Ultrasonic municipal wastewater and garbage treatment device with tail heat utilizing and exhaust purifying functions

A technology for waste treatment device and exhaust gas purification, which is applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, fertilization device, etc. and other issues, to achieve the effect of saving labor, strong creativity, and good prospects for promotion and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

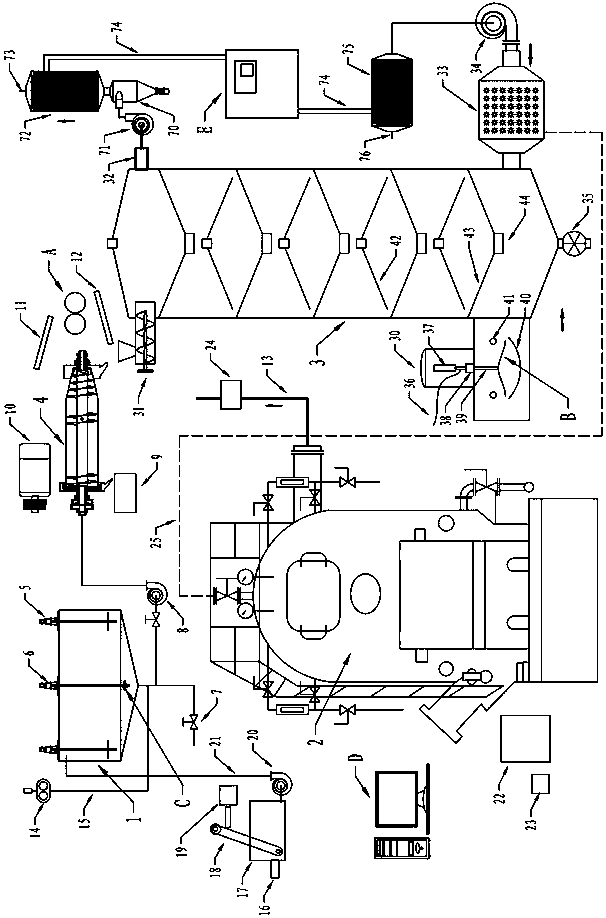

[0026] Now in conjunction with accompanying drawing, the present invention is described in further detail.

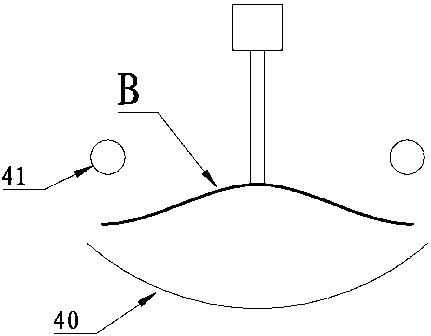

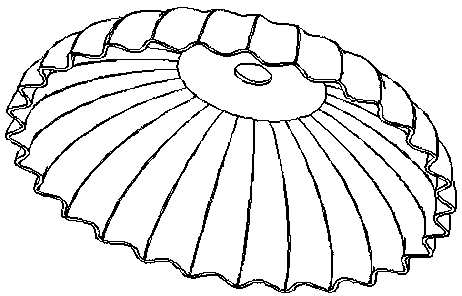

[0027] Such as Figure 1 ~ Figure 3 Shown is an ultrasonic urban waste water and garbage treatment device with exhaust heat utilization and exhaust gas purification, including sewage tank 1, incinerator 2, countercurrent drying tower 3, horizontal screw centrifuge 4, counter-rotating roller A, and heat pump host E and computer control system D, it is characterized in that: urban waste water pipe 16 is connected with the inlet of waste water buffer tank 17, and the waste water buffer tank 17 is provided with grille slag removal machine 18, and the outlet of grille slag removal machine 18 is connected to the centrifuge through conveying The dehydrator 19, the outlet of the waste water buffer tank 17 is connected to the inlet of the large sewage tank 1 through the sewage pipe 21 and the sewage pump 20, and an appropriate amount of stirring device 5 is installed in the larg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com