Plastic pipe turning machine

A plastic tube and turning technology, applied in turning equipment, turning equipment, automatic/semi-automatic lathes, etc., can solve the problems of low efficiency and low positioning accuracy of instrument lathes when turning small, precision parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

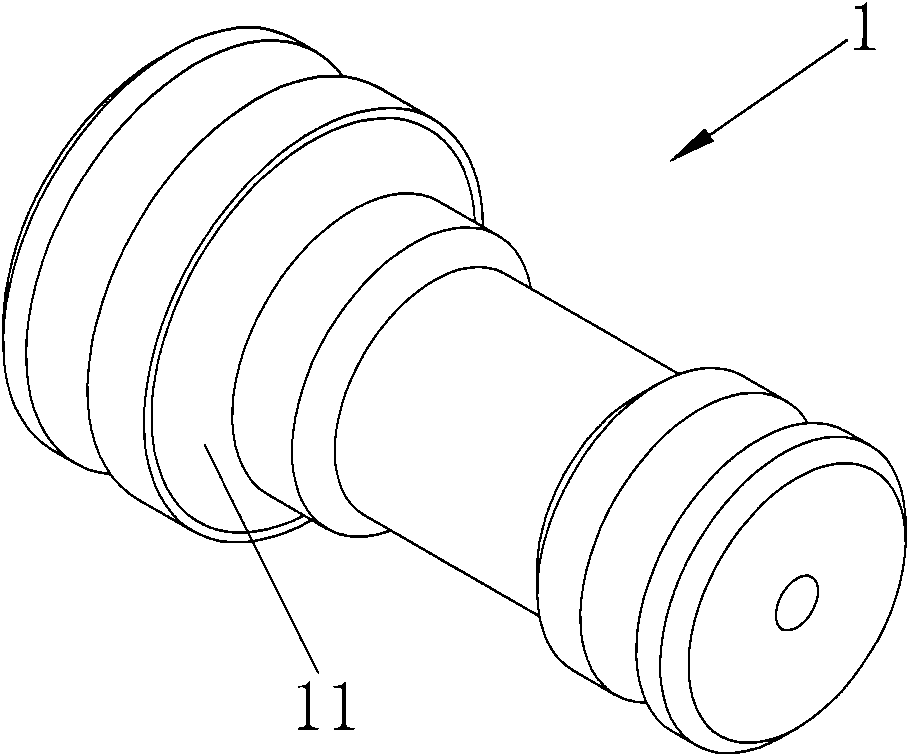

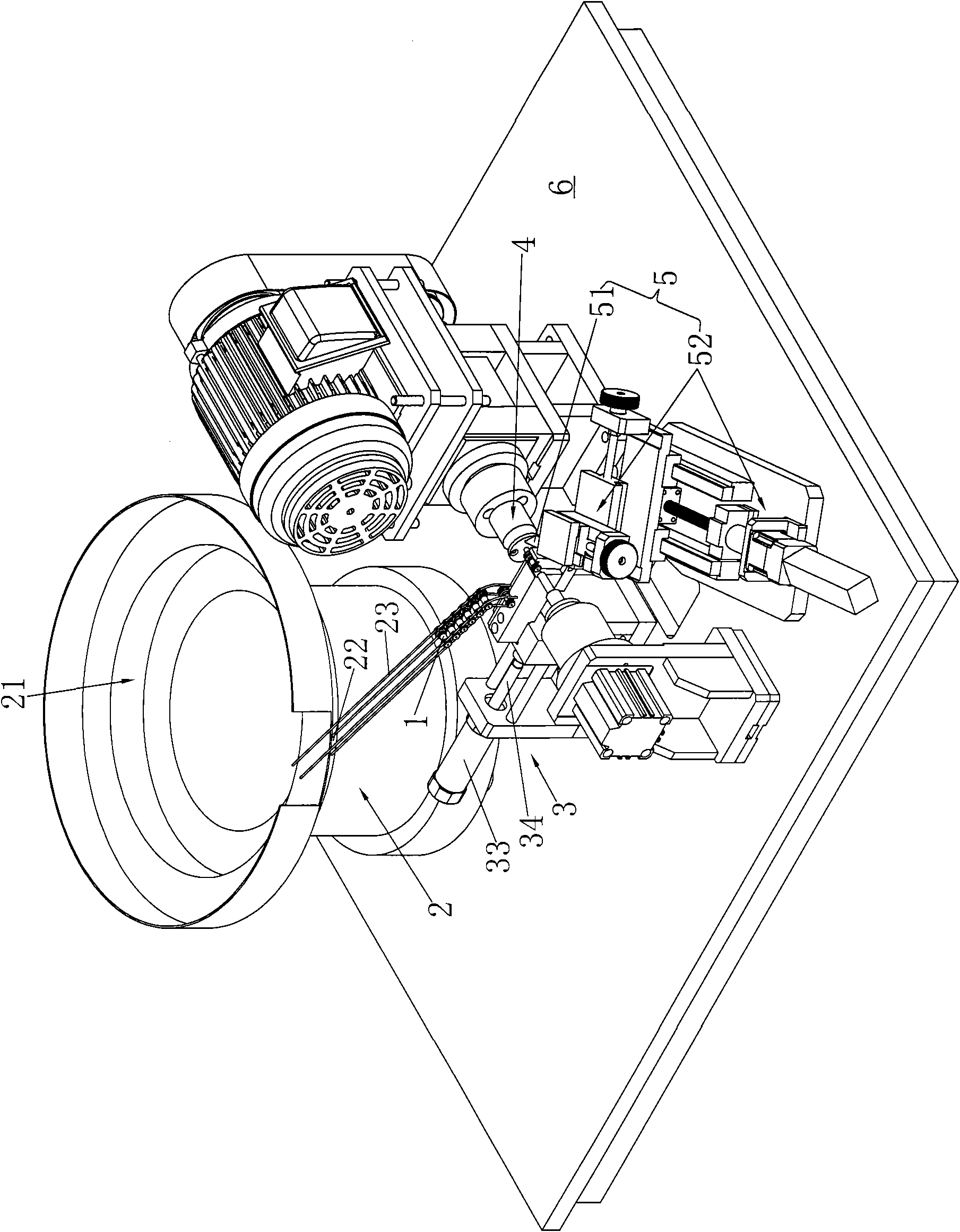

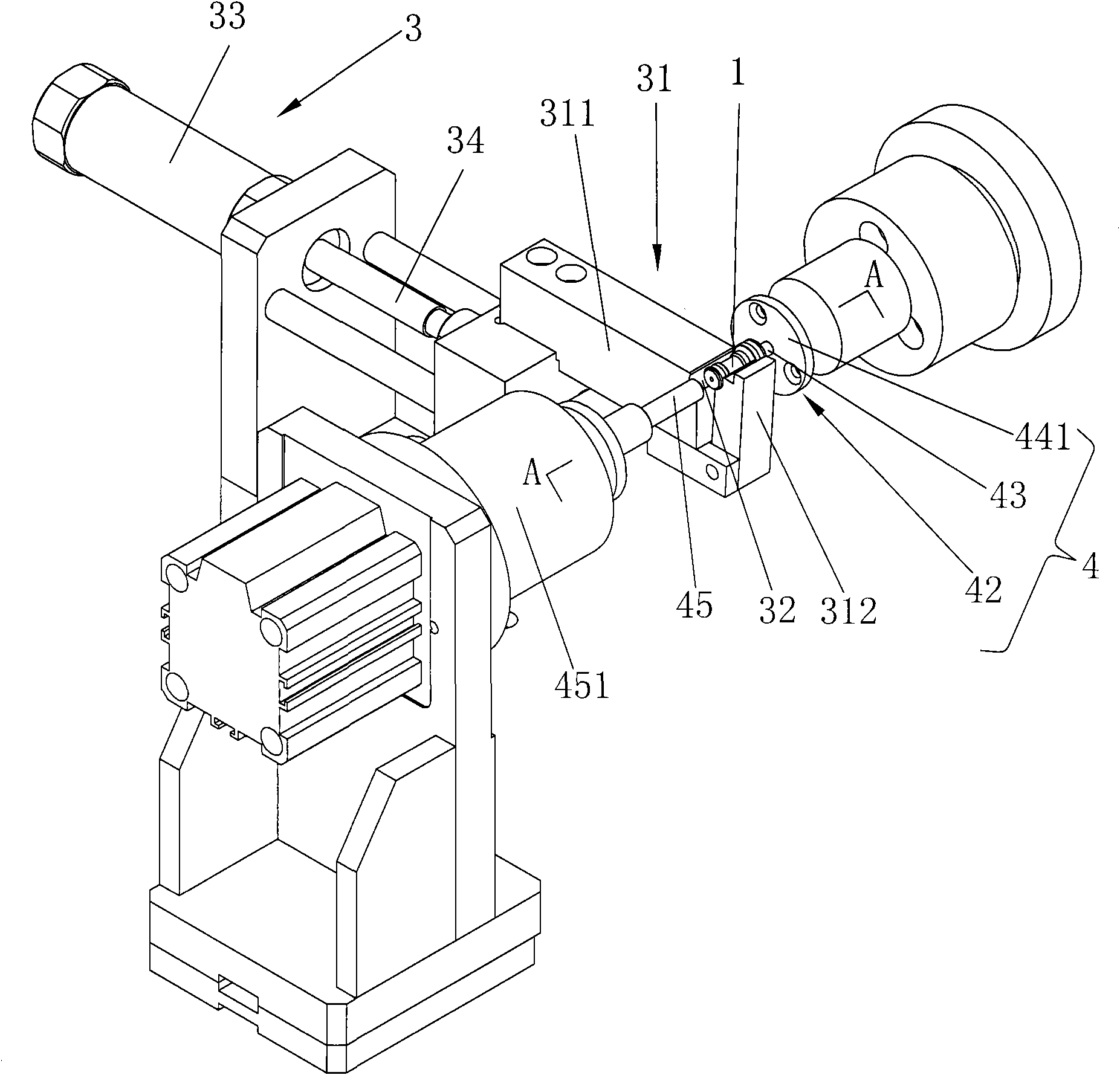

[0020] see figure 2 , image 3 , Figure 4 , when a plastic pipe turning machine of the present invention is located in the state diagram of the ejector rod 45 about to be ejected, as well as an enlarged view and a cross-sectional view. A plastic tube turning machine, including a feeding mechanism 2, a feeding mechanism 3, a clamping mechanism 4, and a turning mechanism 5 arranged on a base 6, wherein the feeding mechanism 2 is used for a plurality of plastics to be processed. The tube blanks 1 are continuously transported to the feeding mechanism 3, and the feeding mechanism 3 is used to transport the plastic tube blanks 1 delivered by the feeding mechanism 2 to the clamping mechanism 4 one by one. 4 is used for clamping the plastic tube blank 1 , and the turning mechanism 5 is used for turning the plastic tube blank 1 clamped on the clamping mechanism 4 . Wherein, the clamping mechanism 4 includes a main shaft capable of high-speed rotation (see figure 2 , the main sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com