Spray head assembling machine

A nozzle group and nozzle technology, which is applied in the direction of assembly machines, metal processing, metal processing equipment, etc., can solve problems such as poor product consistency, inability to guarantee product quality, and error-prone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

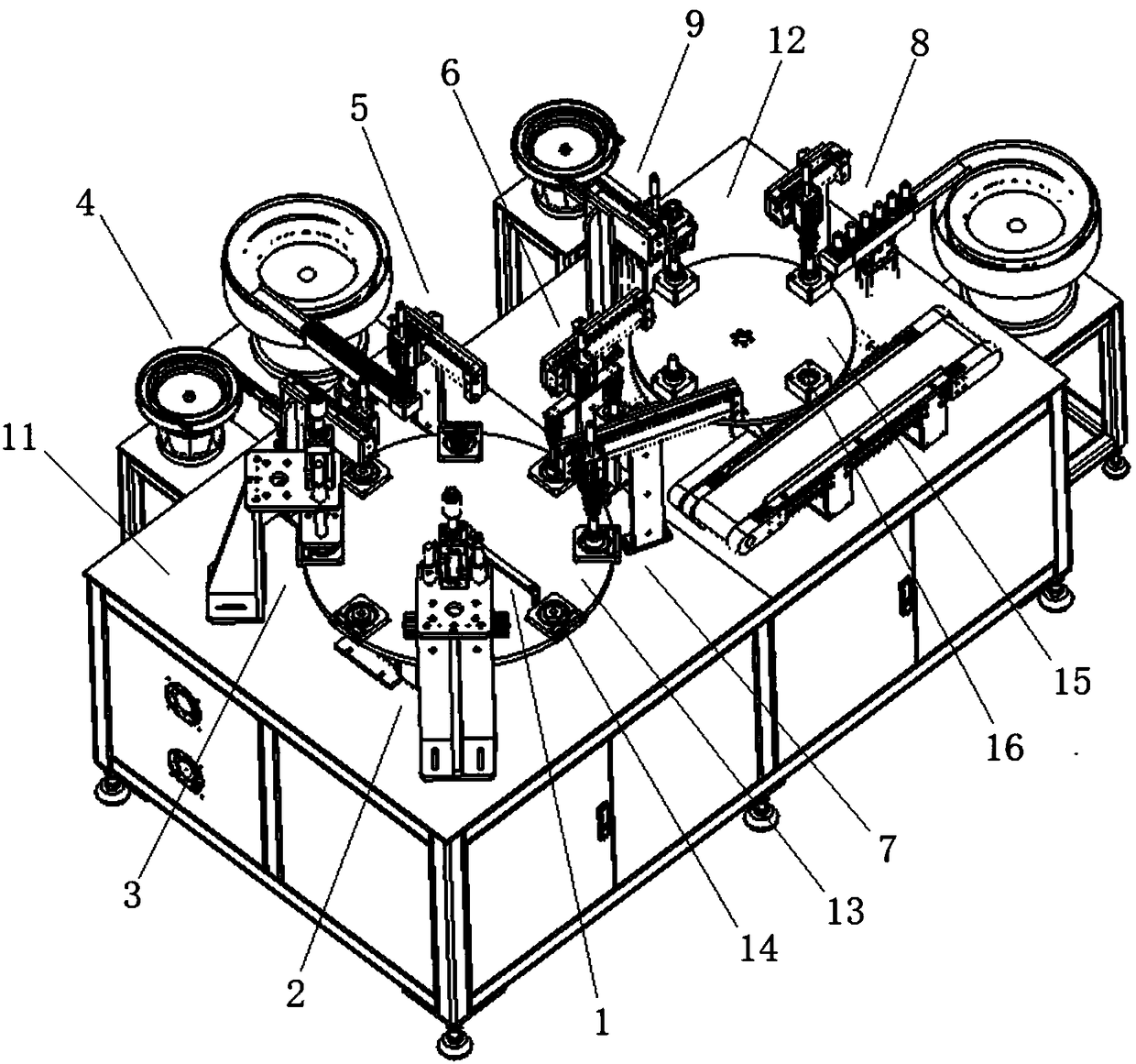

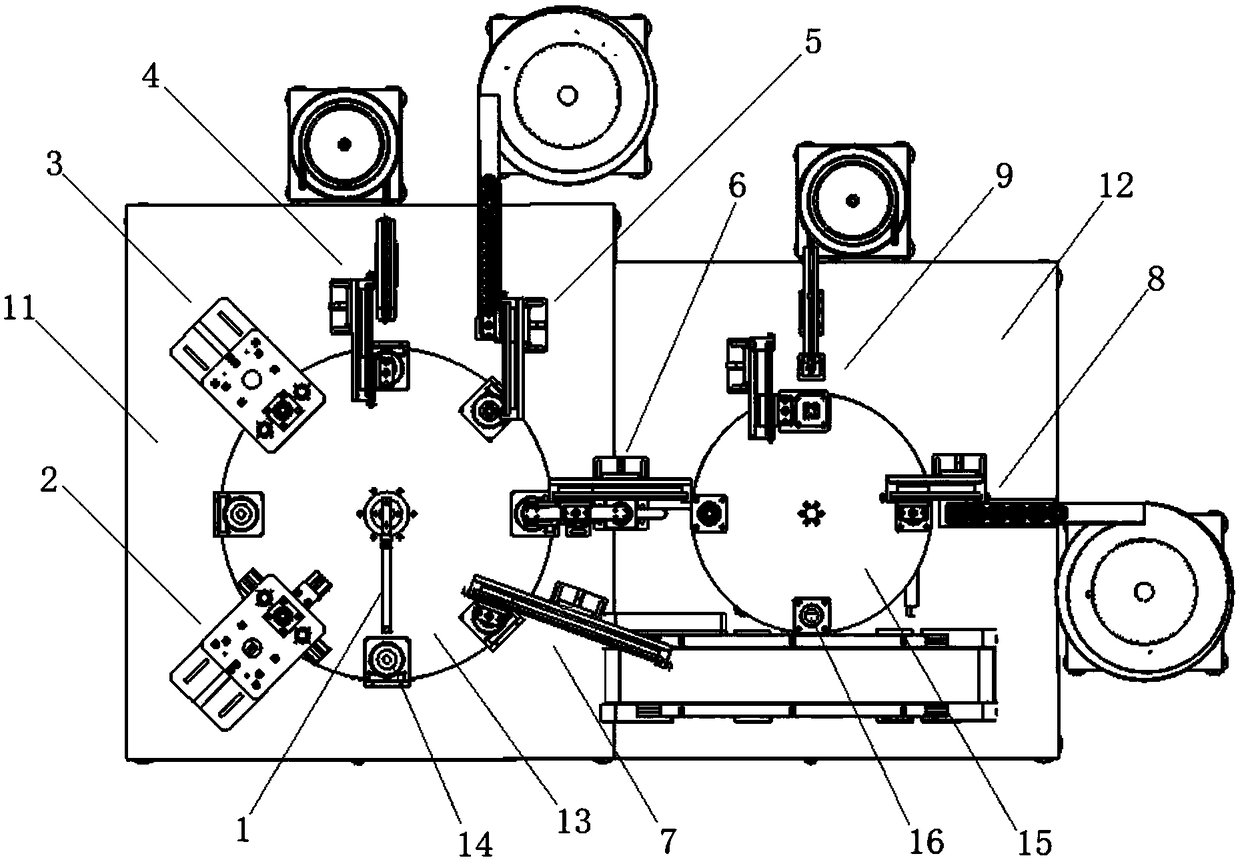

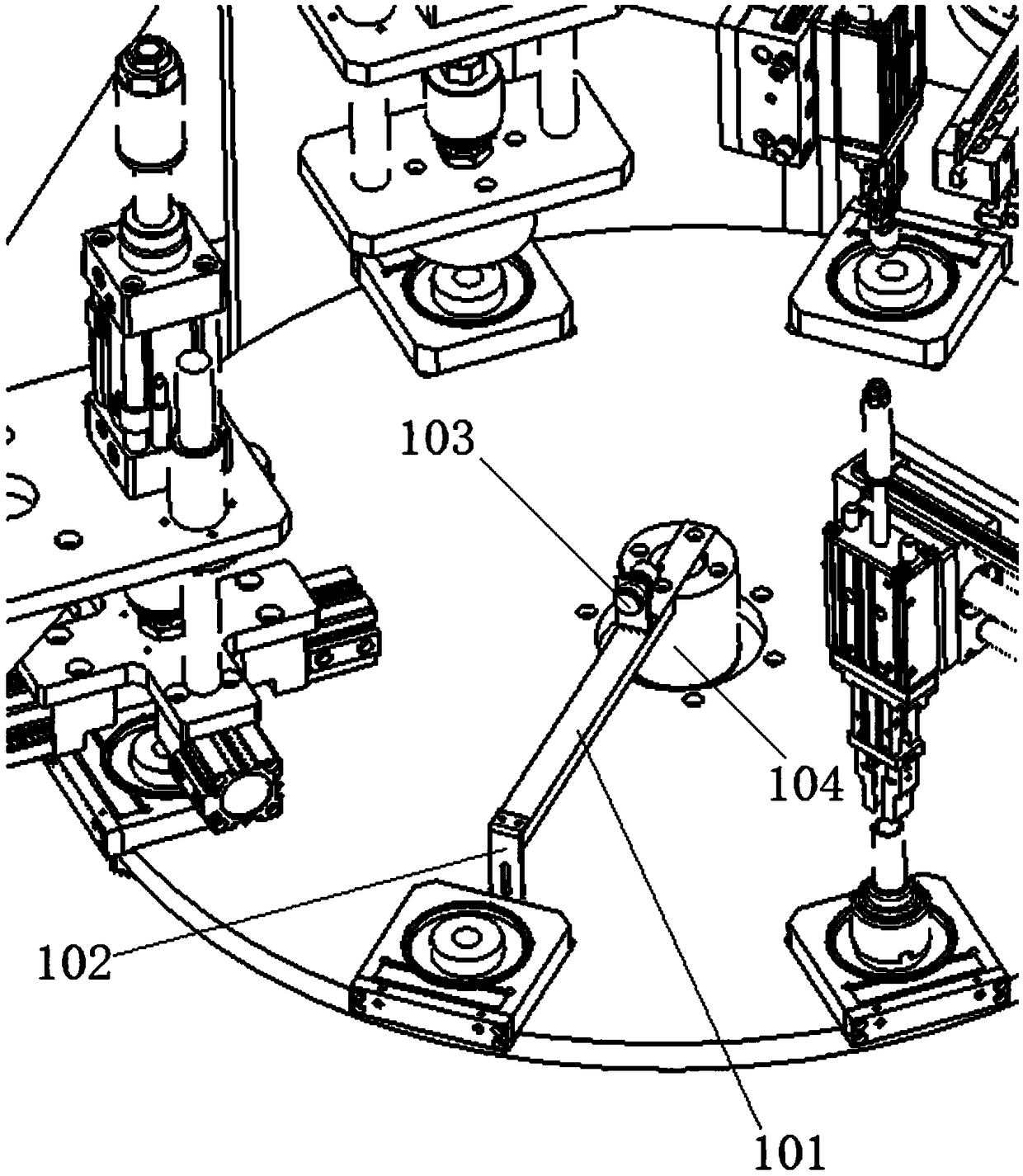

[0040] refer to Figure 1-2 As shown, a nozzle assembly machine includes a main workbench 11 and a sub-workbench 12 arranged side by side; a main installation turntable 13 controlled by a stepping motor is arranged in the center of the main workbench 11, and the main installation turntable 13 8 spray head mounts 14 are evenly arranged on the circumference of the upper surface, and the periphery of the main installation turntable 13 is divided into manual feeding stations corresponding to the 8 print head mounts 14 in the clockwise direction. Pre-pressing station, first reserved station, secondary riveting station, small-size nozzle loading station, large-size nozzle loading station, cover seat placement station and nozzle unloading station; among them, The manual feeding station is provided with a product position sensing mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com