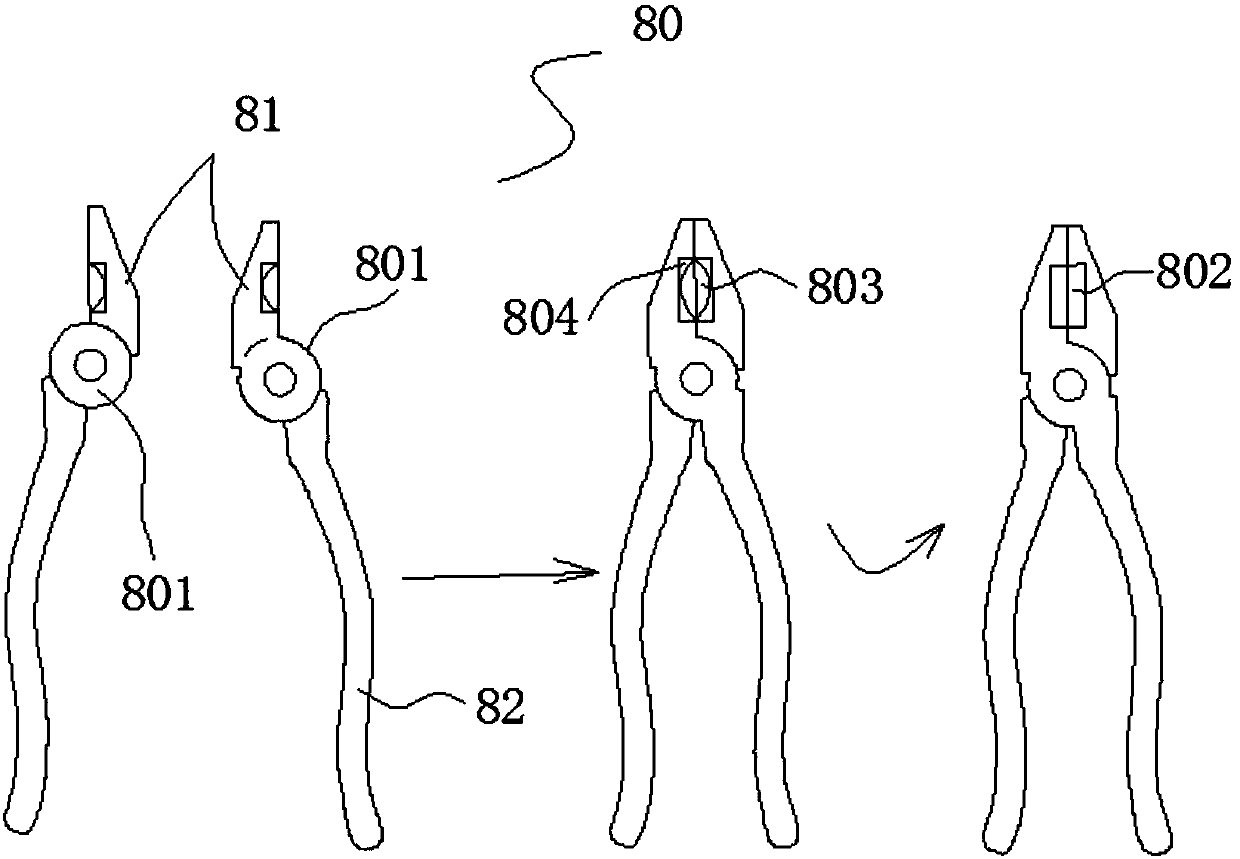

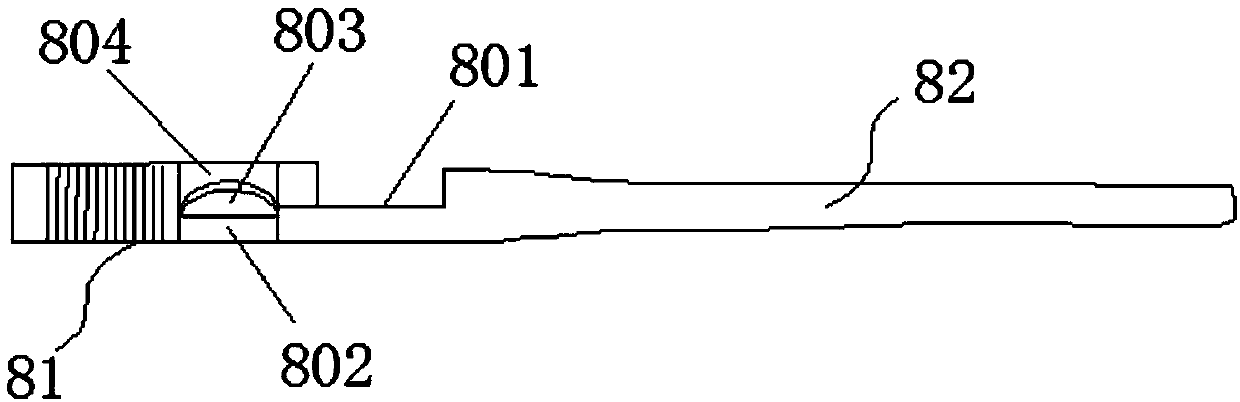

Mechanism used for continuous milling machining of special shapes and thread shapes on inner and outer surfaces of heads of pliers

A milling and pliers technology, applied in the field of hardware tool manufacturing, can solve the problems of inability to achieve automatic processing and feeding, not stacking in a row according to the order, and low production efficiency, so as to facilitate automatic processing and feeding, and control product quality. , the effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

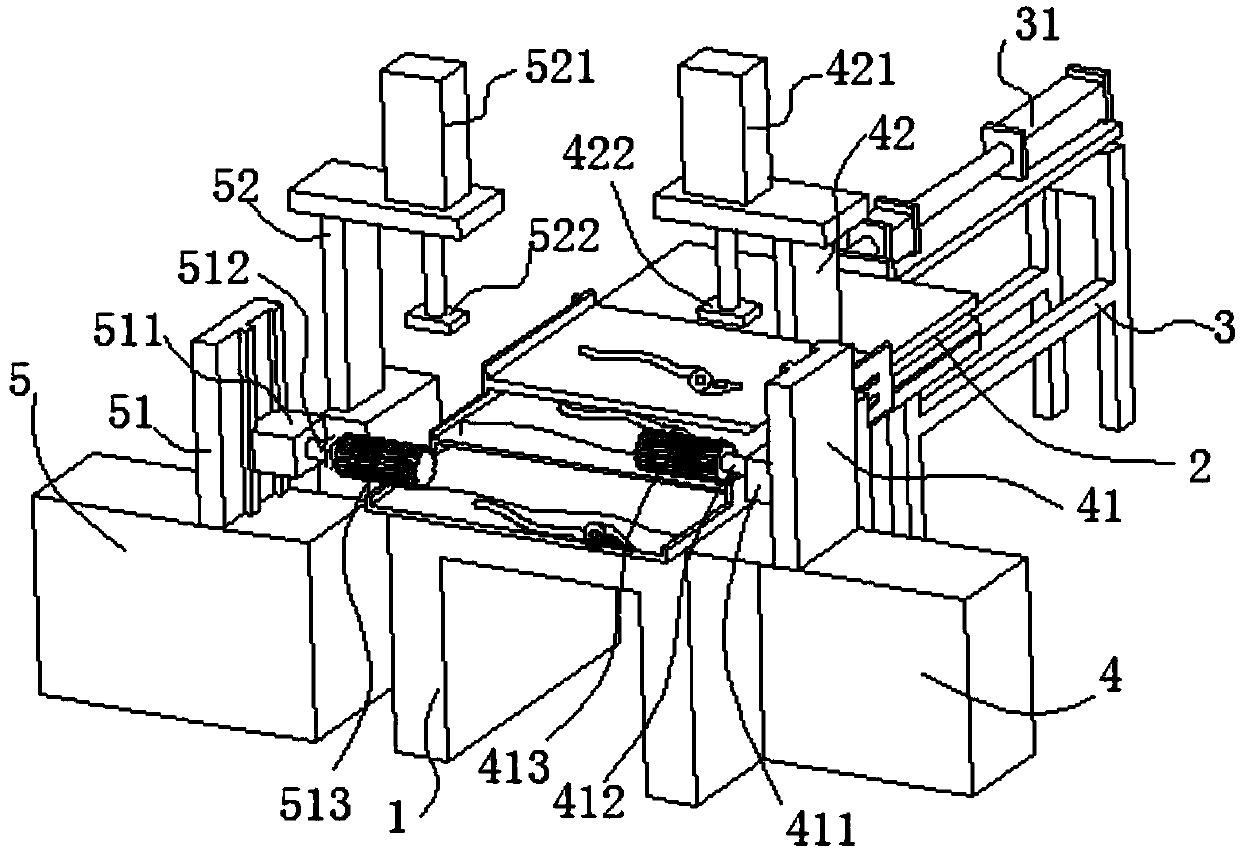

[0032] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. .

[0033] Such as Figure 3-Figure 5 As shown, the specific structure of the present invention is: a mechanism for continuous milling of special-shaped teeth on both sides of the pliers head, which includes a processing seat 1 and stacked processing layers arranged on it, each processing layer from top to bottom The bottoms are stacked one after the other and protrude forward one by one, and the materials to be processed move forward layer by layer from top to bottom; each layer is spaced from each other and there is a push plate layer 2 for coordinating activities in it, and limit baffles are set on both...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com