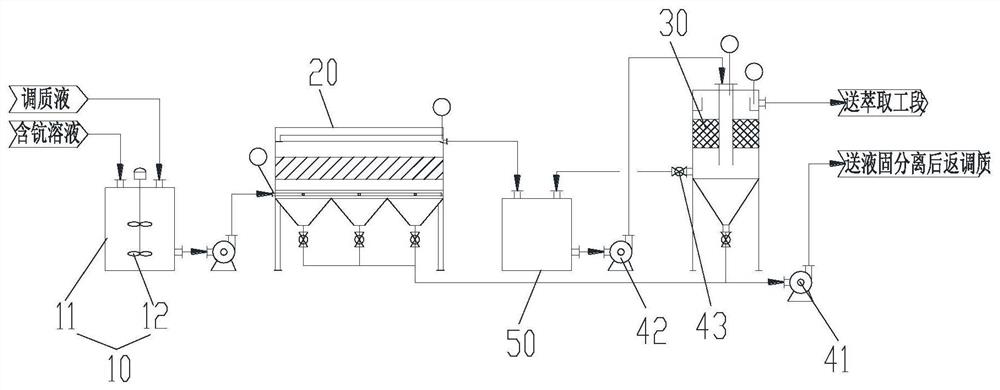

Scandium extraction pretreatment system and treatment method for scandium-containing solution

A treatment method and pretreatment technology, applied in the direction of improving process efficiency, etc., can solve problems such as large area occupation, large equipment investment, and long product production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] (1) Send the scandium-containing solution at 60°C into the conditioning tank, mix it with concentrated sulfuric acid at a ratio of 1:0.01 to make a conditioning solution, and the pH value of the conditioning solution is 2;

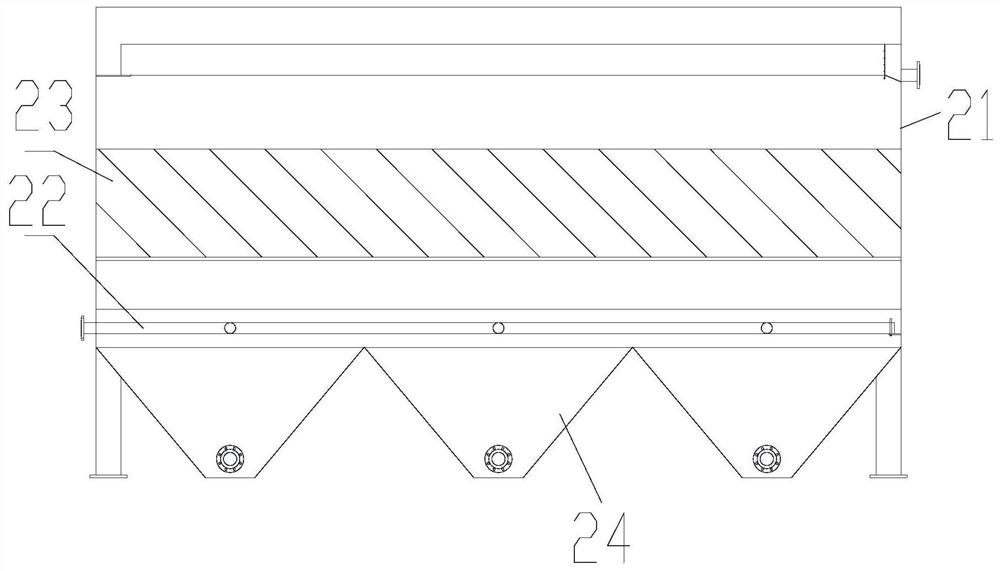

[0067] (2) The conditioning solution obtained in step (1) is pumped into the aging settling tank, and the current frequency of the conditioning solution delivery centrifugal pump is adjusted so that the residence time of the solution in the tank is controlled at 12h, and the online turbidity meter shows , the inlet turbidity is 200ppm, the overflow outlet turbidity is 100ppm, the solution turbidity drops by 50%, and the overflow temperature drops to 35°C;

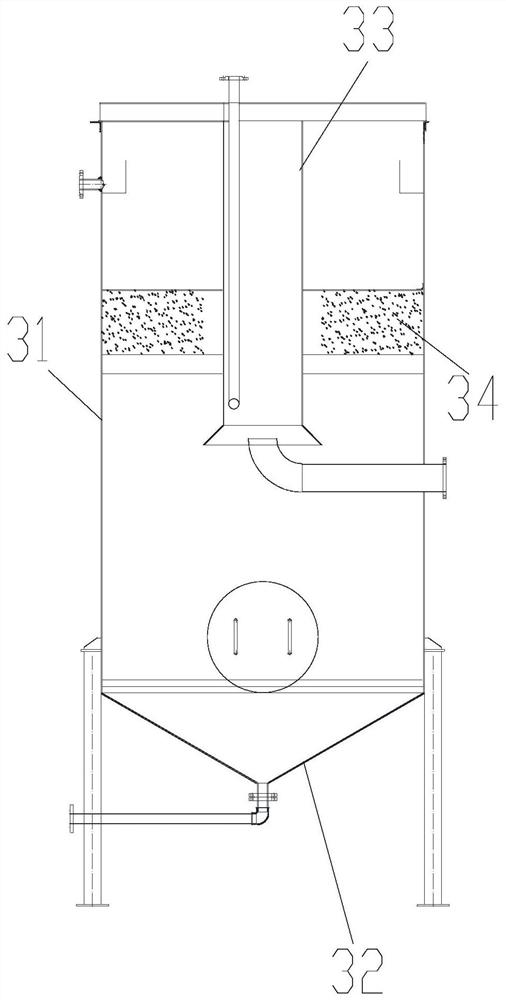

[0068] (3) the overflow that step (2) obtains is sent in the fixed bed clarifier through the overflow intermediate tank with the frequency conversion centrifugal pump, after clarifier fine filtration, the turbidity in the overflow is 80ppm, and calcium sulfate concentration in the solution is 0.1...

Embodiment 2

[0071] (1) Send the scandium-containing solution at 50°C into the conditioning tank, mix it with concentrated sulfuric acid at a ratio of 1:0.1 to make a conditioning solution, and the pH value of the conditioning solution is 0.5;

[0072] (2) The conditioning solution obtained in step (1) is pumped into the aging settling tank, and the current frequency of the centrifugal pump for regulating the conditioning solution is adjusted so that the residence time of the solution in the tank is controlled at 72h, and the online turbidity meter shows , the inlet turbidity is 300ppm, the overflow outlet turbidity is 90ppm, the solution turbidity drops by 70%, and the overflow temperature drops to 25°C;

[0073] (3) the overflow that step (2) obtains is sent in the fixed bed clarifier through the overflow intermediate tank with the frequency conversion centrifugal pump, after clarifier fine filtration, the turbidity in the overflow is 10ppm, and calcium sulfate concentration in the soluti...

Embodiment 3

[0076] (1) Send the scandium-containing solution at 55°C into the conditioning tank, mix it with concentrated sulfuric acid at a ratio of 1:0.05 to make a conditioning solution, and the pH value of the conditioning solution is 1.2;

[0077] (2) The conditioning solution obtained in step (1) is pumped into the aging settling tank, and the current frequency of the centrifugal pump for regulating the conditioning solution is adjusted so that the residence time of the solution in the tank is controlled at 36h, and the online turbidity meter shows , the inlet turbidity is 250ppm, the overflow outlet turbidity is 120ppm, the solution turbidity drops by 52%, and the overflow temperature drops to 30°C;

[0078] (3) the overflow that step (2) obtains is sent in the fixed-bed clarifier through the overflow intermediate tank with the frequency conversion centrifugal pump, after the fine filtration of the clarifier, the turbidity in the overflow is 50ppm, and calcium sulfate concentration ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| turbidity | aaaaa | aaaaa |

| turbidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com