Sine roller-type straw treatment device with tail heat recycle and biomass fuel preparation functions

A tail heat recovery and treatment device technology, which is applied in the direction of biomass post-treatment, biomass pre-treatment, biochemical cleaning devices, etc., can solve the problems of polluting the environment, ineffective utilization, and difficulty in efficient comprehensive treatment and high-efficiency waste utilization. Achieve the effect of saving labor and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

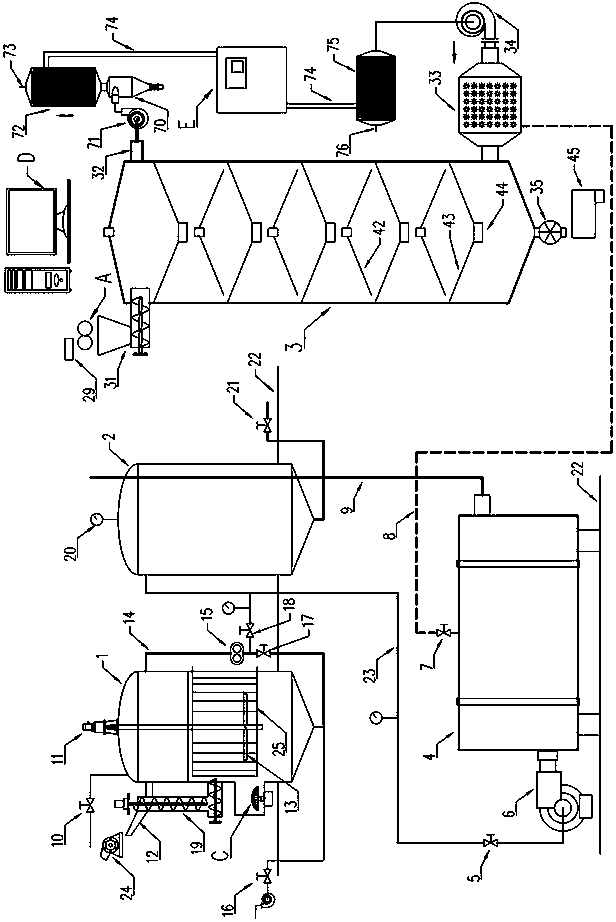

[0028] Now in conjunction with accompanying drawing, the present invention is described in further detail.

[0029] Such as Figure 1 to Figure 7Shown is a sinusoidal roller straw processing device with tail heat recovery and biomass fuel production, including sinusoidal roller A, biogas fermentation tank 1, biogas storage tank 2, countercurrent drying tower 3, biogas burner 6, and biogas boiler 4. The heat pump main engine E and the computer control system D are characterized in that: the middle part of the biogas fermentation tank 1 is provided with a squirrel cage tube heat exchanger 25, and the inside of the biogas fermentation tank 1 is provided with a stirring paddle 13, which passes through the stirring shaft and the top The stirring motor reducer 11 is connected, the top of the biogas fermentation tank 1 is connected to the water supply valve 10 through a pipeline, the upper part is connected to the L-shaped air-tight feeding auger 19, and the upper part of the L-shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com