Method and device for transferring a paper web from a supporting woven fabric to another

A technology for paper webs and fabrics, applied in papermaking, papermaking machines, wet end of paper machines, etc., can solve the problems of expensive purchase, operation and maintenance of suction rolls, complex width of suction area and high cost, and achieve the cost of purchase and operation. Low, reliable conveying web, the effect of solving the problem of wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

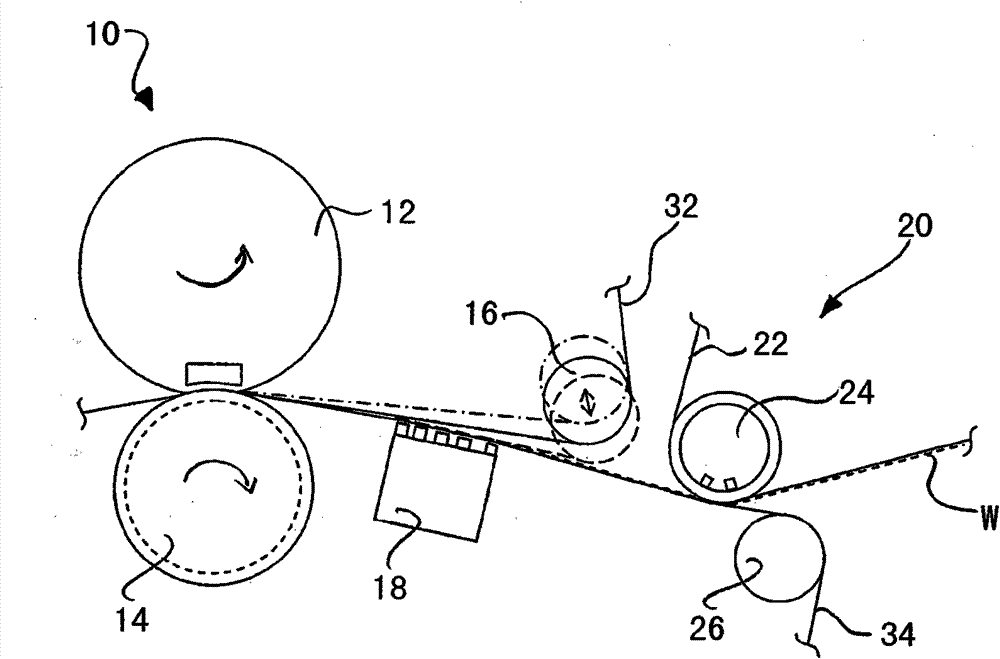

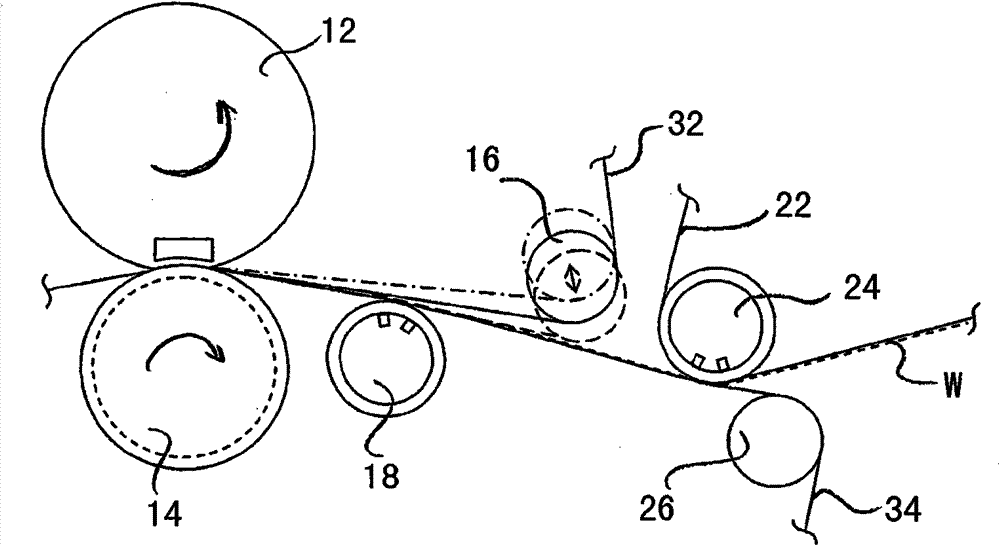

[0030] figure 1Shows a partial view of a paper machine referred to in US patent document 5,888,354 according to the prior art - a press section included in an apparatus for conveying a paper web from one support fabric to another . The pressure section shown in the drawings is composed of a first pressure section 10 and a second pressure section 20 . The first press section is constituted in the figure by the shoe roll 12 and its counter roll 14, the paper web lying between the two felts 32 and 34 passes through the press of the first press section from left to right in the figure. Area. The first felt 32 runs in the form of a loop, in which the shoe roller 12 is located, so that the path of the first felt 32 extends upwards around the shoe roller when the felt guide roller 16 is adjustable. The second felt then travels on counter rolls 14 . On the way between the counter roll 14 and the felt guide roll 16 the paper web W is separated from the first felt 32 by means of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com