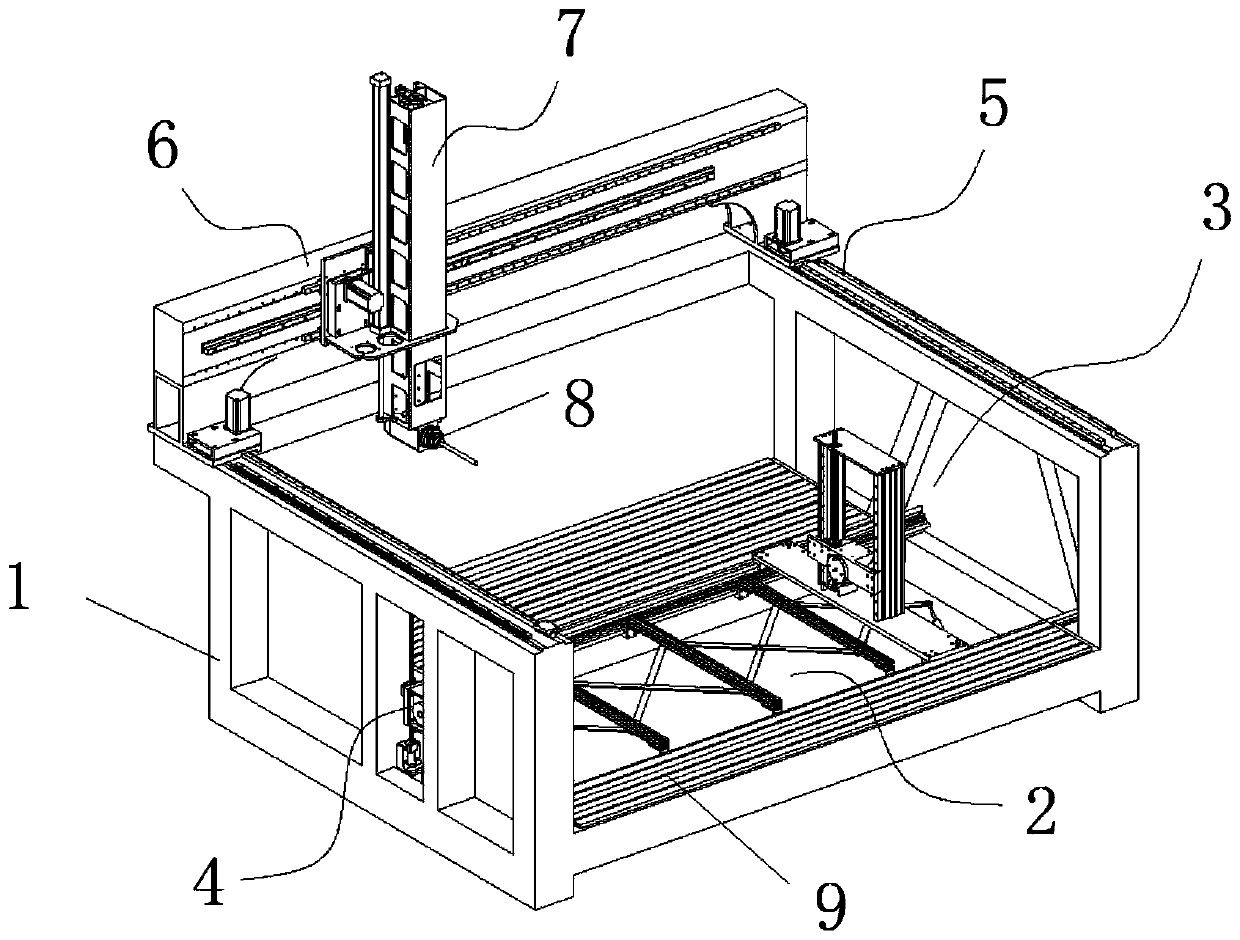

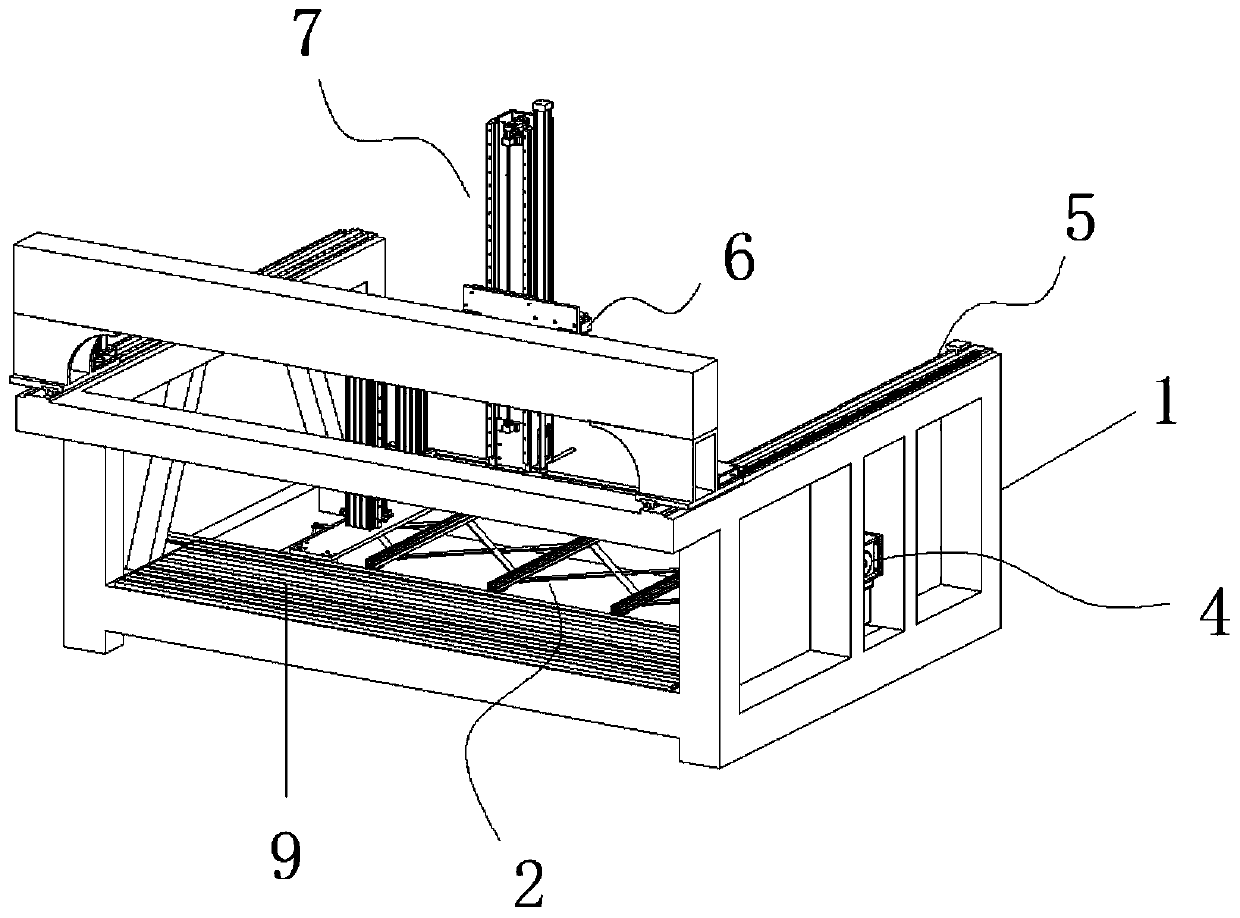

Four-axis double-sided engraving machine

An engraving machine and double-sided technology, applied in the field of engraving machines, can solve problems such as the reduction of engraving accuracy and the influence of product details on the appearance, and achieve the effect of preventing shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

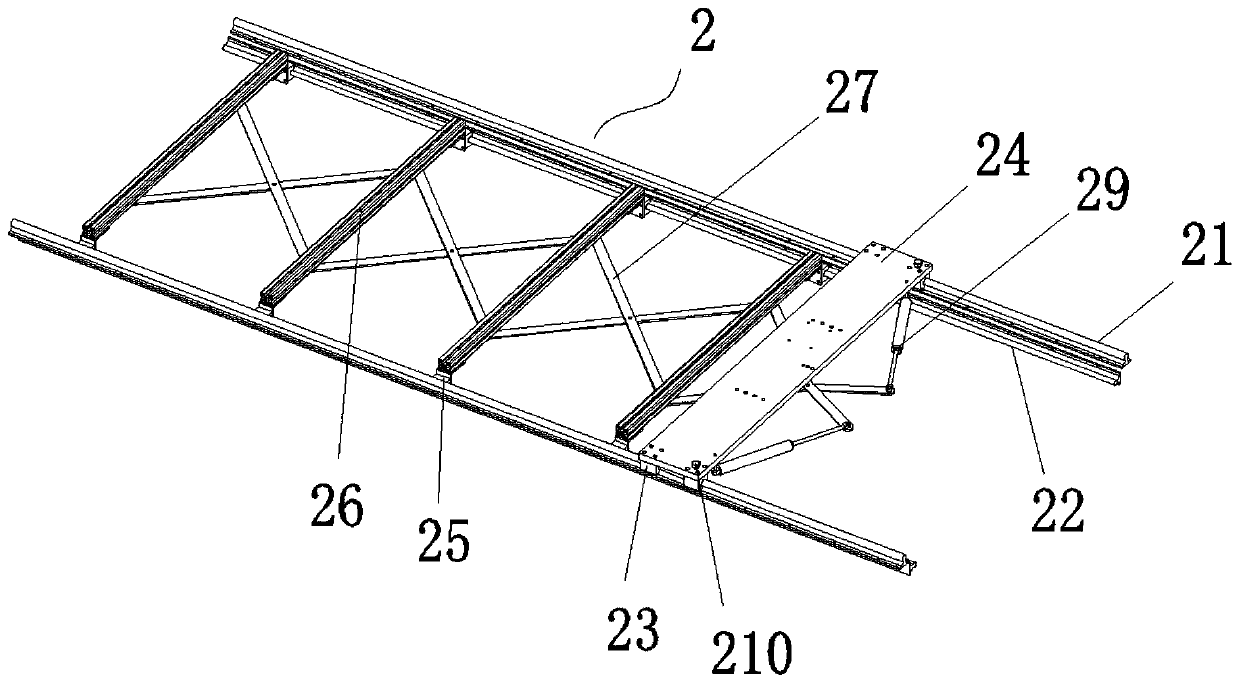

Embodiment 1

[0055]For double-sided engraving processing: the engraving main shaft 8 is installed below the rear side wall of the Z-axis elevating frame 68, and the cutter installed at the output end of the engraving main shaft 8 is installed vertically. After lifting the pressing plate 36 and the flipping plate 46 to a certain height synchronously, the double-sided engraved thick plate-shaped blank is clamped as described above. After the clamping is completed, the scissor telescopic frame 27 is launched, and the workpiece is lifted and pressed. Structure 3 and The workpiece lifting and turning mechanism 4 drives the blank down to the bottom surface and fits the top of the scissors telescopic frame 27, and the top surface processing can be started. After the top surface is processed, the blank is lifted again by the workpiece lifting and pressing structure 3 and the workpiece lifting and turning mechanism 4 Then the scissors telescopic frame 27 is combined, and then the blank is turned 180...

Embodiment 2

[0057] For cylinder engraving processing: the engraving main shaft 8 is installed on the bottom of the Z-axis elevating frame 68, and the cutting tool installed on the output end of the engraving main shaft 8 is installed horizontally forward. After lifting the pressure plate 36 and the turning plate 46 to a certain height synchronously, the double-sided engraved cylindrical blank is clamped as described above, and can be processed after clamping. Since the horizontal dimension of the cylindrical sculpture is equivalent to the vertical dimension, One-sided deflection is not easy to occur, and the jitter is not obvious during processing, and the workpiece lifting and pressing structure 3 and the workpiece lifting and turning mechanism 4 may be required to drive the blank to rotate during processing to cooperate with the spindle for processing, so the shears are generally not used in this embodiment. Fork telescopic frame 27 carries out auxiliary support.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com