Patents

Literature

42results about How to "Realize automatic continuous processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

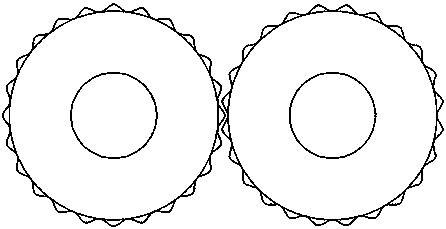

Method for efficient discharge milling with hollow long electrode

InactiveCN1397399AComprehensive effect of efficient processingComprehensive effect of accurate processingMachining electrodesElectrical-based machining electrodesTitanium alloyMachining

A discharge mill technology using simple hollow long electrode is based on the numeral control technique and features use of simple hollow long electrode plus guider. The said electrode features simple cross-section, hollow structure for delivering liquid and high length-radium ratio (more than 3:1). Its advantages are high productivity to Ti-alloy, refrectory alloy and stainless steel.

Owner:苏州中特机电科技有限公司

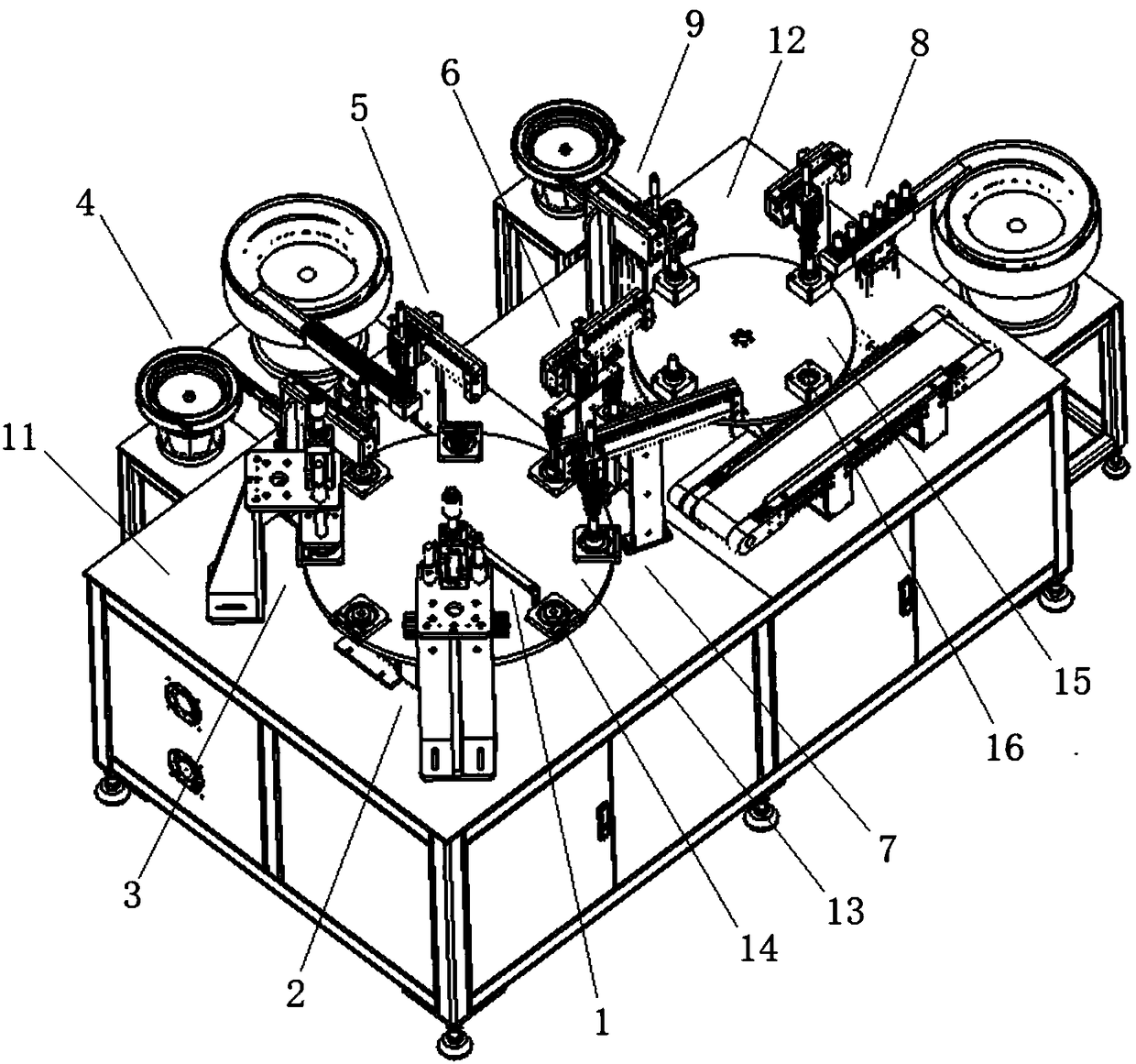

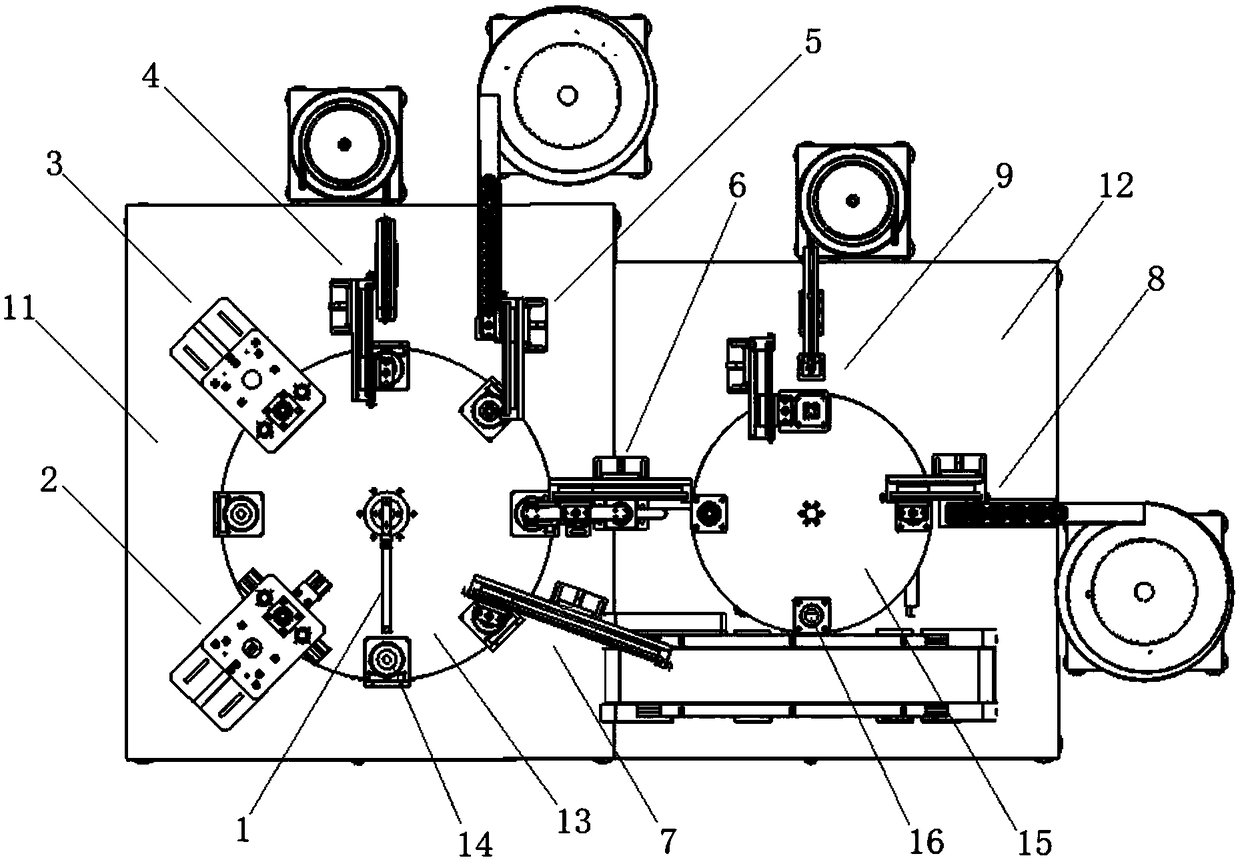

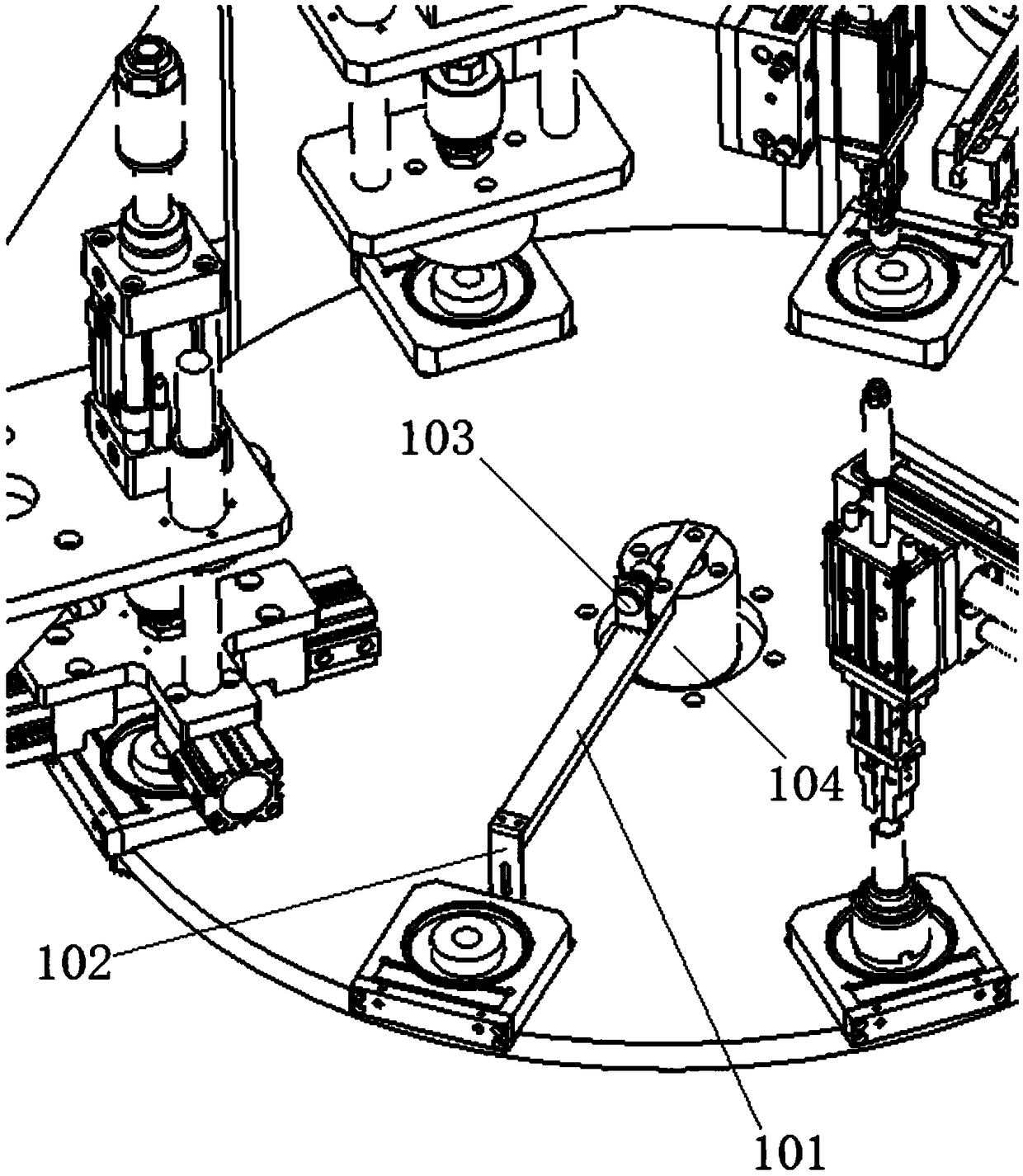

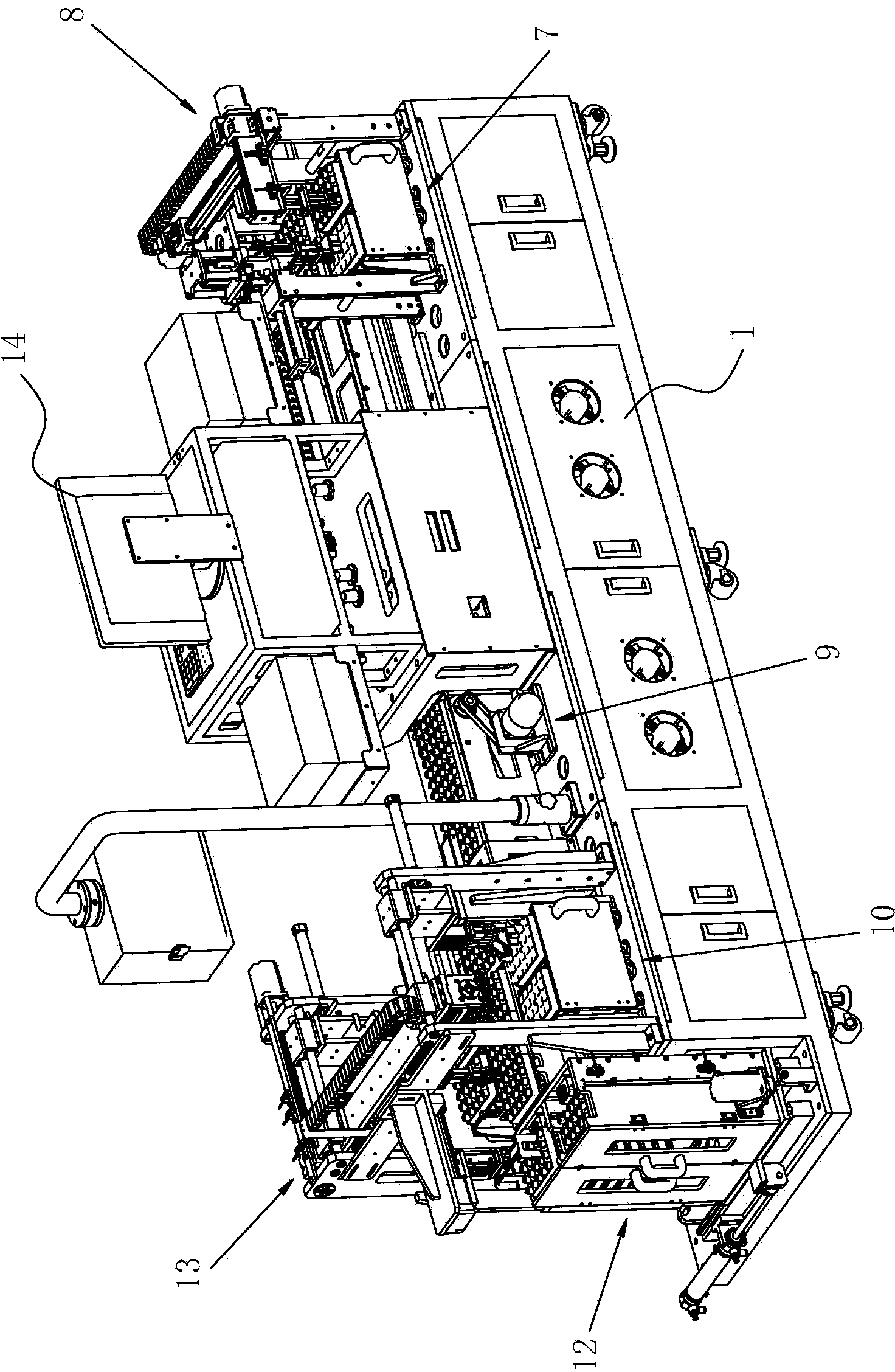

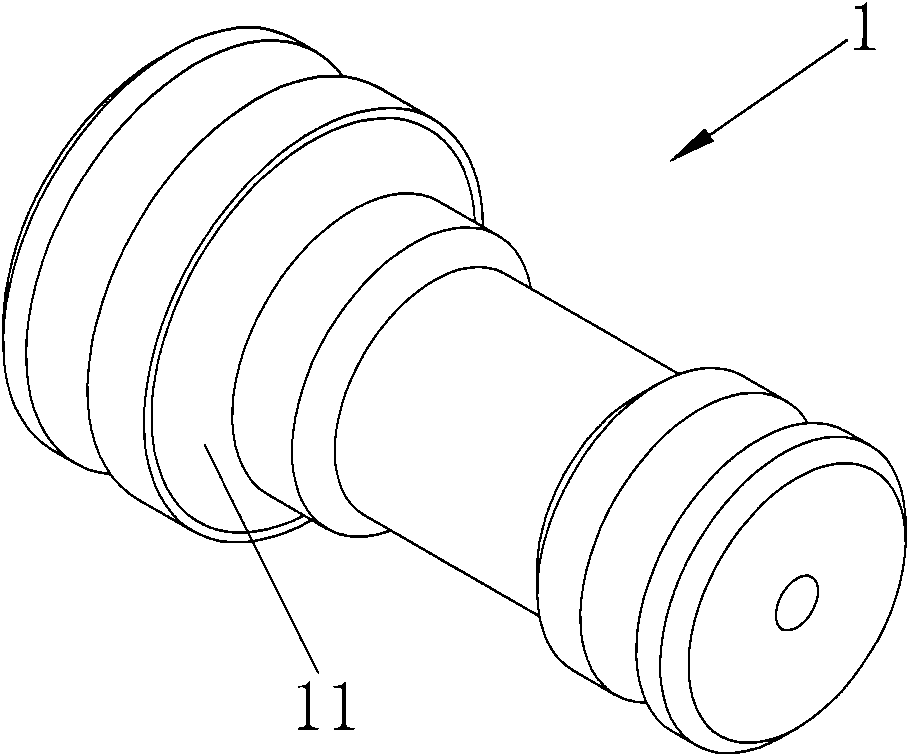

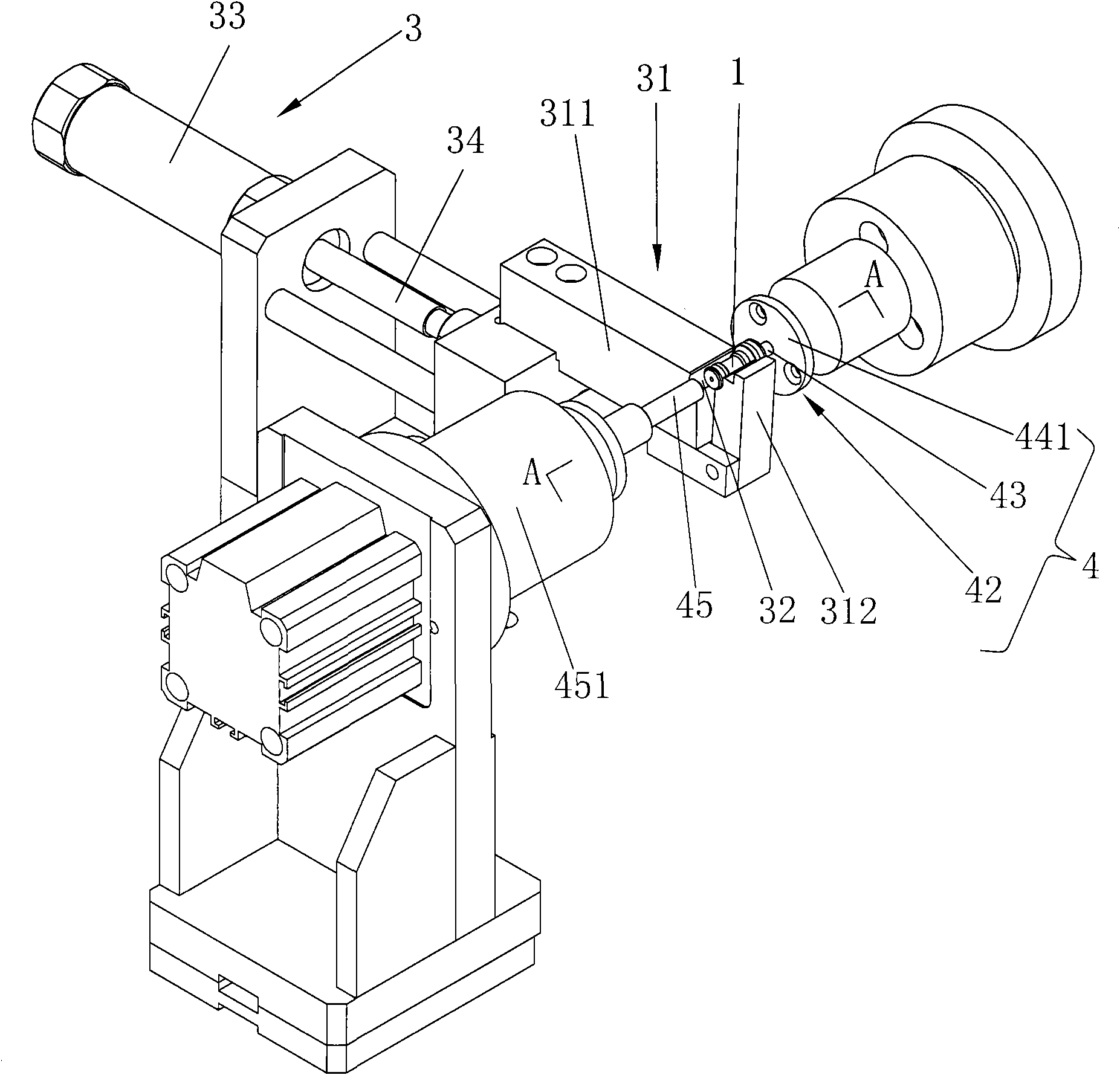

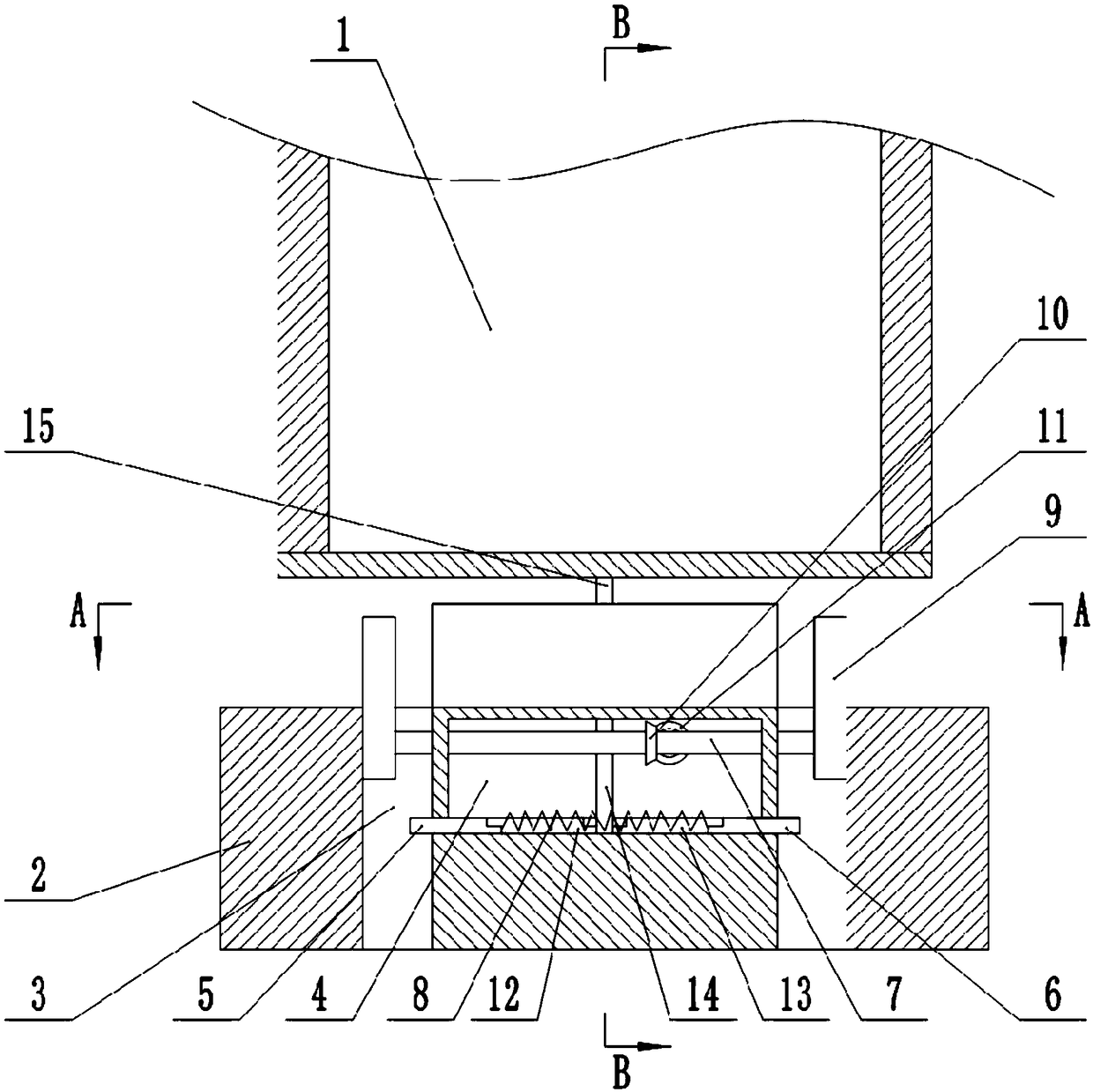

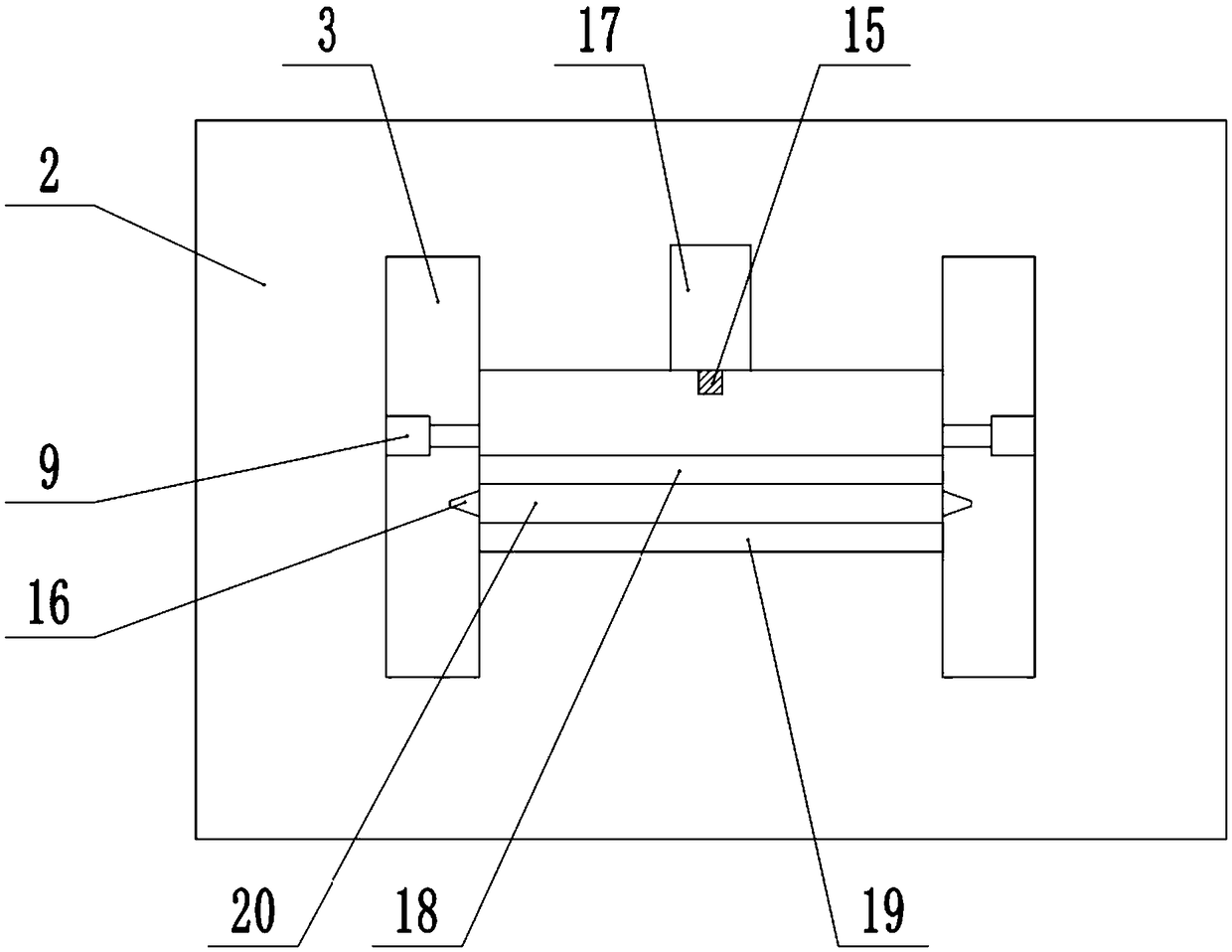

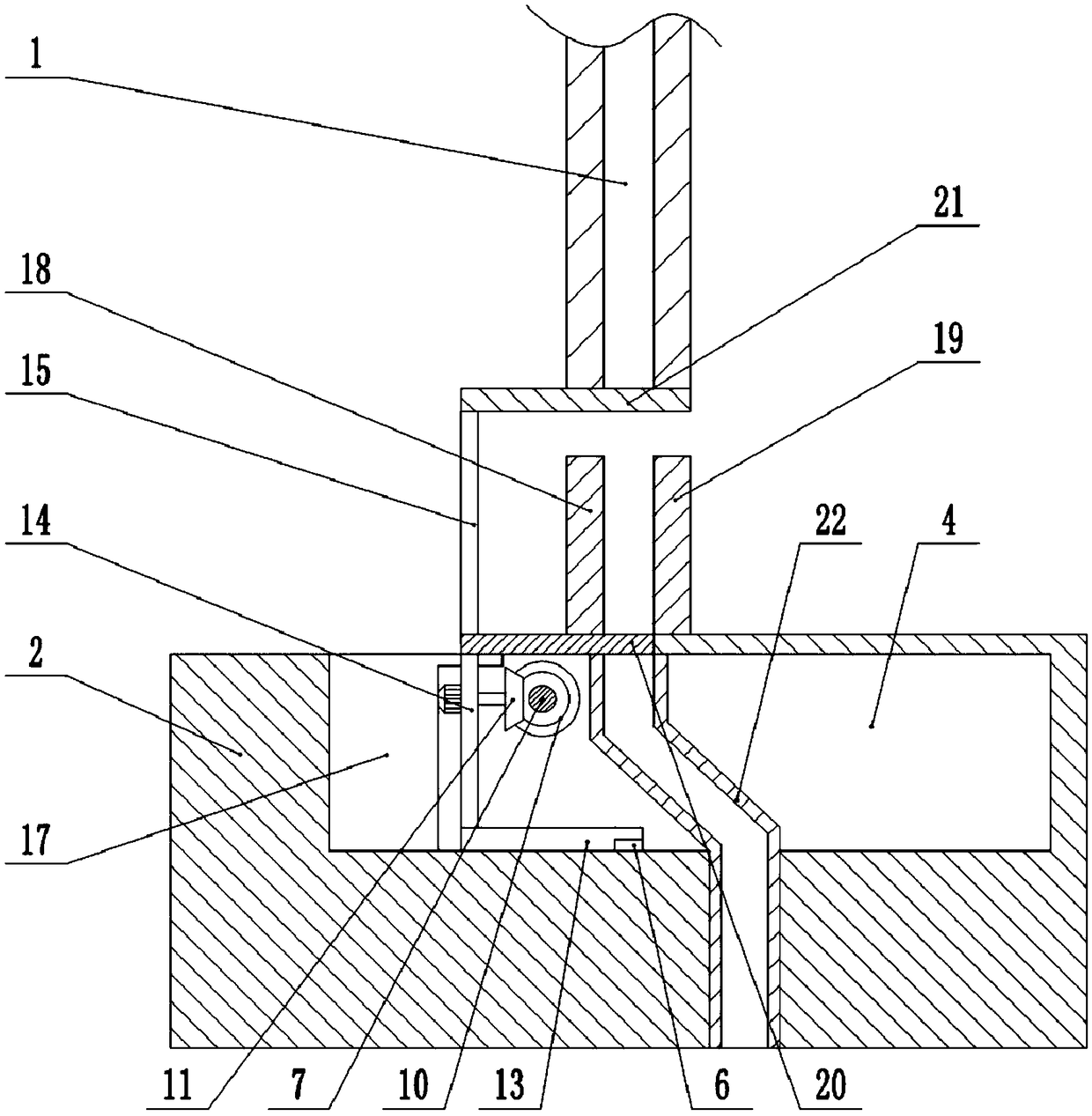

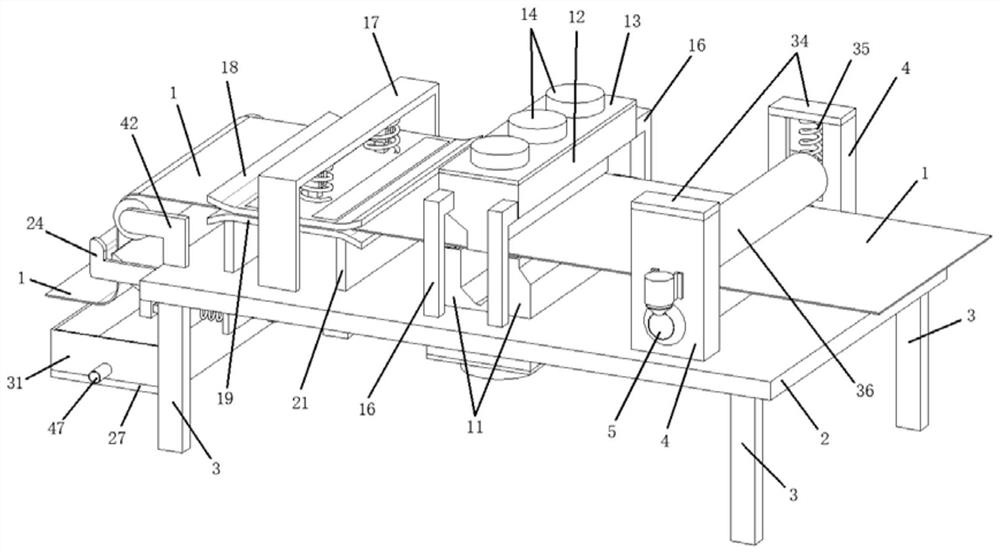

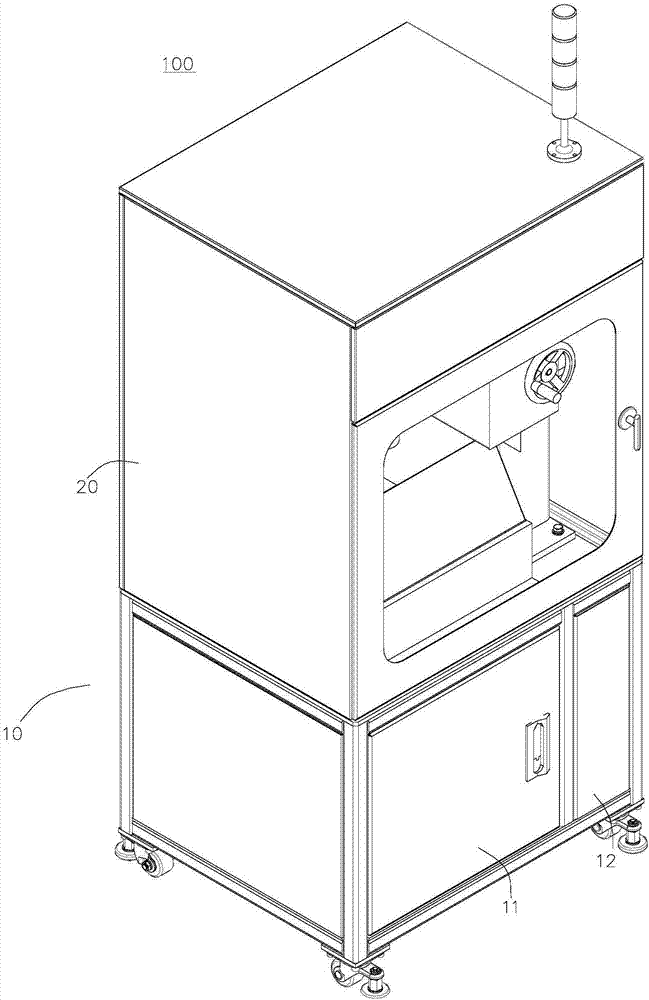

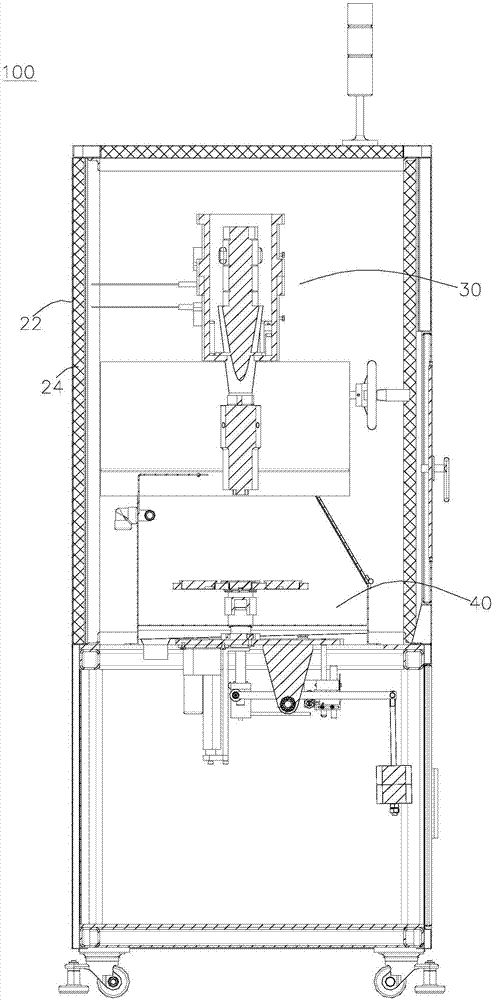

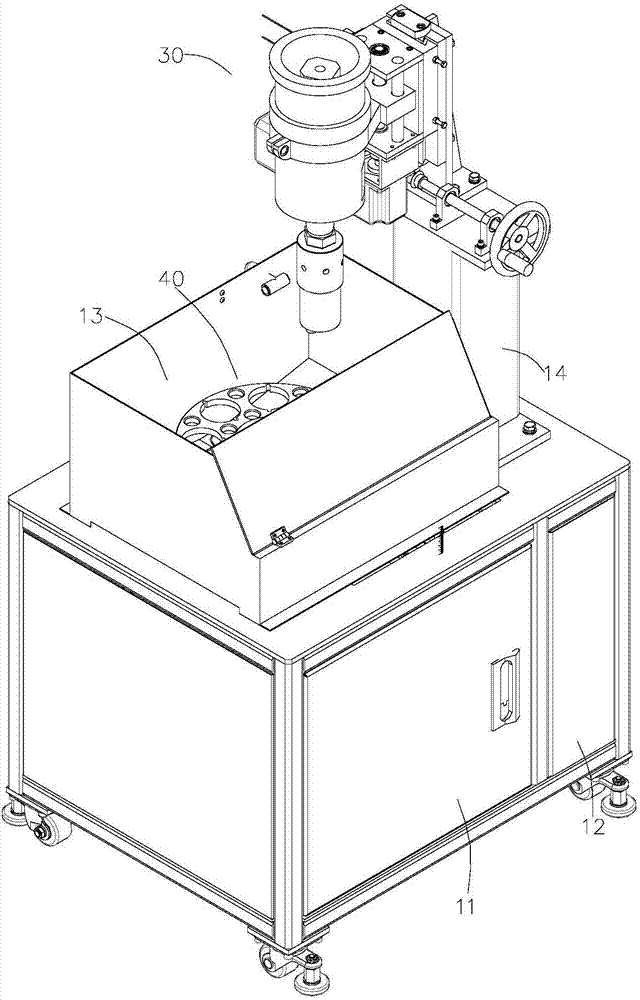

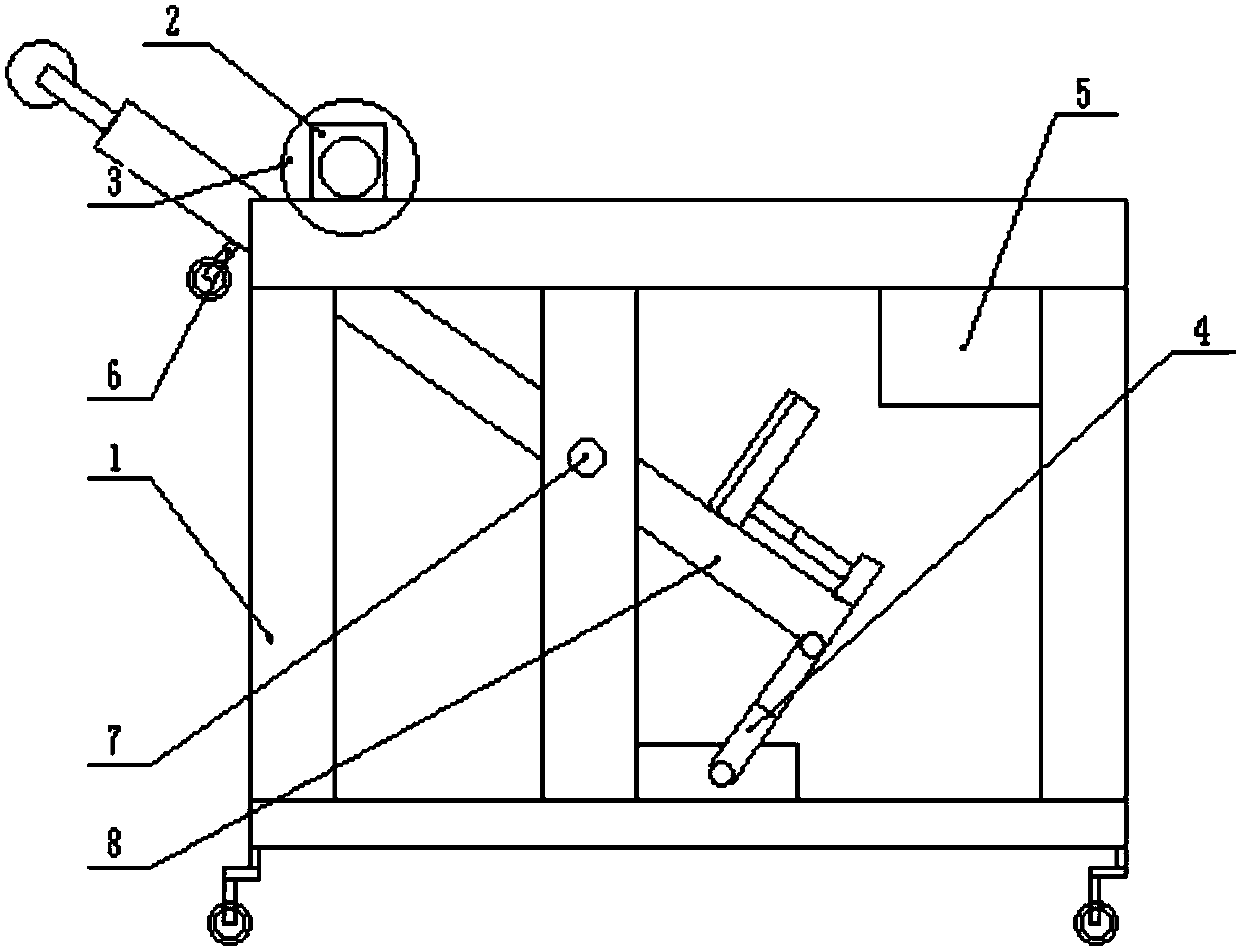

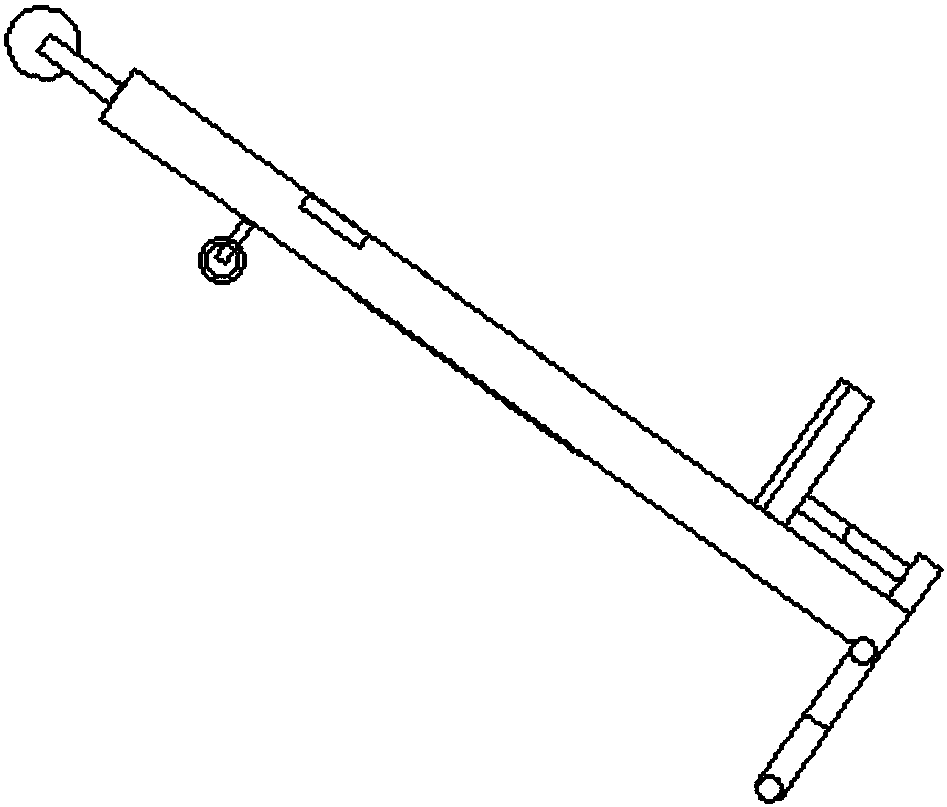

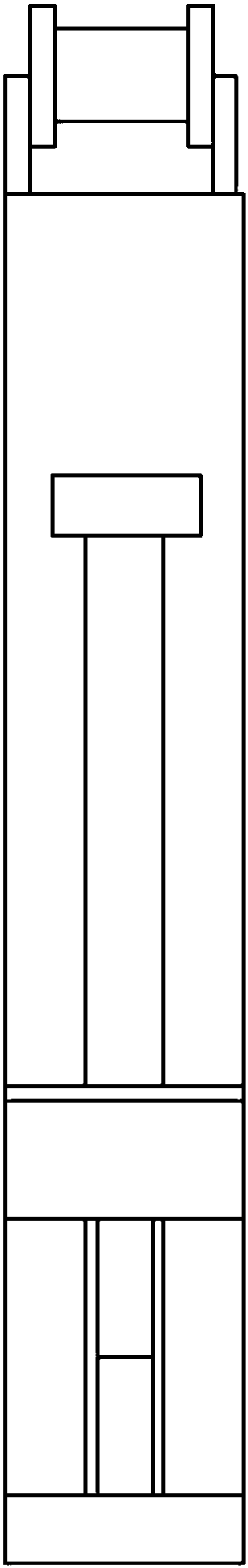

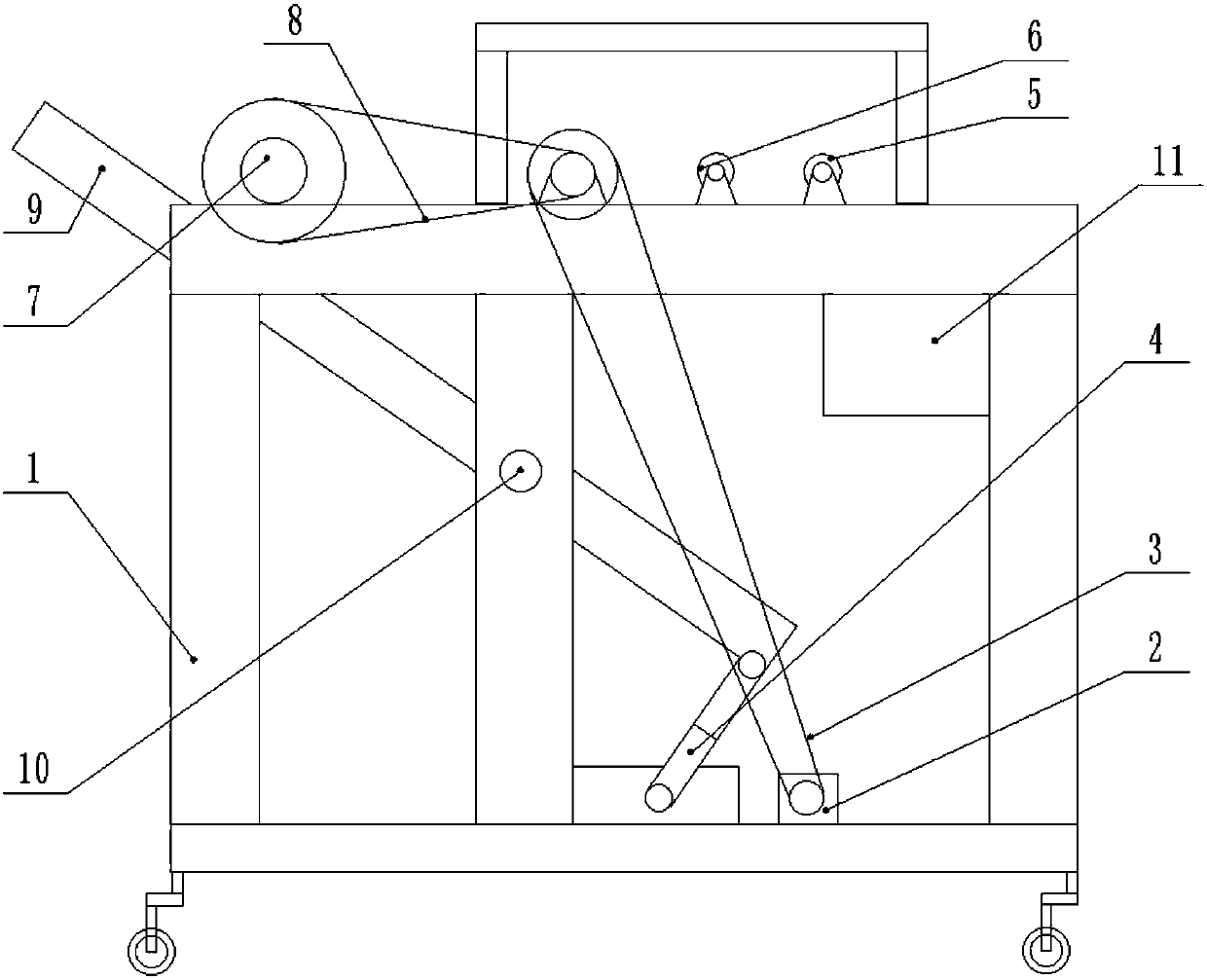

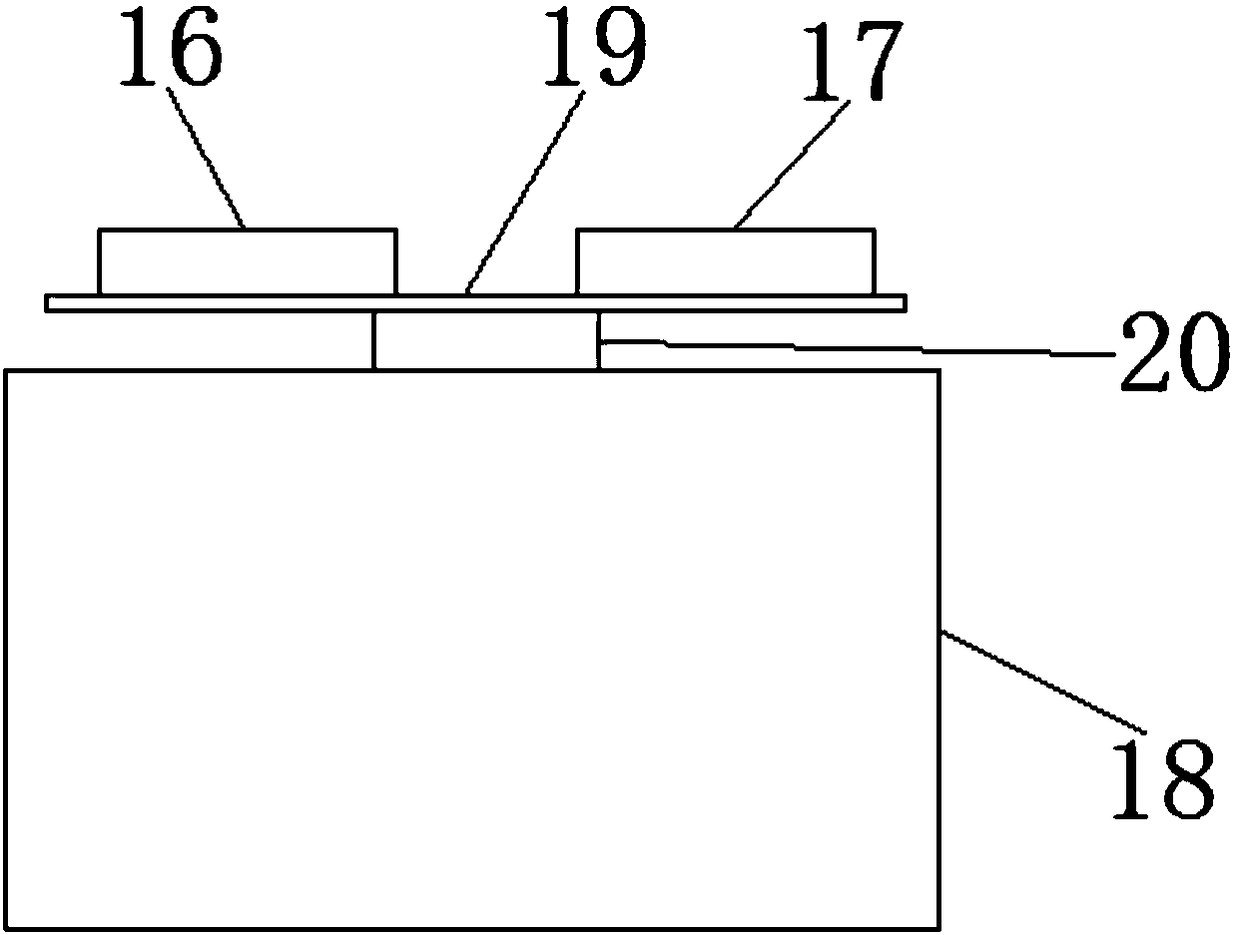

Spray head assembling machine

PendingCN108372404ARealize automatic continuous processingImprove processing efficiencyAssembly machinesMetal working apparatusUltimate tensile strengthNozzle

The invention discloses a sprayer assembling machine, which comprises a main workbench and a sub-workbench; a main mounting rotating table is arranged on the main workbench. 8 sprayer mounting seats are arranged on the main mounting rotating table. A product position induction mechanism, a primary pre-pressing mechanism, a secondary riveting mechanism, a first nozzle feeding mechanism, a second nozzle feeding mechanism, a cover seat grabbing and mounting mechanism, a product fixing heating jig and a spray head blanking mechanism are sequentially arranged around the main mounting rotating table. A sub-mounting rotating table is arranged on the sub-workbench. Four cover seat fixing seats are arranged on the sub-mounting rotating table. A cover seat feeding mechanism and a sealing ring feeding mechanism are arranged around the sub-mounting rotating table. According to the invention, automatic and continuous processing of the spray head is realized. Only one operator can automatically carry out primary pre-pressing, secondary riveting, nozzle mounting, sealing ring mounting, cover seat correction and heating, cover seat mounting and final blanking and other working procedures of the spray head, so that not only the processing efficiency is greatly improved, but also the labor intensity is obviously reduced.

Owner:苏州润禄自动化科技有限公司

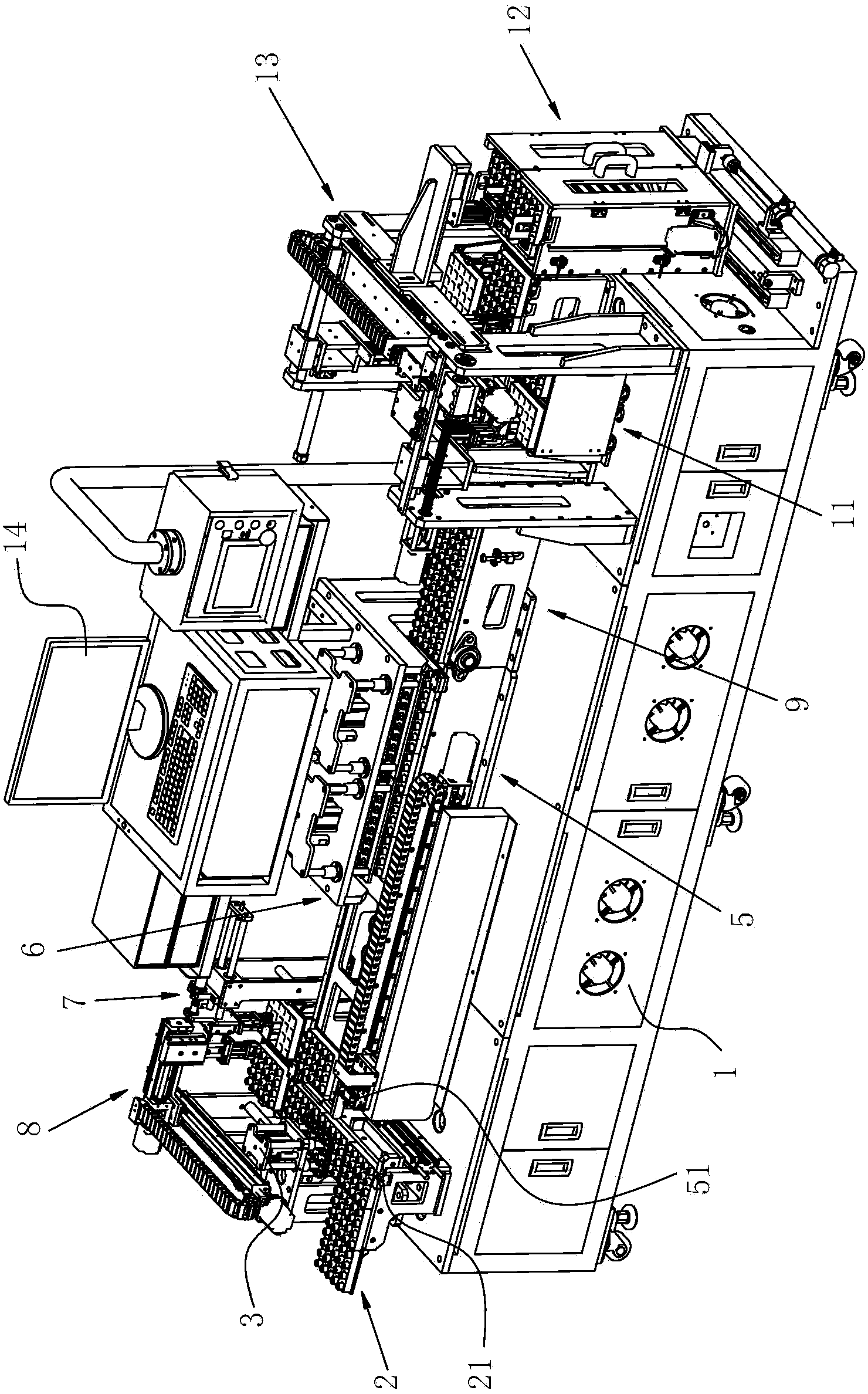

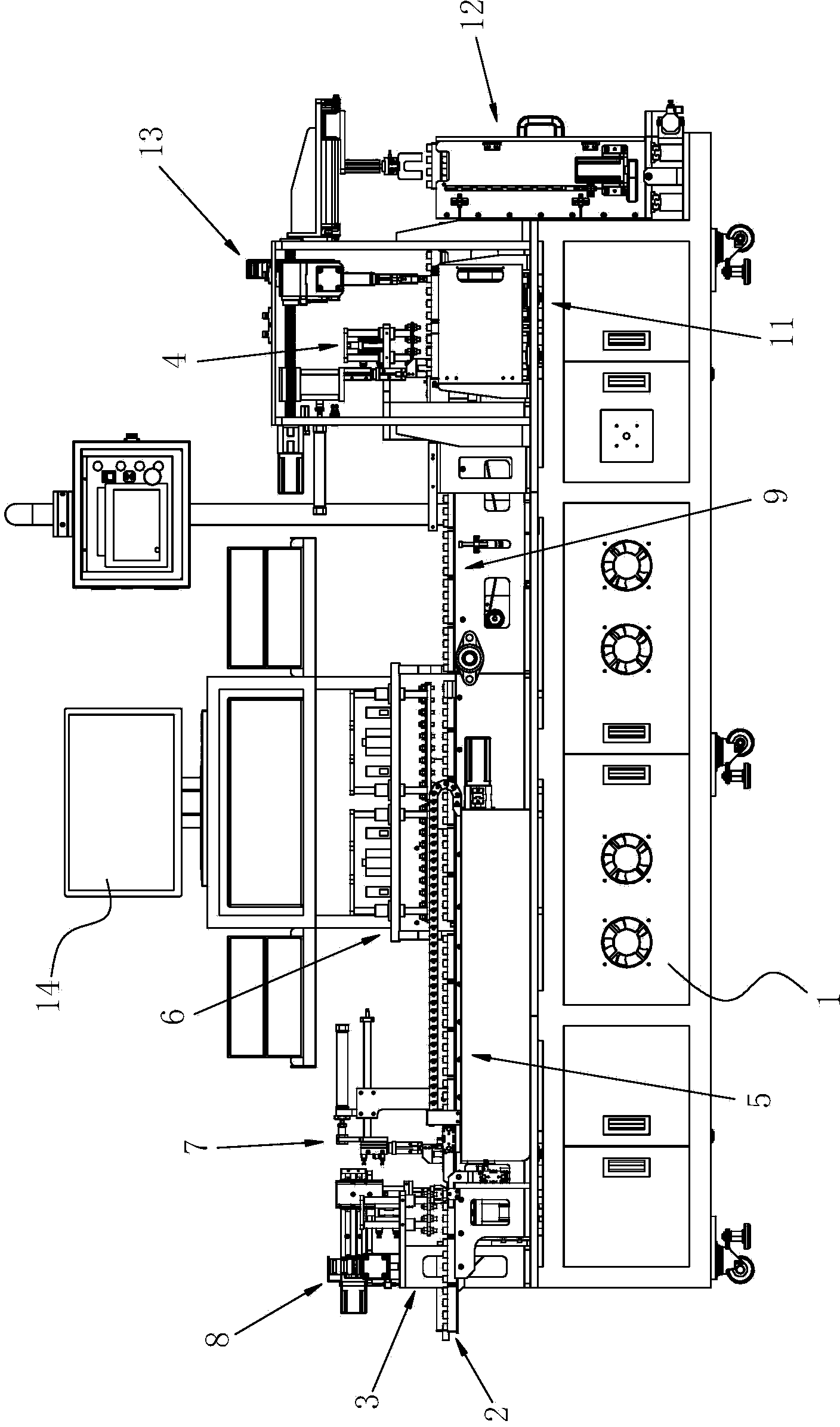

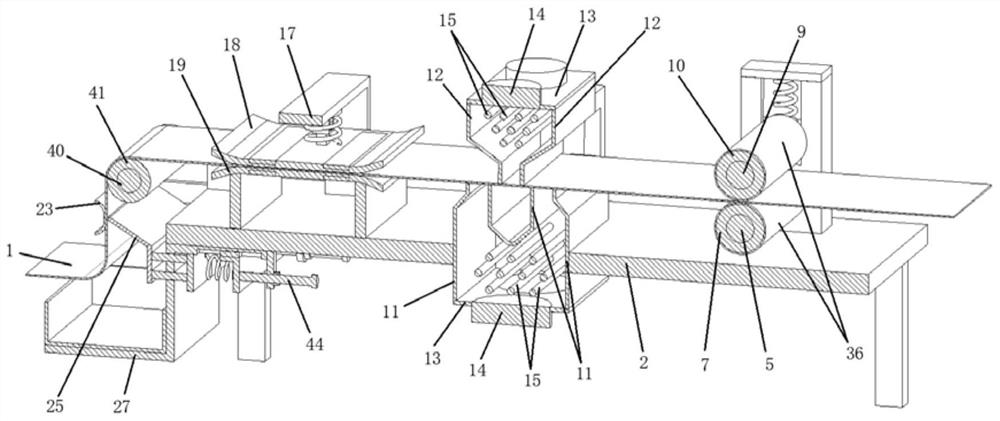

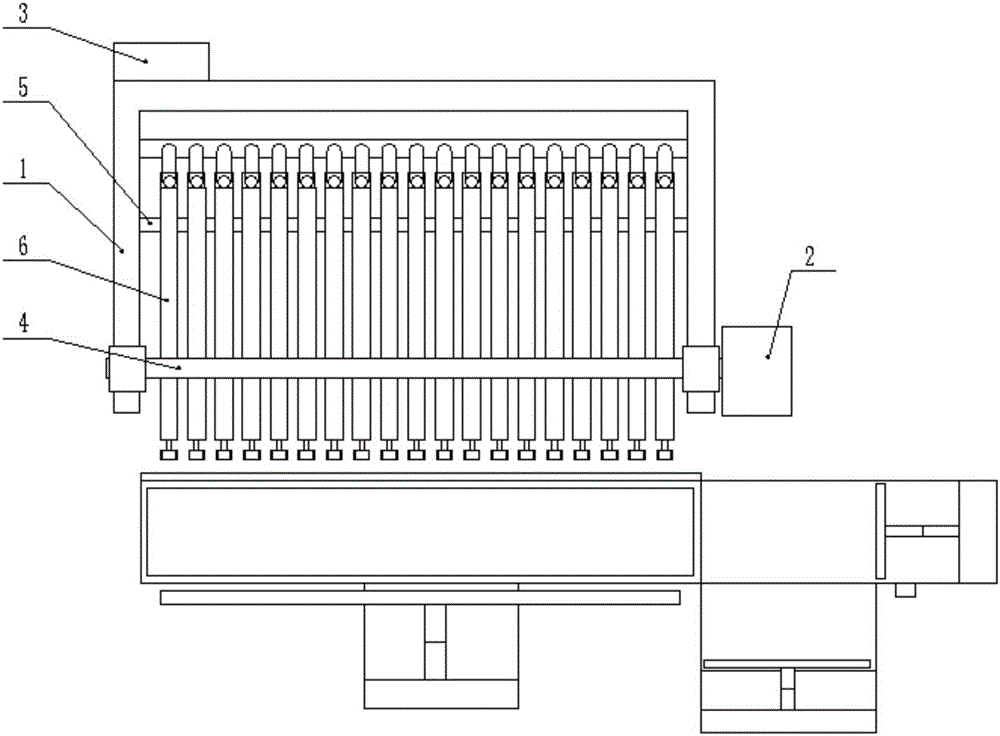

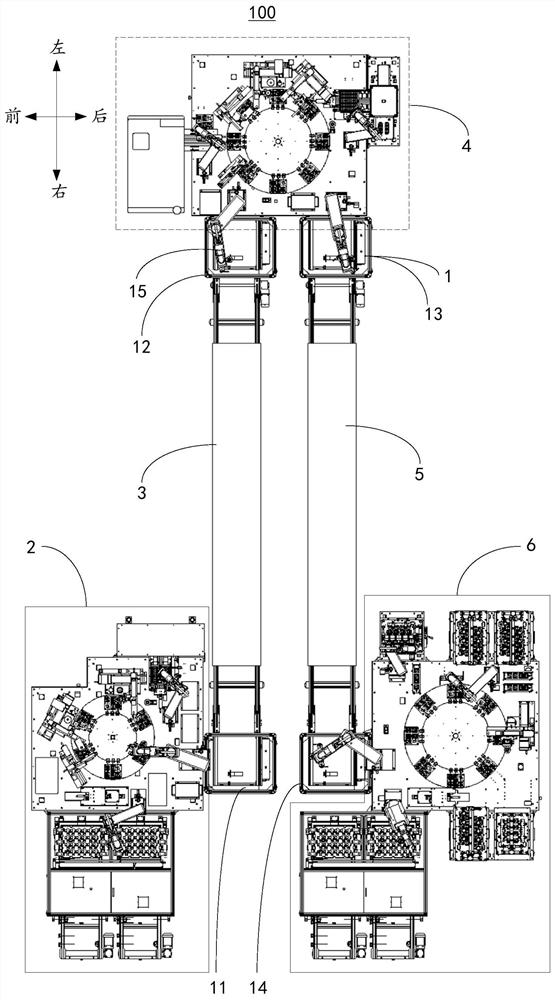

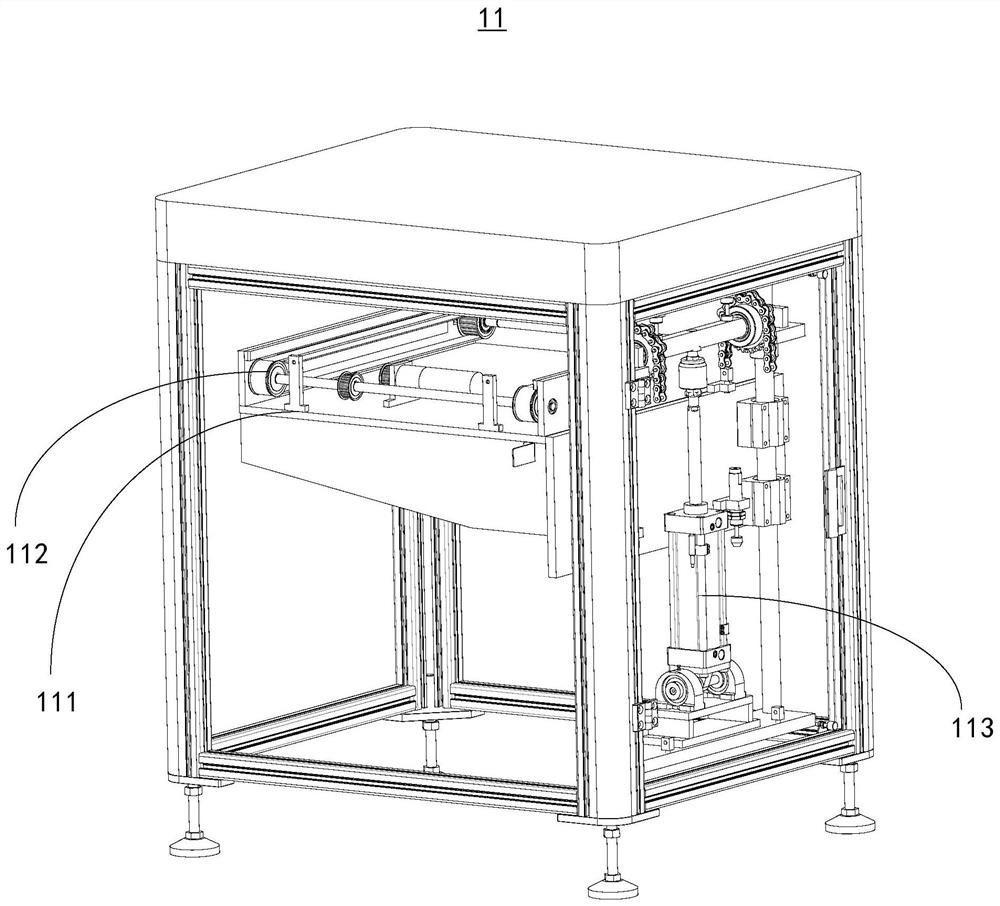

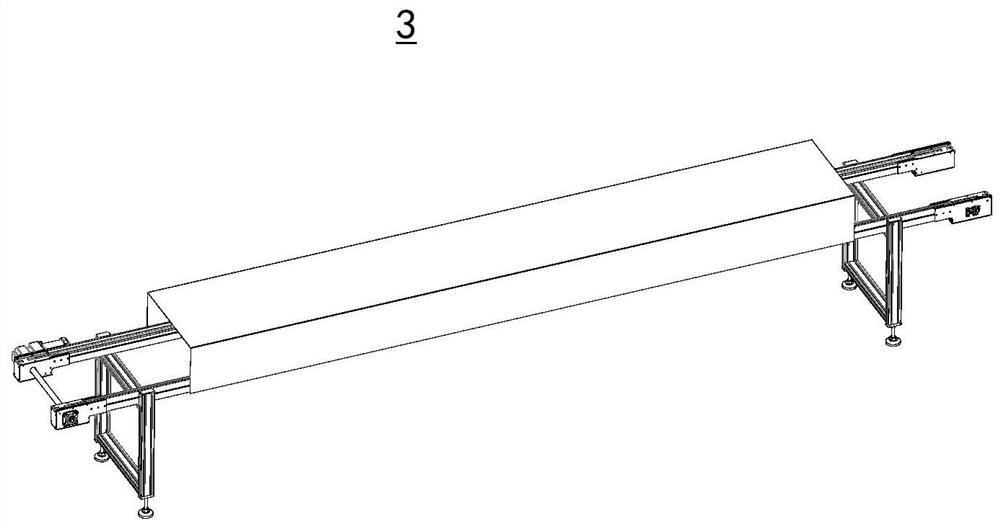

Columnar discharging and testing machine and method for carrying out discharging and testing on batteries through columnar discharging and testing machine

ActiveCN104375089ARealize batch automatic dischargeIncrease productivityFinal product manufacturePrimary cellsBiochemical engineeringManipulator

The invention discloses a columnar discharging and testing machine. The columnar discharging and testing machine comprises a discharging track and a discharging mechanism. A first testing mechanism is arranged at one end of the discharging track, and a second testing mechanism is arranged at the other end of the discharging track. A first inferior-quality product collecting mechanism is arranged on one side of the first testing mechanism, and a first inferior-quality product mechanical arm is arranged between the first testing mechanism and the first inferior-quality product collecting mechanism. A second inferior-quality product collecting assembly and a qualified product supplementing assembly are arranged on the two sides of the second testing mechanism respectively. A qualified product collecting mechanism is arranged on the side, far away from the first testing mechanism, of the second testing mechanism. A combined product rotating mechanism is arranged above the second testing mechanism, the second inferior-quality product collecting assembly, the qualified product supplementing assembly and the qualified product collecting mechanism. The invention further discloses a battery testing and discharging method. By means of the columnar discharging and testing machine and the battery testing and discharging method, batch automatic discharging of batteries can be achieved, testing and discharging can be automatically and continuously carried out on the batteries, and the production efficiency and the product quality of the batteries are effectively improved.

Owner:HUIZHOU JINYUAN PRECISION AUTOMATION EQUIP

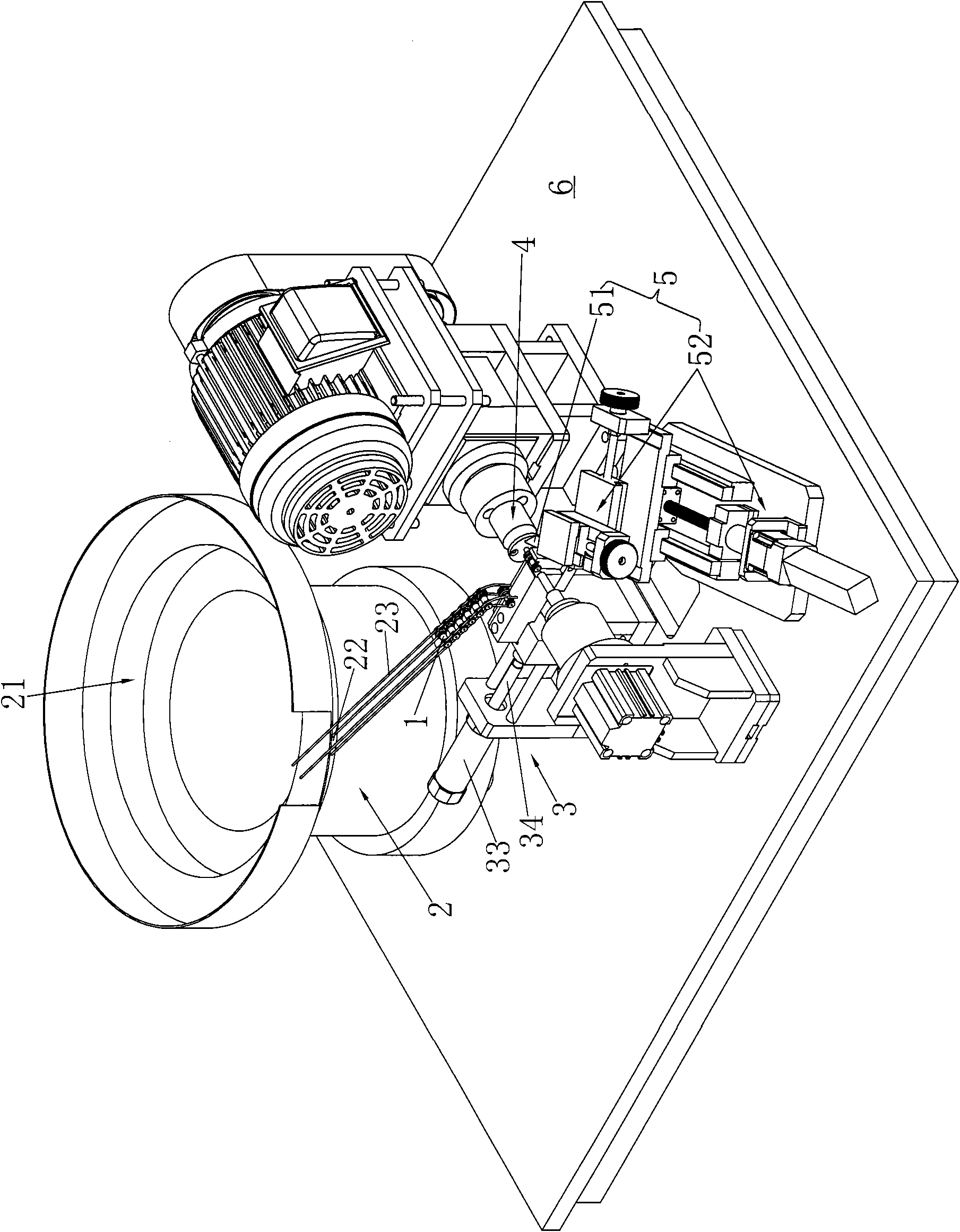

Plastic pipe turning machine

InactiveCN101623766AIncrease productionImprove efficiencyAutomatic conveying/guiding stockTurning machinesEngineeringMechanical engineering

The invention discloses a plastic pipe turning machine, which is specially used for processing plastic pipes. The plastic pipe turning machine comprises a loading mechanism, a feeding mechanism, a clamping mechanism and a turning mechanism which are arranged on a substrate, wherein the clamping mechanism comprises a main shaft rotating at a high speed and a clamping part connected with the main shaft; the turning mechanism comprises a turning tool and a control mechanism used for regulating the position of the turning tool and controlling the turning tool to realize the turning; the feeding mechanism comprises a feeding block capable of moving relative to the main shaft; the upper surface of the feeding block is provided with a feeding groove used for accommodating a plastic pipe blank; and the clamping part comprises a positioning rod which is fixed on the main shaft and is used for positioning the plastic pipe blank, and an ejector rod which is used for clamping the plastic pipe blank on the positioning rod. The turning machine not only can realize automatic continuous processing and high efficiency, but also has high positioning accuracy, and improves the output and the efficiency of processing the plastic pipes.

Owner:庄添财

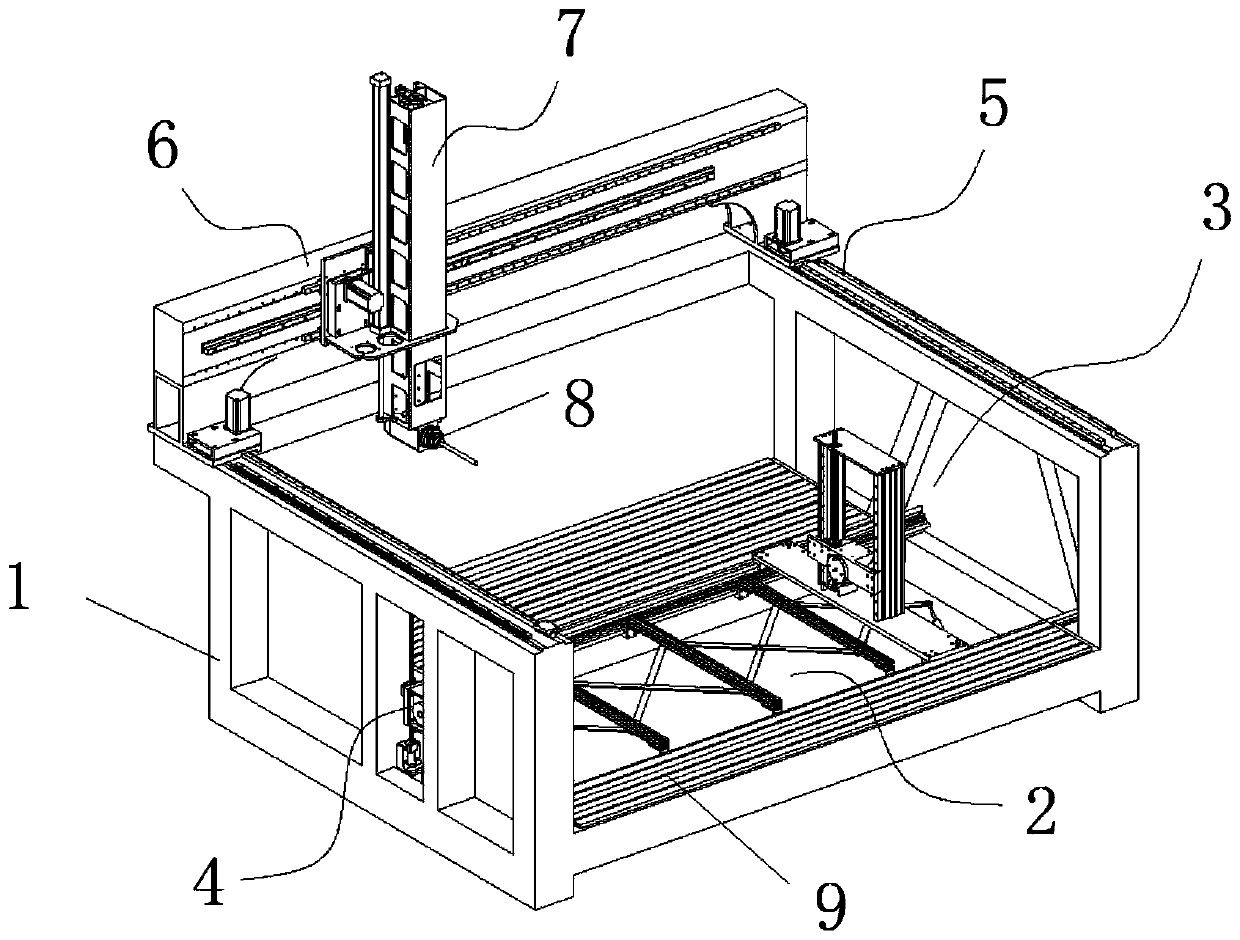

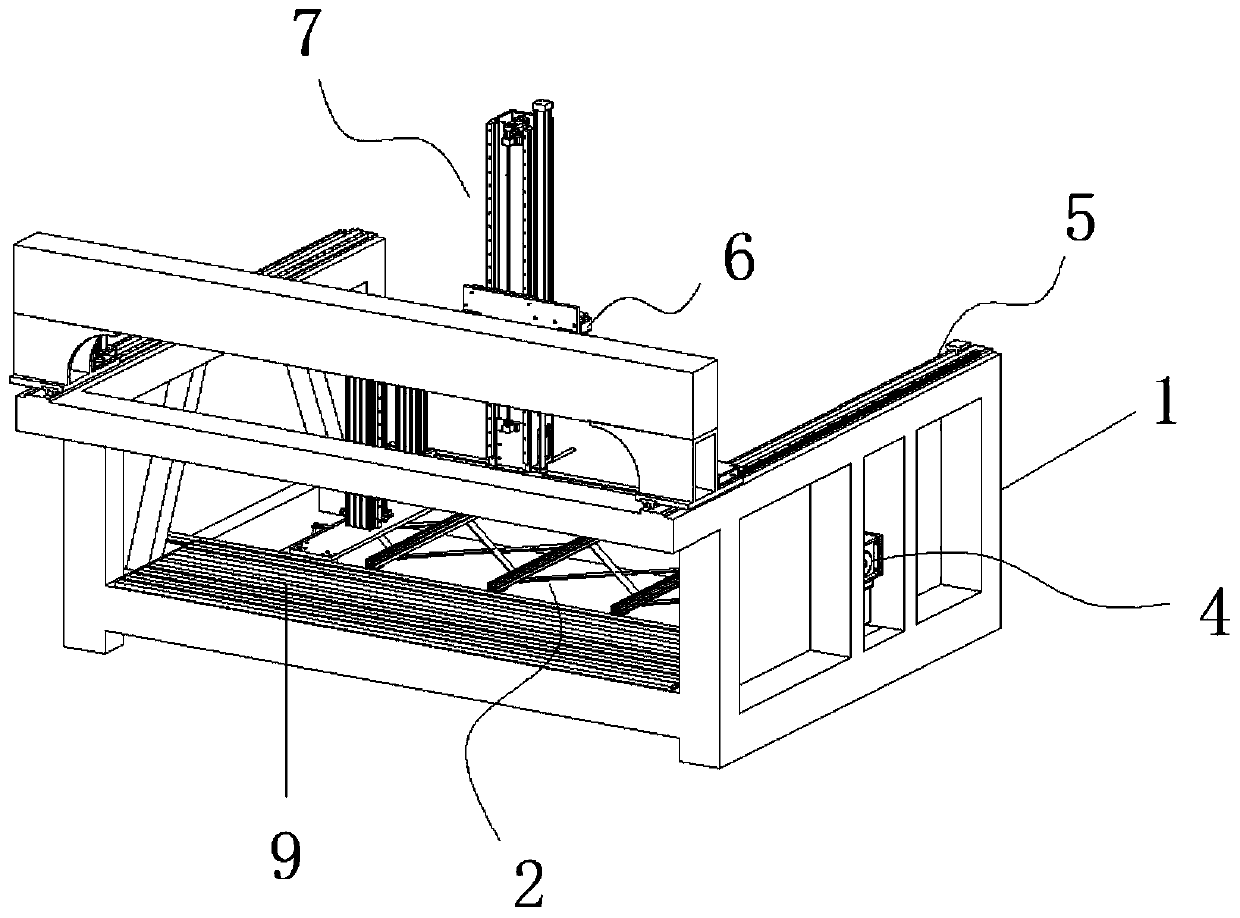

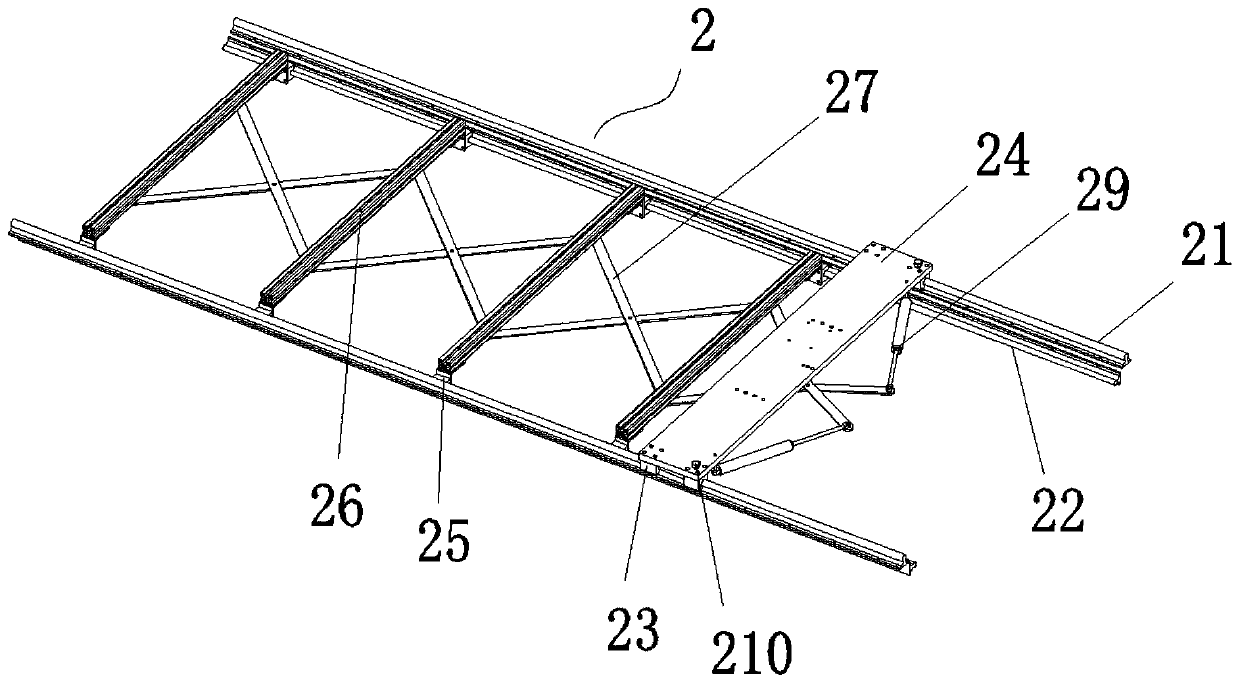

Four-axis double-sided engraving machine

PendingCN110842996ARealize automatic continuous processingPrevent detail appearance from affectingMetal working apparatusStructural engineeringIndustrial engineering

The invention discloses a four-axis double-sided engraving machine in the technical field of engraving machines. The four-axis double-sided engraving machine comprises a main frame, wherein a telescopic supporting mechanism is arranged at the bottom of an inner cavity of the main frame; the telescopic supporting mechanism can slide and adjust leftward and rightward relative to the main frame; a workpiece lifting and pressing structure is arranged at the top of the telescopic supporting mechanism; a workpiece lifting and overturning mechanism is arranged at the left side of the main frame; a Y-axis moving mechanism is arranged at the top of the main frame; an X-axis moving mechanism is arranged at the top moving end of the Y-axis moving mechanism; the front moving end of the X-axis moving mechanism is provided with a Z-axis moving mechanism; and a carving spindle is arranged below the front lifting end of the Z-axis moving mechanism. After the four-axis double-sided engraving machine isunfolded by the telescopic support mechanism, the four-axis double-sided engraving machine can be attached to the bottom surface of a blank with a larger surface size and more engraving details to assist in supporting the blank, so as to prevent shaking in the processing process from affecting the appearance of product details.

Owner:厦门特雕科技有限公司

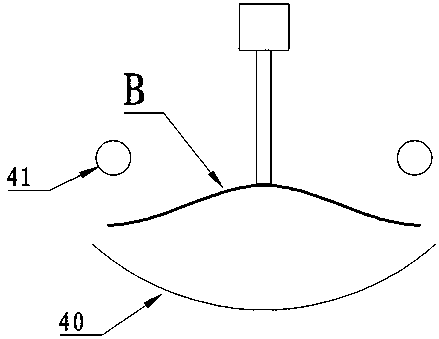

Device for bending metal pipe

ActiveCN108856395ABending realizationRealize automatic continuous processingMetal-working feeding devicesStripping-off devicesStraight tubeEngineering

The invention belong to a device for bending rods, profiles or pipes, and particularly discloses a device for bending a metal pipe, which comprises a workbench, a feeding pipe is arranged above the workbench, the lower end of the feeding pipe is opened, two press bending through holes are arranged on the workbench, the distance between the two press bending holes is less than the length of a workpiece, a press bending mechanism is arranged in the press bending through hole, a cavity is arranged in the workbench, between the two press bending through holes, a discharge channel is arranged in the cavity, a feeding control mechanism is arranged on the feeding pipe, and a discharge control mechanism is arranged on the discharge channel, the feeding control mechanism and the discharge controlmechanism are driven by a bending mechanism. The aim of the invention is to solve the problem that a prior pipe bending machine needs continuously loading and unloading the work pieces by a worker when straight pipe are processed.

Owner:重庆祥越管道配件制造有限公司

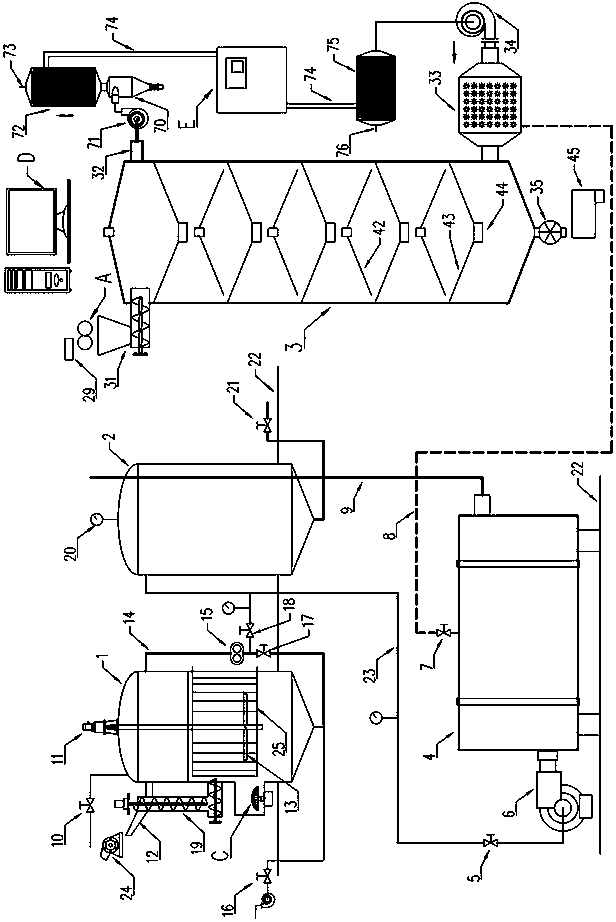

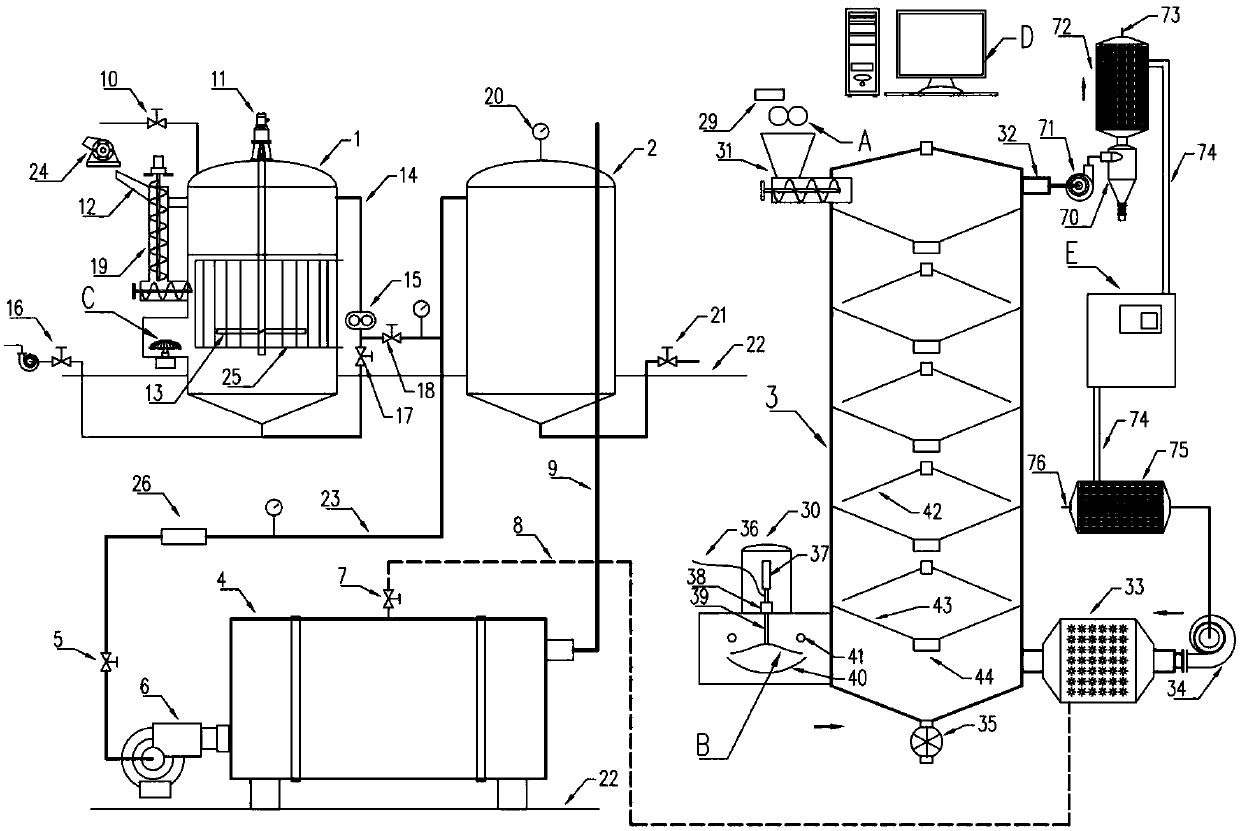

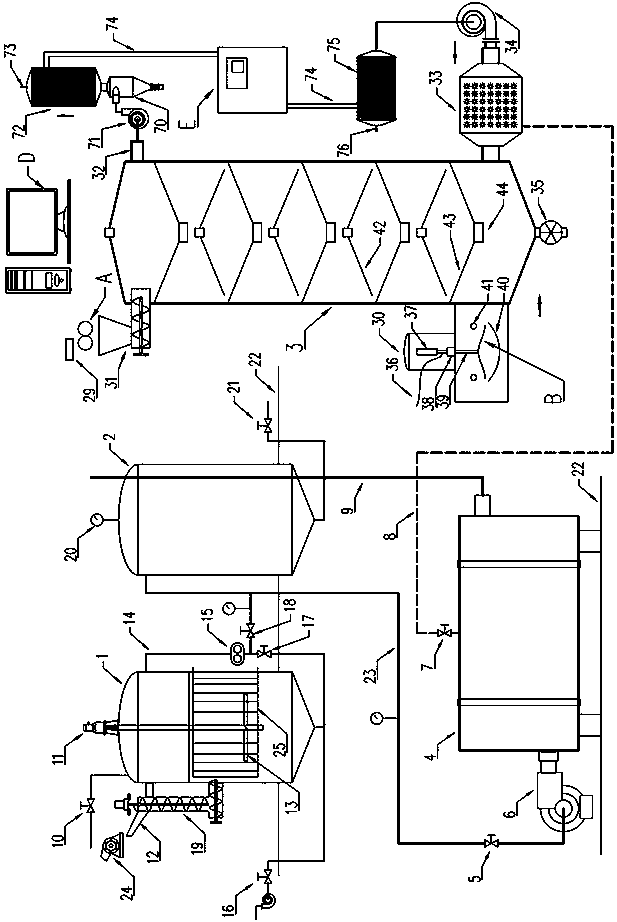

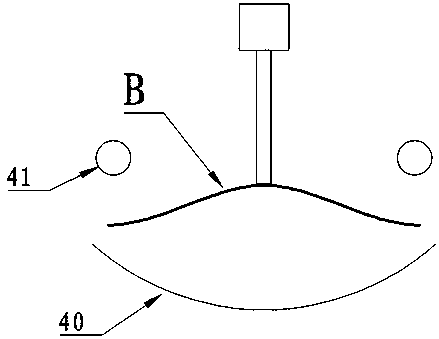

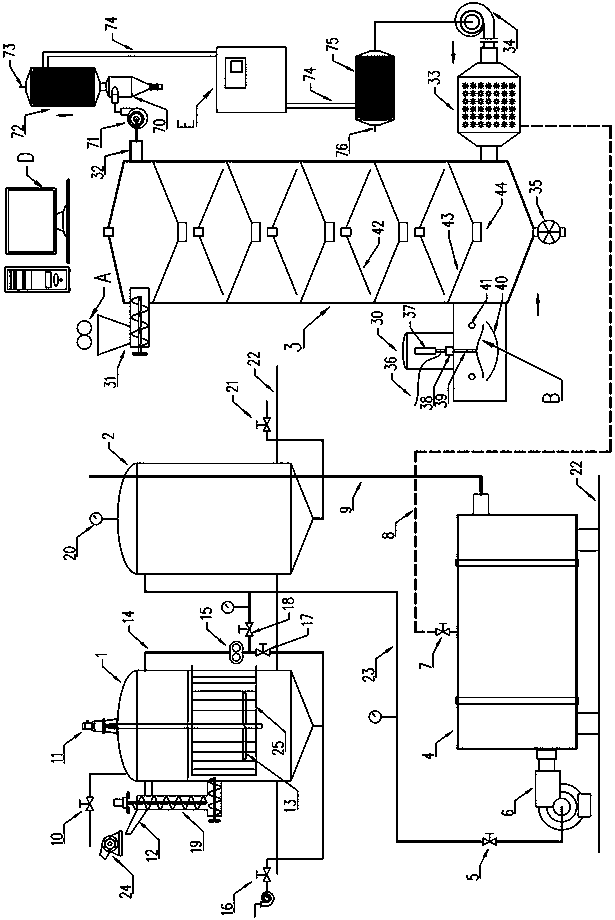

Sine roller-type straw treatment device with tail heat recycle and biomass fuel preparation functions

InactiveCN107893025AContinuous monitoring of production dataRealize automatic continuous processingBioreactor/fermenter combinationsBiological substance pretreatmentsProcess engineeringUltrasonic vibration

The invention discloses a sine roller-type straw treatment device with tail heat recycle and biomass fuel preparation functions. The device comprises a sine roller, a biogas fermentation tank, a biogas storage tank, a reverse flow drying tower, a biogas burner, a biogas boiler, a heat pump main unit and a computer. A sine ultrasonic vibration exciter is arranged on the lower left portion of the biogas fermentation tank, the upper right portion of the biogas fermentation tank is connected with a tank bottom through a pipe and a roots fan, and the biogas storage tank is connected to an outlet ofthe roots fan; the biogas storage tank is connected with the biogas boiler through a pipe and the biogas burner, the biogas boiler is connected with the reverse flow drying tower through a steam finair heater, a spiral wind-closing feeder, the sine roller and a segment cutting machine are connected to the upper left portion of the reverse flow drying tower in sequence, a tail gas pipe is connected with the heat pump system, and the treatment device is controlled by the computer. According to the sine roller-type straw treatment device with the tail heat recycle and biomass fuel preparation functions, both the sine roller and the sine ultrasonic vibration exciter have distinct characteristics, and cooperation of comprehensive development and utilization of crop straw and waste with extremely high moisture content gradient can be reliably achieved.

Owner:向澍予

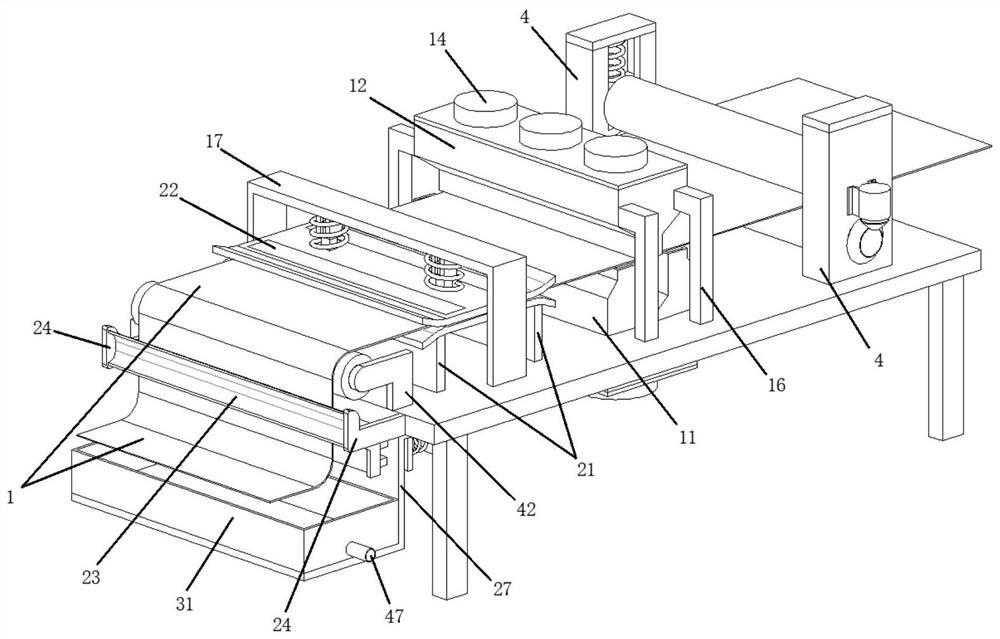

Double-sided drying equipment for polyester fabric production and processing

ActiveCN112647228AAvoid looseImprove stabilityLiquid/gas/vapor removal by squeezingTextile shapingPolyesterPolymer science

The invention relates to the technical field of cloth processing, in particular to double-sided drying equipment for polyester fabric production and processing. The double-sided drying equipment comprises polyester fabric, a processing table plate is arranged on one side of the polyester fabric, a plurality of supporting legs are fixedly arranged on one side of the processing table plate, two fixing columns are fixedly arranged on one side of the processing table plate, a driving shaft is arranged on one side of the processing table plate, through holes are formed in one sides of the fixing columns, the driving shafts are rotationally connected to the inner sides of the through holes, motors are arranged on one sides of the driving shafts and fixedly connected to one sides of the fixing columns, and transmission devices are arranged between the motors and the driving shafts. By arranging a feeding barrel, a pressing barrel, an automatic pressing device, a double-opening drying cover, a single-opening drying cover, the air inlet fan, an electric heating pipe, an upper ironing plate, a lower ironing plate, a spring A, a constant-temperature electric heating block, a water squeezing plate and a water squeezing frame, and the double-sided drying equipment for polyester fabric production and processing has the functions of automatic continuous processing, double-sided automatic drying, automatic ironing, automatic dewatering, squeezing force adjusting and the like.

Owner:吴江保利化纺有限公司

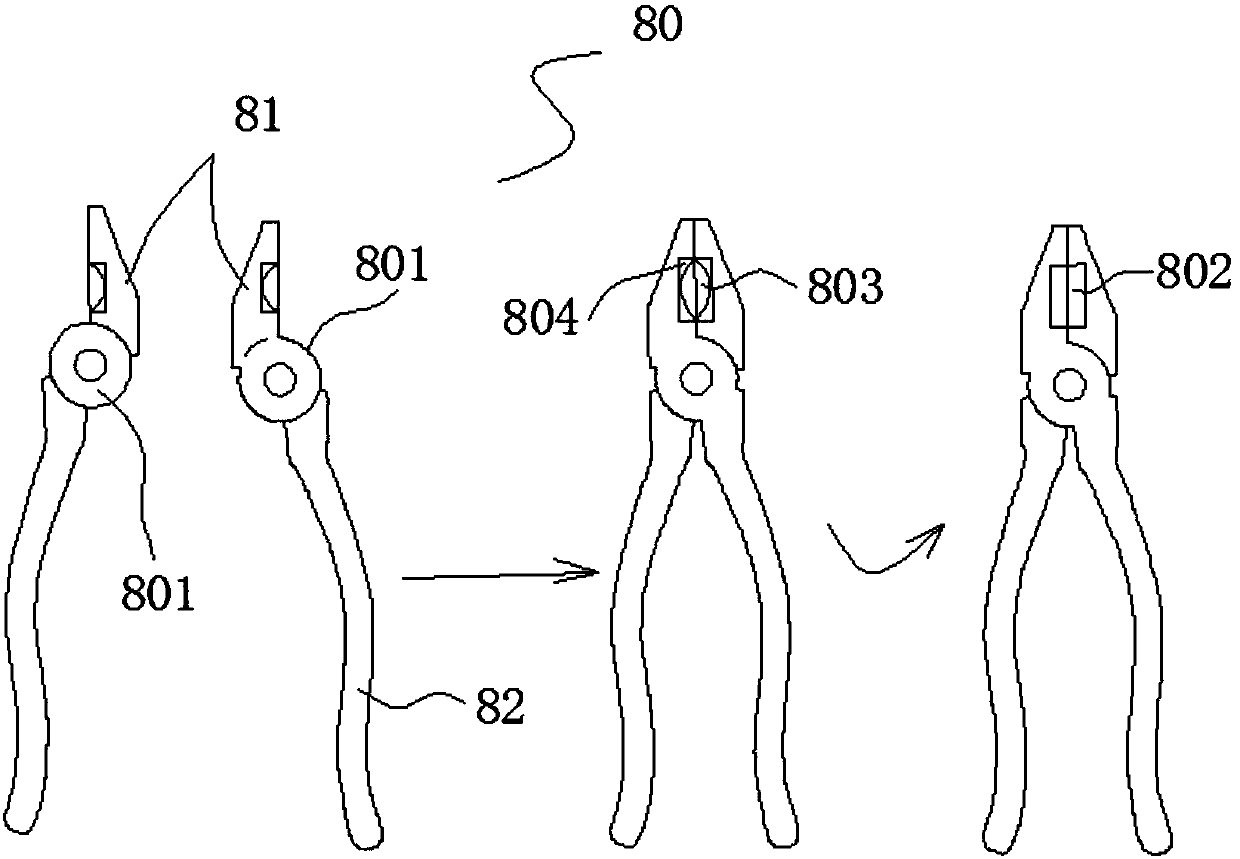

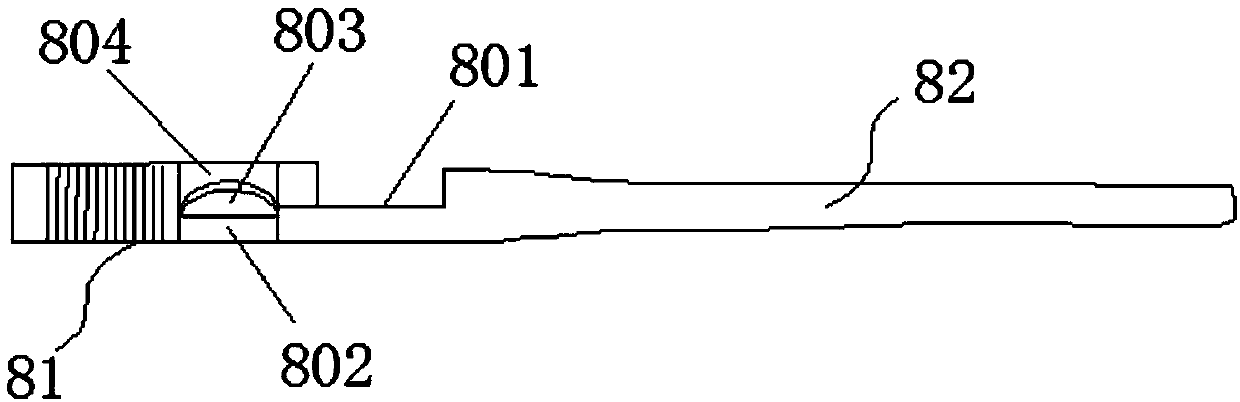

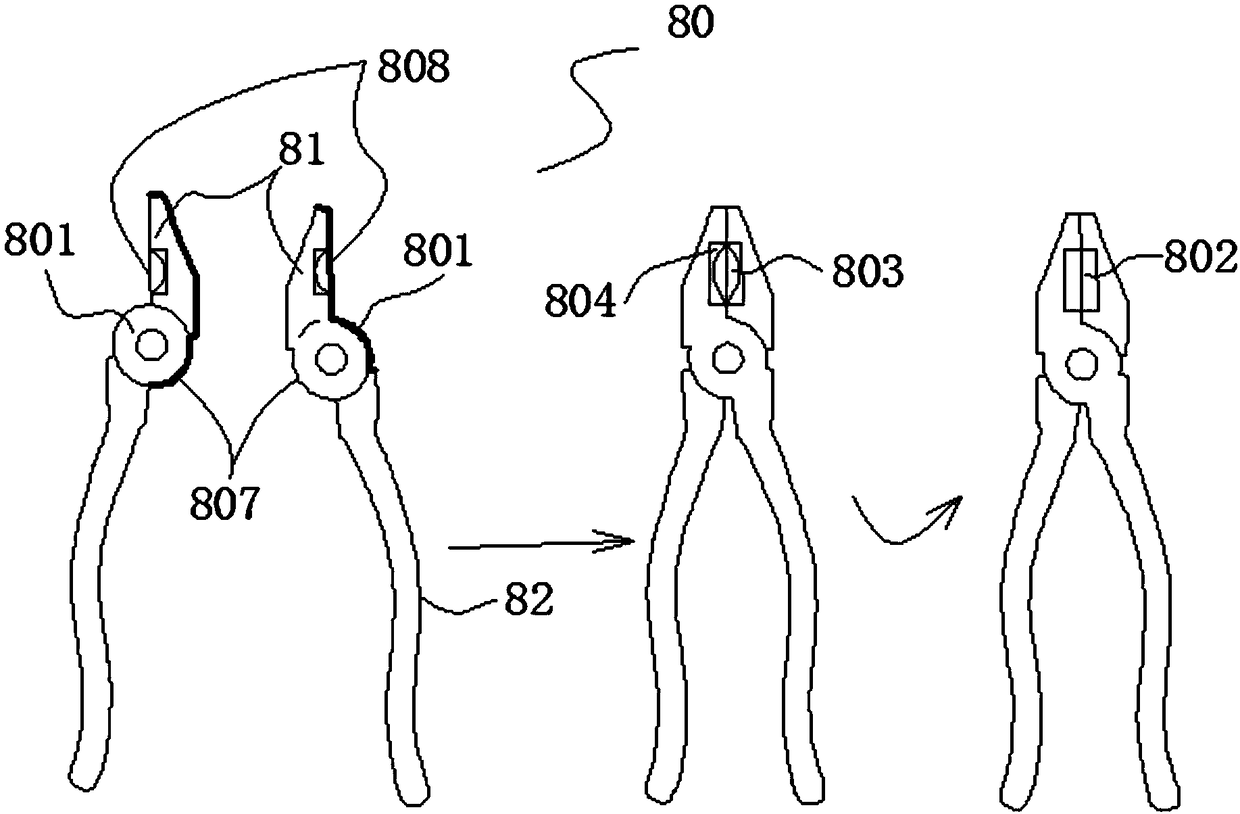

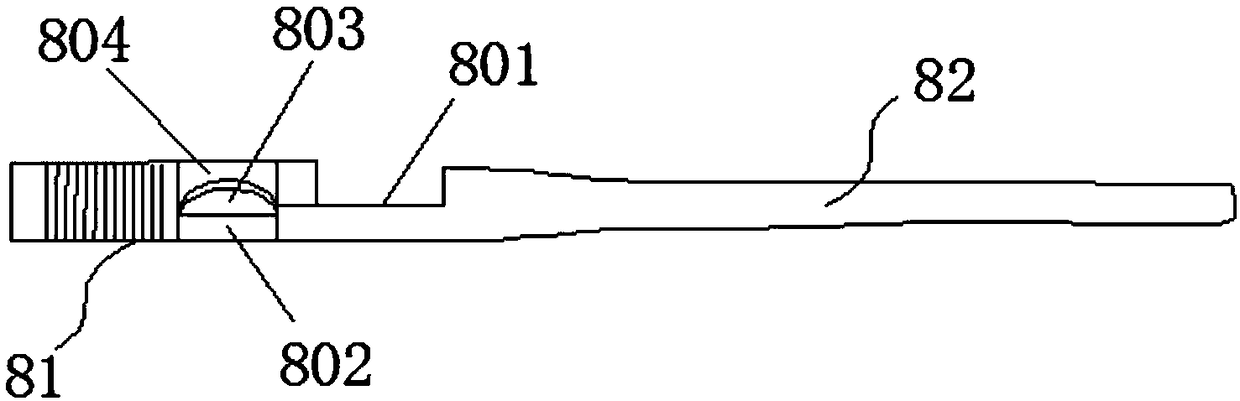

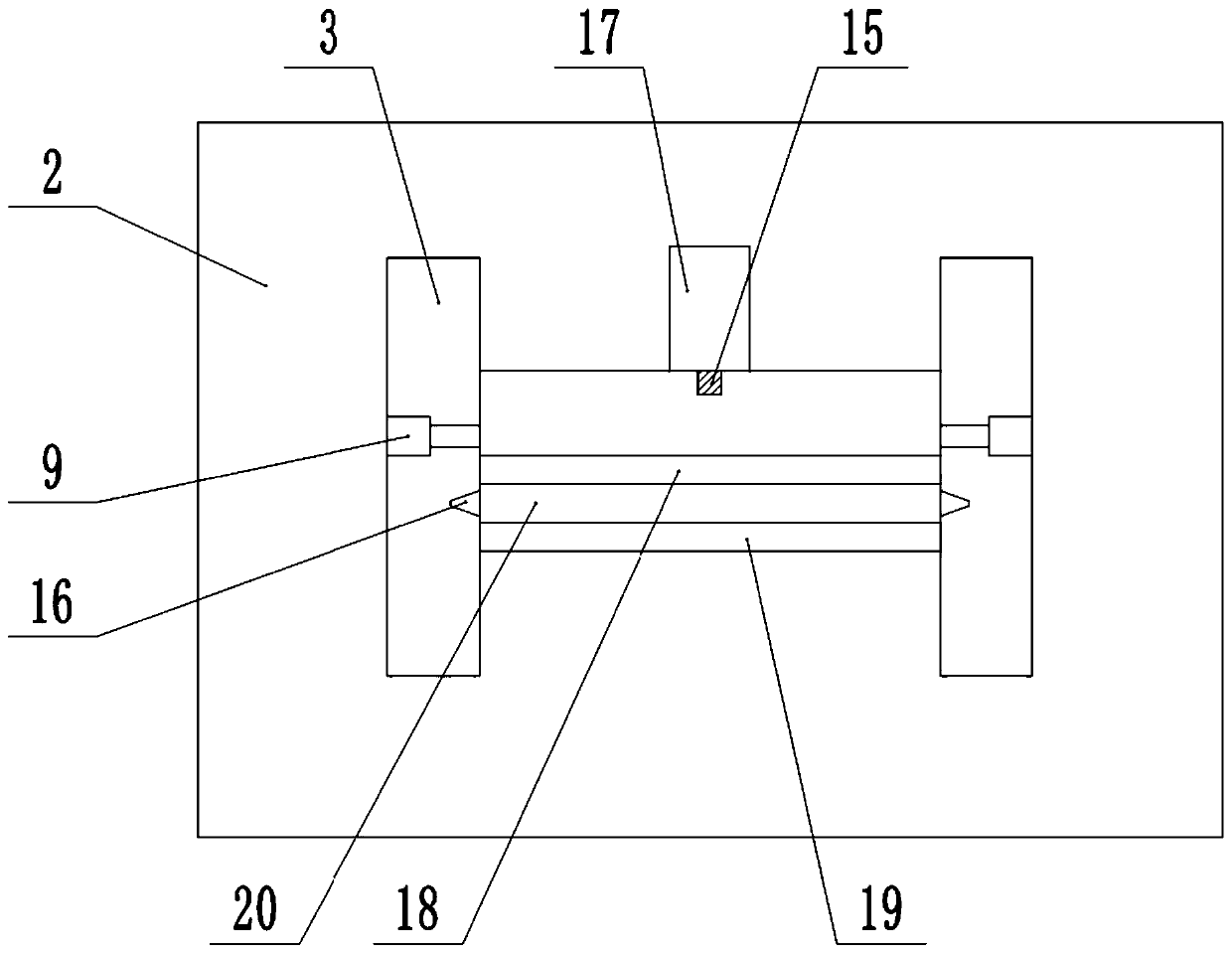

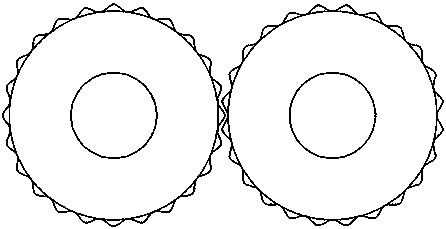

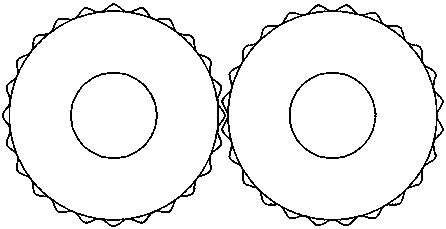

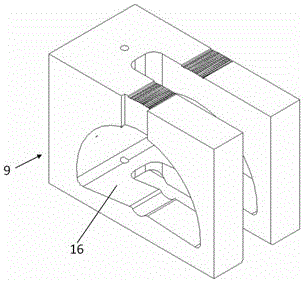

Mechanism used for continuous milling machining of special shapes and thread shapes on inner and outer surfaces of heads of pliers

PendingCN108015599AConvenient automatic discharge and placementReduce processing stepsMilling machinesMilling equipment detailsMachiningMachine material

The invention discloses a mechanism used for continuous milling machining of special shapes and thread shapes on inner and outer surfaces of heads of pliers. The mechanism comprises a machining seat and laminated machining layers arranged on the machining seat. All the machining layers are orderly stacked from the top to the bottom and gradually protrude. To-be-machined material moves forward layer by layer from the top to the bottom. All the layers are separated to each other and movably cooperated with push-plate layers. Two sides of each machining layer are provided with limiting baffle plates. An outer milling assembly and an inner milling assembly are respectively installed on the side surface of each machining layer and above the side surface of each machining layer. Each outer milling assembly and each inner milling assembly are used for a plier head outer side surface special-shape mechanism and a plier head inner side surface special-shape mechanism. Tail ends of the push-plate layers are connected with push rods, below which push-rod support seats are arranged. The invention is intended to providing the mechanism used for continuous milling machining of special shapes andthread shapes on inner and outer surfaces of heads of pliers which facilitates machining bodies of pliers, reduces machining procedures and is convenient for automated machining and feeding. As a result, speed and efficiency is increased while cost is lowered.

Owner:湖南精专自动化技术有限公司

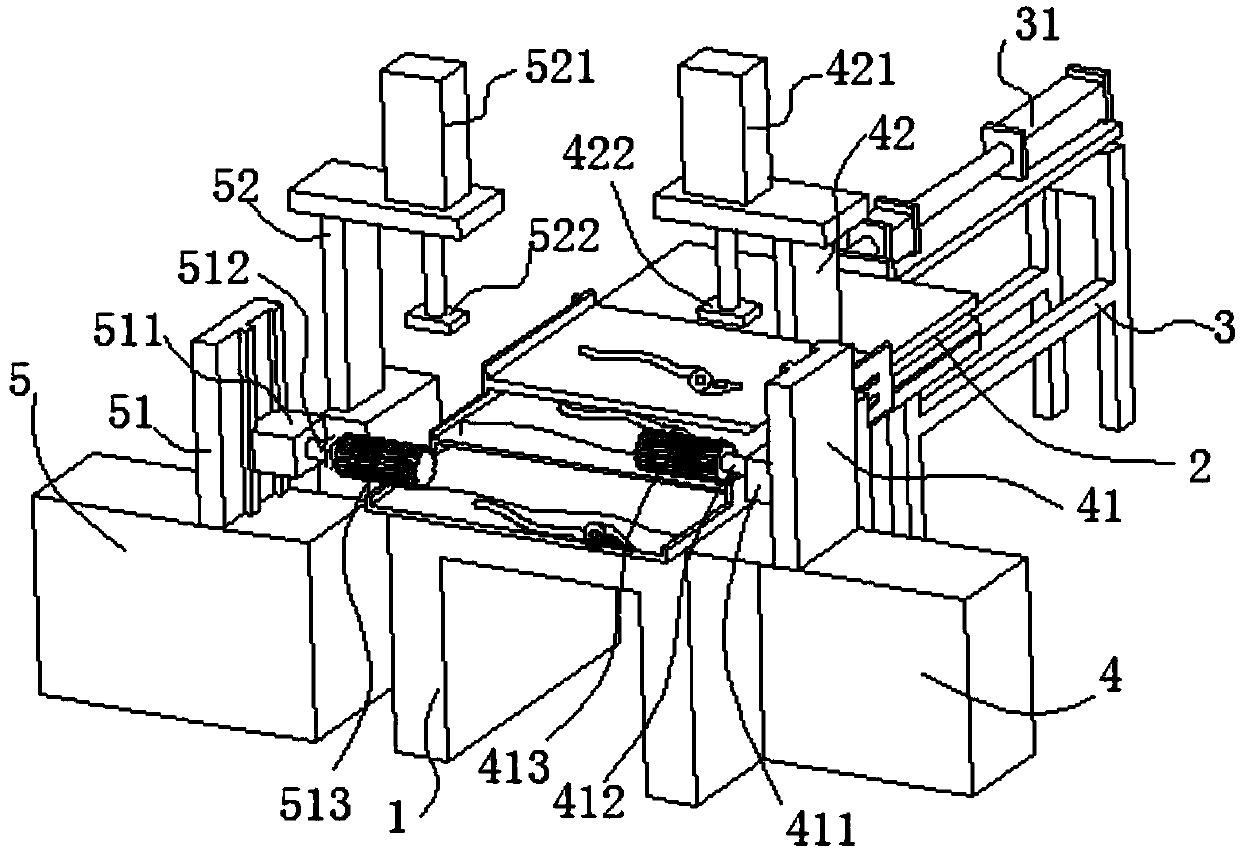

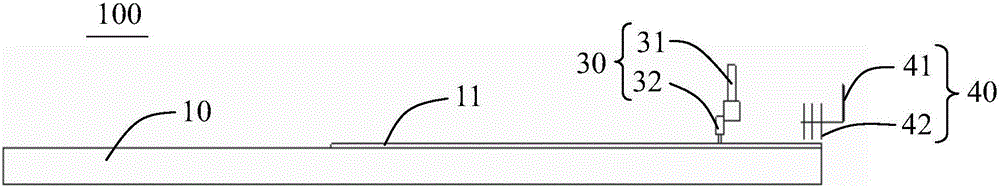

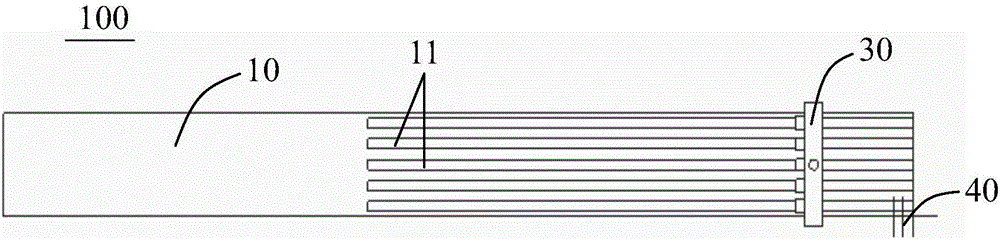

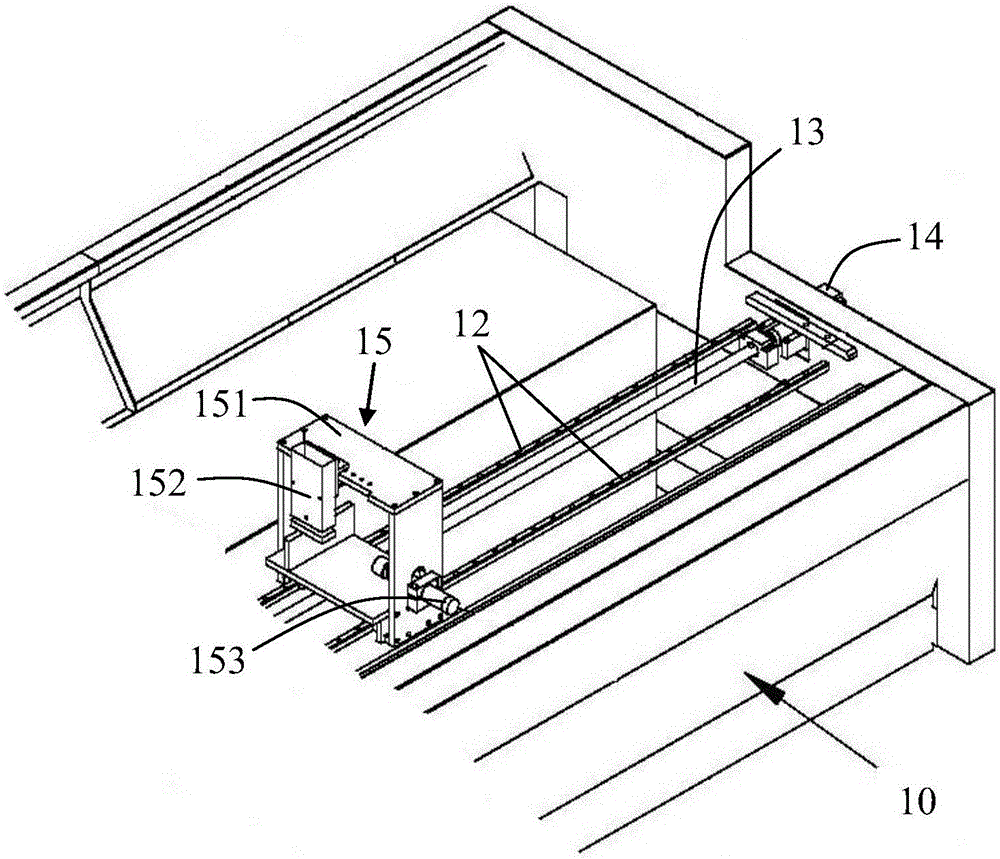

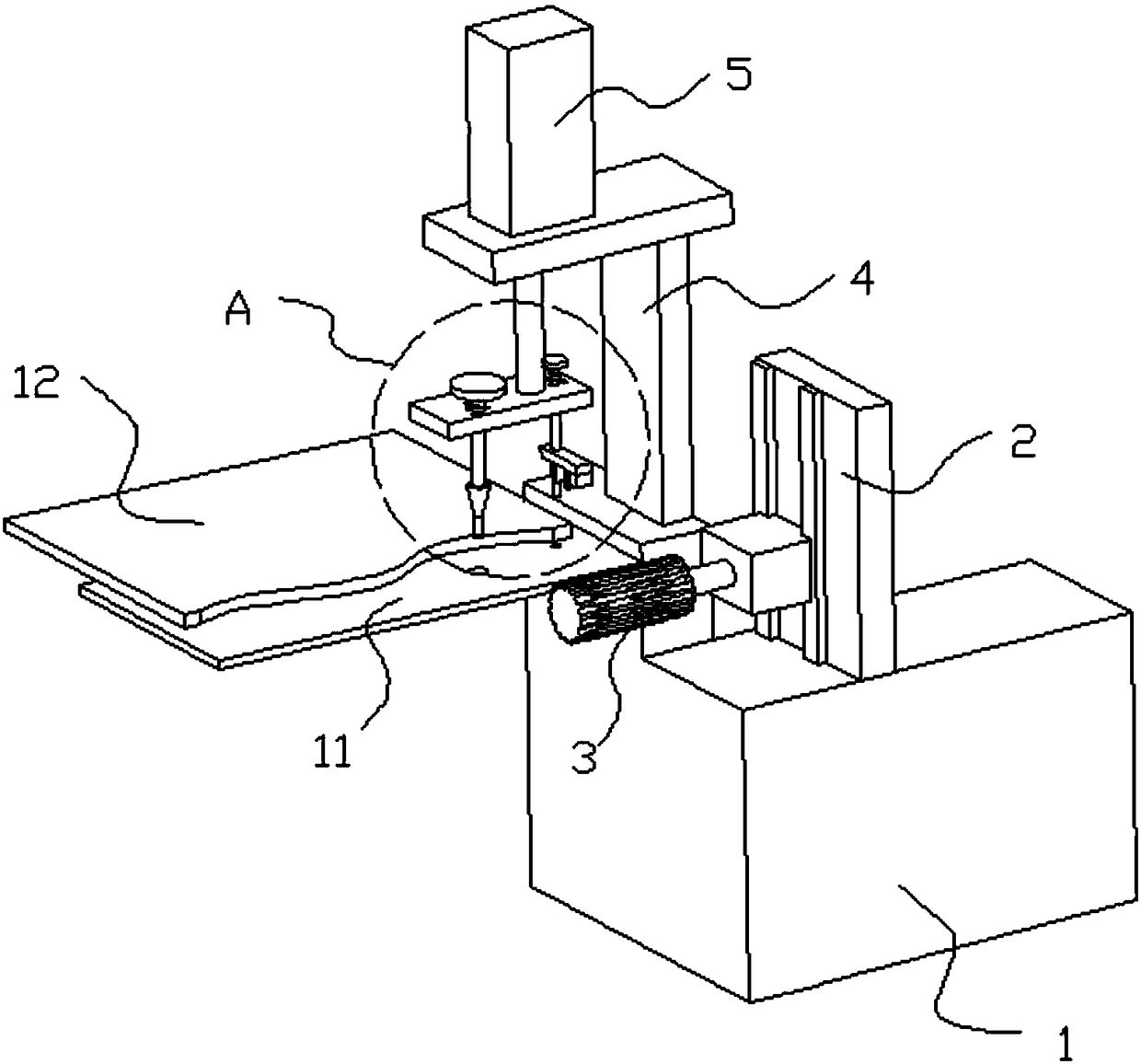

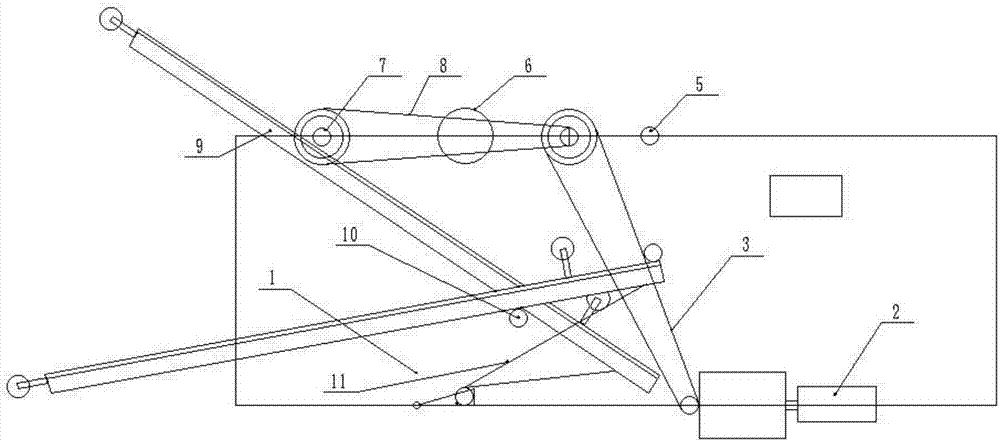

Profile machining equipment and profile machining method

ActiveCN106475778AImprove processing efficiencyRealize automatic continuous processingOther manufacturing equipments/toolsAgricultural engineeringMachine tool

The invention discloses profile machining equipment and a profile machining method. The profile machining equipment comprises a worktable, a feeding mechanism arranged on the worktable for bearing and pushing machined profiles, a profile machining mechanism arranged on the worktable for machining the machined profiles, and a profile cutting mechanism arranged on the worktable for cutting the machined profiles as preset sizes. The profile machining equipment with a novel structure and the profile machining method finish machining and cutting of the profiles on the same machine tool, cut the profiles after machining, realize automatic and continuous machining of small-size profiles, and improve the profile machining efficiency.

Owner:杭州衡鼎科技有限公司

Automatic incense bundling machine and working method thereof

InactiveCN107572032ARealize automatic continuous processingLargest diameterBinding material applicationRod-shaped articlesMotor driveMachining

The invention discloses an automatic incense bundling machine, and relates to the field of machining. The automatic incense bundling machine aims at solving the problems that during existing dou incense manufacturing, manual machining is needed, efficiency is low, and existing machining cannot be continuously carried out. The automatic incense bundling machine comprises a rack, a motor arranged onthe rack, a transmission module arranged on the rack and an incense bundling module. The motor drives the incense bundling module to work through the transmission module. The automatic incense bundling machine has the beneficial effects that dou incense continuous machining can be achieved, the machining efficiency is high, continuous machining can be carried out, and the maximum degree of machined dou incense is large.

Owner:武备

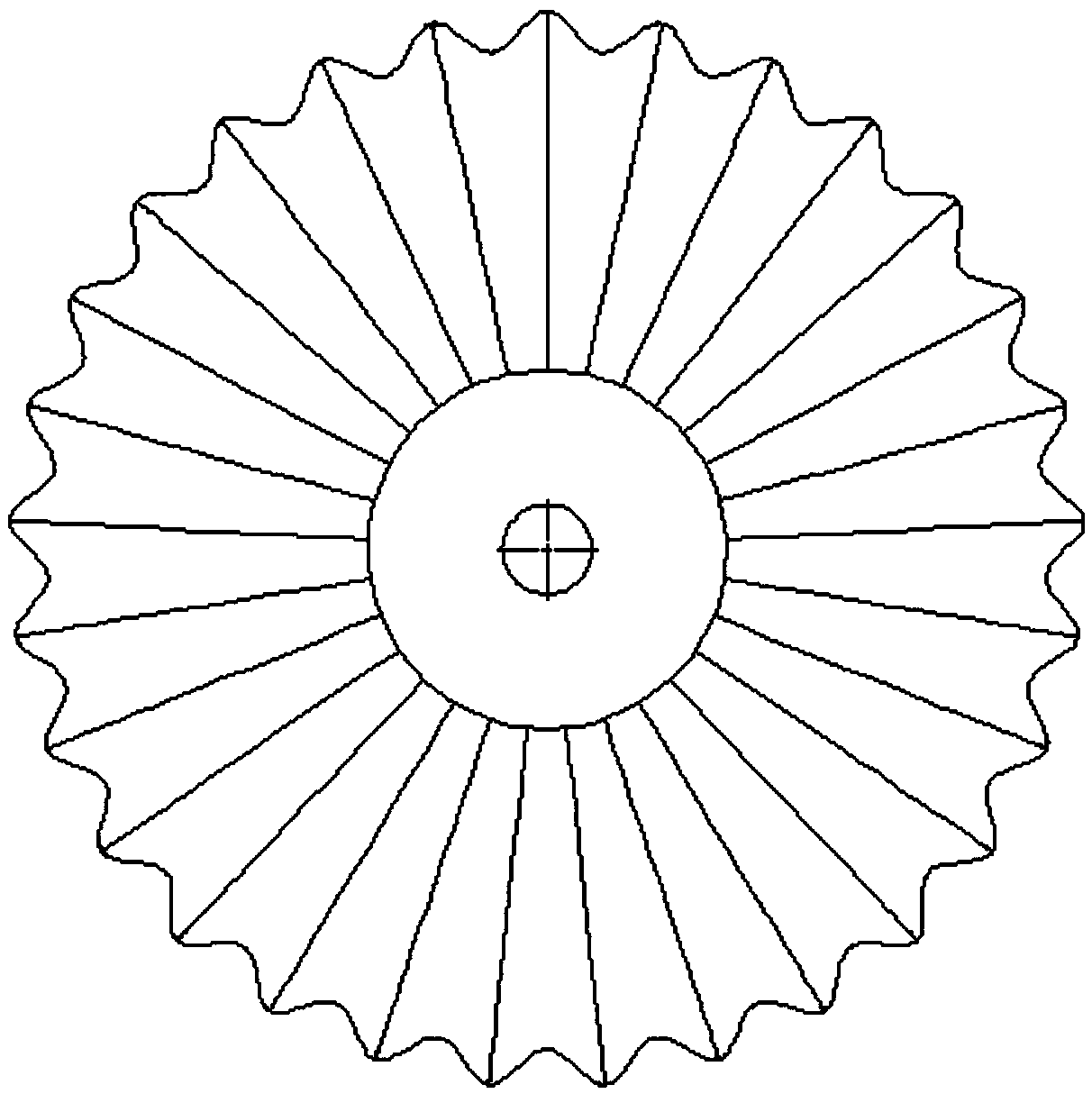

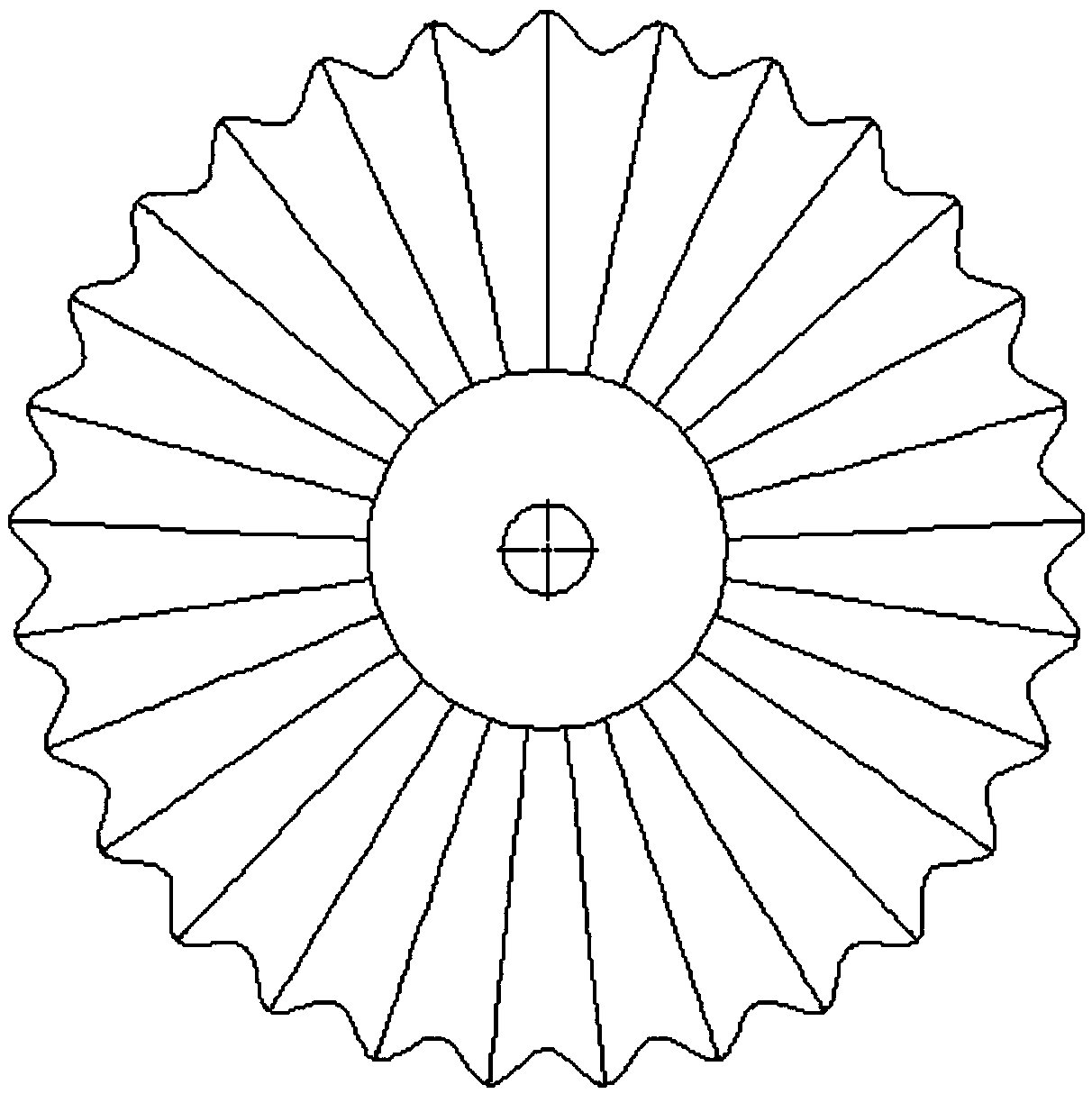

Ultrasonic jade engraving machine

PendingCN107953708AEasy to carveAvoid pollutionOther artistic work equipmentsModel makingEngravingTransducer

The invention discloses an ultrasonic jade engraving machine. The ultrasonic jade engraving machine comprises a machine base, an engraving device and a rotating device, wherein the engraving device comprises a regulating structure and an engraving structure; the engraving structure comprises an ultrasonic generator, a transducer and an engraving head; ultrasonic waves generated by the ultrasonic generator are converted into kinetic energy through the transducer, and the kinetic energy is transmitted to the engraving head; the regulating structure is mounted on the machine base; the transduceris fixedly mounted on the regulating structure; the regulating structure drives the engraving head to move in a vertical direction relative to the machine base; the rotating device comprises a rotarydisc structure and a pressing structure; the rotary disc structure comprises a rotary disc which is rotatably mounted on the machine base; a through hole is formed in the rotary disc; the pressing structure comprises a pressure rod and an ejecting structure; the ejecting structure abuts against the pressure rod, so that the pressure rod can pass through the through hole to abut against a jade on the rotary disc; the engraving head and the pressure rod are used for pressing the jade, so that the engraving head engraves; the rotary disc rotates for being automatically switched to the engraving station after engraving on each station is completed, so that automatic and continuous processing is realized; and a machine enclosure reduces equipment noises, and prevents dust pollution.

Owner:四会市金东泰机械设备有限公司

Method for efficient discharge milling with hollow long electrode

InactiveCN1270861CReduce the number of replacementsDecrease productivityMachining electrodesElectrical-based machining electrodesTitanium alloyGas turbines

Owner:苏州中特机电科技有限公司

Automatic loading and incense production machine

InactiveCN107521743ARealize automatic continuous processingContinuous incense making processBinding material applicationBundling machine detailsMaximum diameterElectric machinery

The invention discloses an automatic feeding incense making machine, which relates to the field of mechanical processing. In order to solve the shortcomings of manual processing, low efficiency and non-continuous work of existing mechanical processing in order to solve the existing bucket incense production; the automatic feeding incense making machine includes A feeding module and an incense making module, the incense making module includes a frame, a motor arranged on the frame, a control module arranged on the frame, an incense binding shaft arranged on the frame, an Incense binding plate installation shaft, incense binding plate set on the incense binding plate installation shaft, tape installation frame set on the incense binding plate, tape guide wheel set on the incense binding plate, pressure sensor set on the incense binding plate And a telescopic rod arranged on the incense board. The automatic and continuous processing of the bucket incense is realized, and has the beneficial effects of high processing efficiency, continuous processing and a large maximum diameter of the processed bucket incense.

Owner:LIXIN COUNTY FENGYASONG ELECTROMECHANICAL TECH CO LTD

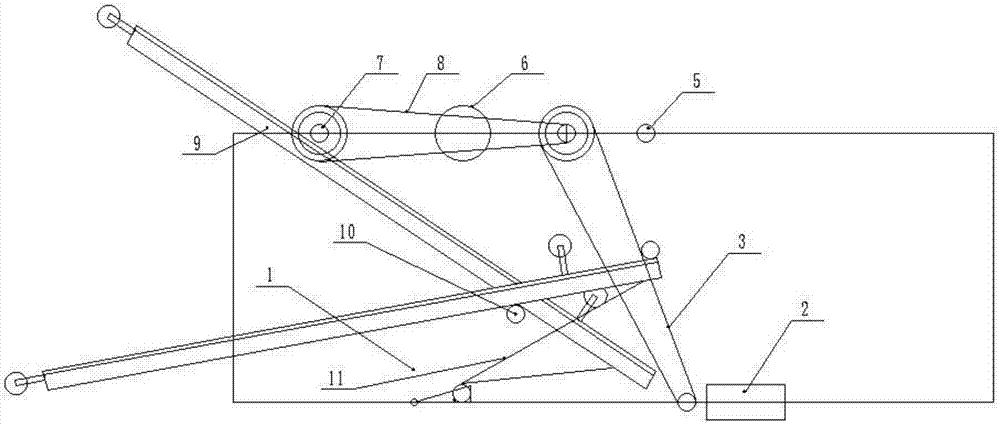

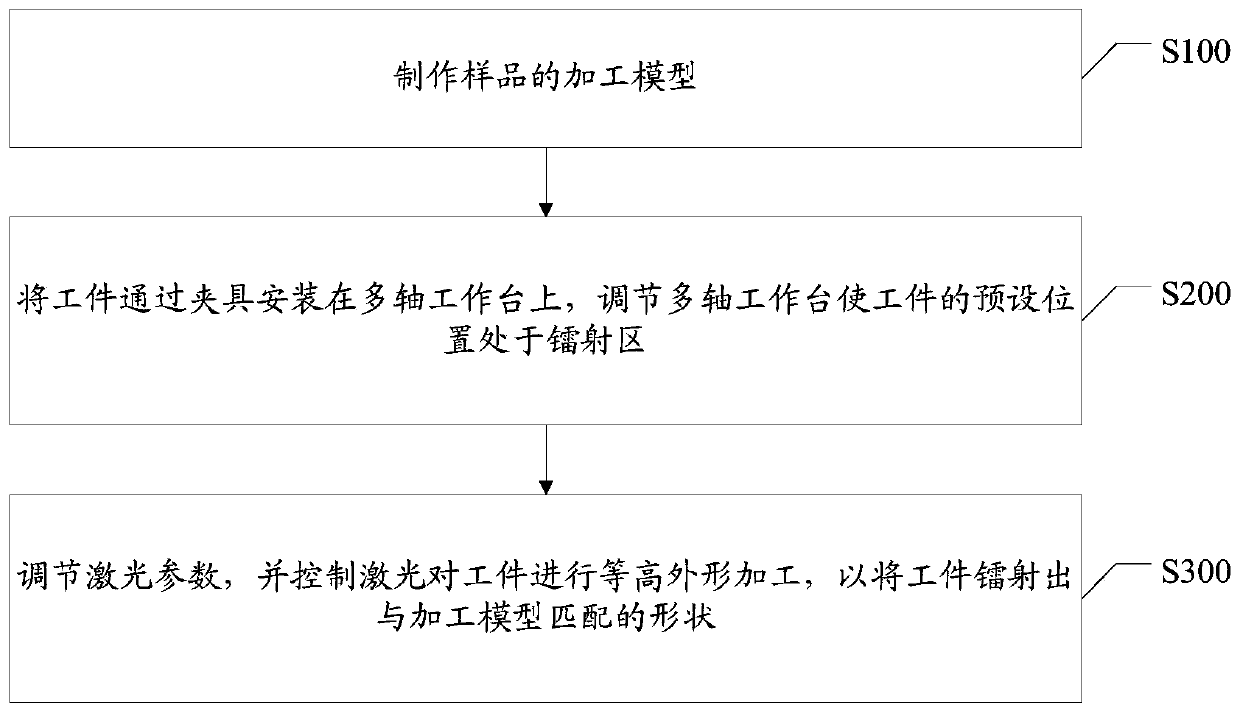

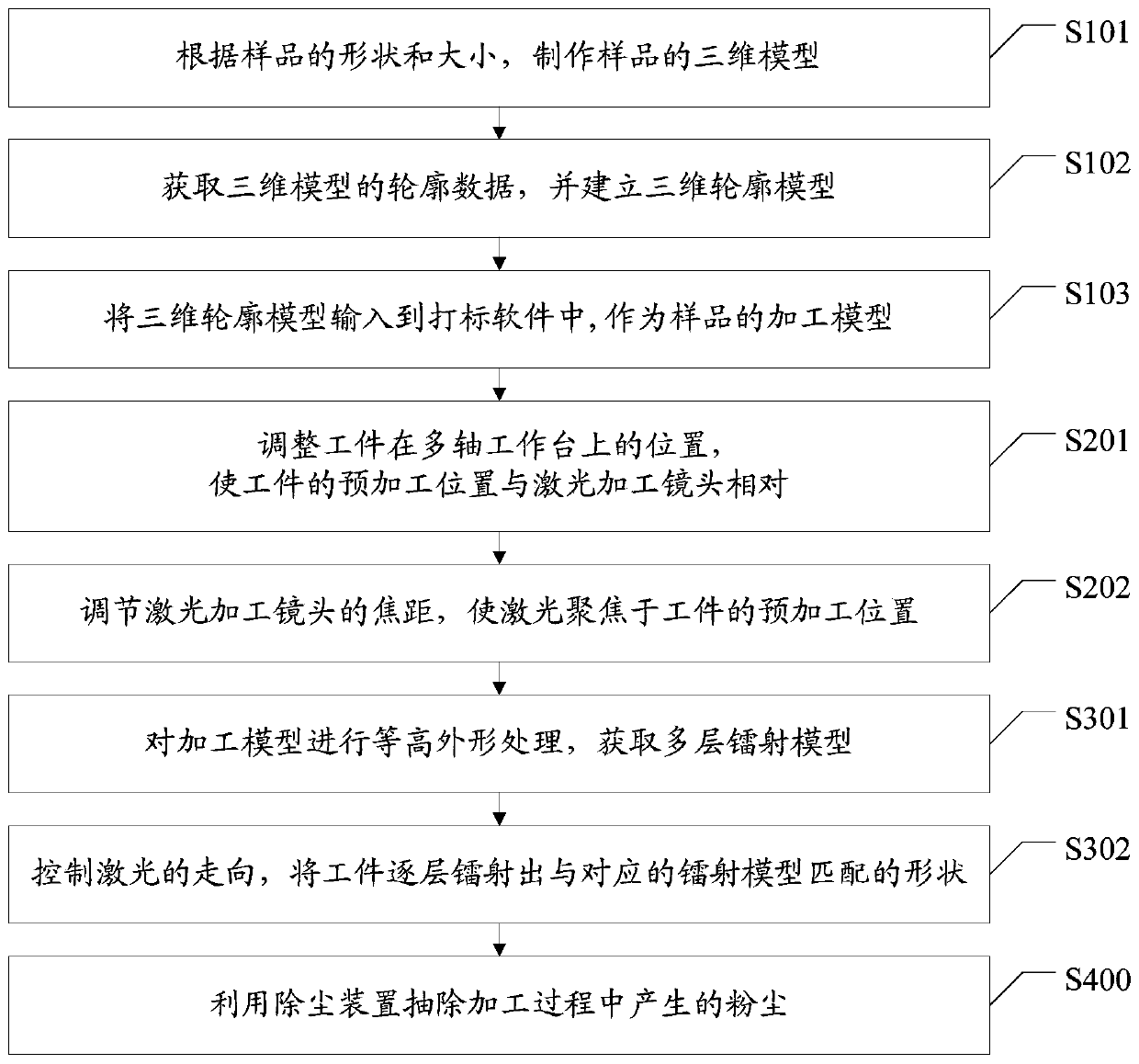

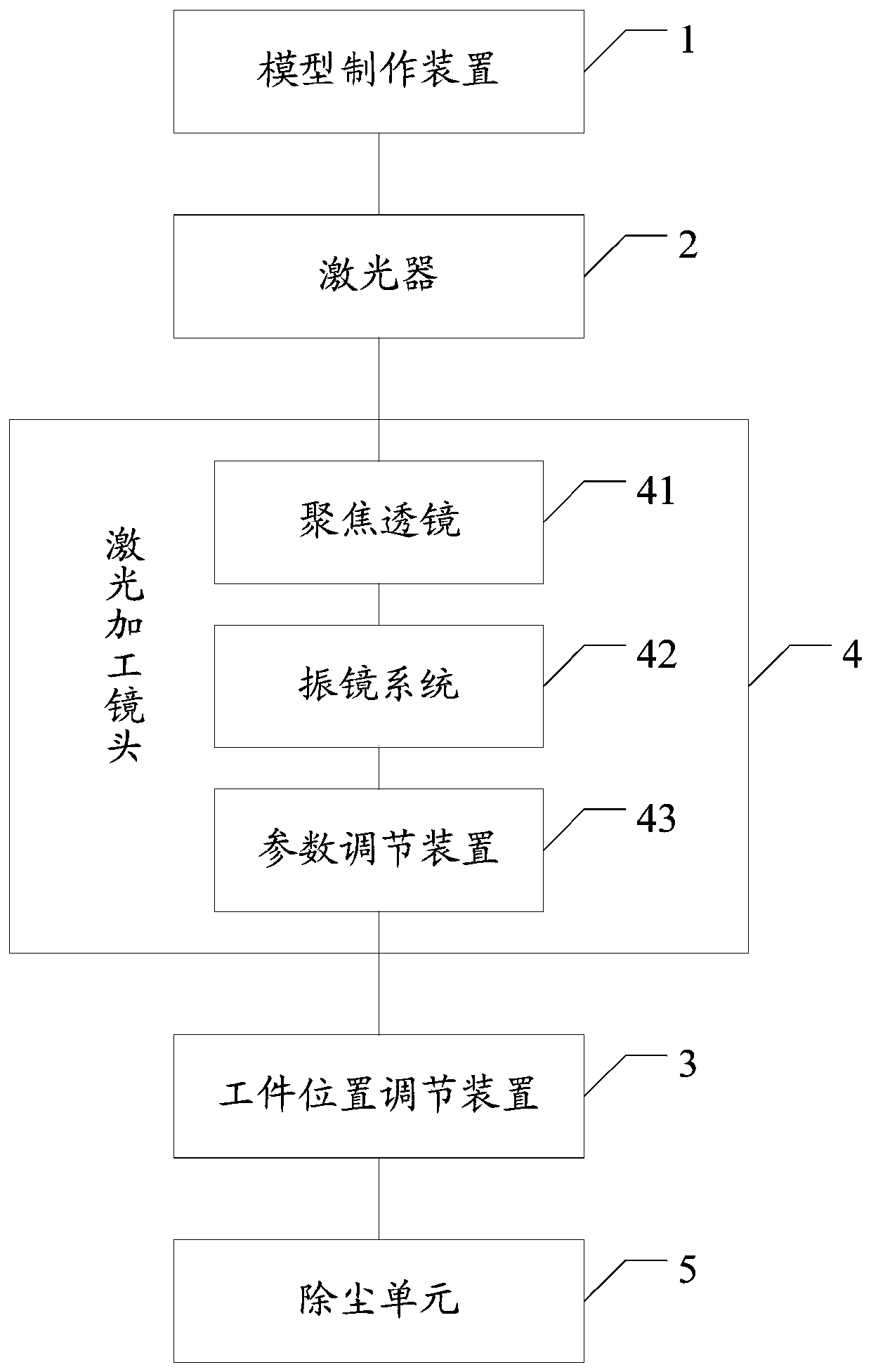

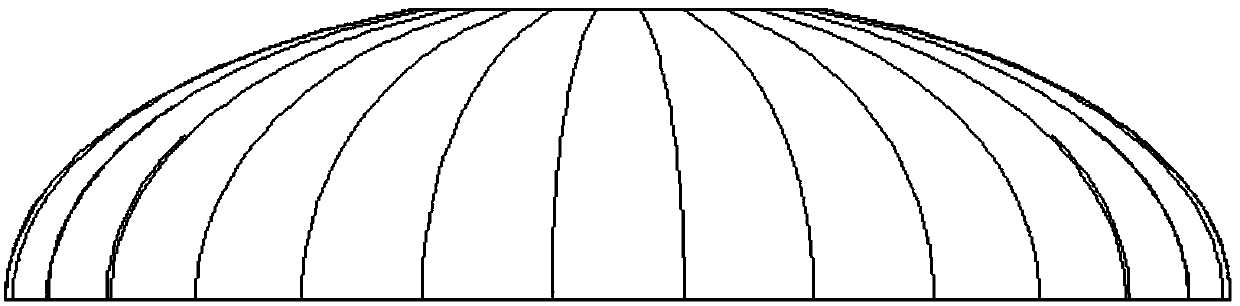

Laser processing method and facility

The invention belongs to the field of laser processing, and provides a laser processing method and facility. The method comprises the steps that a sample machining model is manufactured; a workpiece is arranged on a multi-axis workbench through a clamp, and the preset position of the workpiece is located at the laser area through adjustment of the multi-axis workbench; and laser parameters are adjusted, lasers are controlled to conduct equal-height appearance machining on the workpiece, and accordingly the workpiece can be subjected to laser treatment into the shape matched with the shape of the machining model. Through application of the provided method, a machining technical scheme in which high precision, high efficiency and low cost are integrated can be achieved.

Owner:HANS LASER TECH IND GRP CO LTD

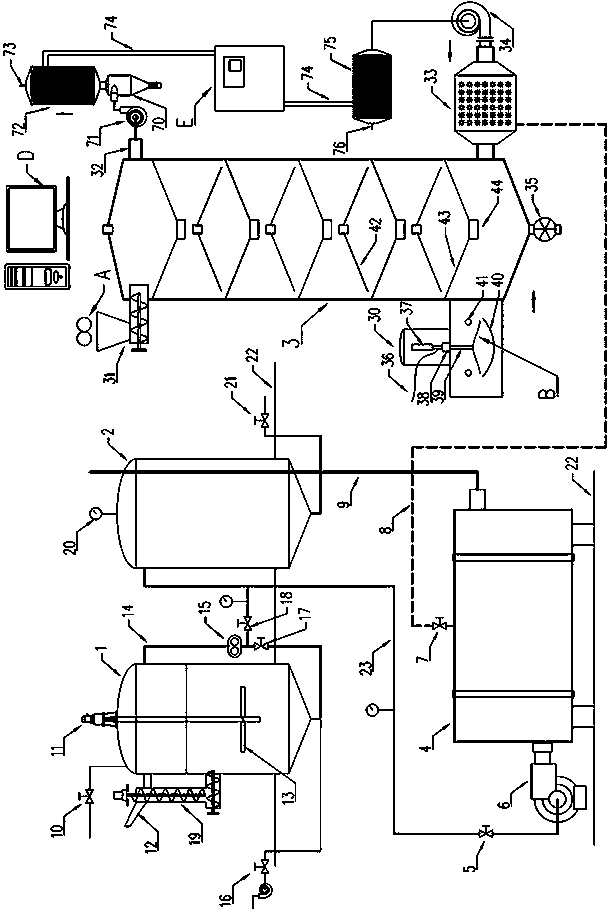

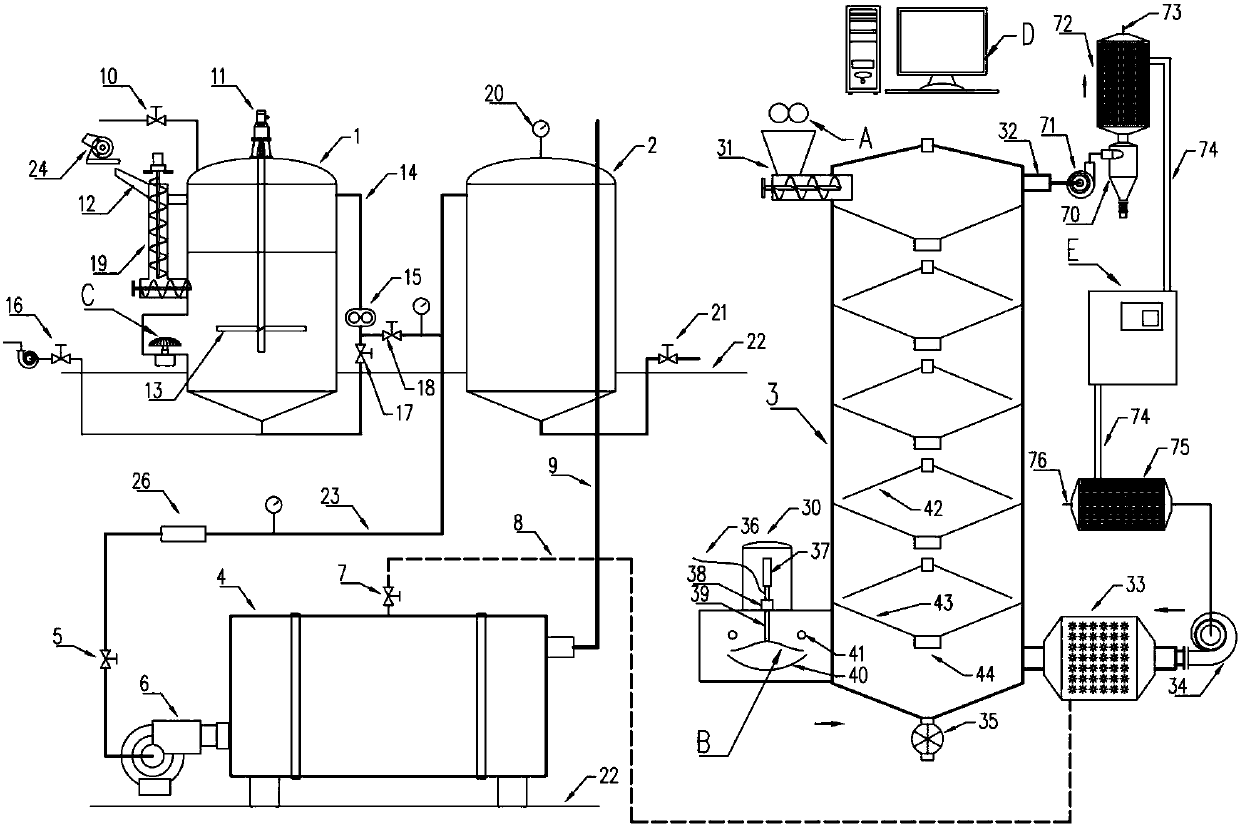

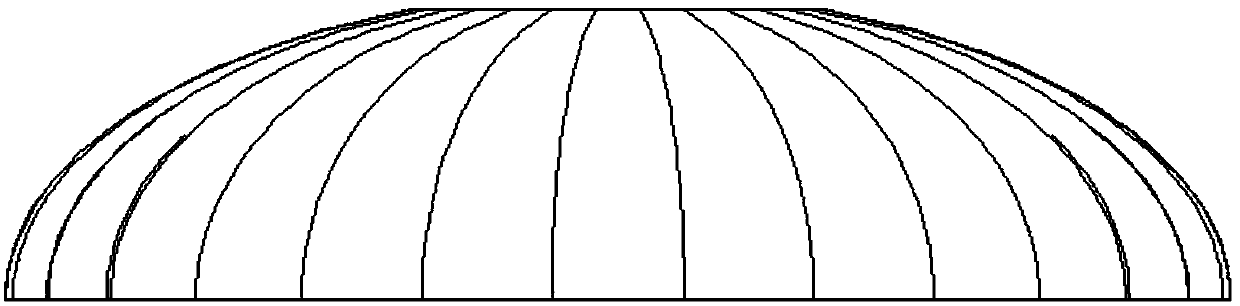

Pulse aeration type comprehensive straw treatment device with tail gas recycling and air sealed material feeding

InactiveCN107739707AContinuous monitoring of production dataRealize automatic continuous processingBioreactor/fermenter combinationsBiological substance pretreatmentsCombustorCounter flow

The invention discloses a pulse aeration type comprehensive straw treatment device with tail gas recycling and air sealed material feeding. The device comprises a sine roller, a biogas fermentation tank, a biogas storage tank, a counter-flow drying tower, a biogas combustor, a biogas boiler, a heat pump main machine and a computer, wherein the upper right part of the biogas fermentation tank is connected with a tank bottom through a pipeline and a Roots blower; the outlet of the Roots blower is connected with the biogas storage tank; the biogas storage tank is connected with the biogas boilerthrough a pipeline and the biogas combustor; the biogas boiler is connected with the counter-flow drying tower through a steam fin hot air machine; a spiral air sealed material feeding machine and thesine roller are sequentially connected with the upper left part of the counter-flow drying tower; a tail gas tube is connected with a heat pump system; a cosine pulse disc pulse aeration device is arranged at the lower left part of the counter-flow drying tower; the treatment device is controlled by the computer. The sine roller and the cosine pulse disc pulse aeration device of the device both have distinct characteristics, and crop straw and wastes with particularly large moisture content gradients can be comprehensively developed and utilized in a reliable synergetic manner.

Owner:向明翠

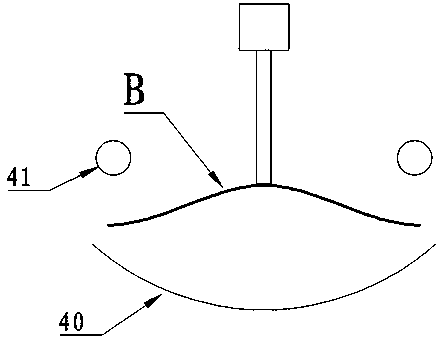

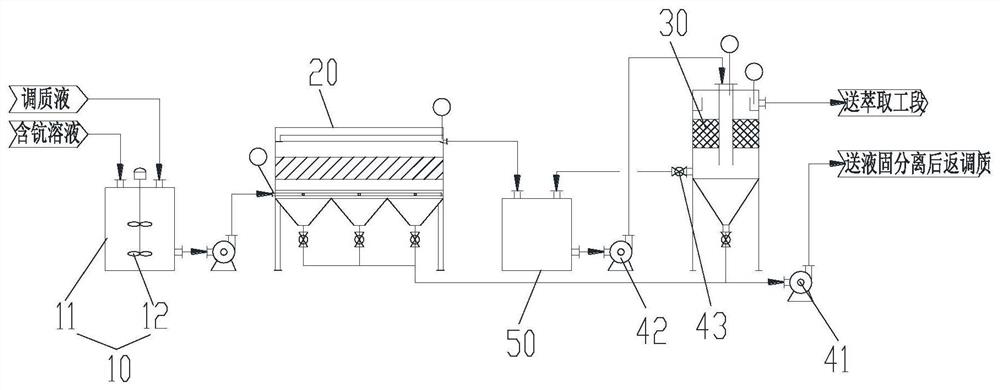

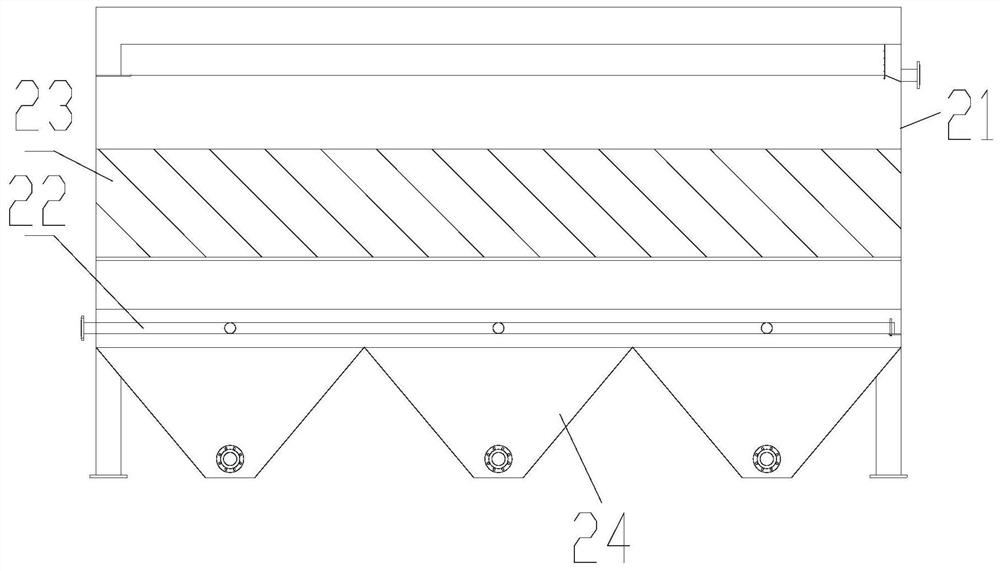

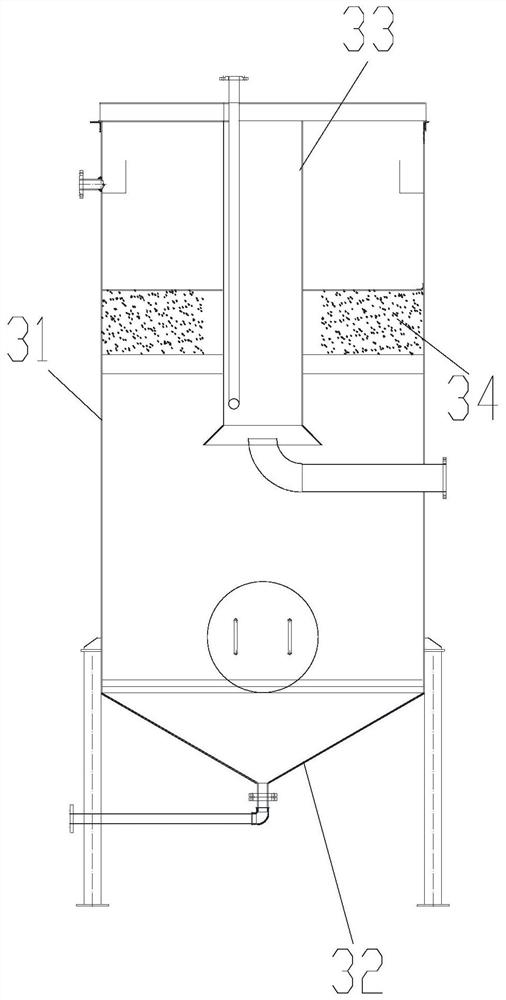

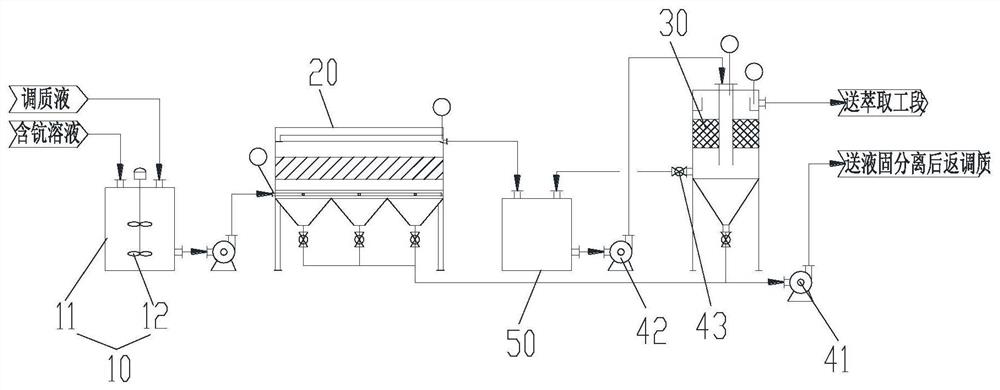

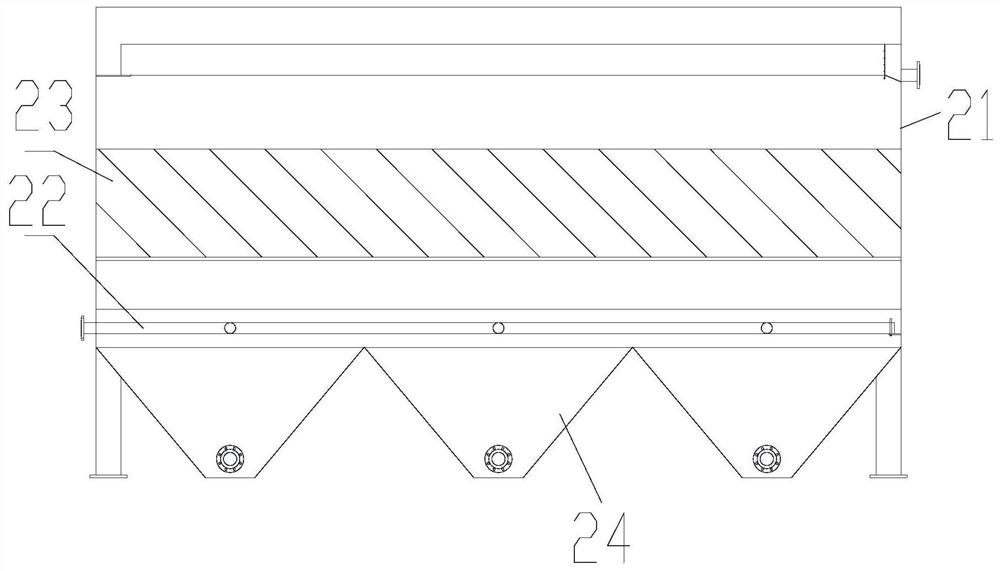

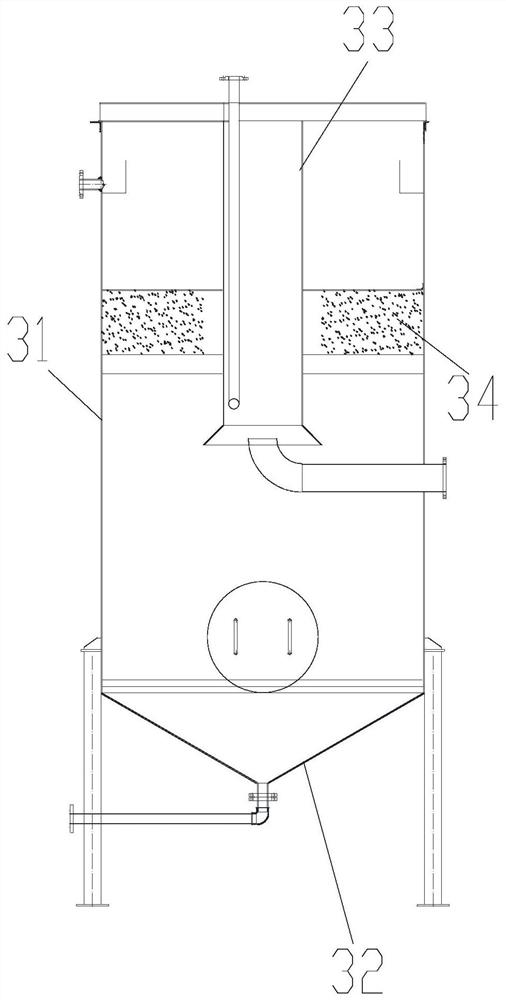

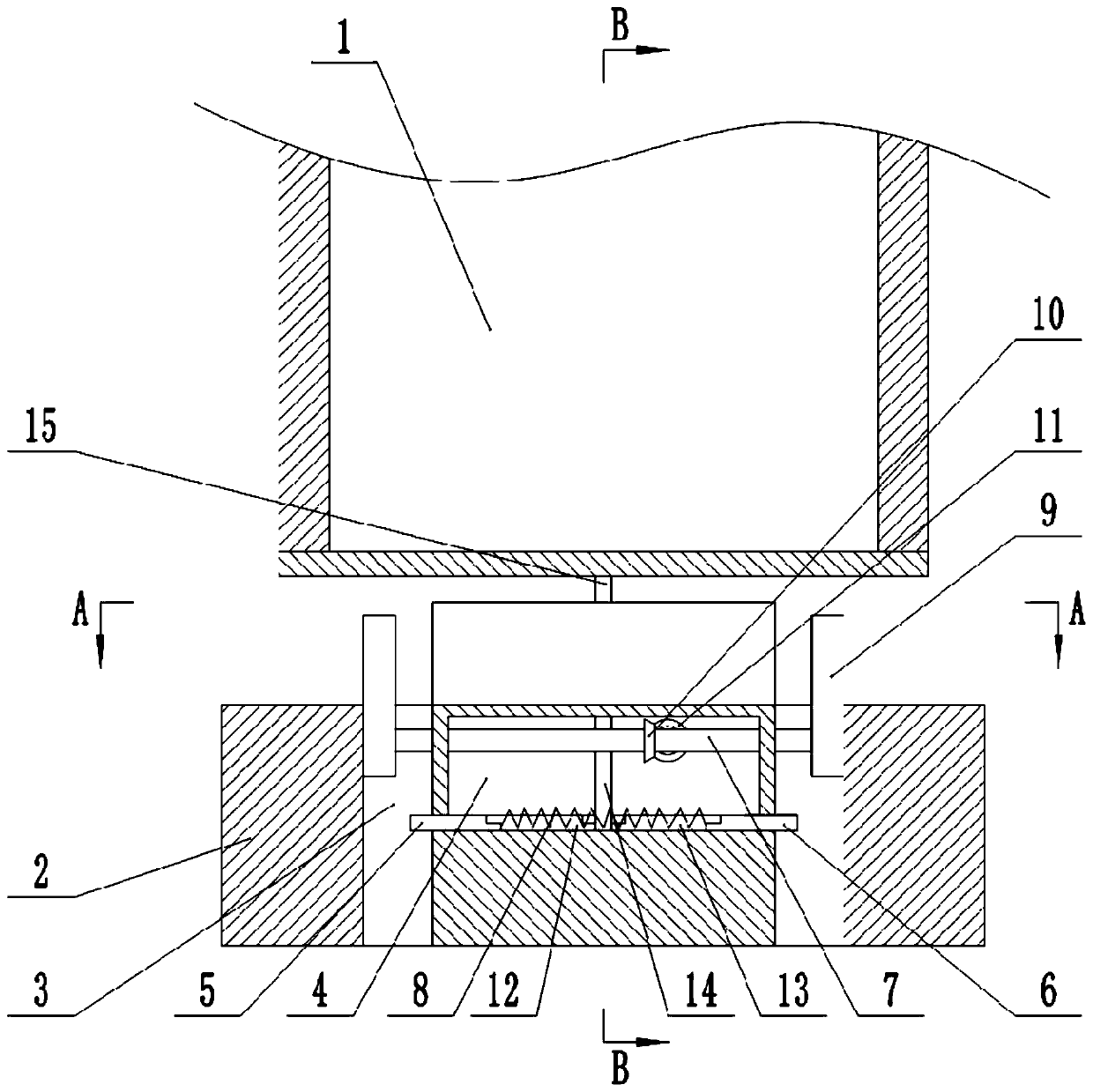

Scandium extraction pretreatment system, and treatment method for scandium-containing solution

ActiveCN113046580ARealize automatic continuous processingLess investmentProcess efficiency improvementSlagFixed bed

The invention provides a scandium extraction pretreatment system, and a treatment method for a scandium-containing solution. The scandium extraction pretreatment system comprises a hardening and tempering part provided with a first inlet, a second inlet and a hardening and tempering liquid outlet, an aging and settling part, a fixed bed and a first transfer pump, wherein the first inlet is used for inputting the scandium-containing solution, the second inlet is used for inputting concentrated sulfuric acid, and the hardening and tempering liquid outlet is used for outputting hardening and tempering liquid; the aging and settling part is provided with a first overflow port, a first liquid inlet and a first slag discharging port which are distributed from top to bottom, and the first liquid inlet communicates with the hardening and tempering liquid outlet; the fixed bed is provided with a second liquid inlet, a second overflow port and a second slag discharging port which are distributed from top to bottom, and the second liquid inlet communicates with the first overflow port; and both the first slag discharging port and the second slag discharging port communicate with the first transfer pump. By adopting the scheme, the content of solid particles in the scandium-containing solution can be effectively reduced, and the aging and settling process is completed; a plurality of tanks are not needed, and the equipment investment is low; and the production cycle of a product is shortened.

Owner:CHINA ENFI ENGINEERING CORPORATION

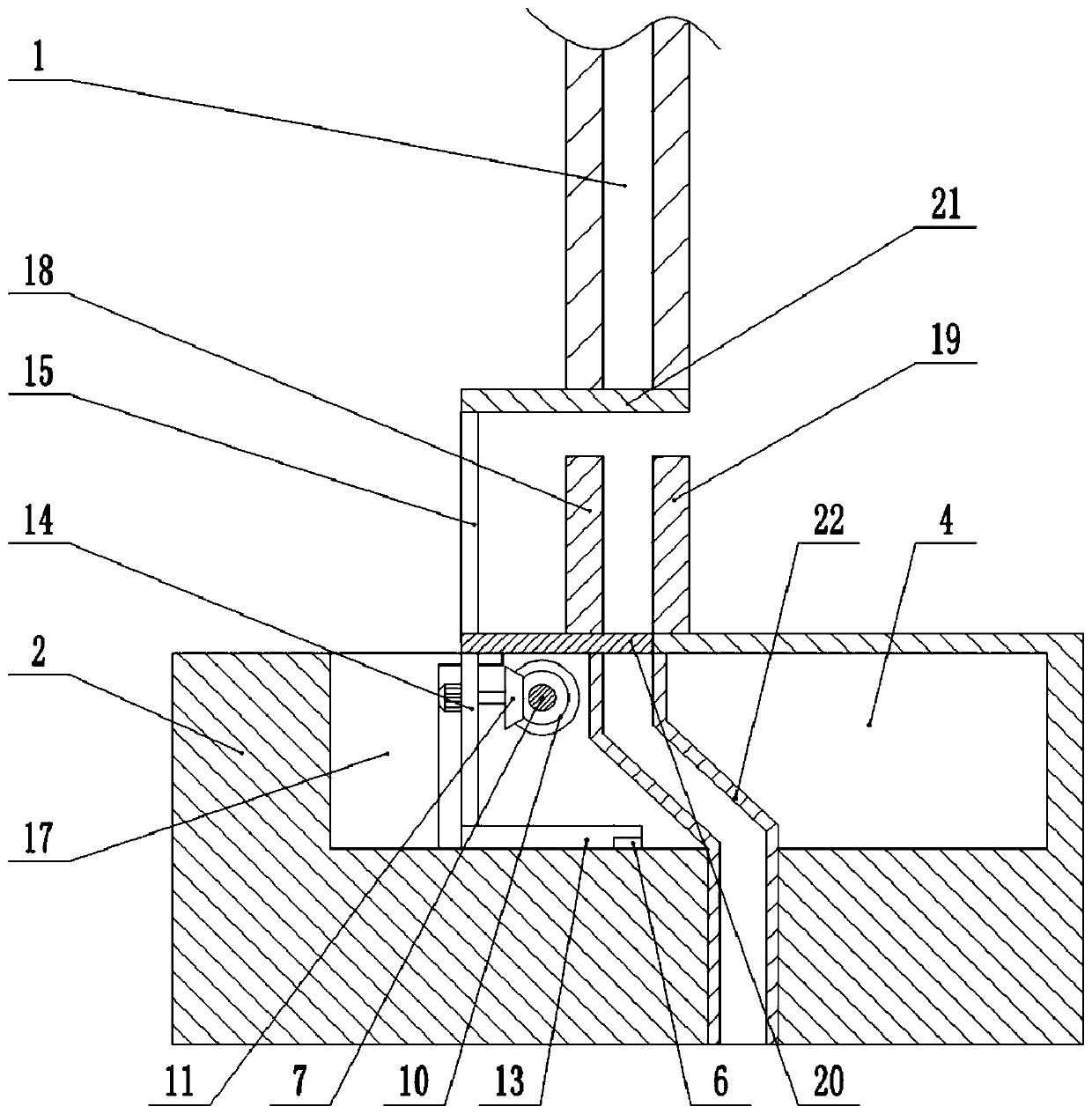

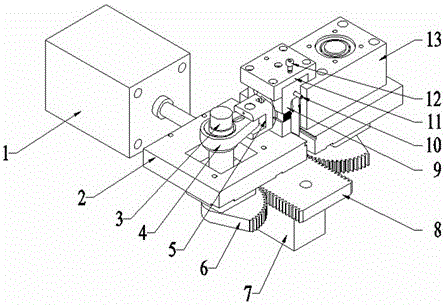

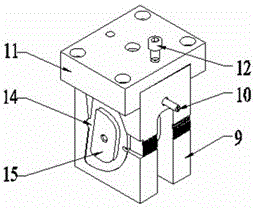

Clamp for automatic milling of inner and outer tooth profiles of pliers body

ActiveCN108058044AConvenient automatic discharge and placementStable and efficient fixationPositioning apparatusMetal-working holdersMilling cutterEngineering

The invention discloses a clamp for automatic milling of inner and outer tooth profiles of a pliers body. According to the clamp for automatic milling of the inner and outer tooth profiles of the pliers, a clamp body is arranged on a base and is arranged at a milling cutter support and the feeding front end of a milling cutter; a clamp support is arranged side by side with the milling cutter support; a support driver is arranged on the clamp support; a guide rod support is fixed to a lower connecting rod which is in connected to the support driver; a positioning rod and a clamp rod are arranged under the guide rod support side by side at interval; a positioning rod hole and a clamp rod hole are correspondingly formed in a machining plate below the positioning rod and the clamp rod; a clamphead is arranged on the clamp rod; and the positioning rod corresponds to a millstone hole of the pliers body. The clamp for automatic milling of the inner and outer tooth profiles of the pliers bodyhas the advantages that the pliers body can be conveniently automatically discharged and placed for machining, the pliers body can be stably and efficiently fixed, technical support can be provided for efficient production, and subsequent automatic machining and feeding can be facilitated.

Owner:湖南精专自动化技术有限公司

Scandium extraction pretreatment system and treatment method for scandium-containing solution

ActiveCN113046580BRealize automatic continuous processingLess investmentProcess efficiency improvementSlagFixed bed

The invention provides a scandium extraction pretreatment system and a treatment method for a scandium-containing solution. The scandium extraction pretreatment system includes: a conditioning section, the conditioning section has a first inlet, a second inlet, and a conditioning solution outlet, the first inlet It is used to input scandium-containing solution, the second inlet is used to input concentrated sulfuric acid, and the outlet of the conditioning solution is used to output the conditioning solution; the aging settling part, the aging settling part has the first overflow port distributed from top to bottom, the second A liquid inlet is connected to the first slag discharge port, and the first liquid inlet is connected to the outlet of the conditioning liquid; the fixed bed has a second liquid inlet, a second overflow port and a second row distributed from top to bottom. The slag port, the second liquid inlet are in communication with the first overflow port; the first transfer pump, the first slag discharge port and the second slag discharge port are all in communication with the first transfer pump. Adopting this scheme can effectively reduce the content of solid particles in the scandium-containing solution, complete the aging and sedimentation process, and does not need to use multiple tanks, which reduces equipment investment and reduces the production cycle of the product.

Owner:CHINA ENFI ENGINEERING CORPORATION

Metal tube bending device

ActiveCN108856395BBending realizationRealize automatic continuous processingMetal-working feeding devicesStripping-off devicesStraight tubeTube bending

Owner:重庆祥越管道配件制造有限公司

Integrated straw treatment apparatus with tail heat recovery and segmenting treatment functions and sinusoidal flame arrester

InactiveCN107699479AContinuous monitoring of production dataRealize automatic continuous processingBioreactor/fermenter combinationsBiological substance pretreatmentsFlame arresterUltrasonic vibration

The invention discloses an integrated straw treatment apparatus with tail heat recovery and segmenting treatment functions and a sinusoidal flame arrester. The integrated straw treatment apparatus comprises a sinusoidal roller, a biogas fermentation tank, a biogas storage tank, a countercurrent drying tower, a biogas burner, a biogas boiler and a heat pump host, wherein the left-lower part of thebiogas fermentation tank is provided with a sinusoidal ultrasonic vibration exciter, and the right-upper part of the biogas fermentation tank is connected with the tank bottom via a pipeline and a Roots blower; the outlet of the Roots blower is connected with the biogas storage tank; the biogas storage tank is connected with a the biogas boiler through a pipeline, the flame arrester and the biogasburner; the biogas boiler is connected with the countercurrent drying tower through a steam fin air-heater; the left-upper part of the countercurrent drying tower is successively connected with a spiral air-closed feeder, the sinusoidal roller and a segmenting machine; a tail gas pipe is connected with a heat pump system; and the left-lower part of the countercurrent drying tower is provided witha cosinusoidal plastic plate pulsed aeration device. The sinusoidal roller, the cosinusoidal plastic disc pulsed aeration device and the sinusoidal ultrasonic vibration exciter all have distinctive characteristics and can reliably cooperate with each other so as to realize comprehensive development and utilization of crop straw and waste with particularly large water content gradients.

Owner:JISHOU UNIVERSITY

Straw comprehensive treatment apparatus with tail heat recycling, crushing and sinusoidal flame retarder

InactiveCN107642978AContinuous monitoring of production dataRealize automatic continuous processingBioreactor/fermenter combinationsBiological substance pretreatmentsDetonatorCombustor

The invention discloses a straw comprehensive treatment apparatus with tail heat recycling, crushing and a sinusoidal flame retarder, comprising a sinusoidal roller, a biogas fermenting tank, a biogasstorage tank, a reverse flow drying column, a biogas combustor, a biogas boiler, a heat pump main unit and a computer; the lower left of the biogas fermenting tank is provided with a sinusoidal ultrasonic exciter, the upper right of the biogas fermenting tank is connected with a tank bottom through a pipeline and a Roots blower, an outlet of the Roots blower is connected with the biogas storage tank, the biogas storage tank is connected with the biogas boiler through a pipeline, the flame retarder and the biogas combustor, the biogas boiler is connected with the reverse flow drying column through a steam finned hot air fan, the upper left of the reverse flow drying column is sequentially connected with a spiral closed-air feeder and the sinusoidal roller, a tail gas pipe is connected witha heat pump system, the lower left of the reverse flow drying column is provided with a cosinusoidal rubber-disc pulse gas detonator. All the sinusoidal roller, the cosinusoidal rubber-disc pulse gasdetonator and the sinusoidal ultrasonic exciter have distinctive features and can reliably cooperate to provide comprehensive development and utilization of crop straws and wastes having very high moisture content gradient.

Owner:JISHOU UNIVERSITY

Pulse gas explosion type straw comprehensive treatment device with tail heat recycling and cutting functions

InactiveCN107815399AContinuous monitoring of production dataRealize automatic continuous processingBioreactor/fermenter combinationsBiological substance pretreatmentsGas explosionCounter current

The invention discloses a pulse gas explosion type straw comprehensive treatment device with tail heat recycling and cutting functions. The pulse gas explosion type straw comprehensive treatment device with the tail heat recycling and cutting functions comprises a sine roller drum, a methane fermentation tank, a methane storage tank, a counter-current drying tower, a methane burner, a methane boiler, a heat pump main machine and a computer, wherein the upper right part of the methane fermentation tank is connected with tank bottom by virtue of a pipeline and a roots blower, the outlet of the roots blower is connected with the methane storage tank, the methane storage tank is connected with the methane boiler by virtue of a pipeline and the methane burner, the methane boiler is connected with the counter-current drying tower by virtue of a steam fin hot air machine, the upper left part of the counter-current drying tower is sequentially connected with a spiral airlock feeding machine, the sine roller drum and a cutting machine, a tail gas pipe is connected with a heat pump system, a cosine plastic plate pulse gas exploration device is arranged at the lower left part of the counter-current drying tower, and a treatment device is controlled by the computer. The pulse gas explosion type straw comprehensive treatment device disclosed by the invention has the advantage that the sineroller drum and the cosine plastic plate pulse gas exploration device respectively have distinct characteristics and can realize comprehensive development and utilization on crop straw with especiallylarge moisture content gradient and waste reliably and synergistically.

Owner:向明翠

Controllable incense bundling machine and working method thereof

InactiveCN107572075ARealize automatic continuous processingLargest diameterRod-shaped articlesBundling machine detailsElectric machineEngineering

The invention discloses a controllable incense bundling machine, and relates to the field of machining. The controllable incense bundling machine solves the problems that during existing dou incense manufacturing, manual machining is needed, efficiency is low, existing machining cannot be continuously carried out, and speed cannot be controlled. The controllable incense bundling machine comprisesa rack, a motor arranged on the rack, a speed changing box arranged on the rack and connected with the motor, a transmission module arranged on the rack, an incense bundling module arranged on the rack and a control module arranged on the rack. An output shaft of the motor is communicated with an input shaft of the speed changing box, and an output shaft of the speed changing box drives the incense bundling module through the transmission module to work. The controllable incense bundling machine has the beneficial effects that the machining efficiency is high, continuous machining can be carried out, the maximum degree of machined dou incense is large; and the raw material putting speed basically keeps unchanged.

Owner:武备

Incense manufacturing machine enabling incense to be easily discharged and application method of incense manufacturing machine

InactiveCN107719805ARealize automatic continuous processingLargest diameterBinding material applicationMaximum diameterElectric machinery

The invention discloses an incense manufacturing machine enabling incense to be easily discharged and an application method of the incense manufacturing machine, and relates to the field of machining.The incense manufacturing machine and the application method aim to solve the problems that during existing hopper incense manufacturing, manual machining is needed, efficiency is low, and existing machining cannot work continuously. The incense manufacturing machine enabling the incense to be easily discharged comprises a rack, a motor and an incense bundling module, wherein the motor and the incense bundling machine are arranged on the rack. The incense bundling module is driven by the motor through a transmission module to work. Automatic and continuous machining on the hopper incense is achieved; and the incense manufacturing machine has the beneficial effects that the machining efficiency is high, continuous machining can be achieved, and the maximum diameter of the machined hopper incense is large.

Owner:ANHUI POLYTECHNIC UNIV

Automatic incense manufacturing machine

InactiveCN107600506ARealize automatic continuous processingLargest diameterBinding material applicationPaper/cardboard containersMotor driveMaximum diameter

The invention discloses an automatic incense manufacturing machine and relates to the field of machining. The defects that an existing tower-shaped incense manufacturing mode needs manual processing and is low in efficiency, and existing machining cannot be carried out continuously are overcome. The automatic incense manufacturing machine comprises a machine frame, a motor, a transmission module and an incense binding module, wherein the motor, the transmission module and the incense binding module are arranged on the machine frame. The motor drives the incense binding module to work through the transmission module. Tower-shaped incense can be machined automatically and continuously. The automatic incense manufacturing machine has the beneficial effects that the machining efficiency is high, continuous machining can be achieved, and the maximum diameter of the machined tower-shaped incense is large.

Owner:LIXIN COUNTY FENGYASONG ELECTROMECHANICAL TECH CO LTD

Pulse detonation gas type straw comprehensive treatment device with tail heat recovery function and heat exchanger

InactiveCN107655307AContinuous monitoring of production dataRealize automatic continuous processingBioreactor/fermenter combinationsBiological substance pretreatmentsDetonationProcess engineering

The invention discloses a pulse detonation gas type straw comprehensive treatment device with a tail heat recovery function and a heat exchanger. The pulse detonation gas type straw comprehensive treatment device comprises a sine roller, a biogas fermentation tank, a biogas storage tank, a countercurrent drying tower, a biogas burner, a biogas boiler, a heat pump main machine and a computer; the upper right part of the biogas fermentation tank is connected with the tank bottom through a pipeline and a Roots fan, an outlet of the Roots fan is connected with the biogas storage tank, and the biogas storage tank is connected with the biogas boiler through a pipeline and the biogas burner; the biogas boiler is connected with the countercurrent drying tower through a steam fin hot air machine, the upper left part of the countercurrent drying tower is sequentially connected with a spiral closed-wind feeder and the sine roller, and a tail gas pipe is connected with a heat pump system; and a cosine rubber disk pulse detonation gas device is arranged on the lower left part of the countercurrent drying tower, and a processing device is controlled through the computer. According to the pulse detonation gas type straw comprehensive treatment device, both the sine roller and the cosine rubber disk pulse detonation gas device have distinct characteristics and can reliably and synergisticallyrealize comprehensive development and utilization of crop straw and waste which are particularly large in the moisture content gradient.

Owner:向明翠

Sensor assembling equipment

ActiveCN113202848ARealize automatic continuous processingIncrease productivityMaterial gluingMechanical engineeringMachining

The invention discloses sensor assembling equipment. The sensor assembling equipment comprises a conveying mechanism and a core packaging device, a first high-temperature curing device, an upper cover mounting device, a second high-temperature curing device and a conditioning testing device which are sequentially arranged in the machining direction. According to the technical scheme, the conveying mechanism is arranged, the core packaging device, the first high-temperature curing device, the upper cover mounting device, the second high-temperature curing device and the conditioning testing device are sequentially arranged in the machining direction, therefore, core mounting, upper cover mounting and conditioning testing procedures can be orderly and automatically carried out, automatic and continuous machining of sensor assembly is achieved, and the production efficiency is improved.

Owner:WUHAN FINEMEMS

Small-sized part flattening device

ActiveCN106391960ASimple structureLow costForging/hammering/pressing machinesEngineeringMechanical engineering

The invention discloses a small-sized part flattening device comprising dies mounted in sliding chutes of an internal adjusting block, an adjusting mechanism, an executing mechanism and driving mechanisms; the adjusting mechanism comprises an external adjusting block, the internal adjusting block and a top cover arranged above the external adjusting block and fixedly connected with a shell; the executing mechanism comprises an air cylinder; a rack mounted on a rack seat is fixedly connected with a piston rod of the air cylinder; a mounting plate is arranged above the rack; the two sets of driving mechanisms are symmetrically arranged relative to the center surface of the adjusting mechanism, and each set of driving mechanism comprises an eccentric shaft mounted on the shell, a gear is mounted at the lower end of the eccentric shaft and is meshed with the rack; a connecting rod is mounted at a shaft neck at an eccentric section of the eccentric shaft; and a slide block is mounted in a sliding chute in the inner wall of the shell, is connected with the connecting rod and is fixedly connected with the dies. The small-sized part flattening device is particularly suitable for flattening small-sized parts, has the characteristics of simple structure, small space occupation, convenience for removal and the like, provides convenience for the integration of one-step mounting and multi-station processing equipment and is beneficial to the increment of production efficiency.

Owner:CHINA NTAIONAL NUCLEAR TIANJIN MACHINERY

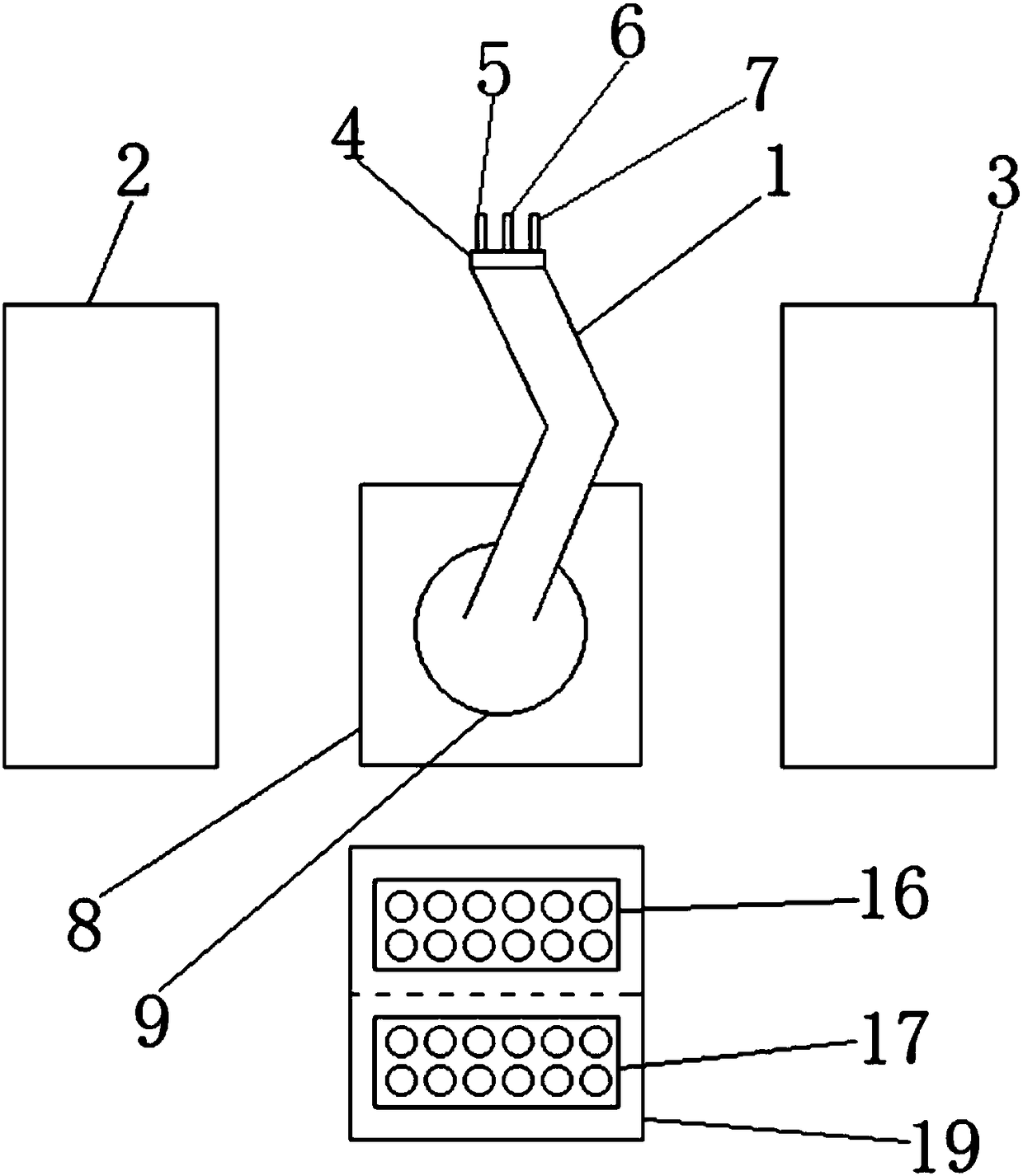

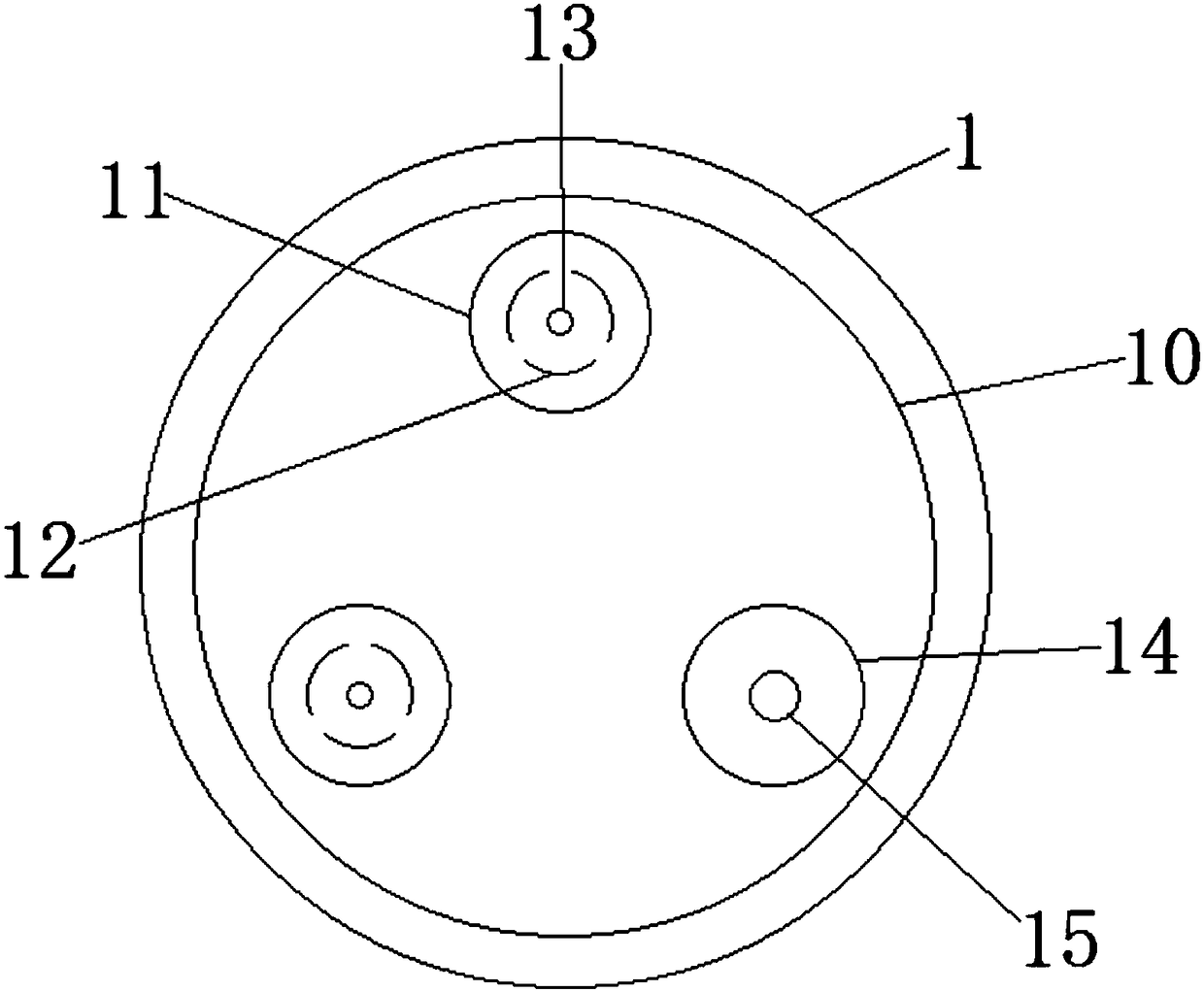

Automatic machining device for energy-conservation and emission-reduction vehicle parts

PendingCN108214069ARealize automatic continuous processingEasy to operateMetal working apparatusMaintainance and safety accessoriesManipulatorMachine tool

The invention relates to an automatic machining device for energy-conservation and emission-reduction vehicle parts. The device comprises a rotary mechanical arm base, a mechanical arm arranged on therotary mechanical arm base, and a first machine tool, a second machine tool and a product storage unit arranged around the rotary mechanical arm base; a rotary manipulator is arranged at the top endof the mechanical arm; and the rotary manipulator comprises a manipulator rotating mechanism arranged at the top end of the mechanical arm, and a first clamping mechanism, a second clamping mechanismand an air blowing and cleaning mechanism arranged on the manipulator rotating mechanism. Compared with the prior art, through alternate operation of the mechanical arm among the first machine tool, the second machine tool and the product storage unit, automatic continuous machining of products, inputting of products to be machined and outputting of machined products are realized, the operation issimple, the production efficiency is high, the operator number is reduced, and the cost is reduced.

Owner:SHANGHAI CENSI AUTOMOBILE PARTS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com