Pulse gas explosion type straw comprehensive treatment device with tail heat recycling and cutting functions

A technology of tail heat recovery and comprehensive treatment, which is applied in dry cargo handling, dry gas arrangement, biomass post-processing, etc., can solve the problems of polluting the environment, ineffective utilization, difficult to efficiently comprehensively treat and efficient waste utilization, etc., and achieve savings Labor, the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

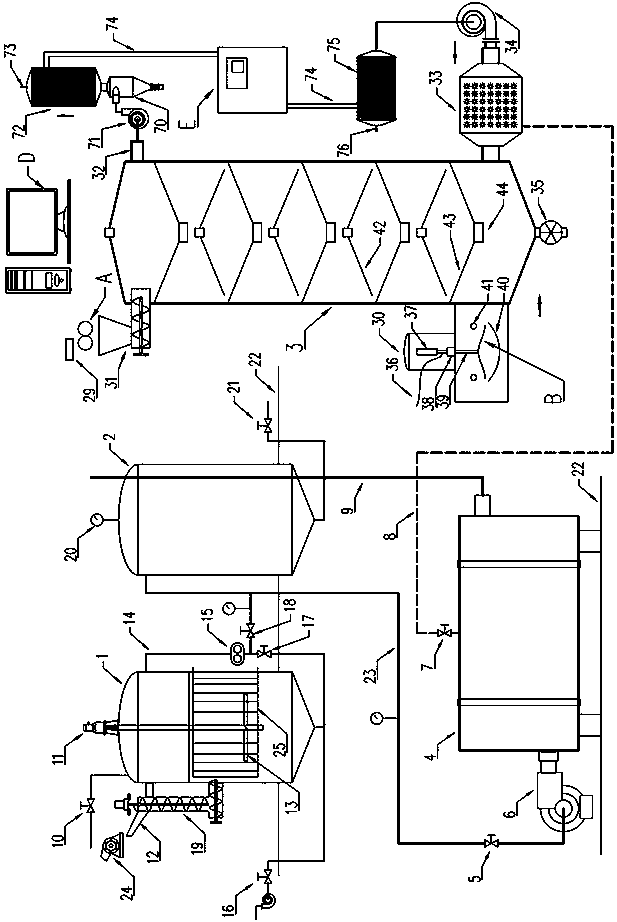

[0027] Now in conjunction with accompanying drawing, the present invention is described in further detail.

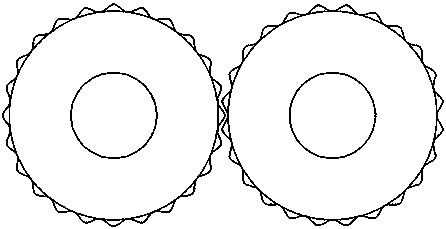

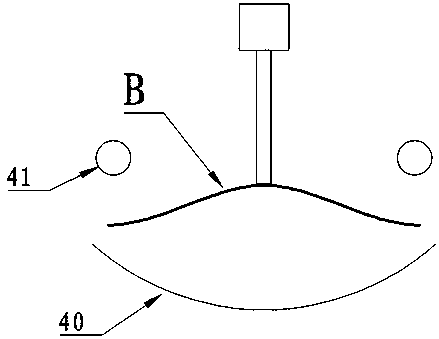

[0028] Such as Figure 1 ~ Figure 3Shown is a pulse-explosive straw comprehensive treatment device with tail heat recovery and shear section treatment, including a sinusoidal roller A, a biogas fermentation tank 1, a biogas storage tank 2, a countercurrent drying tower 3, a biogas burner 6, and a biogas boiler 4. The heat pump main engine E and the computer control system D are characterized in that: the middle part of the biogas fermentation tank 1 is provided with a squirrel cage tube heat exchanger 25, and the inside of the biogas fermentation tank 1 is provided with a stirring paddle 13, which passes through the stirring shaft and the top The stirring motor reducer 11 is connected, the top of the biogas fermentation tank 1 is connected to the water supply valve 10 through a pipeline, the upper part is connected to the L-shaped air-tight feeding auger 19, and the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com