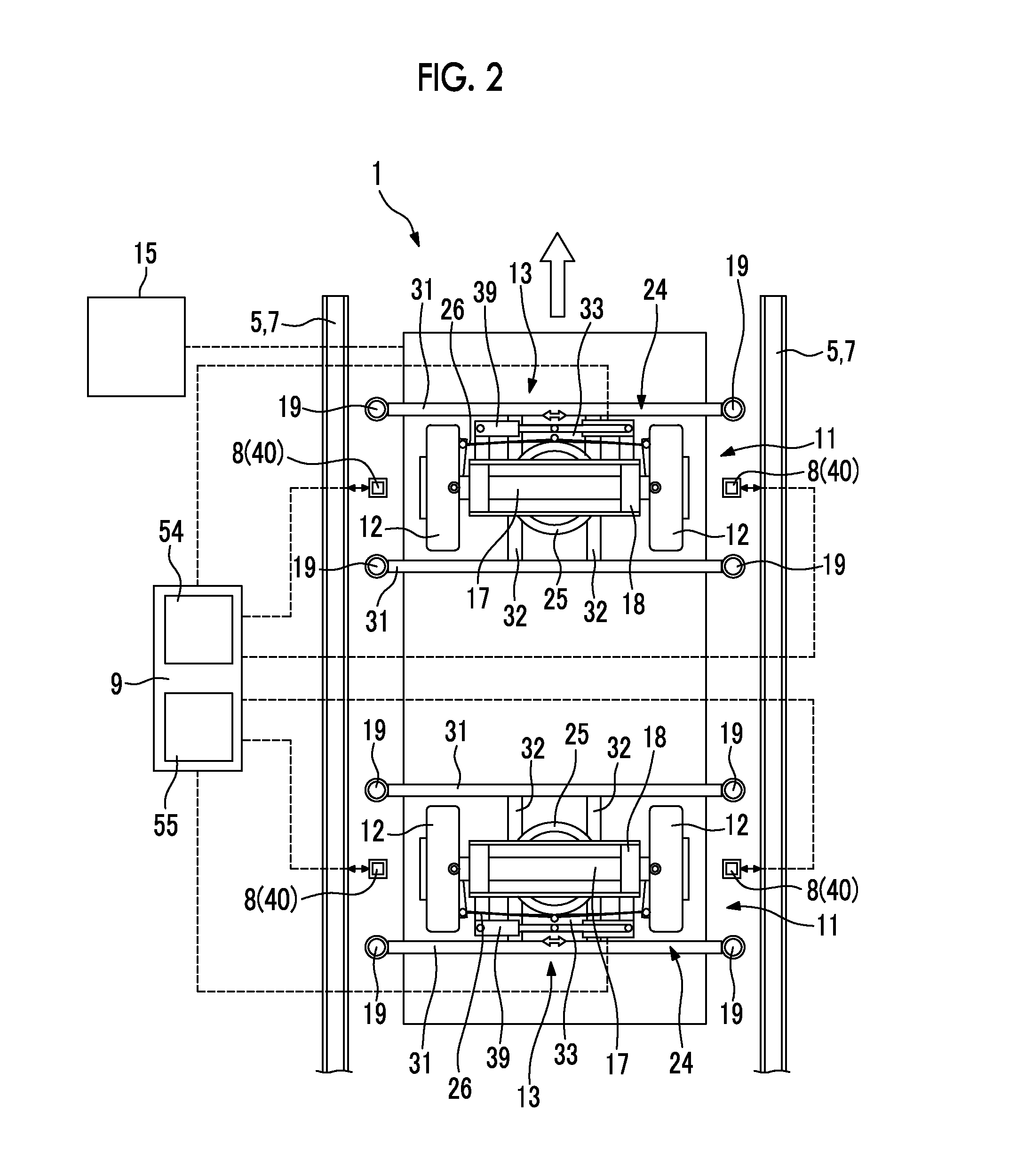

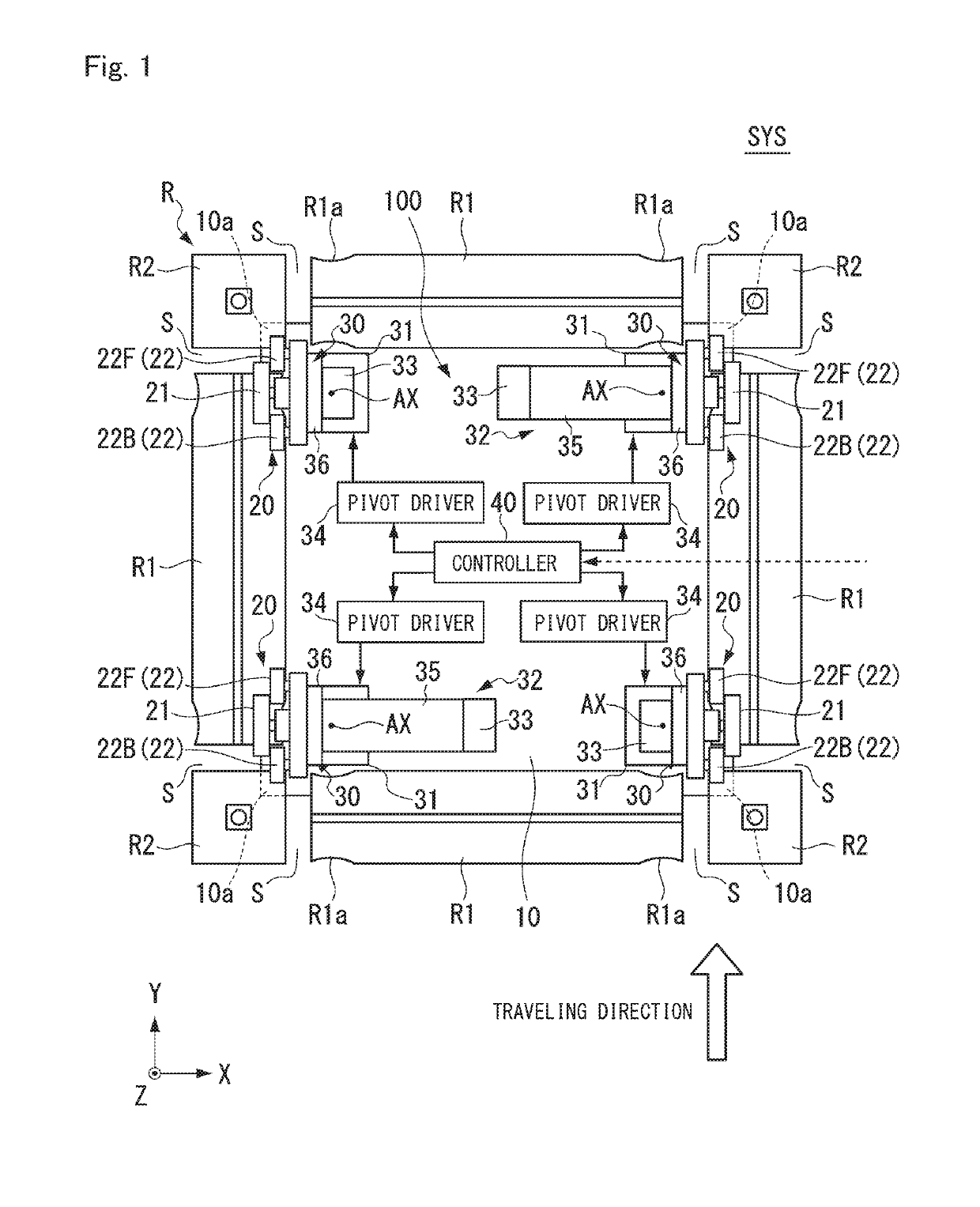

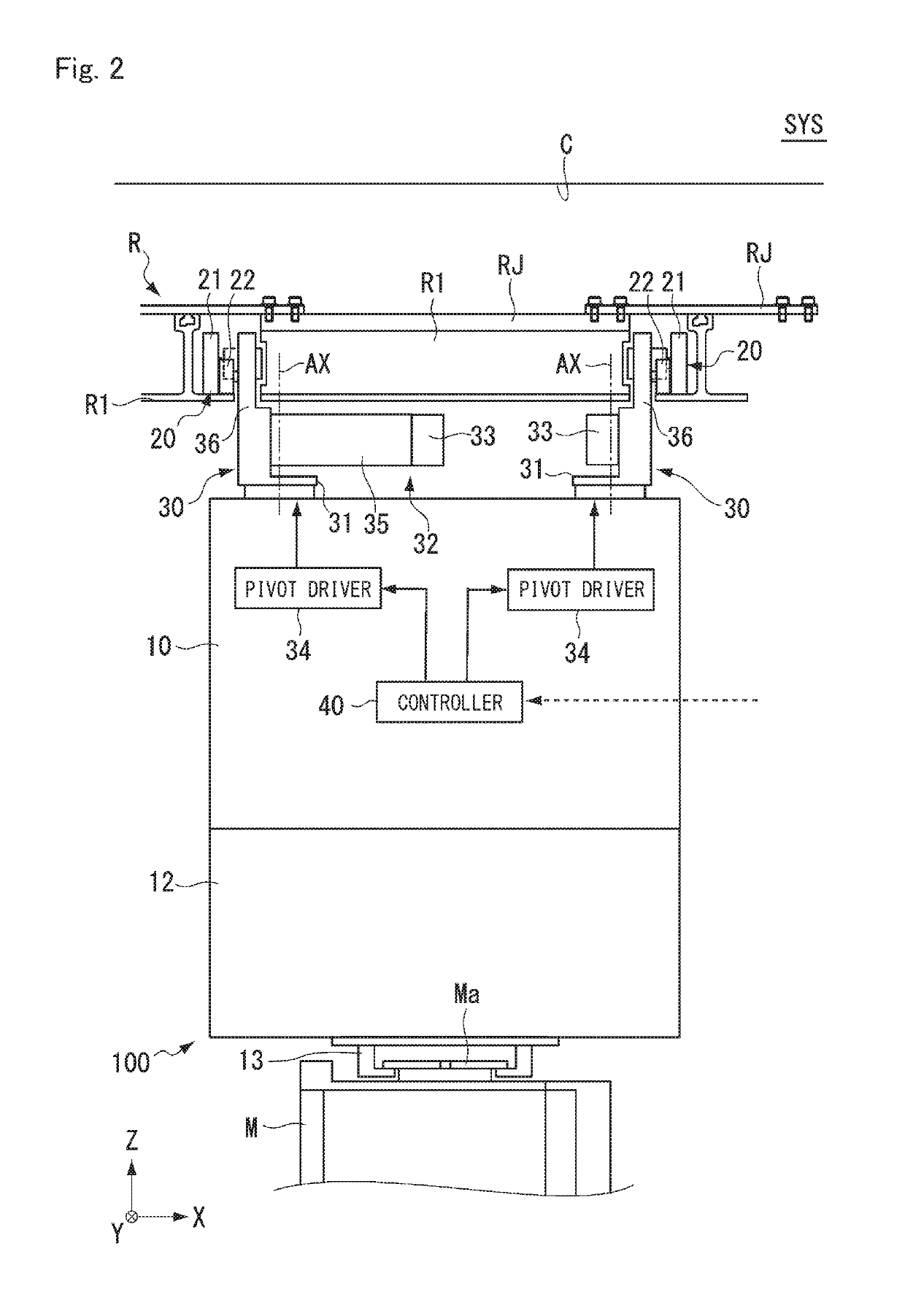

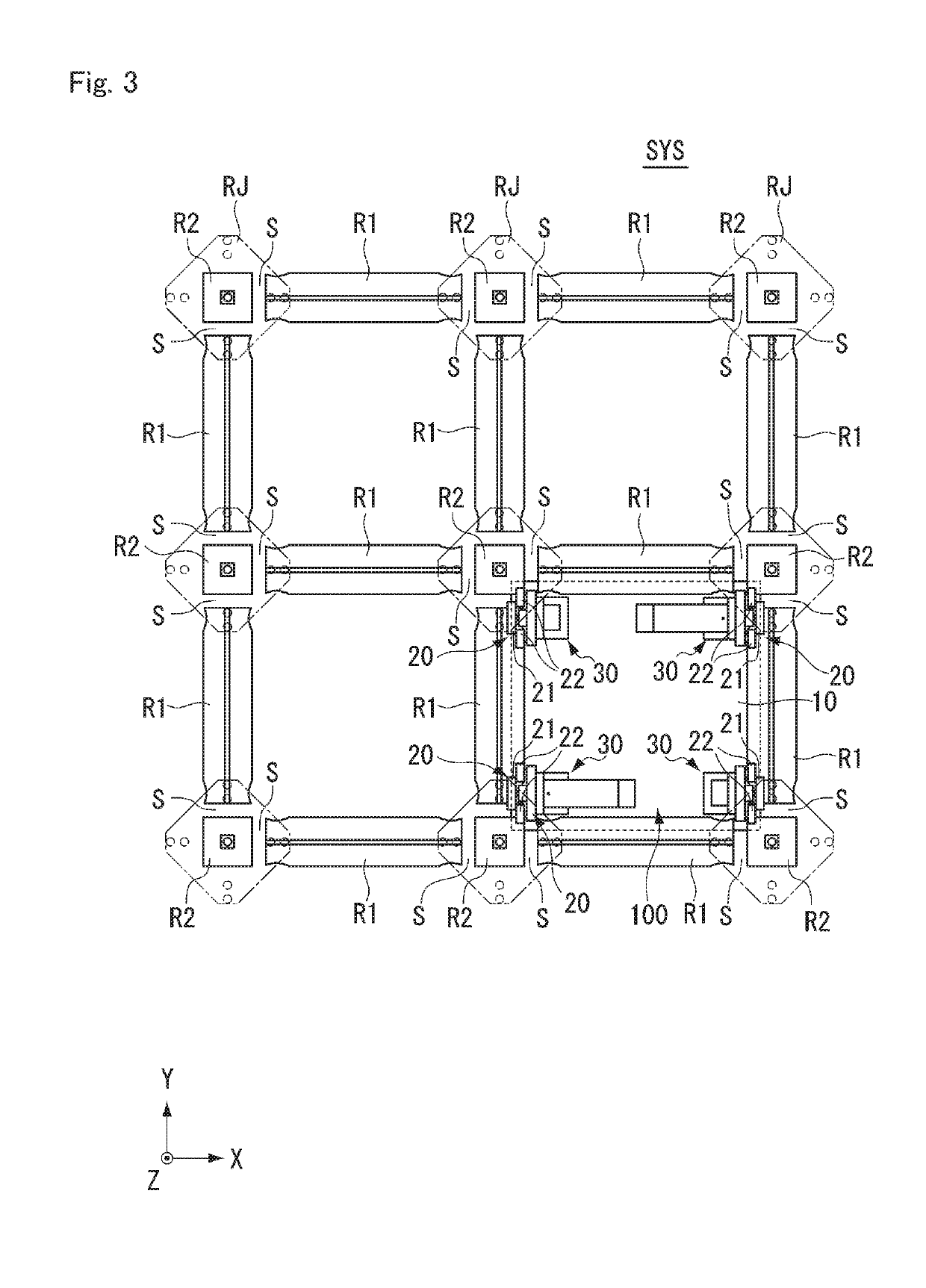

Rail-guided trolley system, and rail-guided trolley

ActiveUS20190189488A1Avoid impactAvoid vibrationConveyorsSemiconductor/solid-state device manufacturingGrid patternAutomotive engineering

A rail-guided trolley system includes a main body that, along rails at least partially in a grid pattern, holds and transports a transportation container on a lower side of the rails, traveling wheels at each of four corners of the main body and that travel on the rails, a controller that controls pivot drivers that change orientations of the traveling wheels, and auxiliary wheels each located at least in either front or rear in a traveling direction of the traveling wheel.

Owner:MURATA MASCH LTD

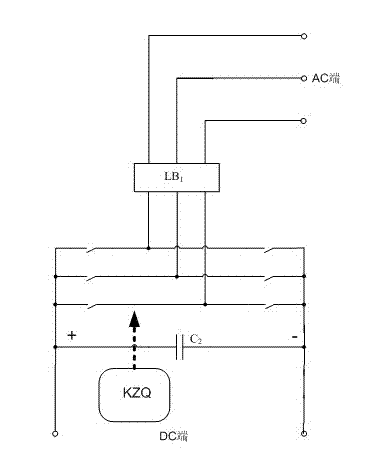

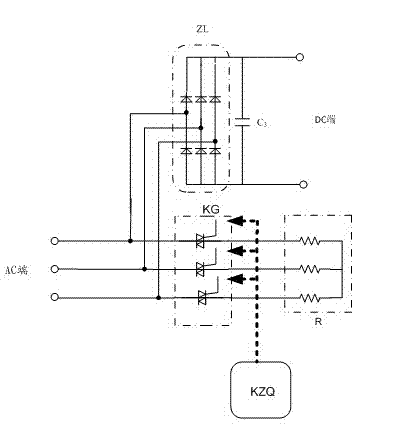

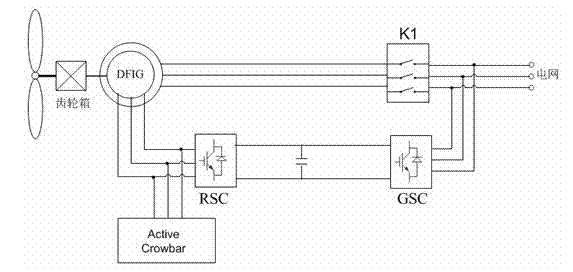

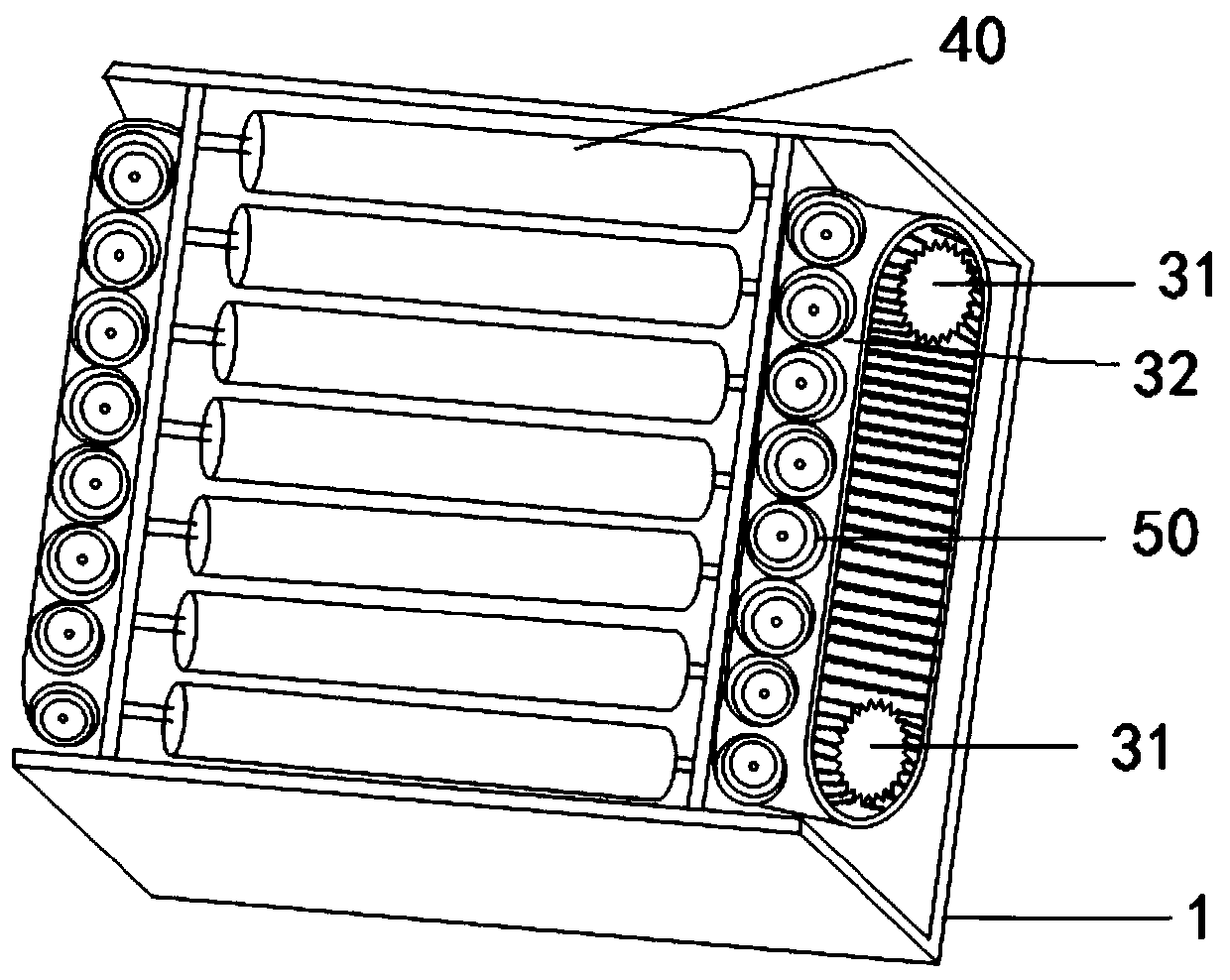

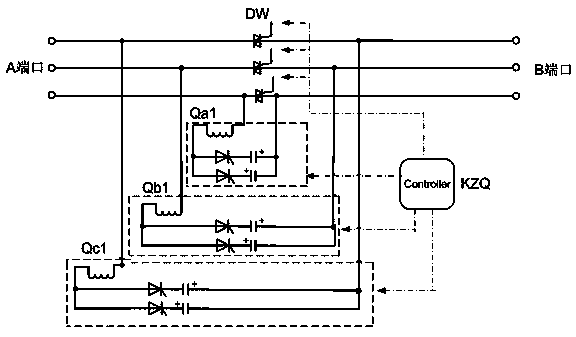

Double-feed current transformer with reliable low-voltage ride-through capability

InactiveCN102832641AExtended service lifeSimplify control algorithms and logicSingle network parallel feeding arrangementsReactive power adjustment/elimination/compensationWind drivenLow voltage ride through

The invention relates to a double-feed current transformer with perfect and reliable low-voltage ride-through capability, which consists of a rapid internetworking switch GK, a direct-current unloading unit DBU, a stator side dynamic power consuming unit DPC, a transient reactive current compensation unit TSTATCOM, an AC / DC (alternating-current / direct-current) rectification switch EK, a filter, a PWM (pulse-width modulation) rectification network side current transformer GSC, a rotor side inverter transformer RSC and a controller KZQ. The double-feed current transformer is provided with a port A, a port B and a port C, wherein the port A is connected with a stator of a double-feed wind-driven power generator, the port B is connected with a power grid, and the port C is connected with a rotor of the double-feed power generator; the stator side dynamic power consuming unit DPC is connected with the stator of the double-feed power generator through the port A, the direct-current unloading unit is connected with public direct-current buses of the GSC and the RSC, the transient reactive current compensation unit TSTATCOM is connected with the power grid side, the alternating-current end of the AC / DC rectification switch EK is connected with the stator of the double-feed power generator, and the direct-current end of the AC / DC rectification switch EK is connected with the public direct-current buses; and the working state of each part of the double-feed current transformer is controlled by signals transmitted by the controller KZQ.

Owner:NANJING JUNENG ELECTRICAL CONTROL AUTOMATION EQUIP

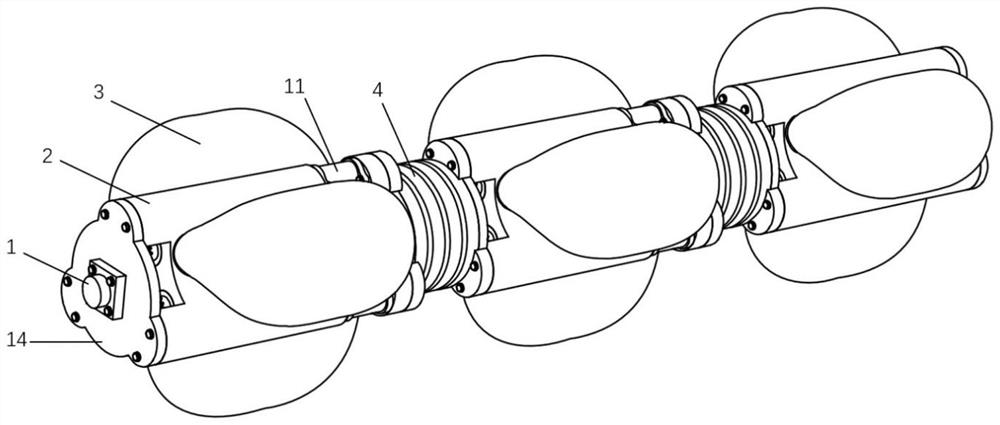

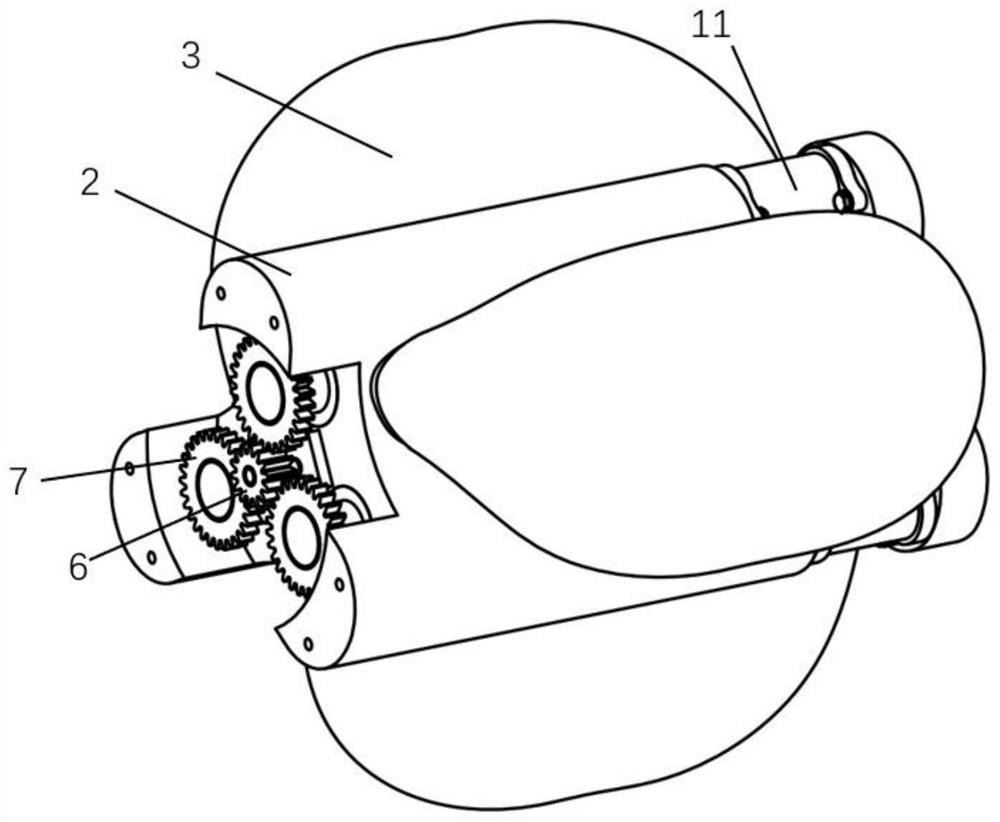

Air bag advancing type snakelike crawling robot

The invention relates to an air bag marching type snakelike crawling robot which comprises a plurality of marching units, a steering unit and detection units arranged on the marching units at the head end and the tail end, a marching motor in each marching unit is arranged on a rack, an output shaft of each marching motor is connected with a driving gear, and a transmission shaft is arranged in a transmission shaft through hole. One end of the transmission shaft is connected with the driven gear, the driven gear is in meshing transmission with the driving gear, the air bag is arranged on the outer side of the rack, the steering unit is arranged between every two adjacent advancing units, and the steering units are connected with the rack through annular end plates. The air bag structure can adapt to the complex unstructured environment, the crawling robot can rapidly advance through rolling of the air bags, reliable and lossless rapid advancing can be achieved under the complex and severe working conditions such as slopes, pipelines and ruins, meanwhile, the expansion state of pneumatic spherical hinges in the steering units can be controlled by controlling an air pump, and therefore the stability of the crawling robot is improved. Therefore, steering of the robot is controlled, and the active obstacle avoidance capability of the robot is improved.

Owner:YANSHAN UNIV

Vehicle and track transportation system

ActiveUS9821824B2Reliable travelEasy to controlMonorailsAutomatic systemsLocation detectionRoad surface

A vehicle includes running wheels traveling on traveling road surfaces of tracks; a pair of position detection parts disposed at an interval in a width direction that output signals by detecting a distance from measured objects; a control unit controlling the amount of steering of the running wheels according to the signals from the position detection parts; and a steering mechanism steering the running wheels via the control unit. Each of the position detection parts outputs a signal having characteristics such that the output increases as the distance from the measured objects increases while an output change ratio is decreased in a range wherein the distance from the measured objects is not less than a predetermined value, and is configured such that, when the distance between one position detection part and the measured object is decreased, the distance between the other position detection part and the measured object is increased.

Owner:MITSUBISHI HEAVY IND ENG LTD

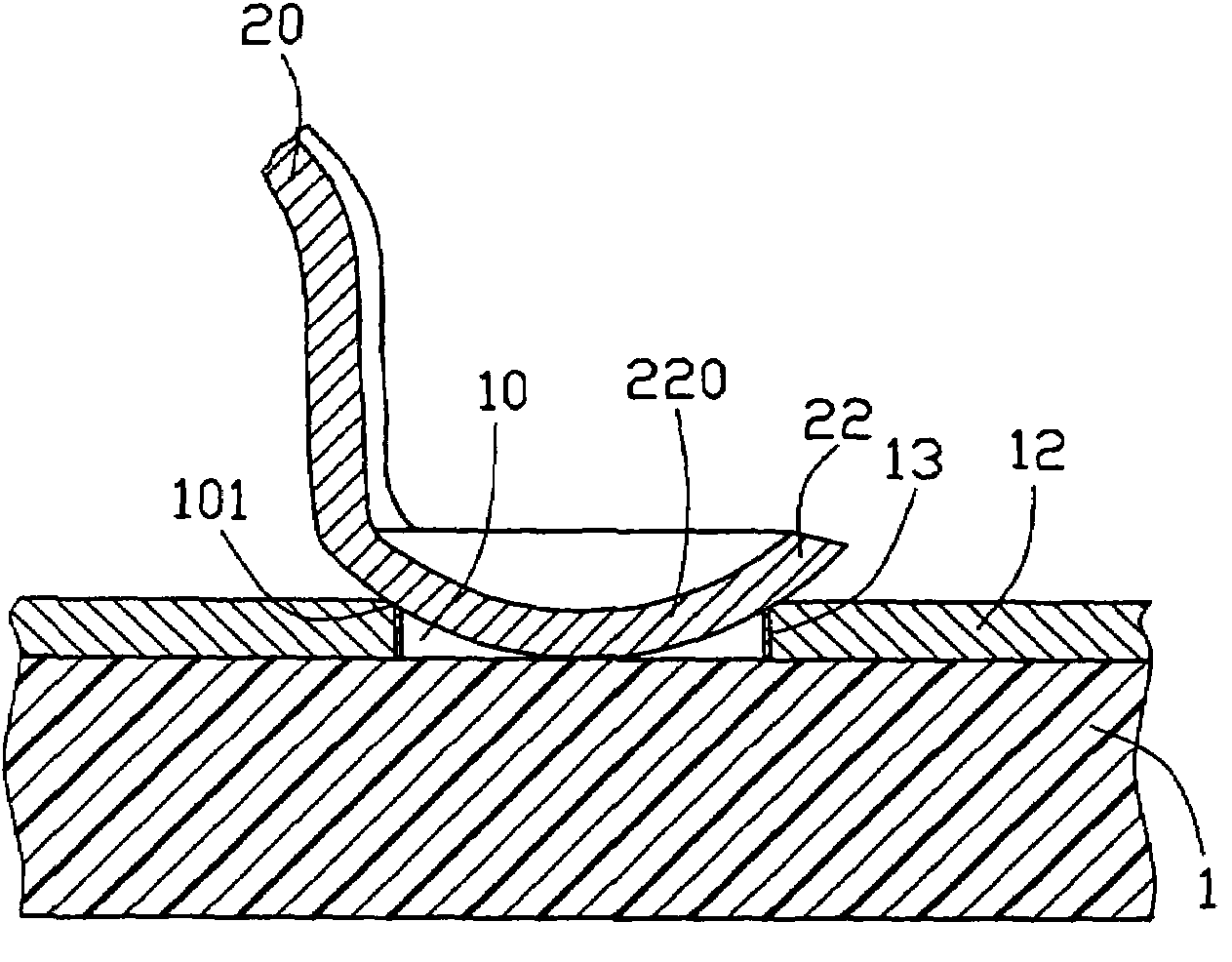

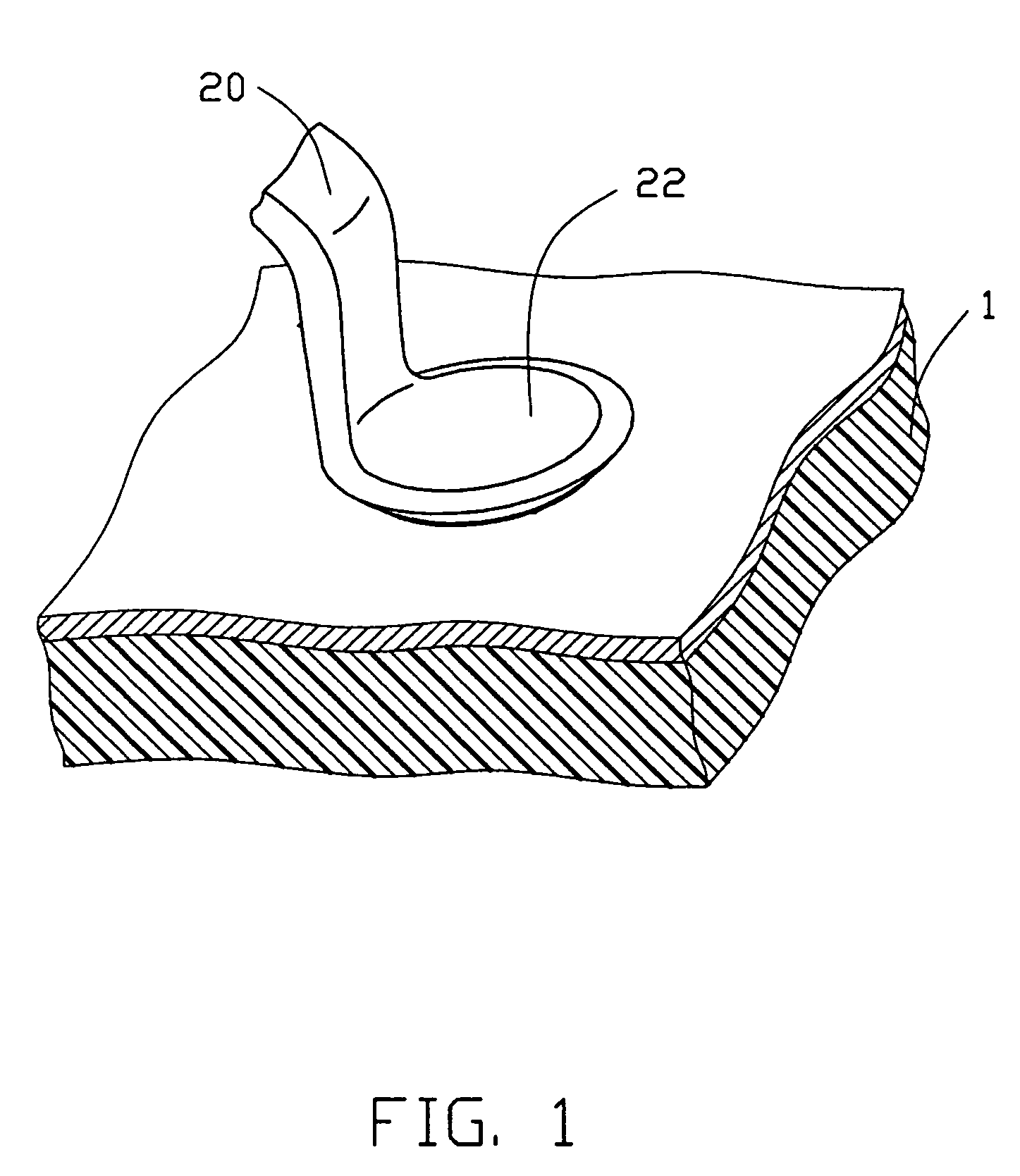

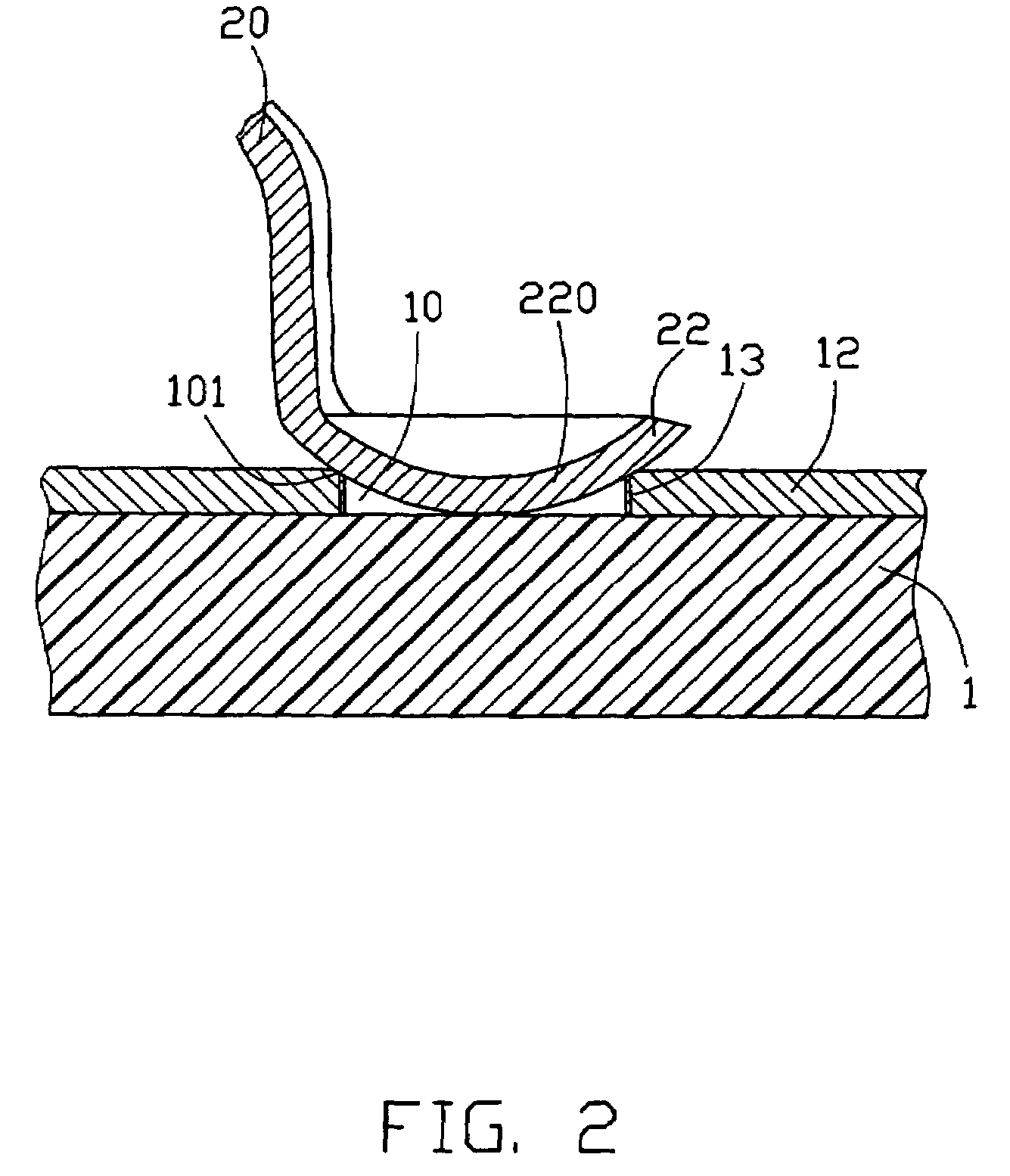

Electrical connector with contact

InactiveUS7267558B1Facilitates guidingReliable travelPrinted circuit aspectsPrinted circuit manufactureContact padEngineering

An electrical connector includes an insulative housing adapted to engage a conductive contact (20). The conductive contact has a tail end, wherein the tail end (22) is angled and has a generally dished shape such that at least a portion of the tail end terminates within a hole (10) in a contact pad (12) of a circuit board (1). The conductive contact tail end in a dished shape has the advantages of facilitating the guiding of the tail end into or out of the hole of the circuit board during wipe actions, without removing gold plated layer, and of achieving a reliable travel of the tail end across the hole of the contact pad of the circuit board.

Owner:HON HAI PRECISION IND CO LTD

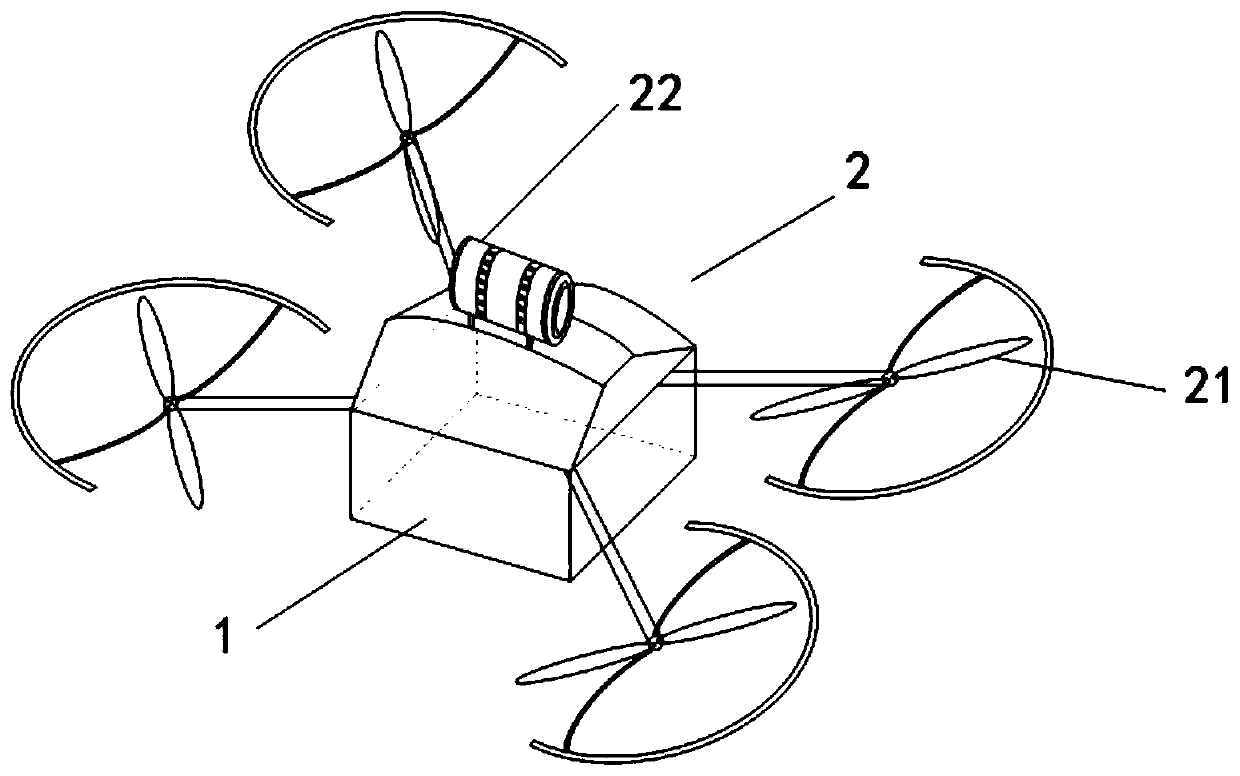

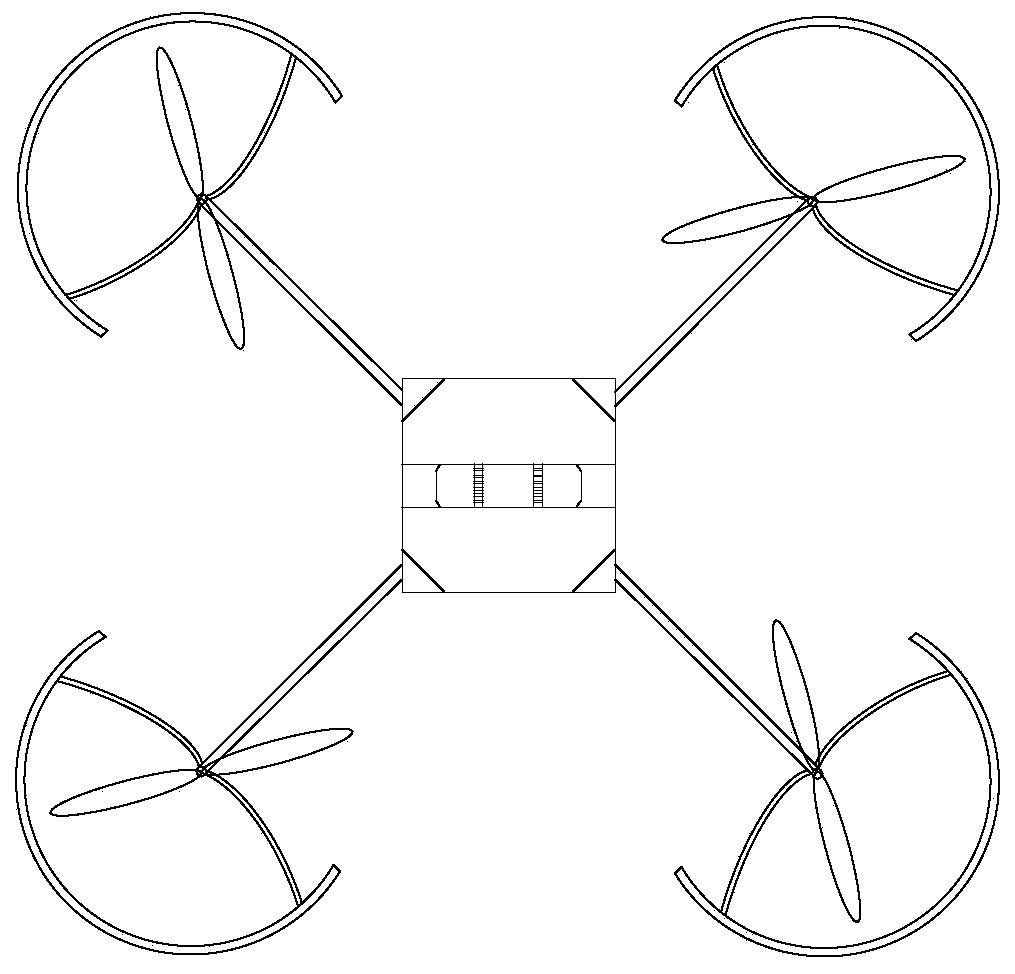

A high-rise glass cleaning robot

ActiveCN107440626BClean thoroughlySolve the problem of accidental dropCarpet cleanersFloor cleanersEngineeringHigh rise

The invention provides a high-rise building glass cleaning robot, which comprises a vehicle body and a flying machine which is connected to the vehicle body, wherein the flying machine is arranged at the upper side of the vehicle body; a dust collection mechanism, a suction mechanism and a moving mechanism are connected to the vehicle body; the dust collection mechanism is arranged in the vehicle body; both the moving mechanism and the suction mechanism are arranged at the bottom of the vehicle body; and the suction mechanism is connected to the moving mechanism. The cleaning robot provided by the invention, by arranging the flying machine, not only can achieve fixed-point cleaning and edge-crossing cleaning, but also can solve the problem that the cleaning robot accidentally drops down in a working process. The cleaning robot provided by the invention is compact in structure, simple and practical and is convenient to operate; cost of cleaning glass curtain walls can be reduced, potential safety troubles of high-altitude cleaning can be eliminated to the greatest extent and cleaning efficiency can be improved; and reliable walking and efficient cleaning on such vertical surfaces as high-rise building glass and the like can be implemented, so that the demand of intelligently cleaning the glass curtain walls can be satisfied.

Owner:CHINA AGRI UNIV

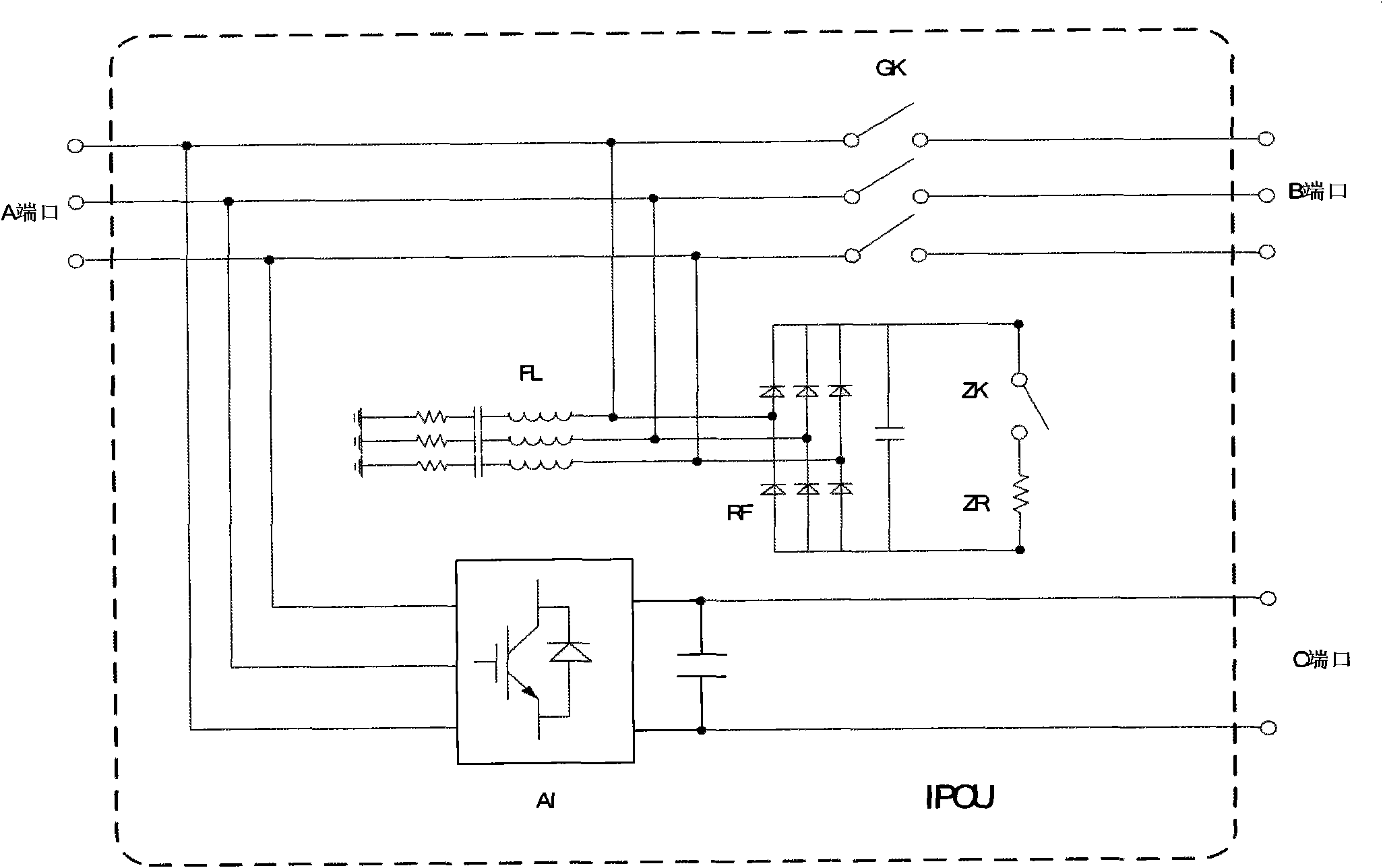

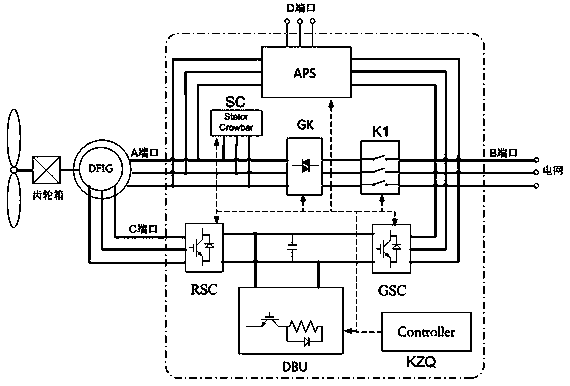

Doubly-fed converter with reliable low voltage ride-through capability

InactiveCN102790406BPerfect low voltage ride through capabilityPerfect high voltage ride through capabilitySingle network parallel feeding arrangementsLow voltageControl theory

The invention relates to a novel doubly-fed converter with perfect and reliable low-voltage ride-through capability. The doubly-fed converter is rapidly switched by a fast grid-connected switch GK, a DC unloading unit DBU, a stator Crowbar, and an auxiliary power supply Unit APS, grid-side power module GSC, rotor-side power module RSC, grid-connected circuit breaker K1 and controller KZQ, etc. This doubly-fed converter is provided with A port, B port, C port and D port, where A port is connected to the doubly-fed wind turbine stator, B port is connected to the grid, C port is connected to the doubly-fed generator rotor, and D The port is connected to the power supply of the main control system of the doubly-fed generator set; the AC end of the stator crowbar is connected to the stator of the doubly-fed generator, and the DC unloading unit is connected to the common DC bus of GSC and RSC; the work of each part of the doubly-fed converter The state is controlled by the signal sent by the controller KZQ.

Owner:NANJING HIGH DRIVE ELECTROMECHANICAL AUTOMATION EQUIP CO LTD

Method for fault location to multi-terminal traveling wave in direct current distribution line

ActiveUS11408924B2Inhibition rangeImprove reliabilityFault location by conductor typesFault location by pulse reflection methodsPath lengthEngineering

A method for fault location to multi-terminal traveling wave in a direct current distribution line, which belongs to the field of power line fault ranging and location technology. The method includes a main site and a plurality of acquisition points installed into the distribution line and includes steps as follows. Step 1001: collecting and uploading a traveling wave signal by each of the acquisition points after a fault occurs in the line; step 1002: generating a fault record set; step 1003: computing the shortest paths from a central site to other sites and their lengths; step 1004: using expanded two-terminal traveling wave ranging principle for pairing computation; step 1005: converting positions of possible disturbance points into possible disturbance occurrence time points; step 1006: extrapolating from equal path lengths of the possible disturbance points to obtain disturbance time data; and step 1007: determining a final disturbance point.

Owner:SHANDONG UNIV OF TECH

Method and device for transferring a paper web from a supporting woven fabric to another

ActiveCN101868578BReliable travelSolve wear and tearMachine wet endPress sectionWoven fabricPaper machine

The object of the present invention is a method and a device for transferring a paper web from a supporting woven fabric to another. The method according to the invention and the device according to the present invention are therefore suitable, for example, for transferring a web from the wire section onto a press felt and from the press into the dryer section. The use of the method and of the device is particularly advantageous when transferring the paper web in the press section of the paper machine from the first to the second press. The key aspect of the method according to the invention and of the device according to the invention is that when detaching the paper web W from the supporting woven fabric (46) a transfer suction box (56) is used in conjunction with the felt guide roller (54), wherein the cover of said box substantially has the same direction as the paper web (W) running from the felt guide roller (54) to the subsequent roller (64) such that said cover does not change the running direction of the web W and suctions an air layer strip (200) on both sides of the web W through the woven fabric (46).

Owner:VALMET CHINA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com